- The document discusses Rolls-Royce's lease engine pool and strategies for improvement. It aims to establish a consistent, world-class spare engine service for customers.

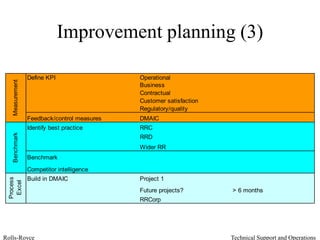

- It analyzes customer satisfaction data and defects to identify areas for improvement. It also considers using on-wing care to reduce engine downtime and costs from post-lease checks.

- The proposed improvements include overhauling processes, implementing firm engine status categories, improving fleet management, and gaining approval for changes from key stakeholders. The goal is to enhance service levels and maximize revenue from the lease engine pool.