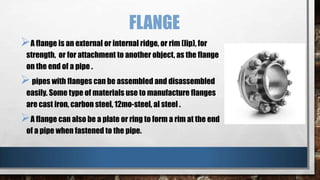

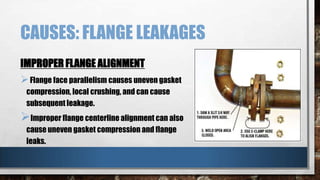

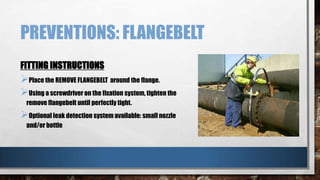

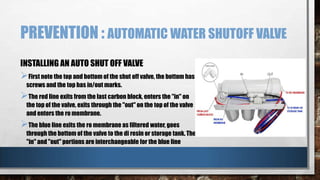

The document discusses flanges, valves, causes of flange and valve leakage, detection of leaks using acoustic leak detectors, and prevention of leaks through flangebelts and automatic water shutoff valves. Flanges are rims or ridges used to join pipes and withstand pressure. Valves regulate fluid flow by opening, closing, or partially blocking passages. Common causes of leakage are improper bolt tightening, misalignment, thermal effects, and dirty or damaged surfaces. Acoustic leak detectors use underwater sensors to detect leak sounds. Flangebelts and automatic shutoff valves can help prevent leaks by sealing flanges and stopping water flow if a leak is detected.