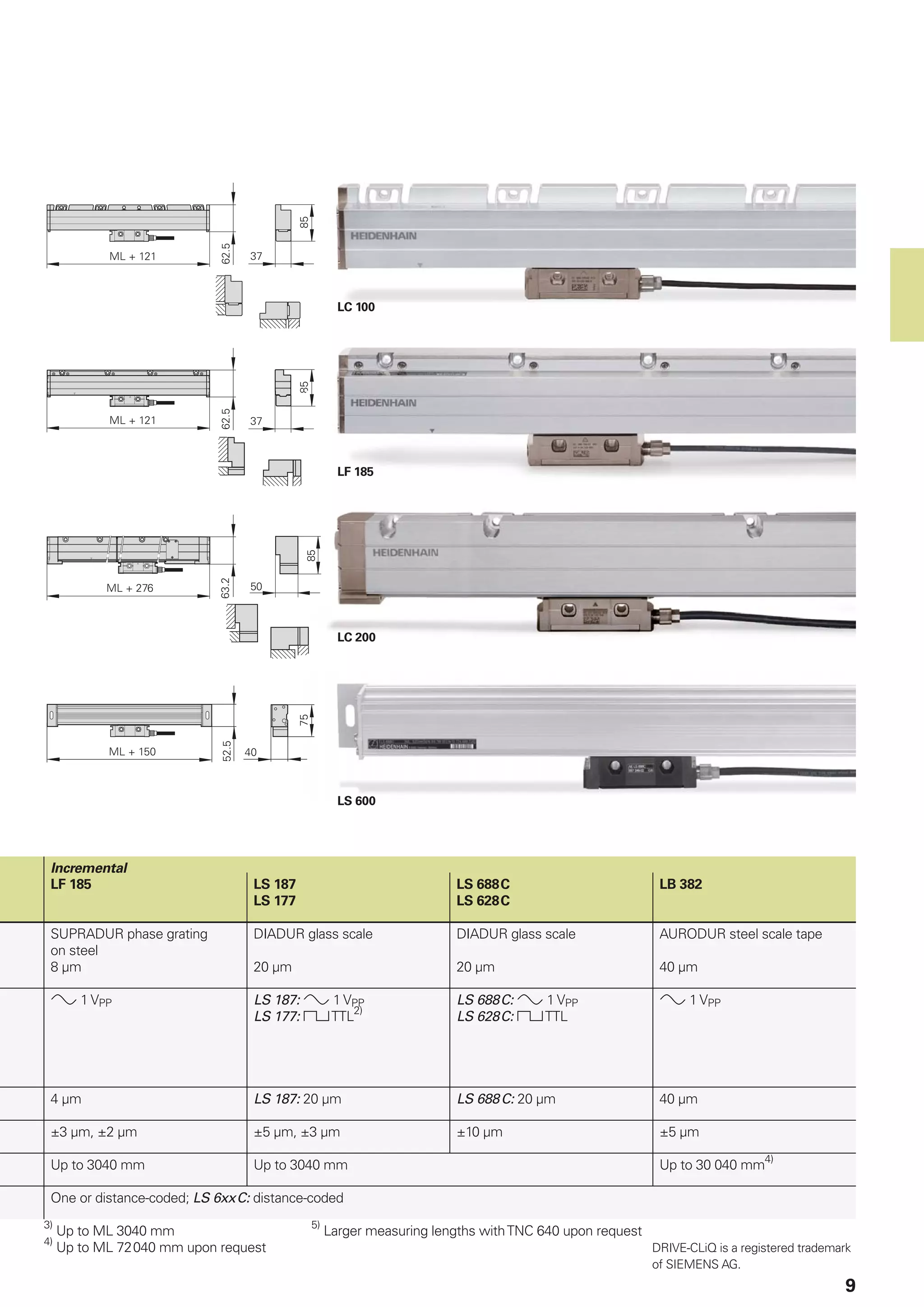

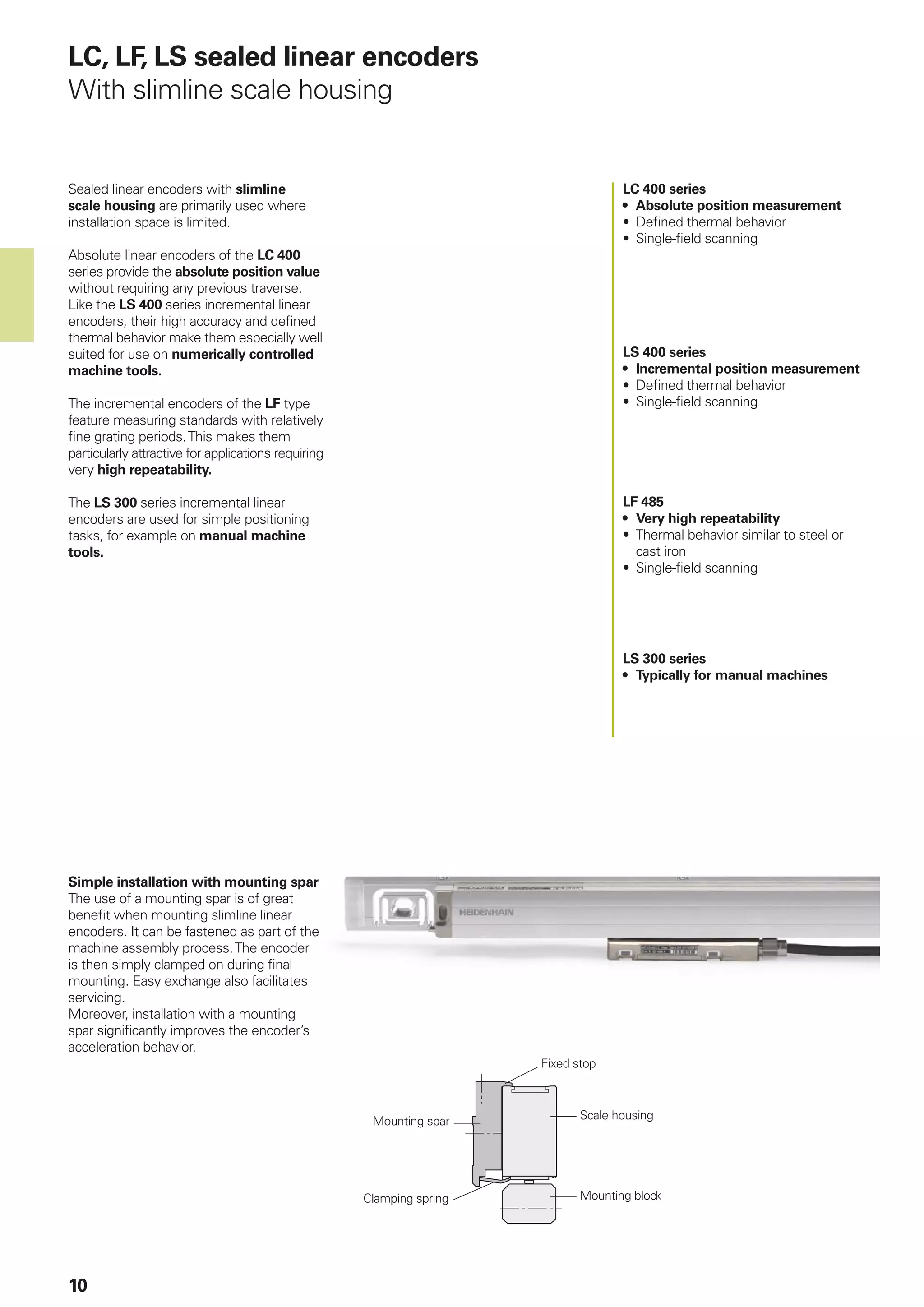

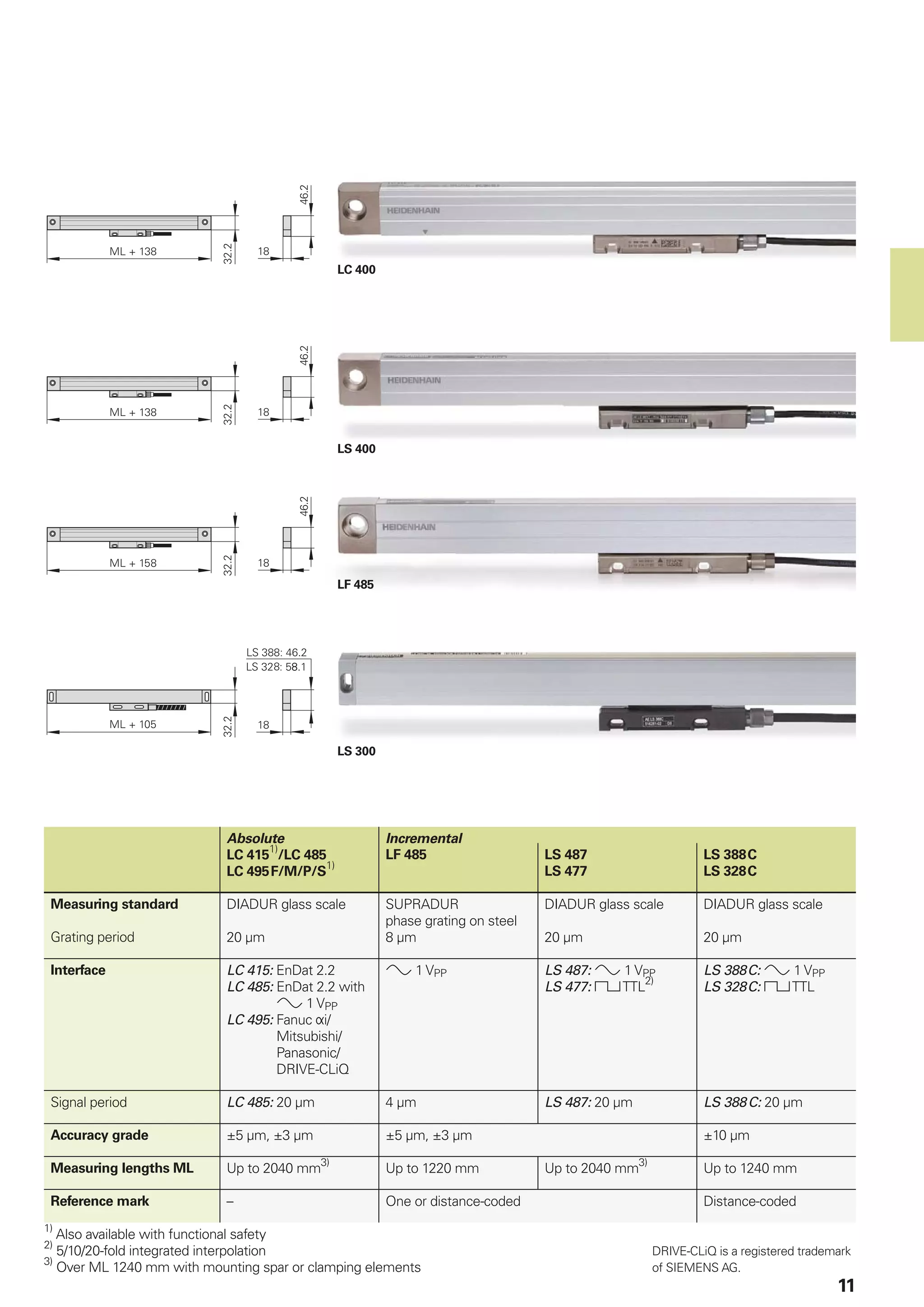

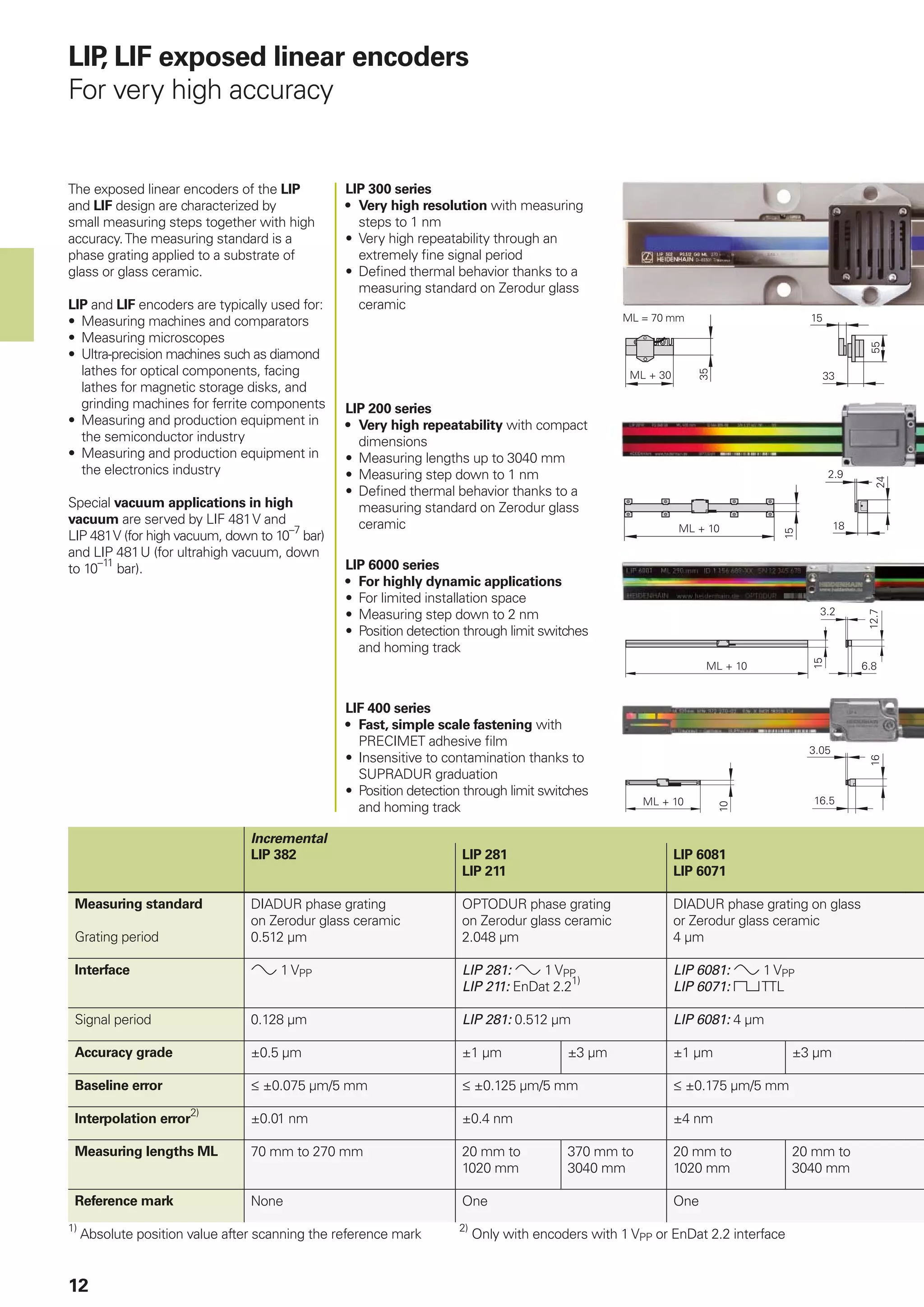

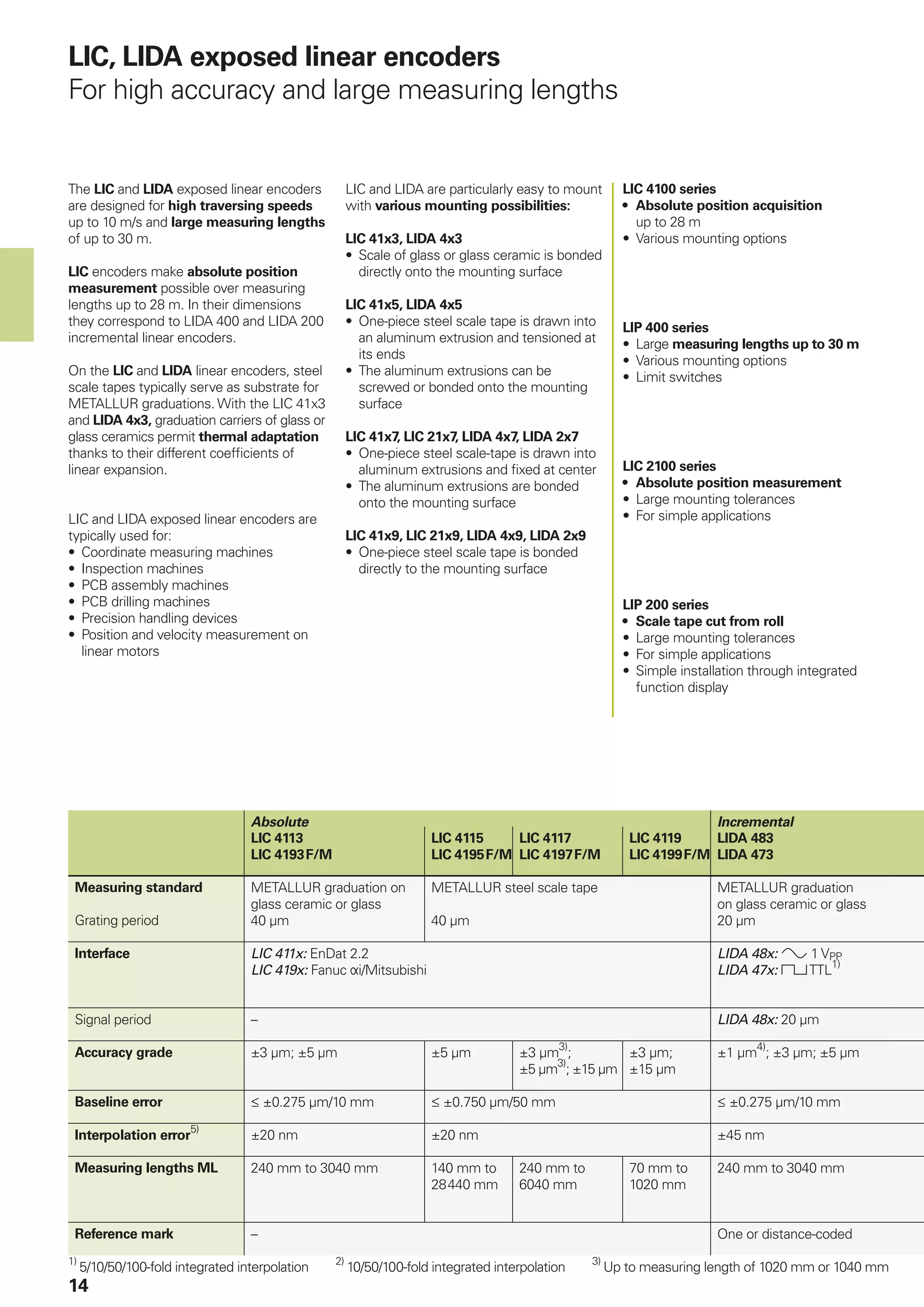

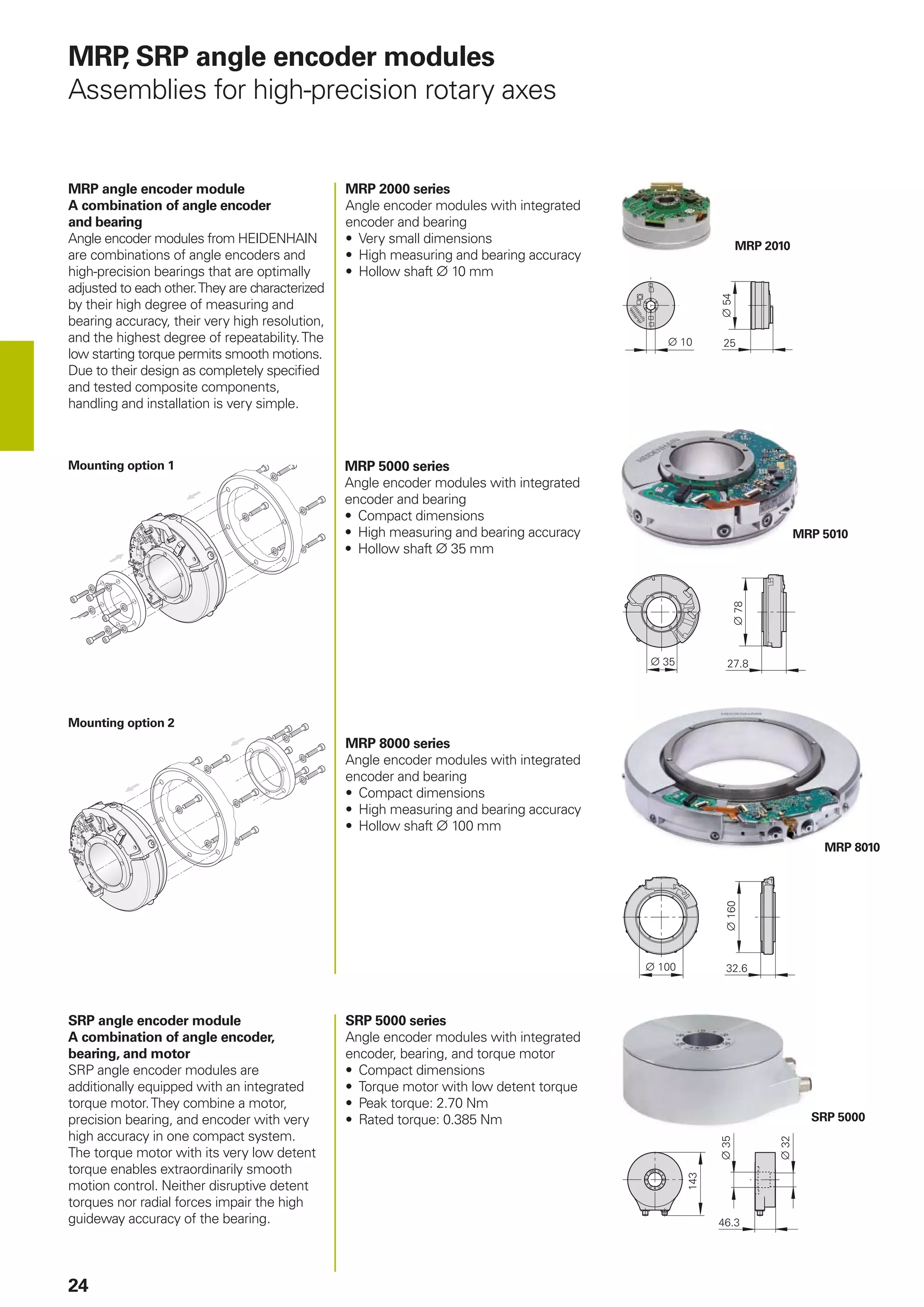

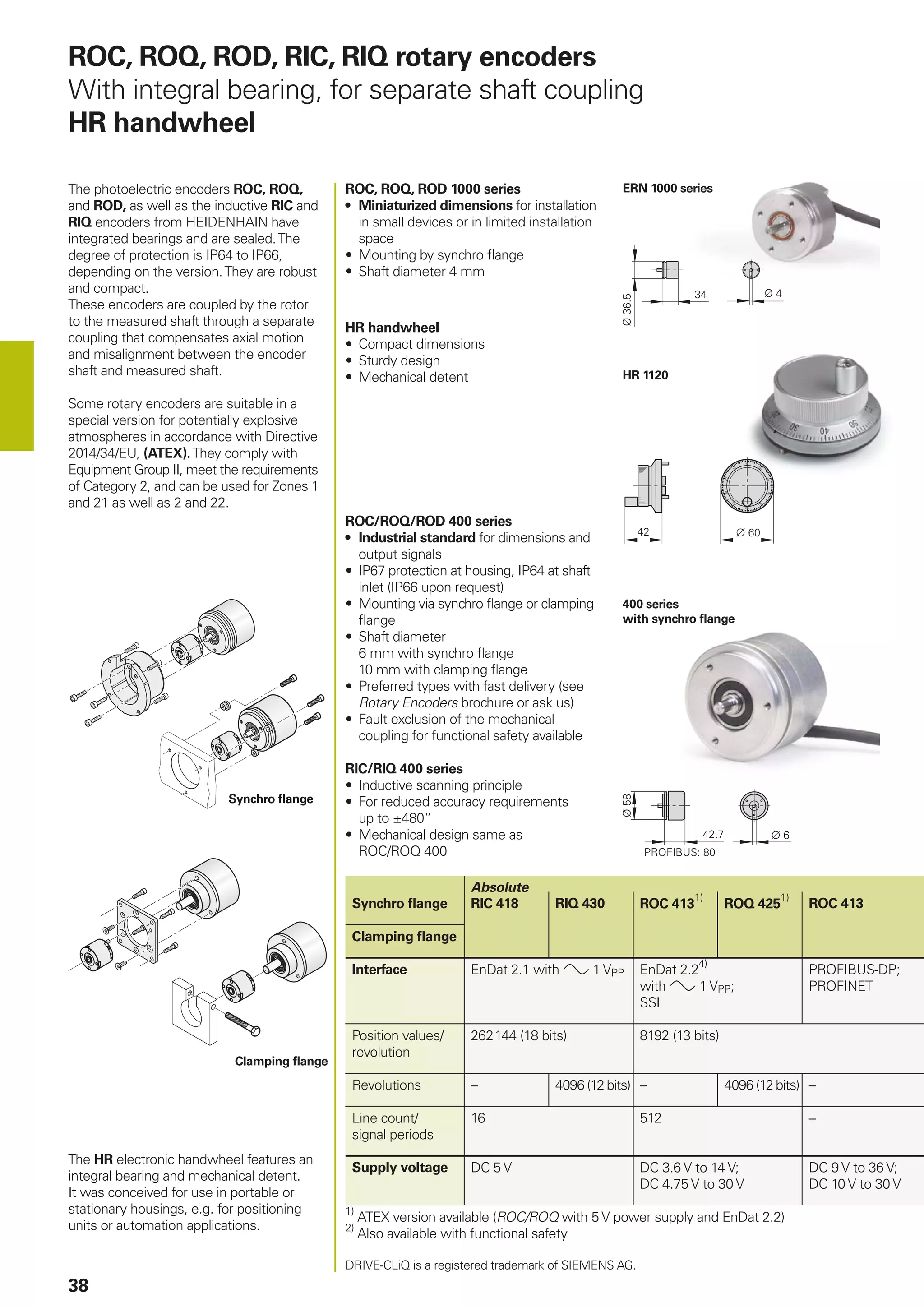

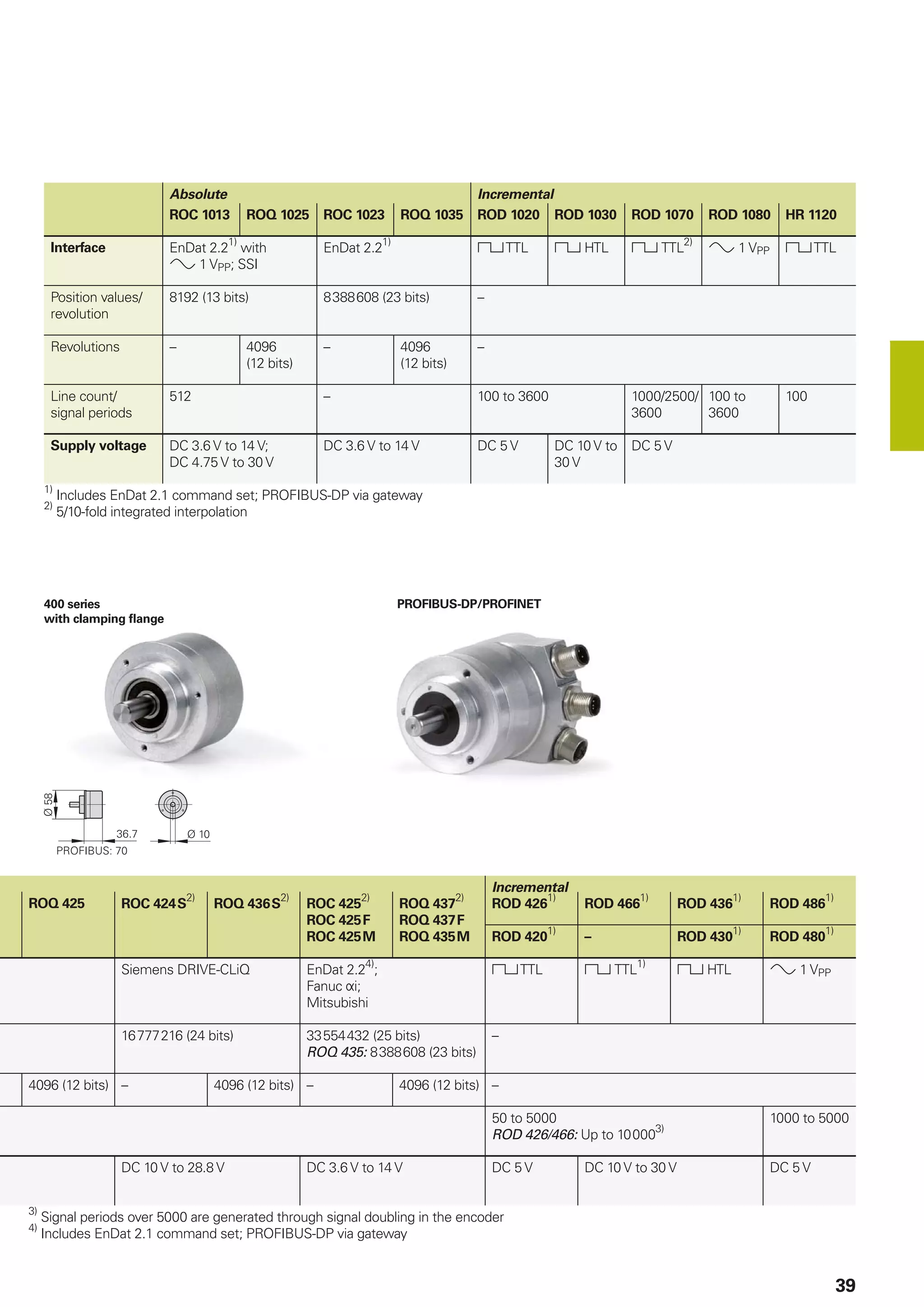

Heidenhain develops and manufactures a range of encoders, including linear, angle, and rotary encoders, as well as evaluation units and numerical controls, mainly for machine tool manufacturers and automated systems in the semiconductor and electronics sectors. The catalog outlines their product offerings, detailing different types of encoders with specifications for accuracy, measuring lengths, and environmental protection features. Heidenhain emphasizes high production quality through specialized facilities and a strong focus on customized solutions for various applications.