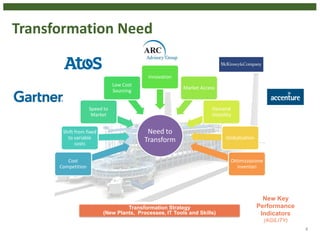

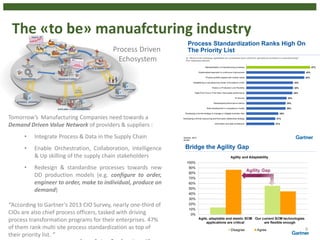

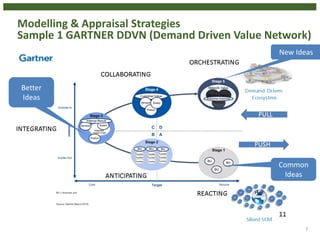

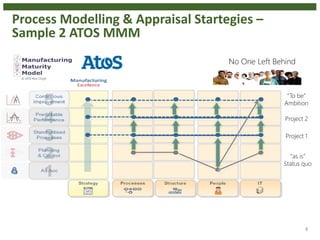

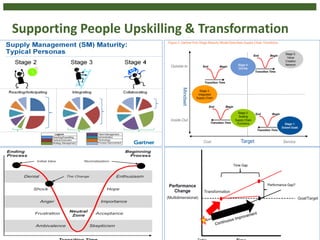

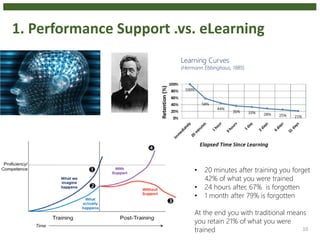

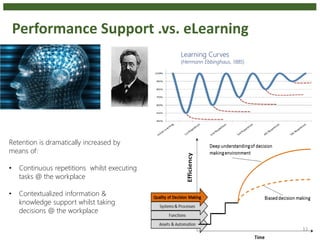

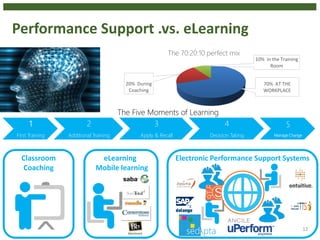

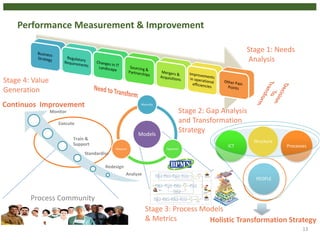

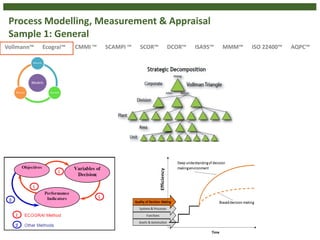

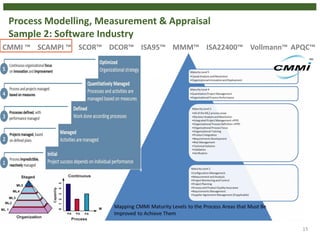

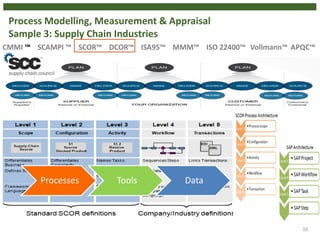

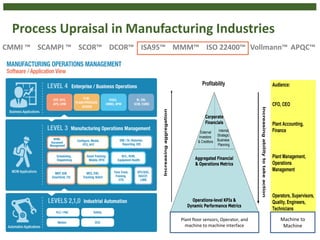

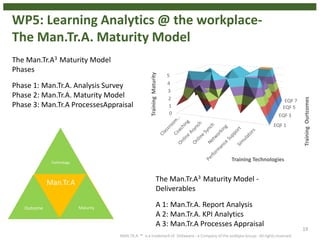

The document discusses the need for transformation in the manufacturing industry towards a demand-driven value network, emphasizing the integration of processes and data across supply chains. It presents the Manufacturing Training Analytics (man.tr.a.) maturity model as a tool for assessing and improving training and performance support within workplaces. The focus is on enhancing learning retention and operational efficiency through continuous, context-based support rather than traditional training methods.