This document provides specifications for a System on Chip (SoC) design containing a Memory Interface Block (MIB) and a Universal Asynchronous Receiver and Transmitter (UART) interface. It includes block diagrams, I/O descriptions, state machines, and verification simulations for the top level design and all internal blocks. The top level interacts with a provided TramelBlaze microcontroller core and contains the MIB and UART blocks. The MIB allows the TramelBlaze to interface with an off-chip memory. The UART block contains independently designed transmit and receive engines that have been verified to successfully transmit and receive serial data to and from a terminal via the UART interface. Revision 4.0

![Prepared by:

Phuong Nguyen

Date:

December 14, 2016

Document Name:

Final Specification

Revision:

4.0

Nguyen 13

Instruction Description Function Zero Carry

ADD sX, kk Add sX with literal kk sX ← sX + kk ? ?

CALL aaa Unconditionally call subroutine at aaa TOS ← PC

PC ← aaa

- -

COMP sX, kk Compare sX with literal kk, Set CARRY and

ZERO flags as appropriate.

If sX=kk, ZERO ← 1

If sX<kk, CARRY ← 1

? ?

ENINT Enable interrupt input INTERRUPT_ENABLE ← 1 - -

FETCH sX, ss Read scratchpad RAM location ss into

register sX

sX ← RAM[ss] - -

INPUT sX, pp Read value on input port location pp into

register sX

PORT_ID ← pp

sX ← IN_PORT

- -

JUMP aaa Unconditionally jump to aaa PC ← aaa - -

JUMPZ aaa If ZERO flag set, jump to aaa If ZERO=1, PC ← aaa - -

LOAD sX, kk Load register sX with literal kk sX ← kk - -

OUTPUT sX, pp Write register sX to output port location

pp

PORT_ID ← pp

OUT_PORT ← sX

- -

RETEN Return from interrupt service routine. PC ← TOS

ZERO ← Preserved ZERO

CARRY ← Preserved CARRY

INTERRUPT_ENABLE ← 1

? ?

RETURN Unconditionally return from subroutine PC ← TOS+1 - -

STORE sX, (sY) Write register sX to scratchpad RAM

location pointed to by register sY

RAM[(sY)] ← sX - -

Table 2: Instructions used by Design

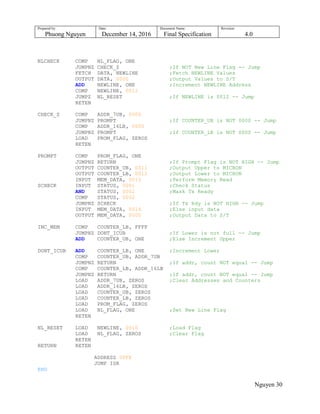

In the development of this design, many of the TramelBlaze‟s instructions were used to

create the ROM. Table 2 goes into detail with every instruction used in the development of the

UART.](https://image.slidesharecdn.com/6a2677cb-2966-481e-8a6c-00b20a1ce095-161224015254/85/Lab4_Report_460-13-320.jpg)

![Prepared by:

Phuong Nguyen

Date:

December 14, 2016

Document Name:

Final Specification

Revision:

4.0

Nguyen 24

4.5.2. Pin Assignment

Input Signals Assignment Output Signals Assignment

clk_in E3 Tx_Out D4

reset E16 ADV_n T13

Rx_In C4 CE_n L18

Parity_ops [2] V6 LB_n J15

Parity_ops [1] V7 UB_n J13

Parity_ops [0] R5 OE_n H14

Baud_Selector [3] R6 WE_n R11

Baud_Selector [2] R7 CRE J14

Baud_Selector [1] U8 mem_clk T15

Baud_Selector [0] U9 Status [7] U6

Status [6] U7

Status [5] T4

Status [4] T5

Status [3] T6

Status [2] R8

Status [1] V9

Status [0] T8

Table 10: Top Level Pin Assignments

Address Bus Data Bus

m_address[22]: U13 m_address[13]: U16 m_address[4]: H16 MIB_IO[1]: P17 MIB_IO[6]: T18

m_address[21]: M16 m_address[12]: P14 m_address[3]: J17 MIB_IO[1]: N17 MIB_IO[5]: R17

m_address[20]: T10 m_address[11]: V12 m_address[2]: H15 MIB_IO[1]: P18 MIB_IO[4]: U18

m_address[19]: U17 m_address[10]: V14 m_address[1]: H17 MIB_IO[1]: M17 MIB_IO[3]: R13

m_address[18]: V17 m_address[9]: U14 m_address[0]: J18 MIB_IO[1]: M18 MIB_IO[2]: U12

m_address[17]: M13 m_address[8]: V16 MIB_IO[1]: G17 MIB_IO[1]: T11

m_address[16]: N16 m_address[7]: N15 MIB_IO[9]: G18 MIB_IO[0]: R12

m_address[15]: N14 m_address[6]: K13 MIB_IO[8]: F18

m_address[14]: R15 m_address[5]: K15 MIB_IO[7]: R18

Table 11: Memory Address and Bidirectional Data Ports

4.5.3. Electrical Characteristics

Switches

o 1.8V are considered Logical 1

o 0V are considered Logical 0

Buttons

o 3.3V are considered Logical 1

o 0V are considered Logical 0](https://image.slidesharecdn.com/6a2677cb-2966-481e-8a6c-00b20a1ce095-161224015254/85/Lab4_Report_460-24-320.jpg)

![Prepared by:

Phuong Nguyen

Date:

December 14, 2016

Document Name:

Final Specification

Revision:

4.0

Nguyen 31

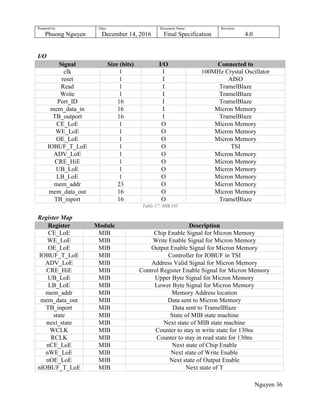

5. Externally Developed Blocks

5.1. Asynchronous In, Synchronous Out (AISO)

Description

This block ensures the reset to every

block‟s reset is synchronous to each other

hence the name. The reset of this block is

directly connected to a button (BTNC), which

when asserted will synchronously reset every

module.

I/O

Signal I/O Connected to

clk_in Input 100MHz Crystal Oscillator

reset Input BTNC

sync Output Every Block‟s Reset

Table 12: AISO I/O

Register Map

Register Usage Description

flop [1:0] Synchronize Upon reset, sends a single pulse to all modules

Table 13: AISO Register Map

Source Code: Appendix A17

Figure 10: AISO Block Diagram](https://image.slidesharecdn.com/6a2677cb-2966-481e-8a6c-00b20a1ce095-161224015254/85/Lab4_Report_460-31-320.jpg)

![Prepared by:

Phuong Nguyen

Date:

December 14, 2016

Document Name:

Final Specification

Revision:

4.0

Nguyen 32

5.2. TramelBlaze

Description

The TramelBlaze is a 16-bit soft-

core microcontroller that emulates the

PicoBlaze. The TramelBlaze provides the

instantiation for a ROM, which it will read

from and perform actions based on the

instructions provided by the ROM. In this

application, the TramelBlaze utilize every

port in order to receive ASCII values and

to transmit ASCII values to a Serial

Terminal. The READ_STROBE and

WRITE_STROBE will be outputted to

UART which will help the UART

determine whether to use the Transmit or

Receive Engine during a specific operation.

I/O

Signal I/O Connected to

IN_PORT [15:0] Input UART

CLK Input 100MHz Crystal Oscillator

INTERRUPT Input RS Flop

RESET Input AISO

OUT_PORT [15:0] Output UART

PORT_ID [15:0] Output UART & In_Sel MUX

INTERRUPT_ACK Output RS Flop

READ_STROBE Output UART

WRITE_STROBE Output UART

Table 14: TramelBlaze I/O

Register Map

Register Usage Description

R[15:0] PROM Functions individually in TramelBlaze PROM

Table 15: TramelBlaze Register Map

Figure 11: TramelBlaze Block Diagram](https://image.slidesharecdn.com/6a2677cb-2966-481e-8a6c-00b20a1ce095-161224015254/85/Lab4_Report_460-32-320.jpg)

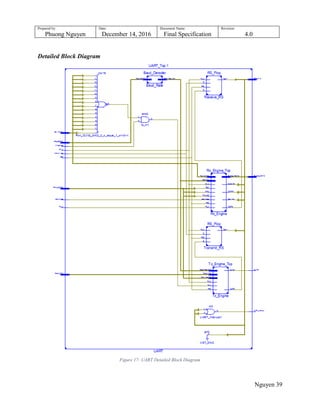

![Prepared by:

Phuong Nguyen

Date:

December 14, 2016

Document Name:

Final Specification

Revision:

4.0

Nguyen 43

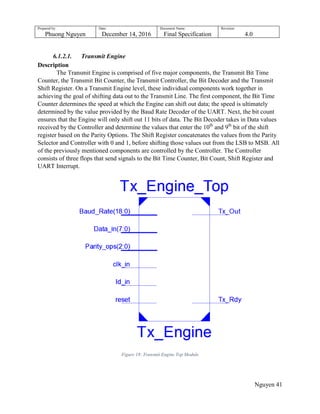

I/O

Signal Size (bits) I/O Connected to

clk_in 1 I 100MHz Crystal Oscillator

reset 1 I AISO

ld_in 1 I Write Strobe & Port ID

Baud_Rate 19 I Baud Rate Decoder

Data_in 8 I TramelBlaze

Parity_ops 3 I On-Board Switches

Tx_Rdy 1 I UART Interrupt

Tx_Out 1 I USB

Table 20: Transmit Engine I/O

Register Map

Register Module Description

count [18:0] Time_Counter Baud Rate Counter

count [3:0] Bit_Count Fixed number on how many times shift register can shift

Tx_Rdy Controller Acknowledge that Transmission is Ready

Load_D1 Controller Delays data to reach DoIt and Shift Register for one clock period

DoIt Controller Allows Bit Count and Bit Time Counter to increment

D_out [7:0] Controller Takes in Data from TramelBlaze

bit_10_9 Bit Decoder Determines what bit 10 and 9 of shift register will do

register [10:0] Shift Register Prepare data to be shifted out to a designated pin

SD0 Shift Register Takes in Data from TramelBlaze

Table 21: Transmit Engine Register Map

Source Code: Appendix A5

Verification

Figure 20: Transmit Engine Verification

The Transmit Engine is able to shift out data through the Tx_out line in accordance to the

requirements. This was done by giving the Transmit Engine different values, different Baud

Rates, and different Parity options to ensure that It was shifting out data properly.](https://image.slidesharecdn.com/6a2677cb-2966-481e-8a6c-00b20a1ce095-161224015254/85/Lab4_Report_460-43-320.jpg)

![Prepared by:

Phuong Nguyen

Date:

December 14, 2016

Document Name:

Final Specification

Revision:

4.0

Nguyen 47

Bit Decoder

Description

The Bit Decoder determines the

values that will be placed in the 10th

and 9th

bit location of the Transmit Shift Register.

This is entirely based on the values of the

Eight, Parity Enable, and oHeL lines which

are taken directly from the Nexys 4‟s on-

board switches. Table 25 provides the True

Table logic for the decoder.

Eight Parity oHeL 10 9

0 0 0 1 1

0 0 1 1 1

0 1 0 1 ^Data [6:0]

0 1 1 1 ~^Data [6:0]

1 0 0 1 Data [7]

1 0 1 1 Data [7]

1 1 0 ^Data [7:0] Data [7]

1 1 1 ~^ Data [7:0] Data [7]

Table 25: Bit Decoder Truth Table

I/O

Signal Size (bits) I/O Connected to

Reg8_in 8 I Tx Controller

bits_parity_oHeL 3 I On-board Switches

bit_10_9 2 O Tx Shift Register

Table 26: Bit Decoder I/O

Source Code: Appendix A9

Verification

Figure 28: Bit Decoder Verification

This Test Bench proves how the different options work with the same data of 8H‟9E.

Figure 27: Bit Decoder Module](https://image.slidesharecdn.com/6a2677cb-2966-481e-8a6c-00b20a1ce095-161224015254/85/Lab4_Report_460-47-320.jpg)

![Prepared by:

Phuong Nguyen

Date:

December 14, 2016

Document Name:

Final Specification

Revision:

4.0

Nguyen 51

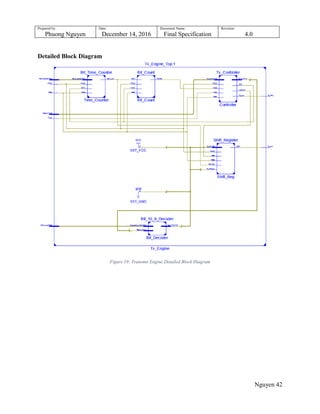

I/O

Signal Size (bits) I/O Connected to

clk_in 1 I 100MHz Crystal Oscillator

reset 1 I AISO

Rx_In 1 I USB

Eight 1 I On-Board Switches

Parity_En 1 I On-Board Switches

oHeL 1 I On-Board Switches

read_strobe 1 I TramelBlaze

Rate 19 I Baud Rate Decoder

Port_ID 16 I TramelBlaze

Rx_Rdy 1 O UART Interrupt

Parity_Err 1 O On-Board LED

Frame_Err 1 O On-Board LED

Overflow 1 O On-Board LED

Rx_Data_TB 8 O TramelBlaze

Table 28: Receive Engine I/O

Register Map

Register Module Description

count [18:0] Rx Time Counter Baud Rate Counter

Start State Machine Detection of a Start bit

DOIT State Machine Allows Counter to count

State [1:0] State Machine Current position in receiving

next_state [1:0] State Machine Holds value of next state

next_Start State Machine Holds value of next Start

next_DOIT State Machine Holds value of next DOIT

count [3:0] Rx Bit Count Fixed number on how many times shift register can shift

bits [3:0] Rx Bit Count Based on Parity Options, determines compare value

Rx_Rdy Rx Controller Signify readiness to take in data

Parity_Err Rx Controller If asserted, generate Parity does not match received

Frame_Err Rx Controller Stop Bit not detected

Overflow Rx Controller Too much information

F_Check Rx Controller Holds last value received by Shift Register

Data_Ctrl [9:0] Rx Shift Register Data sent to Rx Controller

Data_TB [7:0] Rx Shift Register Data sent to TramelBlaze

Data_Out [9:0] Rx Shift Register Raw Data shifted from Transmitter

Table 29: Receive Engine Register Map

Source Code: Appendix A11](https://image.slidesharecdn.com/6a2677cb-2966-481e-8a6c-00b20a1ce095-161224015254/85/Lab4_Report_460-51-320.jpg)

![Prepared by:

Phuong Nguyen

Date:

December 14, 2016

Document Name:

Final Specification

Revision:

4.0

Nguyen 61

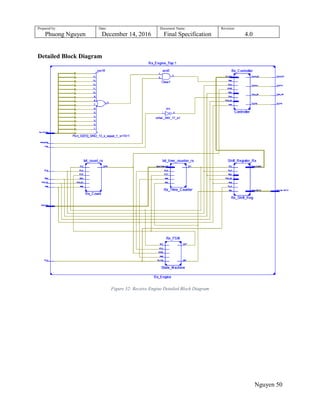

6.1.3. Baud Rate Decoder

Description

The Baud Rate Decoder is a 4-bit

Decoder that determines the speed at which the

Transmit and Receive Engine run at.

I/O

Signal Size (bits) I/O Connected to

Rate_Sel 4 I R6, R7, U8, U9

Baud_Rate 19 O Transmit Engine

Table 36: Baud Rate Decoder I/O

Register Map

Register Usage Description

Baud_Rate

[18:0]

Constant Change the constant that Bit Time Counter compares to

Table 37: Baud Rate Decoder Register Map

Source Code: Appendix A17

Verification

Figure 52: Baud Rate Decoder Verification

The Baud Rate Decoder proves that it is working properly by associating the correct

value with the correct switch orientation.

Figure 51: Baud Rate Decoder Module](https://image.slidesharecdn.com/6a2677cb-2966-481e-8a6c-00b20a1ce095-161224015254/85/Lab4_Report_460-61-320.jpg)

![Prepared by:

Phuong Nguyen

Date:

December 14, 2016

Document Name:

Final Specification

Revision:

4.0

Nguyen 62

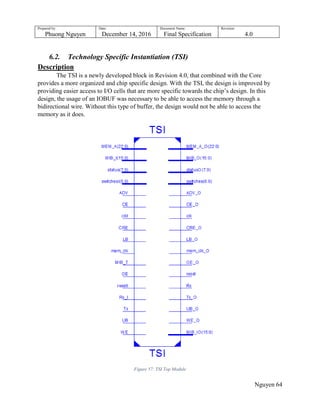

6.1.4. Pulse Maker

Description

This block generates a one clock period

pulse whenever a signal is asserted. With two D

flops inside, it is able to take the signal and generate

a one clock period pulse to the output. In this

application, The D_in input will take in an interrupt

signal from the UART and it will set the Interrupt

through the pulse and sent it over to an RS flop,

which manages the interrupt of the TramelBlaze.

I/O

Signal Size (bits) I/O Connected to

clk_in 1 I 100MHz Crystal Oscillator

D_in 1 I UART

reset 1 I AISO

pulse 1 O RS Flop (S)

Table 38: Pulse Maker I/O

Register Map

Register Usage Description

flop [1:0] Pulse Create a one clock cycle pulse when flop [1:0] = [0, 1]

Table 39: Pulse Maker Register Map

Source Code: Appendix A19

Verification

Figure 54: Pulse Maker Verification

This Test bench proves that the Pulse Maker is working properly, it is only sends a one

clock period pulse regardless of how long the signal may be.

Figure 53: Pulse Maker Module](https://image.slidesharecdn.com/6a2677cb-2966-481e-8a6c-00b20a1ce095-161224015254/85/Lab4_Report_460-62-320.jpg)

![Prepared by:

Phuong Nguyen

Date:

December 14, 2016

Document Name:

Final Specification

Revision:

4.0

Nguyen 71

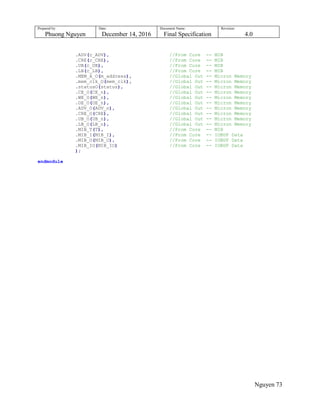

9. Appendix

The Appendix includes the Verilog code to every module developed or mentioned in this

report with the exception of the TramelBlaze.

A1. Top Module Source Code

`timescale 1ns / 1ps

//***********************************************************************//

// Class: CECS 460 - System on Chip Design //

// Project name: Final SOC Specification //

// File name: Lab4_TopModule.v //

// //

// Created by Phuong Nguyen //

// Copyright © 2016 Phuong Nguyen. All rights reserved. //

// //

// Overview: //

// Target Devices: Artix7 (Digilent Nexys 4) //

// Tool versions: Xilinx ISE Project Navigator 14.7 //

// Description: This is the project's top module. It instantiates the //

// Core and the TSI into one module. //

// //

// Revision History: //

// Revision 0.1 - File Created //

// Revision 0.2 - Variable Declaration //

// Revision 0.3 - Wire Declaration //

// Revision 0.4 - Instantiation of Core and TSI //

// Revision 0.5 - Test Benched //

// - Nexys 4 Test //

// Revision 1.0 - Ready for Demonstration //

//***********************************************************************//

module Lab4_TopModule(clk_in, reset, switches,

Rx, Tx,

m_address, status, CE_n, WE_n, OE_n, ADV_n, CRE, UB_n, LB_n,

mem_clk, MIB_IO

);

//FPGA Connection

input clk_in, reset;

input [6:0] switches;

wire c_clk, c_reset;

wire [6:0] c_switches;

//UART Connection

input Rx;

wire c_Tx, c_Rx;

output Tx;

//MIB Connection

wire [22:0] c_mem_addr;

wire [7:0] c_status;

wire c_CE, c_WE, c_OE, c_ADV, c_CRE, c_UB, c_LB;

wire c_mem_clk;

output [22:0] m_address;

output [7:0] status;

output CE_n, WE_n, OE_n, ADV_n, CRE, UB_n, LB_n;

output mem_clk;

output [15:0] MIB_IO;](https://image.slidesharecdn.com/6a2677cb-2966-481e-8a6c-00b20a1ce095-161224015254/85/Lab4_Report_460-71-320.jpg)

![Prepared by:

Phuong Nguyen

Date:

December 14, 2016

Document Name:

Final Specification

Revision:

4.0

Nguyen 72

wire [15:0] MIB_I, MIB_O;

wire T;

//INPUTS: clk_in, reset, Rx_In, [15:0] mem_data_in, [3:0] Baud_Sel,

// [2:0] Parity_ops;

//OUTPUTS: [22:0] mem_addr, [15:0] mem_data_out, IOBUF_T_LoE;

// CE_LoE, WE_LoE, OE_LoE, ADV_LoE, CRE_HiE, UB_LoE, LB_LoE;

// Tx_Out, [7:0] Status, mem_clk

Core Core(

.clk_in(c_clk),

.reset(c_reset),

.Rx_In(c_Rx), //From TSI -- Micro USB

.mem_data_in(MIB_O), //From TSI -- IOBUF

.Baud_Sel(c_switches[3:0]), //From TSI -- Switches

.Parity_ops(c_switches[6:4]), //From TSI -- Switches

.mem_addr(c_mem_addr), //To TSI -- Micron Memory

.mem_data_out(MIB_I), //To TSI -- IOBUF

.IOBUF_T_LoE(T), //To TSI -- IOBUF

.CE_LoE(c_CE), //To TSI -- Micron Memory

.WE_LoE(c_WE), //To TSI -- Micron Memory

.OE_LoE(c_OE), //To TSI -- Micron Memory

.ADV_LoE(c_ADV), //To TSI -- always "0"

.CRE_HiE(c_CRE), //To TSI -- always "0"

.UB_LoE(c_UB), //To TSI -- always "0"

.LB_LoE(c_LB), //To TSI -- always "0"

.Tx_Out(c_Tx), //To TSI -- Micro USB

.Status(c_status), //To TSI -- LEDs

.mem_clk(c_mem_clk) //To TSI -- Micron Memory

);

//FPGA Inputs

//INPUTS: clkI, resetI, [6:0] switchesI, Tx, Rx_I,

// [22:0] MEM_A, [7:0] status, CE, WE, OE, ADV, CRE, UB, LB

// MIB_T, [15:0] MIB_I

//OUTPUTS: clk, reset, [6:0] switches, Tx_O, Rx

// [22:0] MEM_A_O, [7:0] statusO, CE_O, WE_O, OE_O, ADV_O,

// CRE_O, UB_O, LB_O

// [15:0] MIB_O

//INOUTS: [15:0] MIB_IO

TSI TSI (

.clkI(clk_in), //Global In -- System Clock

.resetI(reset), //Global In -- Reset

.switchesI(switches), //Global In -- Switches

.clk(c_clk), //To Core -- System Clock

.reset(c_reset), //To Core -- Reset

.switches(c_switches), //To Core -- Switches

.Tx(c_Tx), //From Core -- Transmit Engine

.Rx_I(Rx), //Global In -- Receive Engine

.Tx_O(Tx), //Global Out -- Transmit Engine

.Rx(c_Rx), //To Core -- Receive Engine

.MEM_A(c_mem_addr), //From Core -- MIB

.status(c_status), //From Core -- Statuses

.mem_clk(c_mem_clk), //From Core -- Top

.CE(c_CE), //From Core -- MIB

.WE(c_WE), //From Core -- MIB

.OE(c_OE), //From Core -- MIB](https://image.slidesharecdn.com/6a2677cb-2966-481e-8a6c-00b20a1ce095-161224015254/85/Lab4_Report_460-72-320.jpg)

![Prepared by:

Phuong Nguyen

Date:

December 14, 2016

Document Name:

Final Specification

Revision:

4.0

Nguyen 74

A2. Core Source Code

`timescale 1ns / 1ps

//***********************************************************************//

// Class: CECS 460 - System on Chip Design //

// Project name: Final SOC Specification //

// File name: Core.v //

// //

// Created by Phuong Nguyen //

// Copyright © 2016 Phuong Nguyen. All rights reserved. //

// //

// Overview: //

// Target Devices: Artix7 (Digilent Nexys 4) //

// Tool versions: Xilinx ISE Project Navigator 14.7 //

// Description: The Core contains the instantiation of design's //

// processor, its interfaces, and its accessory modules. //

// //

// Revision History: //

// Revision 0.1 - File Created //

// Revision 0.2 - Variable Declaration //

// Revision 0.3 - Wire Declaration //

// Revision 1.0 - Imported from CECS 460 Project 3: Full UART //

// Revision 1.1 - Name change to Core //

// Revision 1.2 - Instantiation of MIB //

// - Modification of conditional assignment //

// - MIB variables declared //

// Revision 1.3 - Creation of mem_clk conditional assignment //

// Revision 1.4 - Test Benched //

// Revision 2.0 - Ready for Demonstration //

//***********************************************************************//

module Core(clk_in, reset, Rx_In, mem_data_in, Baud_Sel, Parity_ops,

mem_addr, mem_data_out, IOBUF_T_LoE, CE_LoE, WE_LoE, OE_LoE,

ADV_LoE, CRE_HiE, UB_LoE, LB_LoE, Tx_Out, Status, mem_clk,

);

input clk_in, reset, Rx_In;

input [15:0] mem_data_in;

input [3:0] Baud_Sel;

input [2:0] Parity_ops;

output [22:0] mem_addr;

output [15:0] mem_data_out;

output IOBUF_T_LoE;

output wire CE_LoE, WE_LoE, OE_LoE, ADV_LoE, CRE_HiE, UB_LoE, LB_LoE;

output wire Tx_Out;

output wire [7:0] Status;

output wire mem_clk;

wire [15:0] TB_In, TB_inport;

wire [15:0] Port_ID;

wire [15:0] TB_outport;

wire [7:0] Rx_Data;

wire reset_sync;

wire write_strobe, read_strobe, UART_Int;

wire Pulse, Interrupt, Interrupt_Ack;

wire ld_in, In_Sel;

assign mem_clk = 1'b0;](https://image.slidesharecdn.com/6a2677cb-2966-481e-8a6c-00b20a1ce095-161224015254/85/Lab4_Report_460-74-320.jpg)

![Prepared by:

Phuong Nguyen

Date:

December 14, 2016

Document Name:

Final Specification

Revision:

4.0

Nguyen 75

assign ld_in = write_strobe && (Port_ID == 16'b0000); //To Tx_Engine

assign TB_In = (Port_ID == 16'h0001) ? {8'b0, Status}:

(Port_ID == 16'h0000) ? {8'b0, Rx_Data}:

(Port_ID == 16'h0014) ? TB_inport:

16'b0;

//INPUTS: clk_in, reset, Read, Write, [15:0] Port_ID, [15:0] mem_data_in,

// [15:0] TB_outport

//OUTPUTS: CE_LoE, WE_LoE, OE_LoE, IOBUF_T_LoE, ADV_LoE, CRE_HiE, UB_LoE,

// LB_LoE, [22:0] mem_addr, [15:0] mem_data_out, [15:0] TB_inport;

MIB MIB (.clk(clk_in),

.reset(reset),

.Port_ID(Port_ID), //From TramelBlaze

.Read(read_strobe), //From TramelBlaze

.Write(write_strobe), //From TramelBlaze

.TB_outport(TB_outport), //From TramelBlaze

.mem_data_in(mem_data_in), //Global -- To TSI

.CE_LoE(CE_LoE), //Global -- To Memory

.WE_LoE(WE_LoE), //Global -- To Memory

.OE_LoE(OE_LoE), //Global -- To Memory

.IOBUF_T_LoE(IOBUF_T_LoE), //Global -- To TSI

.ADV_LoE(ADV_LoE), //Global -- To Memory

.CRE_HiE(CRE_HiE), //Global -- To Memory

.UB_LoE(UB_LoE), //Global -- To Memory

.LB_LoE(LB_LoE), //Global -- To Memory

.mem_addr(mem_addr), //Global -- To Memory

.mem_data_out(mem_data_out), //Global -- To TSI

.TB_inport(TB_inport) //From TramelBlaze

);

//INPUTS: clk_in, reset, *Port_ID, *****Data_In, **Rate_Sel,

// ***Parity_ops, write_strobe, read_strobe, Rx_In,

//OUTPUTS: ****Rx_Data_TB, *****Status, UART_Interrupt, Tx_Out

//*[15:0], **[3:0], ***[2:0], ****[9:0], *****[7:0];

UART_Top UART(.clk_in(clk_in),

.reset(reset_sync),

.Port_ID(Port_ID), //From TramelBlaze

.Data_In(TB_outport), //From TramelBlaze

.Rate_Sel(Baud_Sel), //Global Input – Switches

.Parity_ops(Parity_ops), //Global Input – Switches

.write_strobe(write_strobe), //From TramelBlaze

.read_strobe(read_strobe), //From TramelBlaze

.Rx_In(Rx_In), //From USB***

.Interrupt_Ack(Interrupt_Ack), //From TramelBlaze

.ld_in(ld_in), //From Assign Statement

.Rx_Data_TB(Rx_Data), //To TramelBlaze

.Status(Status), //Global Output

.UART_Interrupt(UART_Int), //To Pulse Maker

.Tx_Out(Tx_Out) //To USB

);

//INPUTS: CLK, RESET, *IN_PORT, INTERRUPT,

//OUTPUTS: *OUT_PORT, *PORT_ID, READ_STROBE, WRITE_STROBE, INTERRUPT_ACK

//*[15:0]

tramelblaze_top TramelBlaze (.CLK(clk_in),

.RESET(reset_sync),

.IN_PORT(TB_In), //From UART,

.INTERRUPT(Interrupt), //From RS Flop

.OUT_PORT(TB_outport), //To UART

.PORT_ID(Port_ID), //To UART, MIB](https://image.slidesharecdn.com/6a2677cb-2966-481e-8a6c-00b20a1ce095-161224015254/85/Lab4_Report_460-75-320.jpg)

![Prepared by:

Phuong Nguyen

Date:

December 14, 2016

Document Name:

Final Specification

Revision:

4.0

Nguyen 77

A3. MIB Source Code

`timescale 1ns / 1ps

//***********************************************************************//

// Class: CECS 460 - System on Chip Design //

// Project name: Final SOC Specification //

// File name: MIB.v //

// //

// Created by Tony Le & Phuong Nguyen //

// Copyright © 2016 Tony Le & Phuong Nguyen. All rights reserved. //

// //

// Overview: //

// Target Devices: Artix7 (Digilent Nexys 4) //

// Tool versions: Xilinx ISE Project Navigator 14.7 //

// Description: The MIB sends signals to the Micron Memory as it //

// receives data and sends data to it based on the //

// signals. //

// //

// Revision History: //

// Revision 0.1 - File Created //

// Revision 0.2 - Variable Declaration //

// Revision 0.3 - Wire Declaration //

// Revision 0.4 - Creation of State Machine //

// Revision 0.5 - Creation of Control Flops //

// Revision 0.6 - Changes to Clock Counter //

// Revision 0.7 - Test Benched with Cell Ram Module //

// Revision 0.8 - Changes to RD_R flop //

// Revision 1.0 - Ready for Demonstration //

//***********************************************************************//

module MIB(clk, reset, Port_ID, Read, Write, //LoE = Low Enable

TB_outport, mem_data_in, //HiE = High Enable

CE_LoE, WE_LoE, OE_LoE, IOBUF_T_LoE,

ADV_LoE, CRE_HiE, UB_LoE, LB_LoE,

mem_addr, mem_data_out, TB_inport

);

input clk, reset;

input Read, Write;

input [15:0] Port_ID;

input [15:0] mem_data_in;

input [15:0] TB_outport;

//control lines

output reg CE_LoE, WE_LoE, OE_LoE, IOBUF_T_LoE; //signal depends on state

output reg ADV_LoE, CRE_HiE, UB_LoE, LB_LoE; //signal will always be 1'b0

//output data signals

output reg [22:0] mem_addr;

output reg [15:0] mem_data_out;

output reg [15:0] TB_inport;

reg [3:0] state, next_state;

reg [3:0] WCLK, RCLK; //counter for read and write state

wire write_done, read_done; //done signal for write and read state

reg nCE_LoE, nWE_LoE, nOE_LoE, nIOBUF_T_LoE; //next state command signal

reg nADV_LoE, nCRE_HiE, nUB_LoE, nLB_LoE;](https://image.slidesharecdn.com/6a2677cb-2966-481e-8a6c-00b20a1ce095-161224015254/85/Lab4_Report_460-77-320.jpg)

![Prepared by:

Phuong Nguyen

Date:

December 14, 2016

Document Name:

Final Specification

Revision:

4.0

Nguyen 78

//internal registers holding the addr and data

reg [6:0] WA_R0;

reg [15:0] WA_R1, WD_R;

reg [15:0] RD_R;

parameter //control word parameter

IDLE = 4'h0,

MEM_WRITE = 4'h1,

MEM_READ = 4'h2,

//operation word parameter

WADDR1 = 16'h11,

WADDR2 = 16'h12,

WDATA = 16'h13,

RDATA = 16'h14,

MEMREAD = 16'h15,

MEMWRITE = 16'h16;

//************************************************************************************

//Control Word Present state logic

always @(posedge clk, posedge reset) begin

if(reset)

begin

state <= IDLE; //reset to idle state

//because low polarity, resets to one

{CE_LoE, WE_LoE, OE_LoE, IOBUF_T_LoE} <= 4'b1_1_1_1;

//signal always 0

{ADV_LoE, CRE_HiE, UB_LoE, LB_LoE} <= 4'b0_0_0_0;

end

else

begin

state <= next_state;

{CE_LoE, WE_LoE, OE_LoE, IOBUF_T_LoE} <=

{nCE_LoE, nWE_LoE, nOE_LoE, nIOBUF_T_LoE};

end

end

//Control Word Next State Logic

always @ (*) begin

case(state)

IDLE: //idle state not accessing memory

begin

{nCE_LoE, nWE_LoE, nOE_LoE, nIOBUF_T_LoE} = 4'b1_1_1_1;

if((Port_ID == 16'h16) && Write) //condition to write

next_state = MEM_WRITE;

else if(Port_ID == 16'h15 && Read) //condition to read

next_state = MEM_READ;

else

next_state = IDLE;

end

MEM_WRITE: //MEM_WRITE access memory to write into it

begin

{nCE_LoE, nWE_LoE, nOE_LoE, nIOBUF_T_LoE} = 4'b0_0_1_0;

if(WCLK == 4'b1100) next_state = IDLE;

else next_state = MEM_WRITE;](https://image.slidesharecdn.com/6a2677cb-2966-481e-8a6c-00b20a1ce095-161224015254/85/Lab4_Report_460-78-320.jpg)

![Prepared by:

Phuong Nguyen

Date:

December 14, 2016

Document Name:

Final Specification

Revision:

4.0

Nguyen 80

//start of operation logic

always @ (posedge clk, posedge reset)

if(reset) begin

WA_R0 <= 7'h0;

WA_R1 <= 16'h0;

WD_R <= 16'h0;

mem_addr <= 16'h0;

mem_data_out <= 16'h0;

TB_inport <= 16'h0;

end

else

case(Port_ID)

WADDR1: if(Write) WA_R0 <= TB_outport[6:0];

else WA_R0 <= WA_R0;

WADDR2: if(Write) WA_R1 <= TB_outport;

else WA_R1 <= WA_R1;

WDATA: if(Write) WD_R <= TB_outport;

else WD_R <= WD_R;

RDATA: TB_inport <= RD_R;

MEMREAD: if(Read)

mem_addr <= {WA_R0, WA_R1};

else

mem_addr <= mem_addr;

MEMWRITE: if(Write) begin

mem_addr <= {WA_R0, WA_R1};

mem_data_out <= WD_R;

end

else begin

mem_addr <= mem_addr;

mem_data_out <= mem_data_out;

end

default: begin

WA_R0 <= WA_R0;

WA_R1 <= WA_R1;

WD_R <= WD_R;

mem_addr <= mem_addr;

mem_data_out <= mem_data_out;

TB_inport <= TB_inport;

end

endcase

always @ (posedge clk, posedge reset)

if(reset) RD_R <= 16'h0000;

else if(RCLK == 4'b1011) RD_R <= mem_data_in;

else RD_R <= RD_R;

endmodule](https://image.slidesharecdn.com/6a2677cb-2966-481e-8a6c-00b20a1ce095-161224015254/85/Lab4_Report_460-80-320.jpg)

![Prepared by:

Phuong Nguyen

Date:

December 14, 2016

Document Name:

Final Specification

Revision:

4.0

Nguyen 81

A4. UART Top Source Code

`timescale 1ns / 1ps

//***********************************************************************//

// Class: CECS 460 - System on Chip Design //

// Project name: Final SOC Specification //

// File name: UART.v //

// //

// Created by Phuong Nguyen //

// Copyright © 2016 Phuong Nguyen . All rights reserved. //

// //

// Overview: //

// Target Devices: Artix7 (Digilent Nexys 4) //

// Tool versions: Xilinx ISE Project Navigator 14.7 //

// Description: The Universal Asynchronous Receiver and Transmitter //

// instantiates the Transmit Engine, Receive Engine and //

// Baud Rate Decoder together. //

// //

// Revision History: //

// Revision 0.1 - File Created //

// Revision 0.2 - Variable Declaration //

// Revision 0.3 - Assign statement for Tx Load, UART Interrupt //

// Revision 0.4 - Concatenate Statuses and Tx_Rdy and Rx_Rdy //

// Revision 1.0 - Ready for Demonstration //

// Revision 2.0 - Imported from CECS 460 Project 3: Full UART //

//***********************************************************************//

module UART_Top(clk_in, reset, Port_ID, Data_In, Rate_Sel, Parity_ops,

write_strobe, read_strobe, Rx_In, Interrupt_Ack, ld_in,

Rx_Data_TB, Status, UART_Interrupt, Tx_Out);

input clk_in, reset;

input [15:0] Port_ID;

input [7:0] Data_In;

input [3:0] Rate_Sel;

input [2:0] Parity_ops;

input write_strobe, read_strobe;

input Rx_In, Interrupt_Ack;

input ld_in;

output [7:0] Rx_Data_TB, Status;

output UART_Interrupt, Tx_Out;

wire [18:0] B_Rate;

wire Rx_Rdy, Tx_Rdy, Rx_RS, Tx_RS;

wire PERR, FERR, OVF;

assign UART_Interrupt = Rx_Rdy || Tx_Rdy; //Global Output

assign Status = {3'b0, OVF, FERR, PERR, Tx_Rdy, Rx_Rdy}; //Global Output

//INPUTS: clk_in, reset, ld_in, [18:0] Baud_Rate, [7:0] Data_in,

// [2:0] Parity_ops;

//OUTPUTS: Tx_Rdy, Tx_Out;

Tx_Engine_Top Tx_Engine (.clk_in(clk_in),

.reset(reset),

.ld_in(ld_in), //Global Input

.Baud_Rate(B_Rate), //From Baud Decoder

.Data_in(Data_In), //Global Input -- TramelBlaze

.Parity_ops(Parity_ops), //Global Input -- Switches

.Tx_Rdy(Tx_RS), //To Transmit RS Flop

.Tx_Out(Tx_Out) //Global Output](https://image.slidesharecdn.com/6a2677cb-2966-481e-8a6c-00b20a1ce095-161224015254/85/Lab4_Report_460-81-320.jpg)

![Prepared by:

Phuong Nguyen

Date:

December 14, 2016

Document Name:

Final Specification

Revision:

4.0

Nguyen 82

);

//INPUT: clk_in, reset, R, S;

//OUTPUT: D_out;

RS_Flop Transmit_RS (.clk_in(clk_in),

.reset(reset),

.R(Interrupt_Ack),

.S(Tx_RS),

.D_out(Tx_Rdy)

);

//INPUTS: clk_in, reset, Rx_In, Eight, Parity_En, oHeL, read_strobe,

// [18:0] Rate, [15:0] Port_ID,

//OUTPUTS: Rx_Rdy, Parity_Err, Frame_Err, Overflow, [7:0] Rx_Data_TB

Rx_Engine_Top Rx_Engine (.clk_in(clk_in),

.reset(reset),

.Rx_In(Rx_In), //Global Input -- USB

.Eight(Parity_ops[2]), //Global Input -- Switches

.Parity_En(Parity_ops[1]), //Global Input -- Switches

.oHeL(Parity_ops[0]), //Global Input -- Switches

.read_strobe(read_strobe), //Global Input -- TB

.Rate(B_Rate), //From Baud Decoder

.Port_ID(Port_ID), //Global Input -- TB

.Rx_Rdy(Rx_RS), //To Status & Receive RS

.Parity_Err(PERR), //To Status

.Frame_Err(FERR), //To Status

.Overflow(OVF), //To Status

.Rx_Data_TB(Rx_Data_TB) //Global Output

);

//INPUT: clk_in, reset, R, S;

//OUTPUT: D_out;

RS_Flop Receive_RS (.clk_in(clk_in),

.reset(reset),

.R(Interrupt_Ack),

.S(Rx_RS),

.D_out(Rx_Rdy)

);

//INPUTS: [3:0] Rate_Sel

//OUTPUTS: [18:0] Baud_Rate

Baud_Decoder Baud_Rate (.Rate_Sel(Rate_Sel), //Global Input -- Switches

.Baud_Rate(B_Rate) //To Tx and Rx Engine

);

endmodule](https://image.slidesharecdn.com/6a2677cb-2966-481e-8a6c-00b20a1ce095-161224015254/85/Lab4_Report_460-82-320.jpg)

![Prepared by:

Phuong Nguyen

Date:

December 14, 2016

Document Name:

Final Specification

Revision:

4.0

Nguyen 83

A5. Transmit Engine Top Source Code

`timescale 1ns / 1ps

//***********************************************************************//

// Created by Phuong Nguyen //

// Copyright © 2016 Phuong Nguyen. All rights reserved. //

// //

// Overview: //

// Target Devices: Artix7 (Digilent Nexys 4) //

// Tool versions: Xilinx ISE Project Navigator 14.7 //

// Description: This module instantiates the Tx Engine together. //

// It connects thes Bit Count, Bit Time Counter, //

// Controller and Shift Register together. //

// //

// Revision History: //

// Revision 0.1 - File Created //

// Revision 0.2 - Variable Declaration //

// Revision 0.3 - Wire Declaration //

// Revision 0.4 - Instantiate all Modules //

// Revision 0.5 - Test Benched //

// Revision 1.0 - Ready for Demonstration //

// Revision 2.0 - Imported from CECS 460 Project 2: Transmit Engine //

// Revision 3.0 - Imported from CECS 460 Project 3: Full UART //

//***********************************************************************//

module Tx_Engine_Top(clk_in, reset, ld_in, Baud_Rate, Data_in, Parity_ops,

Tx_Rdy, Tx_Out);

input clk_in, reset, ld_in;

input [18:0] Baud_Rate;

input [7:0] Data_in;

input [2:0] Parity_ops;

output Tx_Rdy, Tx_Out;

wire [7:0] Reg_out;

wire DoIt, done;

wire Load_D1;

wire BTU;

wire [1:0] bit_10_9;

//INPUTS: clk_in, reset, DOIT, BTU

//OUTPUTS: DONE

Bit_Count_Tx Tx_Count (.clk_in(clk_in),

.reset(reset),

.DOIT(DoIt),

.BTU(BTU),

.DONE(done)

);

//INPUTS: clk_in, reset, DOIT, Baud_Rate*

//OUTPUTS: BTU_out

//*[18:0]

Bit_Time_Counter_Tx Tx_Time_Counter (.clk_in(clk_in),

.reset(reset),

.DOIT(DoIt),

.Baud_Rate(Baud_Rate),

.BTU_out(BTU)

);

//INPUTS: clk_in, reset, done, load, Out_Port*

//OUTPUTS: Tx_rdy, Load_D1, DoIt, D_out*](https://image.slidesharecdn.com/6a2677cb-2966-481e-8a6c-00b20a1ce095-161224015254/85/Lab4_Report_460-83-320.jpg)

![Prepared by:

Phuong Nguyen

Date:

December 14, 2016

Document Name:

Final Specification

Revision:

4.0

Nguyen 84

//*[7:0]

Tx_Controller Controller (.clk_in(clk_in),

.reset(reset),

.done(done),

.load(ld_in),

.Out_Port(Data_in),

.Tx_rdy(Tx_Rdy),

.Load_D1(Load_D1),

.DoIt(DoIt),

.D_out(Reg_out)

);

//INPUTS: Reg8_in*, bits_parity_oHeL**

//OUTPUTS: bit_10_9***

//*[7:0] **[2:0] ***[1:0]

Bit_10_9_Decoder Bit_Decoder (.Reg8_in(Reg_out),

.bits_parity_oHeL(Parity_ops),

.bit_10_9(bit_10_9)

);

//INPUTS: clk_in, reset, load, shift_en, S_Data_in, D_in*

//OUTPUTS: SD0

//*[10:0]

Shift_Register_Tx Tx_Shift_Reg (.clk_in(clk_in),

.reset(reset),

.load(Load_D1),

.shift_en(BTU),

.S_Data_in(1'b1),

.D_in({bit_10_9, Reg_out[6:0], 2'b01}),

.SD0(Tx_Out)

);

endmodule](https://image.slidesharecdn.com/6a2677cb-2966-481e-8a6c-00b20a1ce095-161224015254/85/Lab4_Report_460-84-320.jpg)

![Prepared by:

Phuong Nguyen

Date:

December 14, 2016

Document Name:

Final Specification

Revision:

4.0

Nguyen 85

A6. Transmit Bit Count Source Code

`timescale 1ns / 1ps

//***********************************************************************//

// Created by Phuong Nguyen //

// Copyright © 2016 Phuong Nguyen. All rights reserved. //

// //

// Overview: //

// Target Devices: Artix7 (Digilent Nexys 4) //

// Tool versions: Xilinx ISE Project Navigator 14.7 //

// Description: This module will count the number of times the shift //

// register shifts through. It ensures that the shift //

// register does not shift pass 11 times. //

// //

// Revision History: //

// Revision 0.1 - File Created //

// Revision 0.2 - Variable Declaration //

// Revision 0.3 - Assign statement & Sequential Logic //

// Revision 0.4 - Test Benched //

// Revision 1.0 - Ready for Demonstration //

// Revision 2.0 - Imported from CECS 460 Project 2: Transmit Engine //

// Revision 3.0 - Imported from CECS 460 Project 3: Full UART //

//***********************************************************************//

module Bit_Count_Tx(clk_in, reset, DOIT, BTU, DONE);

input clk_in, reset;

input DOIT, BTU;

output DONE;

reg [3:0] count;

// Pulse when count is 11

assign DONE = (count == 12);

always @(posedge clk_in, posedge reset) begin

if(reset) count <= 4'b0;

else if(DONE) count <= 4'b0;

else

case({DOIT, BTU})

2'b00: count <= 4'b0;

2'b01: count <= 4'b0;

2'b10: count <= count;

2'b11: count <= count + 4'b1;

endcase

end

endmodule](https://image.slidesharecdn.com/6a2677cb-2966-481e-8a6c-00b20a1ce095-161224015254/85/Lab4_Report_460-85-320.jpg)

![Prepared by:

Phuong Nguyen

Date:

December 14, 2016

Document Name:

Final Specification

Revision:

4.0

Nguyen 86

A7. Transmit Bit Time Counter Source Code

`timescale 1ns / 1ps

//***********************************************************************//

// Created by Phuong Nguyen //

// Copyright © 2016 Phuong Nguyen. All rights reserved. //

// //

// Overview: //

// Target Devices: Artix7 (Digilent Nexys 4) //

// Tool versions: Xilinx ISE Project Navigator 14.7 //

// Description: The Bit Time Counter determines the speed at which //

// the Transmit Engine will run at. It will continuously //

// count to a given Baud Rate Count and assert its //

// output //

// //

// Revision History: //

// Revision 0.1 - File Created //

// Revision 0.2 - Variable Declaration //

// Revision 0.3 - Assign and Always statement //

// Revision 1.0 - Ready for Demonstration //

// Revision 2.0 - Imported from CECS 460 Project 2: Transmit Engine //

// Revision 3.0 - Imported from CECS 460 Project 3: Full UART //

//***********************************************************************//

module Bit_Time_Counter_Tx(clk_in, reset, DOIT, Baud_Rate, BTU_out);

input clk_in, reset;

input DOIT;

input [18:0] Baud_Rate;

output wire BTU_out;

reg [18:0] count;

// Pulse when count is 11

assign BTU_out = (count == Baud_Rate);

always @(posedge clk_in, posedge reset) begin

if(reset) count <= 19'b0;

else if(BTU_out) count <= 19'b0; else

case({DOIT, BTU_out})

2'b00: count <= 19'b0;

2'b01: count <= 19'b0;

2'b10: count <= count + 19'b1;

2'b11: count <= 19'b0;

default: count <= count;

endcase

end

endmodule](https://image.slidesharecdn.com/6a2677cb-2966-481e-8a6c-00b20a1ce095-161224015254/85/Lab4_Report_460-86-320.jpg)

![Prepared by:

Phuong Nguyen

Date:

December 14, 2016

Document Name:

Final Specification

Revision:

4.0

Nguyen 87

A8. Transmit Controller Source Code

`timescale 1ns / 1ps

//***********************************************************************//

// Created by Phuong Nguyen //

// Copyright © 2016 Phuong Nguyen. All rights reserved. //

// //

// Overview: //

// Target Devices: Artix7 (Digilent Nexys 4) //

// Tool versions: Xilinx ISE Project Navigator 14.7 //

// Description: Tx_Controller consists of all the necessary flop in //

// order to dictate the Tx Engine's workings. //

// //

// Revision History: //

// Revision 0.1 - File Created //

// Revision 0.2 - Variable Declaration //

// Revision 0.3 - Sequential Logic for all flops //

// Revision 0.4 - Correction to Tx_Rdy flop //

// Revision 0.5 - Test Benched //

// Revision 1.0 - Ready for Demonstration //

// Revision 2.0 - Imported from CECS 460 Project 2: Transmit Engine //

// Revision 3.0 - Imported from CECS 460 Project 3: Full UART //

//***********************************************************************//

module Tx_Controller(clk_in, reset, done, load, Out_Port, Tx_rdy, Load_D1,

DoIt, D_out);

input clk_in, reset, done, load;

input [7:0] Out_Port;

output reg Tx_rdy, Load_D1, DoIt;

output reg [7:0] D_out;

// Tx_rdy RS flop (reverse logic)

always @ (posedge clk_in, posedge reset) begin

if(reset) Tx_rdy <= 1'b1;

else if (load) Tx_rdy <= 1'b0;

else if (done) Tx_rdy <= 1'b1;

else Tx_rdy <= Tx_rdy;

end

// D Flip Flop output to DoIt and Shift Reg

always @ (posedge clk_in, posedge reset) begin

if(reset) Load_D1 <= 1'b0;

else Load_D1 <= load;

end

// DoIt RS flop

always @ (posedge clk_in, posedge reset) begin

if(reset) DoIt <= 1'b0;

else if(done) DoIt <= 1'b0;

else if(Load_D1) DoIt <= 1'b1;

else DoIt <= DoIt;

end

// Out_Port Load Register

always @ (posedge clk_in, posedge reset) begin

if(reset) D_out <= 8'b0;

else if(load) D_out <= Out_Port;

else D_out <= D_out;

end

endmodule](https://image.slidesharecdn.com/6a2677cb-2966-481e-8a6c-00b20a1ce095-161224015254/85/Lab4_Report_460-87-320.jpg)

![Prepared by:

Phuong Nguyen

Date:

December 14, 2016

Document Name:

Final Specification

Revision:

4.0

Nguyen 88

A9. Transmit Bit 10 & 9 Decoder Source Code

`timescale 1ns / 1ps

//***********************************************************************//

// Created by Phuong Nguyen //

// Copyright © 2016 Phuong Nguyen. All rights reserved. //

// //

// Overview: //

// Target Devices: Artix7 (Digilent Nexys 4) //

// Tool versions: Xilinx ISE Project Navigator 14.7 //

// Description: This Decoder will determine the values that go into //

// bits 10 and 9, it can be an 8th bit, or a parity //

// depending on the user's input. //

// //

// Revision History: //

// Revision 0.1 - File Created //

// Revision 0.2 - Variable Declaration //

// Revision 0.3 - Decode Logic //

// Revision 0.4 - Test Benched //

// Revision 1.0 - Ready for Demonstration //

// Revision 2.0 - Imported from CECS 460 Project 2: Transmit Engine //

// Revision 3.0 - Imported from CECS 460 Project 3: Full UART //

//***********************************************************************//

module Bit_10_9_Decoder(Reg8_in, bits_parity_oHeL, bit_10_9);

input [7:0] Reg8_in;

input [2:0] bits_parity_oHeL;

output reg [1:0] bit_10_9;

always @ (*) begin

case (bits_parity_oHeL)

3'b000: bit_10_9 <= 2'b11;

3'b001: bit_10_9 <= 2'b11;

3'b010: bit_10_9 <= {1'b1, ^Reg8_in[6:0]};

3'b011: bit_10_9 <= {1'b1, ~^Reg8_in[6:0]};

3'b100: bit_10_9 <= {1'b1, Reg8_in[7]};

3'b101: bit_10_9 <= {1'b1, Reg8_in[7]};

3'b110: bit_10_9 <= {^Reg8_in[7:0], Reg8_in[7]};

3'b111: bit_10_9 <= {~^Reg8_in[7:0], Reg8_in[7]};

default: bit_10_9 <= 2'b11;

endcase

end

endmodule](https://image.slidesharecdn.com/6a2677cb-2966-481e-8a6c-00b20a1ce095-161224015254/85/Lab4_Report_460-88-320.jpg)

![Prepared by:

Phuong Nguyen

Date:

December 14, 2016

Document Name:

Final Specification

Revision:

4.0

Nguyen 89

A10. Transmit Shift Register Source Code

`timescale 1ns / 1ps

//***********************************************************************//

// Created by Phuong Nguyen //

// Copyright © 2016 Phuong Nguyen. All rights reserved. //

// //

// Overview: //

// Target Devices: Artix7 (Digilent Nexys 4) //

// Tool versions: Xilinx ISE Project Navigator 14.7 //

// Description: The shift register will take in data from the bit //

// decoder and the controller register and appropriately //

// shift bit outs one by one. //

// //

// Revision History: //

// Revision 0.1 - File Created //

// Revision 0.2 - Variable Declaration //

// Revision 0.3 - Sequential Logic Design for Shift Register //

// Revision 0.4 - Test Benched //

// Revision 1.0 - Ready for Demonstration //

// Revision 2.0 - Imported from CECS 460 Project 2: Transmit Engine //

// Revision 3.0 - Imported from CECS 460 Project 3: Full UART //

//***********************************************************************//

module Shift_Register_Tx(clk_in, reset, load, shift_en, S_Data_in, D_in, SD0);

input clk_in, reset, load, shift_en, S_Data_in;

input [10:0] D_in;

output reg SD0;

reg [10:0] register;

always @ (posedge clk_in, posedge reset) begin

if(reset) begin

register <= 11'h7FF;

SD0 <= 1'b1;

end

else if (load) register <= D_in;

else if (shift_en) begin

register <= {S_Data_in, register[10:1]};

SD0 <= register[0];

end

else begin

register <= register;

SD0 <= SD0;

end

end

endmodule](https://image.slidesharecdn.com/6a2677cb-2966-481e-8a6c-00b20a1ce095-161224015254/85/Lab4_Report_460-89-320.jpg)

![Prepared by:

Phuong Nguyen

Date:

December 14, 2016

Document Name:

Final Specification

Revision:

4.0

Nguyen 90

A11: Receive Engine Top Source Code

`timescale 1ns / 1ps

//***********************************************************************//

// Created by Phuong Nguyen //

// Copyright © 2016 Phuong Nguyen. All rights reserved. //

// //

// Overview: //

// Target Devices: Artix7 (Digilent Nexys 4) //

// Tool versions: Xilinx ISE Project Navigator 14.7 //

// Description: This module instantiates the Rx Engine together. //

// It connects the Shift Register, State Machine, //

// Controller, Bit Count, Bit Time Counter. //

// //

// Revision History: //

// Revision 0.1 - File Created //

// Revision 0.2 - Variable Declaration //

// Revision 0.3 - Wire Declaration //

// Revision 0.4 - Instantiate Shift Register, State Machine, Controller,//

// - Bit Count and Bit Timer Counter //

// Revision 0.5 - Tx Line fed into Rx Line //

// Revision 1.0 - Ready for Demonstration //

// Revision 2.0 - Imported from CECS 460 Project 3: Full UART //

//***********************************************************************//

module Rx_Engine_Top(clk_in, reset, Rx_In, Eight, Parity_En, oHeL, read_strobe,

Rate, Port_ID, Rx_Rdy, Parity_Err, Frame_Err, Overflow,

Rx_Data_TB);

input clk_in, reset, Rx_In, Eight, Parity_En, oHeL, read_strobe;

input [18:0] Rate;

input [15:0] Port_ID;

output Rx_Rdy, Parity_Err, Frame_Err, Overflow;

output [7:0] Rx_Data_TB;

wire [9:0] Data_Ctrl;

wire BTU, Start;

wire DONE, DOIT;

wire Clear;

assign Clear = read_strobe && (Port_ID == 16'b0000);

//INPUTS: clk_in, reset, BTU, Start, Rx_In, DONE, Eight, Parity_En,

//OUTPUTS: *Data_Ctrl, **Data_TB

//*[9:0], ** [7:0]

Shift_Register_Rx Rx_Shift_Reg (.clk_in(clk_in),

.reset(reset),

.BTU(BTU), //From Bit Time Counter

.Start(Start), //From FSM

.Rx_In(Rx_In), //Global Input

.Eight(Eight), //Global Input

.Parity_En(Parity_En), //Global Input

.Data_Ctrl(Data_Ctrl), //To Controller

.Data_TB(Rx_Data_TB) //Global Out

);

//INPUTS: clk_in, reset, Rx_Line, BTU, DONE;

//OUTPUTS: Start, DOIT

Rx_FSM State_Machine (.clk_in(clk_in),

.reset(reset),

.Rx_Line(Rx_In), //Global Output](https://image.slidesharecdn.com/6a2677cb-2966-481e-8a6c-00b20a1ce095-161224015254/85/Lab4_Report_460-90-320.jpg)

![Prepared by:

Phuong Nguyen

Date:

December 14, 2016

Document Name:

Final Specification

Revision:

4.0

Nguyen 91

.BTU(BTU), //From Bit Time Counter

.DONE(DONE), //From Bit Count

.Start(Start), //To Shift Register and Time Counter

.DOIT(DOIT) //To Bit Count and Bit Time Counter

);

//INPUTS: clk_in, reset, DONE, Clear, Eight, Parity_En, Even, *D_In;

//OUTPUTS: Rx_Rdy, Parity_Err, Frame_Err, Overflow;

//*[9:0]

Rx_Controller Controller(.clk_in(clk_in),

.reset(reset),

.DONE(DONE), //From Bit Count

.Clear(Clear), //Global Input

.Eight(Eight), //Global Input

.Parity_En(Parity_En), //Global Input

.Even(!oHeL), //Global Input

.D_In(Data_Ctrl), //From Shift Register

.Rx_Rdy(Rx_Rdy), //Global Output

.Parity_Err(Parity_Err), //Global Output

.Frame_Err(Frame_Err), //Global Output

.Overflow(Overflow) //Global Output

);

//INPUTS: clk_in, reset, DOIT, BTU, Eight, Parity_En

//OUTPUTS: DONE

bit_count_rx Rx_Count(.clk_in(clk_in),

.reset(reset),

.DOIT(DOIT), //From FSM

.BTU(BTU), //From Bit Time Counter

.Eight(Eight), //Global Input

.Parity_En(Parity_En), //Global Input

.DONE(DONE) //To FSM, Controller,

);

//INPUTS: clk_in, reset, DOIT, Start, Baud_Rate*

//OUTPUTS: BTU

//*[18:0]

bit_time_counter_rx Rx_Time_Counter(.clk_in(clk_in),

.reset(reset),

.DOIT(DOIT), //From FSM

.Start(Start), //From FSM

.Baud_Rate(Rate), //Global Input

.BTU(BTU) //To FSM,SR, Bit Counter

);

endmodule](https://image.slidesharecdn.com/6a2677cb-2966-481e-8a6c-00b20a1ce095-161224015254/85/Lab4_Report_460-91-320.jpg)

![Prepared by:

Phuong Nguyen

Date:

December 14, 2016

Document Name:

Final Specification

Revision:

4.0

Nguyen 92

A12: Receive Shift Register Source Code

`timescale 1ns / 1ps

//***********************************************************************//

// Created by Phuong Nguyen //

// Copyright © 2016 Phuong Nguyen. All rights reserved. //

// //

// Overview: //

// Target Devices: Artix7 (Digilent Nexys 4) //

// Tool versions: Xilinx ISE Project Navigator 14.7 //

// Description: This module acts as the data receive of the Receive //

// Engine, any data gets shifted into this module before //

// it goes to any other modules //

// //

// Revision History: //

// Revision 0.1 - File Created //

// Revision 0.2 - Variable Declaration //

// Revision 0.3 - Wire Declaration //

// Revision 0.4 - Create Shift Register Block //

// Revision 0.5 - Create assign statement //

// Revision 0.6 - Changed Combinational Block Behavior //

// Revision 0.7 - Test Benched, Verified //

// Revision 1.0 - Ready for Demonstration //

// Revision 2.0 - Imported from CECS 460 Project 3: Full UART //

//***********************************************************************//

module Shift_Register_Rx(clk_in, reset, BTU, Start, Rx_In, Eight, Parity_En,

Data_Ctrl, Data_TB);

input clk_in, reset, BTU, Start, Rx_In;

input Eight, Parity_En;

output reg [9:0] Data_Ctrl;

output reg [7:0] Data_TB;

reg [9:0] Data_Out;

wire Shift_En;

assign Shift_En = BTU && !Start;

/***Raw Data shifted in***/

always @ (posedge clk_in, posedge reset) begin

if(reset) Data_Out <= 10'b0;

else if (Shift_En) Data_Out <= {Rx_In, Data_Out[9:1]};

else Data_Out <= Data_Out;

end

always @ (*) begin

case ({Eight, Parity_En})

2'b00:{Data_Ctrl, Data_TB} <= {2'b0, Data_Out[9:2], 1'b0, Data_Out[8:2]};

2'b01:{Data_Ctrl, Data_TB} <= {1'b0, Data_Out[9:1], 1'b0, Data_Out[7:1]};

2'b10:{Data_Ctrl, Data_TB} <= {1'b0, Data_Out[9:1], Data_Out[8:1]};

2'b11:{Data_Ctrl, Data_TB} <= {1'b0, Data_Out[8:0], Data_Out[7:0]};

default:{Data_Ctrl, Data_TB} <= Data_Out;

endcase

end

endmodule](https://image.slidesharecdn.com/6a2677cb-2966-481e-8a6c-00b20a1ce095-161224015254/85/Lab4_Report_460-92-320.jpg)

![Prepared by:

Phuong Nguyen

Date:

December 14, 2016

Document Name:

Final Specification

Revision:

4.0

Nguyen 93

A13. Receive State Machine Source Code

`timescale 1ns / 1ps

//***********************************************************************//

// Created by Phuong Nguyen //

// Copyright © 2016 Phuong Nguyen. All rights reserved. //

// //

// Overview: //

// Target Devices: Artix7 (Digilent Nexys 4) //

// Tool versions: Xilinx ISE Project Navigator 14.7 //

// Description: This module detects the Start bit of the data //

// received and allows the counters to work when it is //

// detected. The state machine will allow the counter to //

// keep counting up until the counter send a signal to //

// signify its completion of data reception. //

// //

// Revision History: //

// Revision 0.1 - File Created //

// Revision 0.2 - Variable Declaration //

// Revision 0.3 - Wire Declaration //

// Revision 0.4 - Create Next State Logic Block //

// Revision 0.5 - Create Present State Combinational Block //

// Revision 0.6 - Changed FSM State Machine to Modified Moore //

// Revision 0.7 - Test Benched, Verified //

// Revision 1.0 - Ready for Demonstration //

// Revision 2.0 - Imported from CECS 460 Project 3: Full UART //

//***********************************************************************//

module Rx_FSM(clk_in, reset, Rx_Line, BTU, DONE, Start, DOIT);

input clk_in, reset;

input Rx_Line, BTU, DONE;

output reg Start, DOIT;

reg [1:0] state, next_state;

reg next_Start, next_DOIT;

parameter IDLE = 0, START = 1, DO_IT = 2;

/***Next State Logic***/

always @ (posedge clk_in, posedge reset) begin

if(reset) begin

state <= IDLE;

Start <= 1'b0;

DOIT <= 1'b0;

end

else begin

state <= next_state;

Start <= next_Start;

DOIT <= next_DOIT;

end

end

/***Present State Logic***/

always @ (*) begin

case (state)

IDLE: begin

if(Rx_Line)

{next_state, next_Start, next_DOIT} = {IDLE, 2'b00};

else

{next_state, next_Start, next_DOIT} = {START, 2'b11};

end

START: begin](https://image.slidesharecdn.com/6a2677cb-2966-481e-8a6c-00b20a1ce095-161224015254/85/Lab4_Report_460-93-320.jpg)

![Prepared by:

Phuong Nguyen

Date:

December 14, 2016

Document Name:

Final Specification

Revision:

4.0

Nguyen 95

A14. Receive Controller Source Code

`timescale 1ns / 1ps

//***********************************************************************//

// Created by Phuong Nguyen //

// Copyright © 2016 Phuong Nguyen. All rights reserved. //

// //

// Overview: //

// Target Devices: Artix7 (Digilent Nexys 4) //

// Tool versions: Xilinx ISE Project Navigator 14.7 //

// Description: The controller determines the parity of the data //

// received by the receive engine. At the same time, //

// this module sends a signal to denote that it is ready //

// to receive data. //

// //

// Revision History: //

// Revision 0.1 - File Created //

// Revision 0.2 - Variable Declaration //

// Revision 0.3 - Wire Declaration //

// Revision 0.4 - Create Sequential Logic Blocks for parities //

// Revision 0.5 - Create Combinational Block for parity logic //

// Revision 0.6 - Test Benched, Verified //

// Revision 1.0 - Ready for Demonstration //

// Revision 2.0 - Imported from CECS 460 Project 3: Full UART //

//***********************************************************************//

module Rx_Controller(clk_in, reset, DONE, Clear, Eight, Parity_En, Even, D_In,

Rx_Rdy, Parity_Err, Frame_Err, Overflow);

input clk_in, reset, DONE, Clear, Eight, Parity_En, Even;

input [9:0] D_In;

output reg Rx_Rdy, Parity_Err, Frame_Err, Overflow;

//Parity Error Wiring

wire P_REC, Bit8, P_XOR, P_GEN, GEN_REC, Parity_In;

// Framing Error Wiring

reg F_Check;

wire F_Compare, Frame_In;

// Overflow Wiring

wire Over_In;

// Parity Error Set Logic

assign P_REC = Eight ? D_In[8] : D_In[7];

assign Bit8 = Eight ? D_In[7] : 1'b0;

assign P_XOR = ^{Bit8, D_In[6:0]};

assign P_GEN = Even ? P_XOR : !P_XOR;

assign GEN_REC = ^{P_GEN, P_REC};

assign Parity_In = Parity_En && GEN_REC && DONE;

// Framing Error Set Logic

always @ (*) begin

case ({Eight, Parity_En})

2'b00: F_Check = D_In[7];

2'b01: F_Check = D_In[8];

2'b10: F_Check = D_In[8];

2'b11: F_Check = D_In[9];

default: F_Check = D_In[7];

endcase

end](https://image.slidesharecdn.com/6a2677cb-2966-481e-8a6c-00b20a1ce095-161224015254/85/Lab4_Report_460-95-320.jpg)

![Prepared by:

Phuong Nguyen

Date:

December 14, 2016

Document Name:

Final Specification

Revision:

4.0

Nguyen 97

A15: Receive Bit Count Source Code

`timescale 1ns / 1ps

//***********************************************************************//

// Created by Phuong Nguyen //

// Copyright © 2016 Phuong Nguyen. All rights reserved. //

// //

// Overview: //

// Target Devices: Artix7 (Digilent Nexys 4) //

// Tool versions: Xilinx ISE Project Navigator 14.7 //

// Description: This module counts the bits received by the receive //

// engine, it is all determined by the values set in //

// the eight and parity enable options on the on-board //

// switches. //

// //

// Revision History: //

// Revision 0.1 - File Created //

// Revision 0.2 - Variable Declaration //

// Revision 0.3 - Wire Declaration //

// Revision 0.4 - Create Sequential Logic for Counter //

// Revision 0.5 - Create MUX based on Eight and Parity Enable //

// Revision 0.6 - Modification of MUX values //

// Revision 1.0 - Ready for Demonstration //

// Revision 2.0 - Imported from CECS 460 Project 3: Full UART //

//***********************************************************************//

module bit_count_rx(clk_in, reset, DOIT, BTU, Eight, Parity_En, DONE);

input clk_in, reset, DOIT, BTU;

input Eight, Parity_En;

output DONE;

reg [3:0] count, bits;

assign DONE = (count == bits);

always @ (posedge clk_in, posedge reset) begin

if (reset) count <= 4'b0;

else if (DONE) count <= 4'b0;

else begin

case ({DOIT, BTU})

2'b00: count <= 4'b0;

2'b01: count <= 4'b0;

2'b10: count <= count;

2'b11: count <= count + 4'b1;

default: count <= count;

endcase

end

end

always @ (*) begin

case ({Eight, Parity_En})

2'b00: bits = 9;

2'b01: bits = 10;

2'b10: bits = 10;

2'b11: bits = 11;

default: bits = 9;

endcase

end

endmodule](https://image.slidesharecdn.com/6a2677cb-2966-481e-8a6c-00b20a1ce095-161224015254/85/Lab4_Report_460-97-320.jpg)

![Prepared by:

Phuong Nguyen

Date:

December 14, 2016

Document Name:

Final Specification

Revision:

4.0

Nguyen 98

A16: Receive Bit Time Counter Source Code

`timescale 1ns / 1ps

//***********************************************************************//

// Created by Phuong Nguyen //

// Copyright © 2016 Phuong Nguyen. All rights reserved. //

// //

// Overview: //

// Target Devices: Artix7 (Digilent Nexys 4) //

// Tool versions: Xilinx ISE Project Navigator 14.7 //

// Description: Similar to the bit time counter of the transmit, this //

// time counter differs by the way it halves its baud //

// rate whenever a Start bit is detected by the state //

// machine, this allows the receive engine to pick up //

// data at the half way mark of each bit. //

// //

// Revision History: //

// Revision 0.1 - File Created //

// Revision 0.2 - Variable Declaration //

// Revision 0.3 - Wire Declaration //

// Revision 0.4 - Create Sequential Logic Block for Counter //

// Revision 0.5 - Create assign statement to change Baud Rate //

// Revision 1.0 - Ready for Demonstration //

//***********************************************************************//

module bit_time_counter_rx(clk_in, reset, DOIT, Start, Baud_Rate, BTU);

input clk_in, reset, DOIT, Start;

input [18:0] Baud_Rate;

output wire BTU;

reg [18:0] count;

wire [18:0] Rate;

assign BTU = (count == Rate);

assign Rate = Start ? (Baud_Rate >> 1): Baud_Rate;

always @ (posedge clk_in, posedge reset) begin

if (reset) count <= 19'b0;

else if (BTU) count <= 19'b0;

else begin

case ({DOIT, BTU})

2'b00: count <= 19'b0;

2'b01: count <= 19'b0;

2'b10: count <= count + 19'b1;

2'b11: count <= 19'b0;

default: count <= count;

endcase

end

end

endmodule](https://image.slidesharecdn.com/6a2677cb-2966-481e-8a6c-00b20a1ce095-161224015254/85/Lab4_Report_460-98-320.jpg)

![Prepared by:

Phuong Nguyen

Date:

December 14, 2016

Document Name:

Final Specification

Revision:

4.0

Nguyen 99

A17. Baud Rate Decoder Source Code

`timescale 1ns / 1ps

//***********************************************************************//

// Created by Phuong Nguyen //

// Copyright © 2016 Phuong Nguyen. All rights reserved. //

// //

// Overview: //

// Target Devices: Artix7 (Digilent Nexys 4) //

// Tool versions: Xilinx ISE Project Navigator 14.7 //

// Description: The Baud Decoder will determine the speed at which //

// the transmit engine will run. The given values will //

// be sent to the Bit Time Counter which dictates the //

// speed. //

// //

// Revision History: //

// Revision 0.1 - File Created //

// Revision 0.2 - Variable Declaration //

// Revision 0.3 - Decode Logic for Baud Rate //

// Revision 0.4 - Test Benched //

// Revision 1.0 - Ready for Demonstration //

// Revision 2.0 - Imported from CECS 460 Project 2: Transmit Engine //

// Revision 3.0 - Imported from CECS 460 Project 3: Full UART //

//***********************************************************************//

module Baud_Decoder(Rate_Sel, Baud_Rate);

input [3:0] Rate_Sel;

output reg [18:0] Baud_Rate;

//Decode the Baud Rate

always @ (*) begin

case (Rate_Sel)

4'b0000: Baud_Rate = 333333; //300

4'b0001: Baud_Rate = 83333; //1200

4'b0010: Baud_Rate = 41667; //2400

4'b0011: Baud_Rate = 20833; //4800

4'b0100: Baud_Rate = 10417; //9600

4'b0101: Baud_Rate = 5208; //19200

4'b0110: Baud_Rate = 2604; //38400

4'b0111: Baud_Rate = 1736; //57600

4'b1000: Baud_Rate = 868; //115200

4'b1001: Baud_Rate = 434; //230400

4'b1010: Baud_Rate = 217; //460800

4'b1011: Baud_Rate = 109; //921600

default: Baud_Rate = 0;

endcase

end

endmodule](https://image.slidesharecdn.com/6a2677cb-2966-481e-8a6c-00b20a1ce095-161224015254/85/Lab4_Report_460-99-320.jpg)

![Prepared by:

Phuong Nguyen

Date:

December 14, 2016

Document Name:

Final Specification

Revision:

4.0

Nguyen 100

A18. AISO Source Code

`timescale 1ns / 1ps

//***********************************************************************//

// Created by John Tramel //

// Copyright © 2016 John Tramel. All rights reserved. //

// //

// Overview: //

// Target Devices: Artix7 (Digilent Nexys 4) //

// Tool versions: Xilinx ISE Project Navigator 14.7 //

// Description: AISO known better as Asynchronous In, Synchronous Out //

// will synchronize the reset for all modules so that //

// everything runs at the same time. //

// //

// Revision History: //

// Revision 0.1 - File Created //

// Revision 0.2 - Variable Declaration //

// Revision 0.3 - Assign and Always statement //

// Revision 1.0 - Ready for Demonstration //

// Revision 2.0 - Imported from CECS 360 Project 1: Up Down Counter //

// Revision 3.0 - Imported from CECS 460 Project 1: The TramelBlaze //

// Revision 4.0 - Imported from CECS 460 Project 2: Transmit Engine //

// Revision 5.0 - Imported from CECS 460 Project 3: Full UART //

//***********************************************************************//

module AISO(clk_in, reset, sync);

input clk_in, reset;

output sync;

reg [1:0] flop;

assign sync = ~flop[1];

always @ (posedge clk_in, posedge reset) begin

if (reset)

flop <= 2'b0;

else

flop <= {flop[0], 1'b1}; //flop[1] gets flop[0]

end //flop[0] gets 1'b1

endmodule](https://image.slidesharecdn.com/6a2677cb-2966-481e-8a6c-00b20a1ce095-161224015254/85/Lab4_Report_460-100-320.jpg)

![Prepared by:

Phuong Nguyen

Date:

December 14, 2016

Document Name:

Final Specification

Revision:

4.0

Nguyen 101

A19. Pulse Maker Source Code

`timescale 1ns / 1ps

//***********************************************************************//

// Created by Phuong Nguyen //

// Copyright © 2016 Phuong Nguyen. All rights reserved. //

// //

// Overview: //

// Target Devices: Artix7 (Digilent Nexys 4) //

// Tool versions: Xilinx ISE Project Navigator 14.7 //

// Description: This module functions to create pulses based on when //

// a debounced mechanical switch is pressed. It consists //

// of two flops that will output a pulse whenever one of //

// the flops is on and the other is off //

// //

// Revision History: //

// Revision 0.1 - File Created //

// Revision 0.2 - Variable Declaration //

// - Creation of two flops and always statement //

// Revision 0.3 - Correction on syntax of register //

// - Syntax Check //

// Revision 1.0 - Ready for Demonstration //

// Revision 2.0 - Imported from CECS 460 Project 1: The TramelBlaze //

// Revision 3.0 - Imported from CECS 460 Project 2: Transmit Engine //

// Revision 4.0 - Imported from CECS 460 Project 3: Full UART //

//***********************************************************************//

module pulse_maker(clk_in, reset, D_in, pulse);

input clk_in, reset, D_in;

output pulse;

reg [1:0] flop;

assign pulse = ~flop[1] && flop[0];

always @ (posedge clk_in, posedge reset) begin

if(reset) flop <= 2'b0;

else flop <= {flop[0], D_in};

end

endmodule](https://image.slidesharecdn.com/6a2677cb-2966-481e-8a6c-00b20a1ce095-161224015254/85/Lab4_Report_460-101-320.jpg)

![Prepared by:

Phuong Nguyen

Date:

December 14, 2016

Document Name:

Final Specification

Revision:

4.0

Nguyen 103

A21. TSI Source Code

`timescale 1ns / 1ps

//***********************************************************************//

// Created by Phuong Nguyen //

// Copyright © 2016 Phuong Nguyen. All rights reserved. //

// //

// Overview: //

// Target Devices: Artix7 (Digilent Nexys 4) //

// Tool versions: Xilinx ISE Project Navigator 14.7 //

// Description: The TSI handles all the inputs and outputs coming in //

// and out of the Core. //

// //

// Revision History: //

// Revision 0.1 - File Created //

// Revision 0.2 - Variable Declaration //

// Revision 0.3 - IOBUF, IBUF, OBUF, and IBUYF Created //

// Revision 0.4 - Test Benched with Project 3 Code //

// Revision 1.0 - Ready for Demonstration //

//***********************************************************************//

module TSI(clkI, resetI, switchesI,

clk, reset, switches,

Tx, Rx_I,

Tx_O, Rx,

MEM_A, status, mem_clk, CE, WE, OE, ADV, CRE, UB, LB,

MEM_A_O, statusO, mem_clk_O, CE_O, WE_O, OE_O, ADV_O, CRE_O, UB_O, LB_O,

MIB_T, MIB_I, MIB_O, MIB_IO);

//FPGA Inputs

input clkI; //System Clock

input resetI; //Global Reset

input [6:0] switchesI; //Baud Rate & Parity Ops

//Output to Core

output clk;

output reset;

output [6:0] switches;

//UART Interface

input Tx, Rx_I; //Core inputs

output Tx_O, Rx; //FPGA outputs

//Inputs from Core

input [22:0] MEM_A; //Memory Address

input [7:0] status; //Statuses

input mem_clk;

input CE; //Chip Enable

input WE; //Write Enable

input OE; //Output Enable

input ADV;

input CRE;

input UB;

input LB;

//Outputs to FPGA

output [22:0] MEM_A_O;

output [7:0] statusO;

output mem_clk_O;

output CE_O;

output WE_O;](https://image.slidesharecdn.com/6a2677cb-2966-481e-8a6c-00b20a1ce095-161224015254/85/Lab4_Report_460-103-320.jpg)

![Prepared by:

Phuong Nguyen

Date:

December 14, 2016

Document Name:

Final Specification

Revision:

4.0

Nguyen 104

output OE_O;

output ADV_O;

output CRE_O;

output UB_O;

output LB_O;

//dq

input MIB_T;

input [15:0] MIB_I;

output [15:0] MIB_O;

inout [15:0] MIB_IO;

//Dedicated Input Clock Buffer

IBUFG #(

.IOSTANDARD("DEFAULT")

)

Sys_Clk (

.O(clk), //To Core

.I(clkI) //From Top Level Port

);

//System Reset

IBUF #(

.IOSTANDARD("DEFAULT")

)

Sys_Reset(

.O(reset), //To Core

.I(resetI) //From Top Level Port

);

//UART Interface

OBUF #(

.IOSTANDARD("DEFAULT")

)

Transmit(

.O(Tx_O), //To Core

.I(Tx) //From Top Level Port

);

IBUF #(

.IOSTANDARD("DEFAULT")

)

Receive(

.O(Rx), //To Core

.I(Rx_I) //From Top Level Port

);

//Memory Address

OBUF #(

.IOSTANDARD("DEFAULT")

)

MEM_ADDR [22:0](

.O(MEM_A_O[22:0]), //Out to Micron

.I(MEM_A[22:0]) //From Core

);](https://image.slidesharecdn.com/6a2677cb-2966-481e-8a6c-00b20a1ce095-161224015254/85/Lab4_Report_460-104-320.jpg)

, //To FPGA LEDs

.I(status[7:0]) //From Core

);

//Switches buffer

IBUF #(

.IOSTANDARD("DEFAULT")

)

Iswitches [6:0](

.O(switches [6:0]), //To FPGA Switches

.I(switchesI [6:0]) //From Top Level Port

);

OBUF #(

.IOSTANDARD("DEFAULT")

)

mem_clk_out(

.O(mem_clk_O), //Out to Micron

.I(1'b0) //From Core

);

//Memory Signal Interface

OBUF #(

.IOSTANDARD("DEFAULT")

)

CE_LoE(

.O(CE_O), //Out to Micron

.I(CE) //From Core

);

OBUF #(

.IOSTANDARD("DEFAULT")

)

WE_LoE(

.O(WE_O), //Out to Micron

.I(WE) //From Core

);

OBUF #(

.IOSTANDARD("DEFAULT")

)

OE_LoE(

.O(OE_O), //Out to Micron

.I(OE) //From Core

);

OBUF #(

.IOSTANDARD("DEFAULT")

)](https://image.slidesharecdn.com/6a2677cb-2966-481e-8a6c-00b20a1ce095-161224015254/85/Lab4_Report_460-105-320.jpg)

, //buffer input into the module

.IO(MIB_IO[15:0]), //buffer inout port

.I(MIB_I[15:0]), //output value from the module

.T(MIB_T) //output when T is low

);

endmodule](https://image.slidesharecdn.com/6a2677cb-2966-481e-8a6c-00b20a1ce095-161224015254/85/Lab4_Report_460-106-320.jpg)