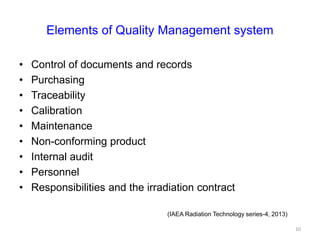

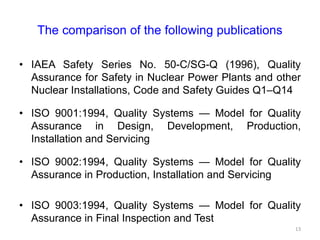

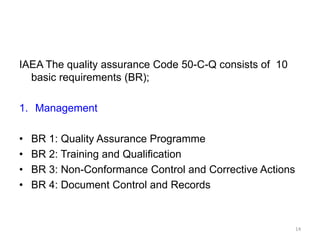

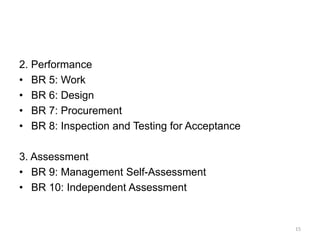

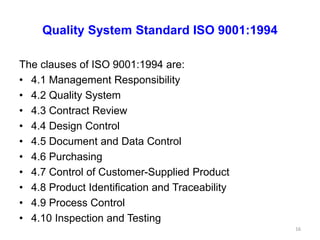

This document discusses quality assurance and quality control programs for industrial radiation practices. It provides definitions of QA and QC, including that QA is a set of processes to ensure desirable outcomes by reducing defects. It outlines the key elements of a comprehensive QA program, including a quality assurance committee, policies and procedures manual, and quality audits. The document also discusses international standards and guidelines for QA programs from organizations like the IAEA and ISO.