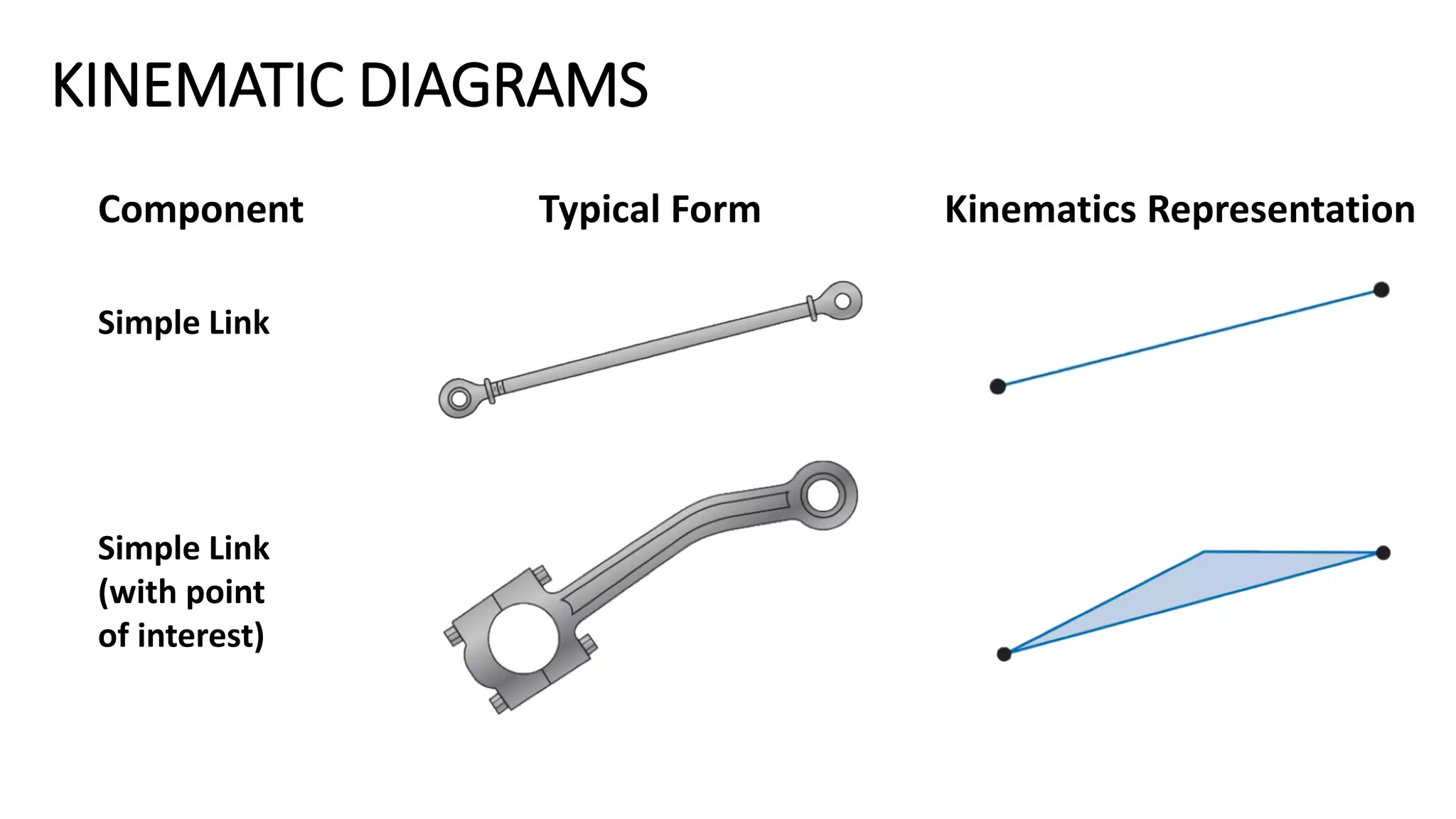

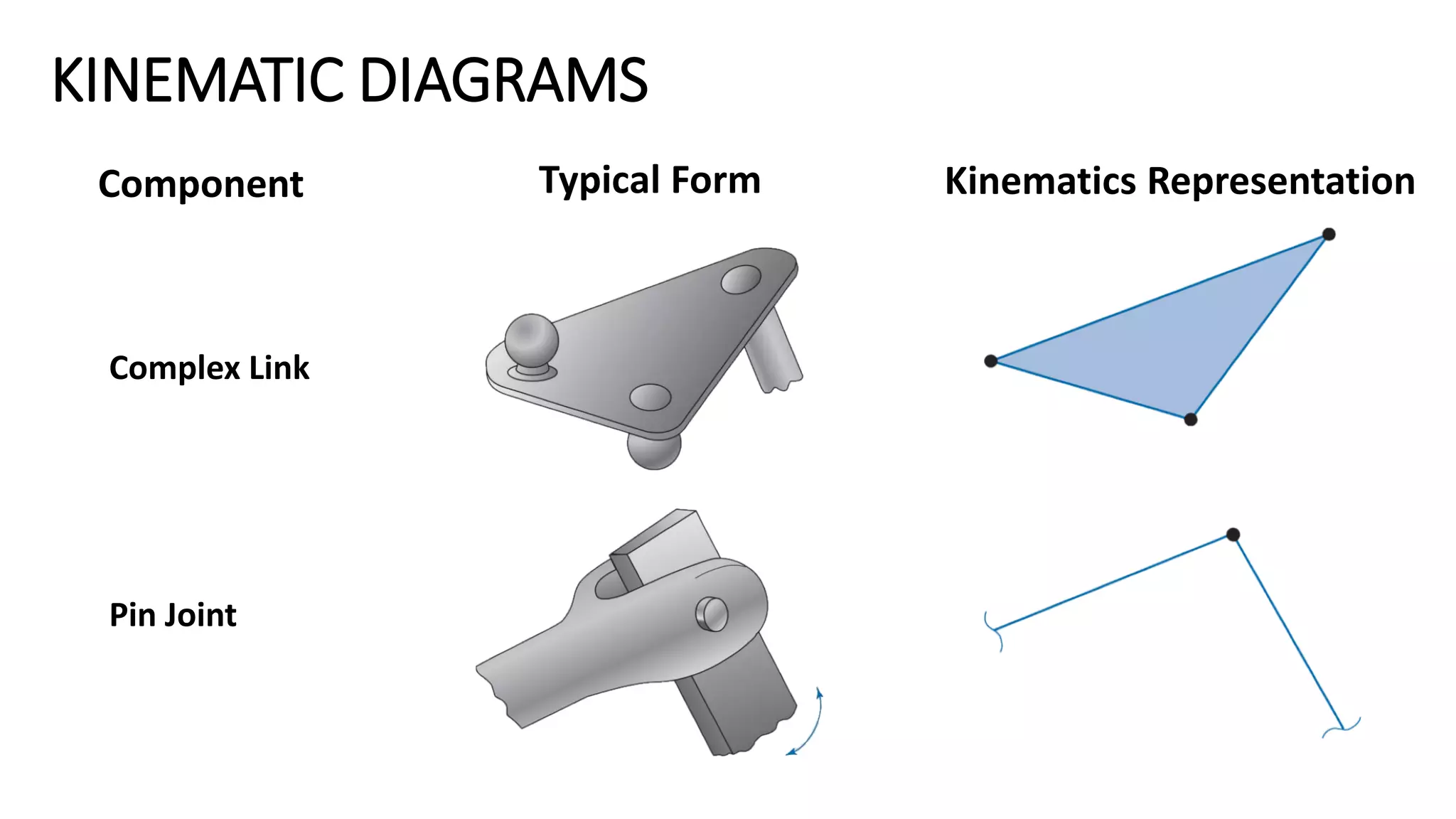

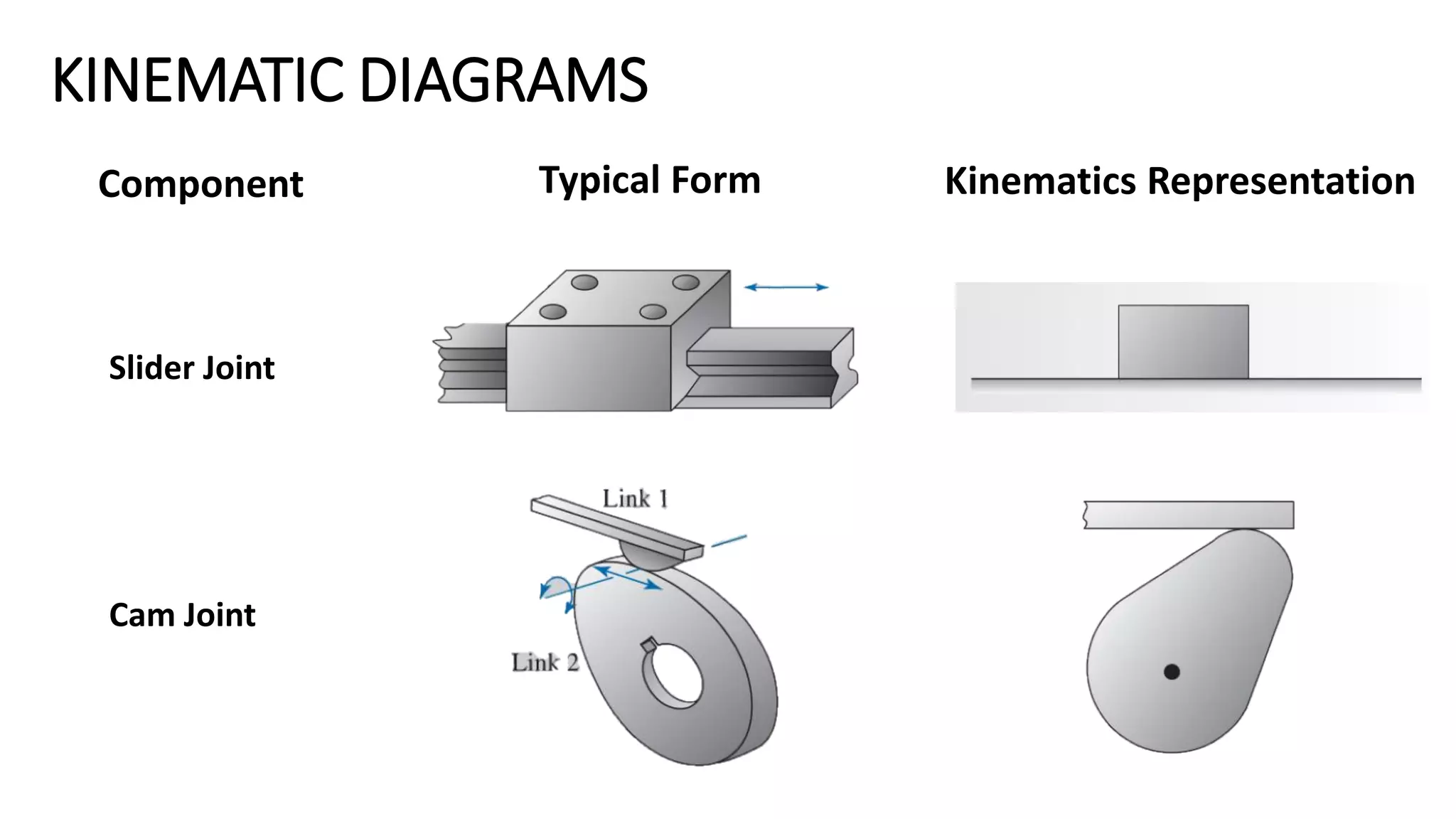

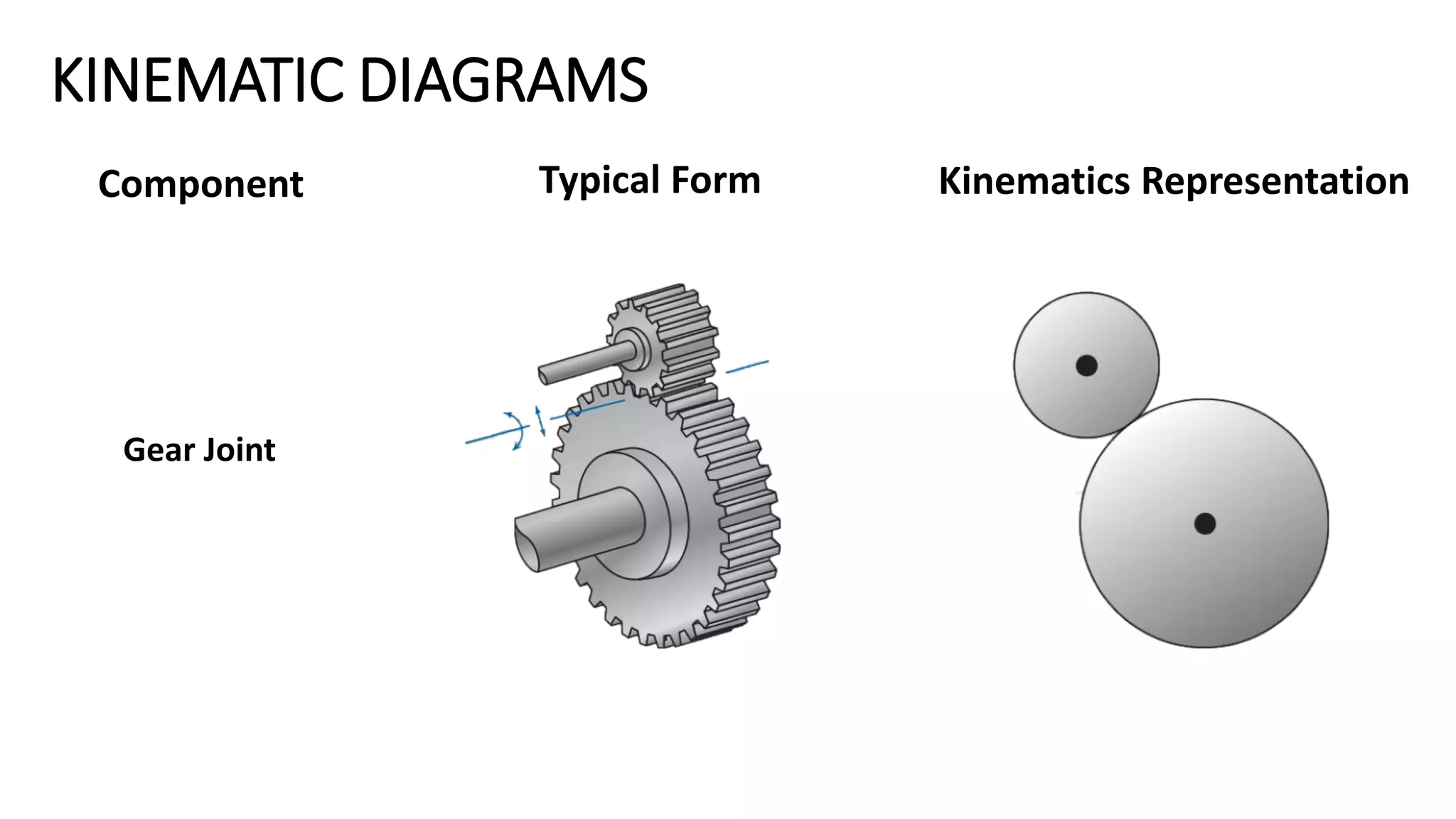

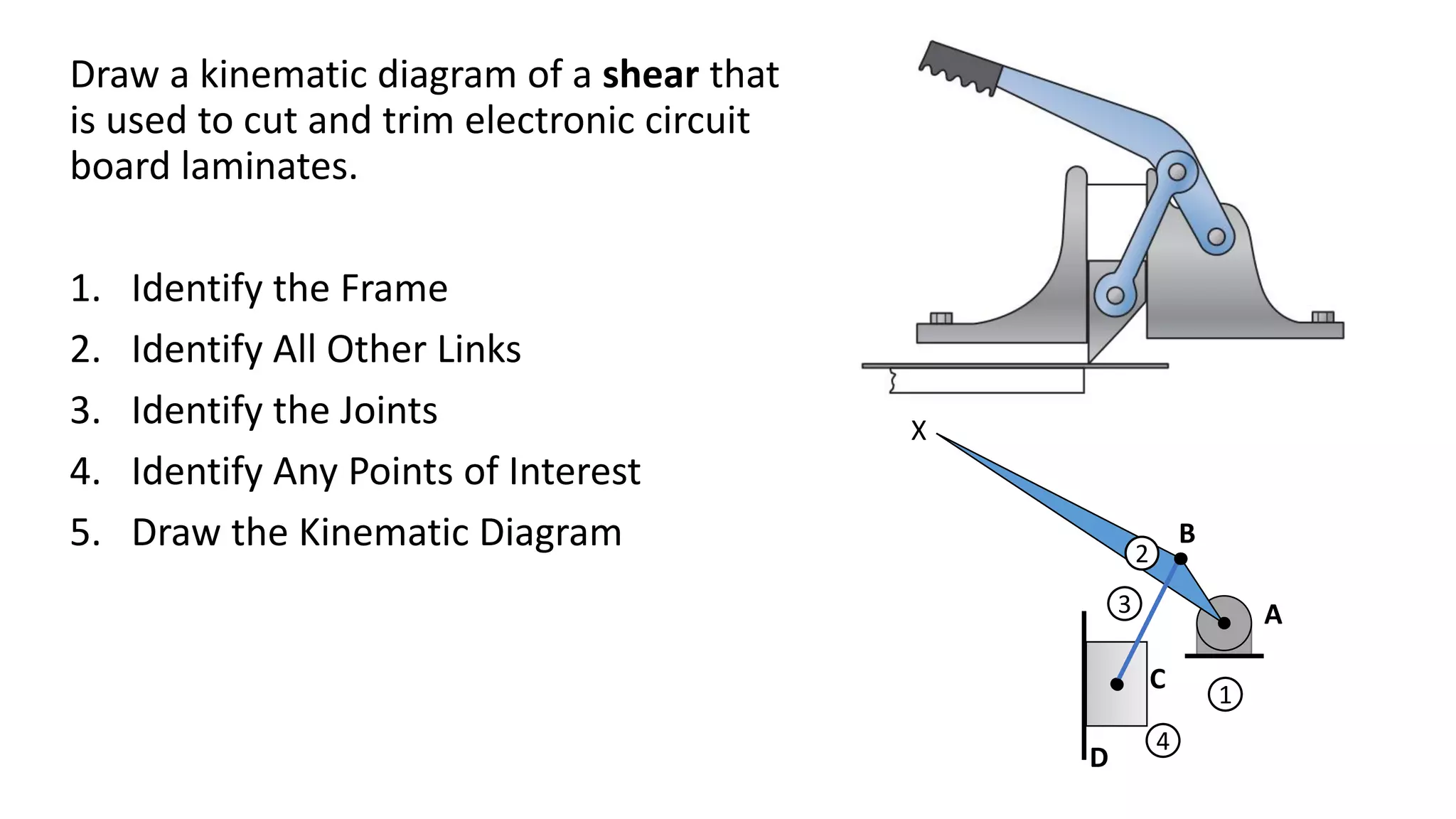

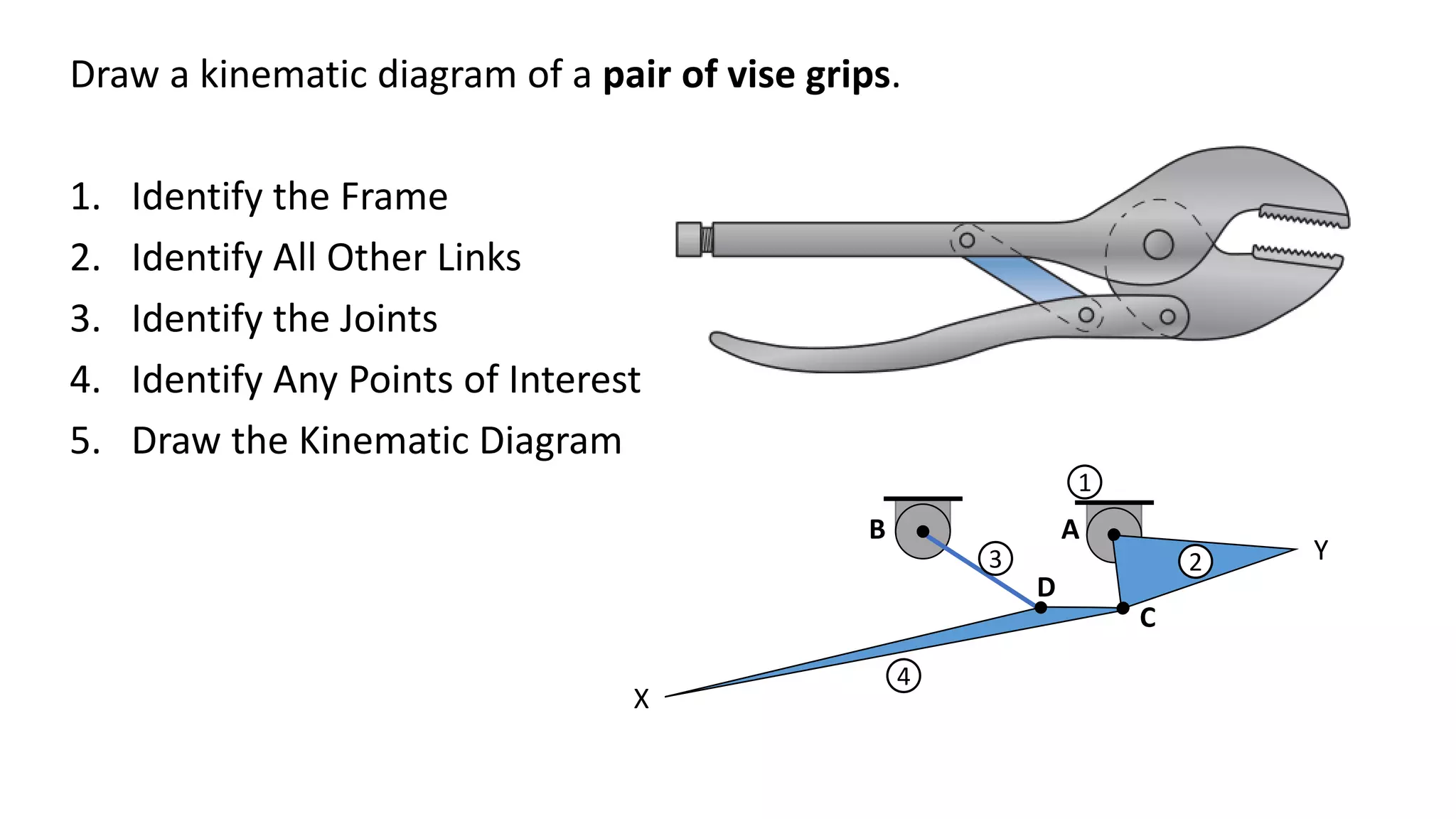

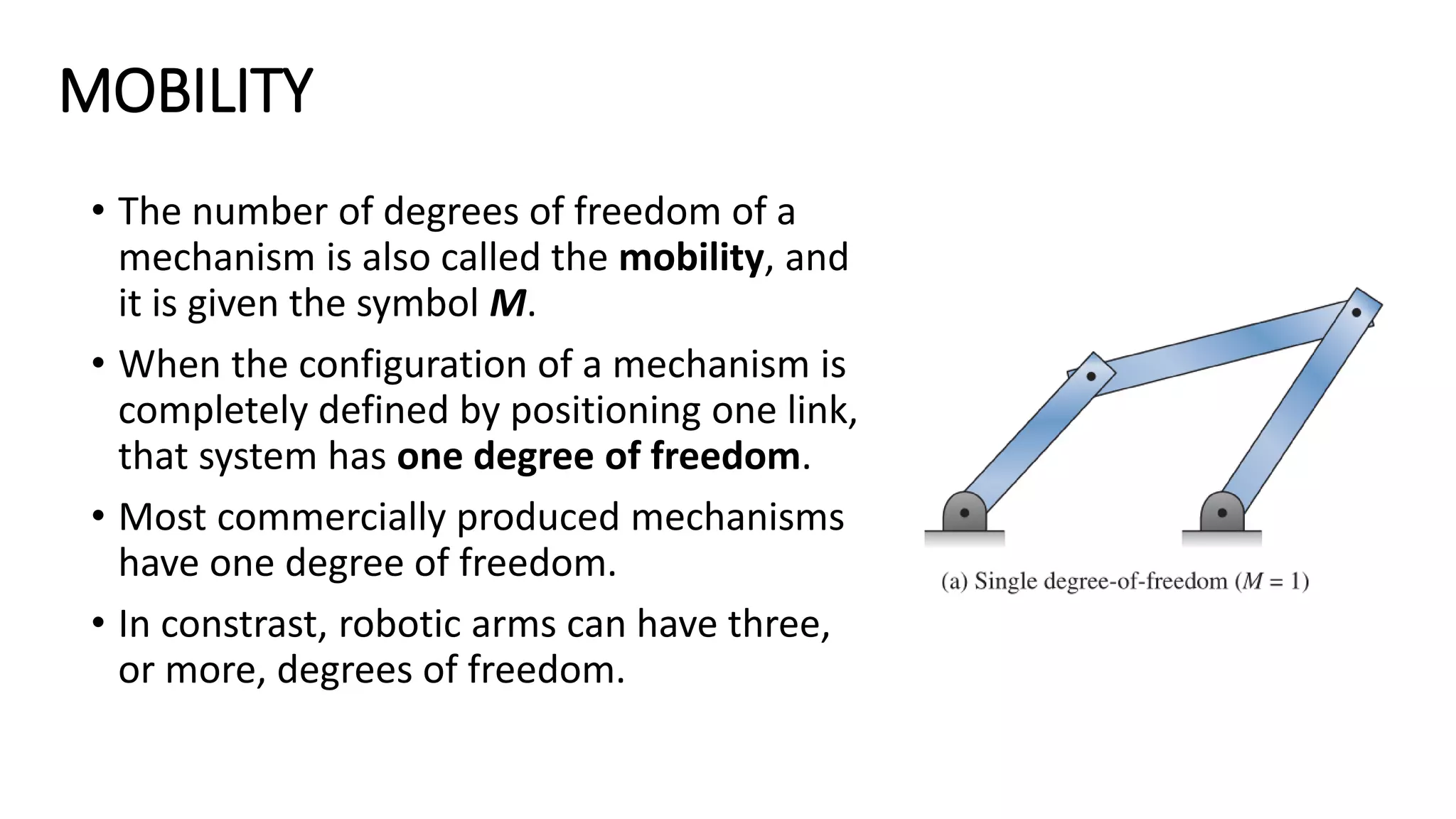

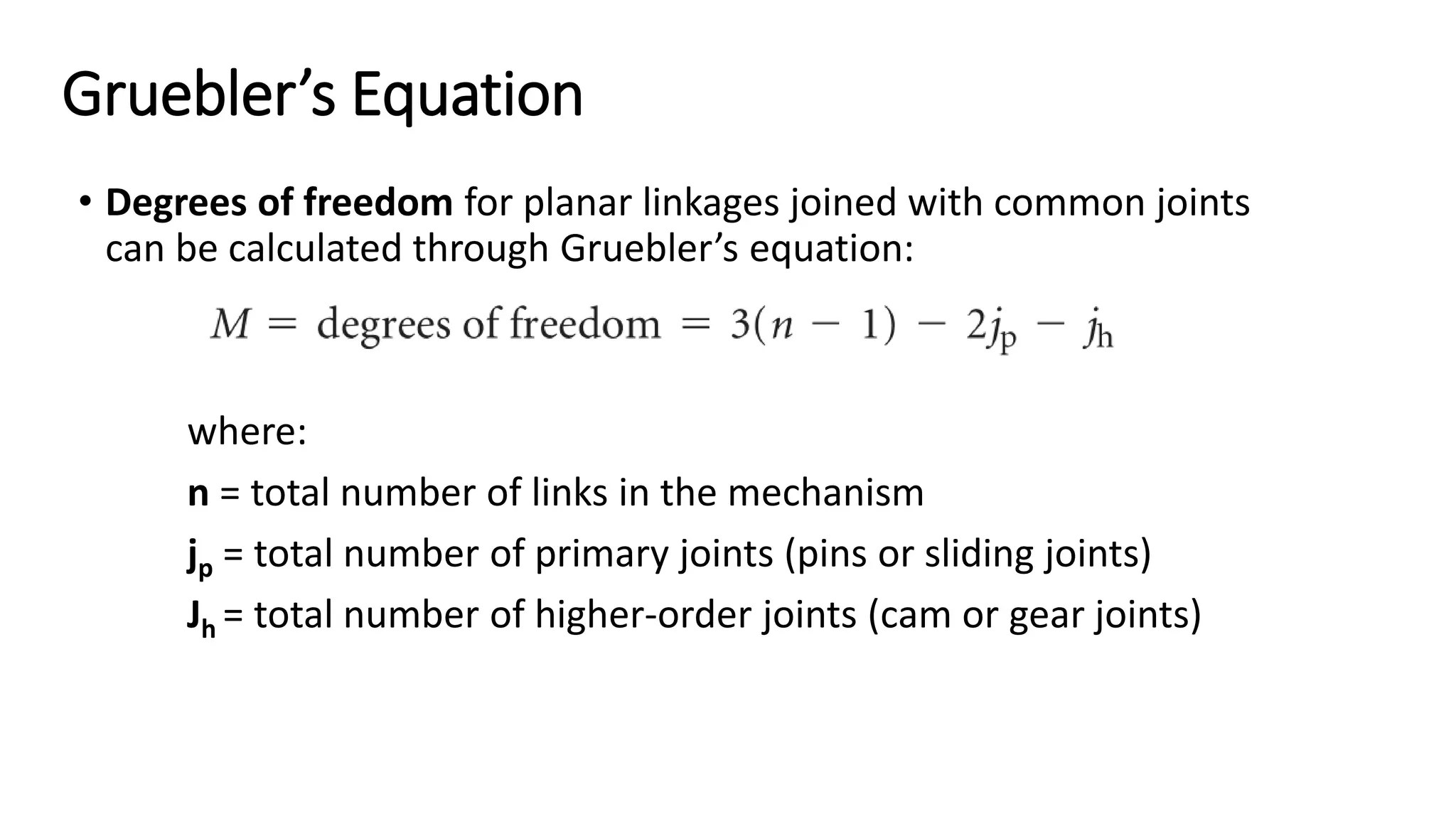

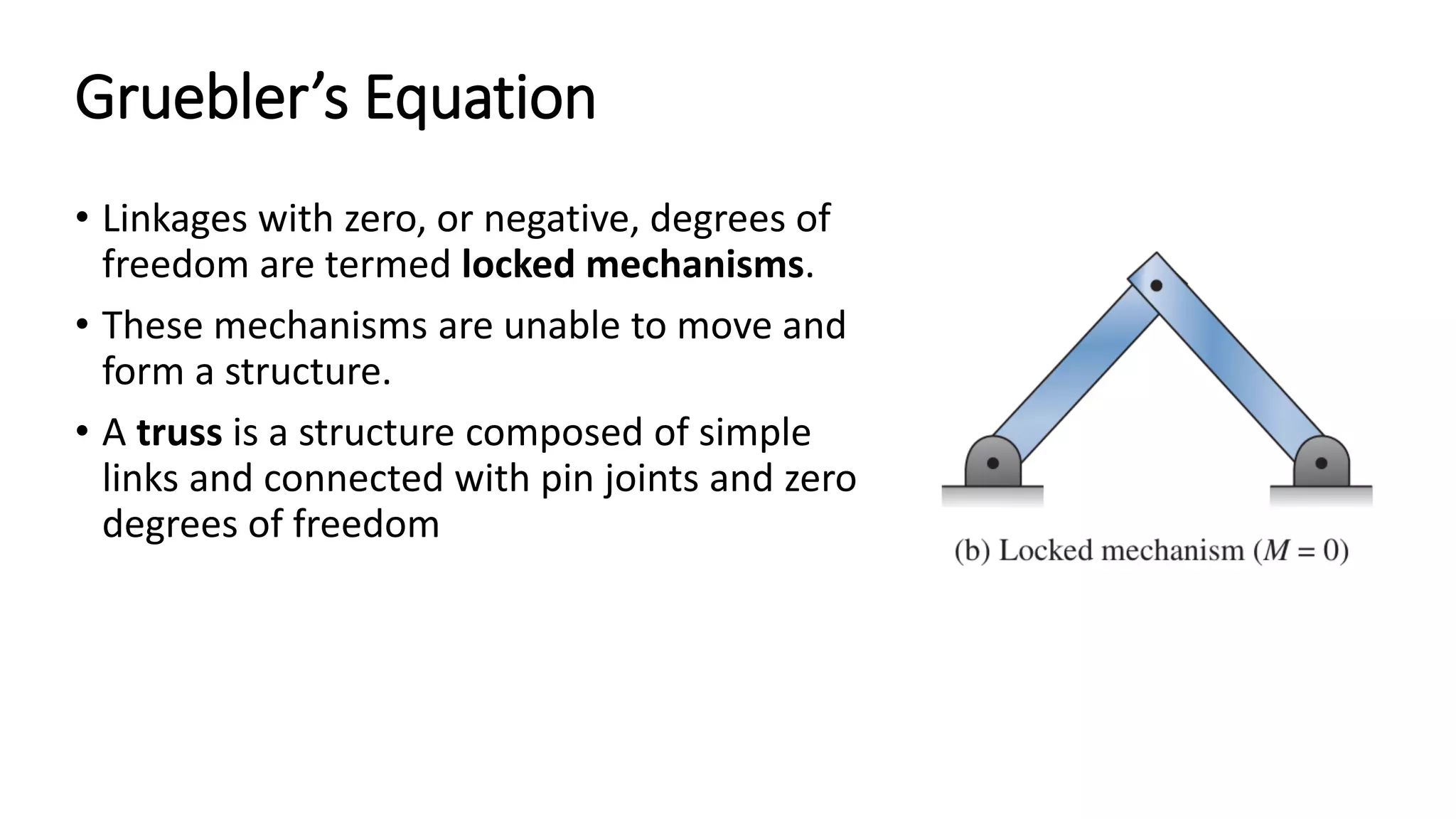

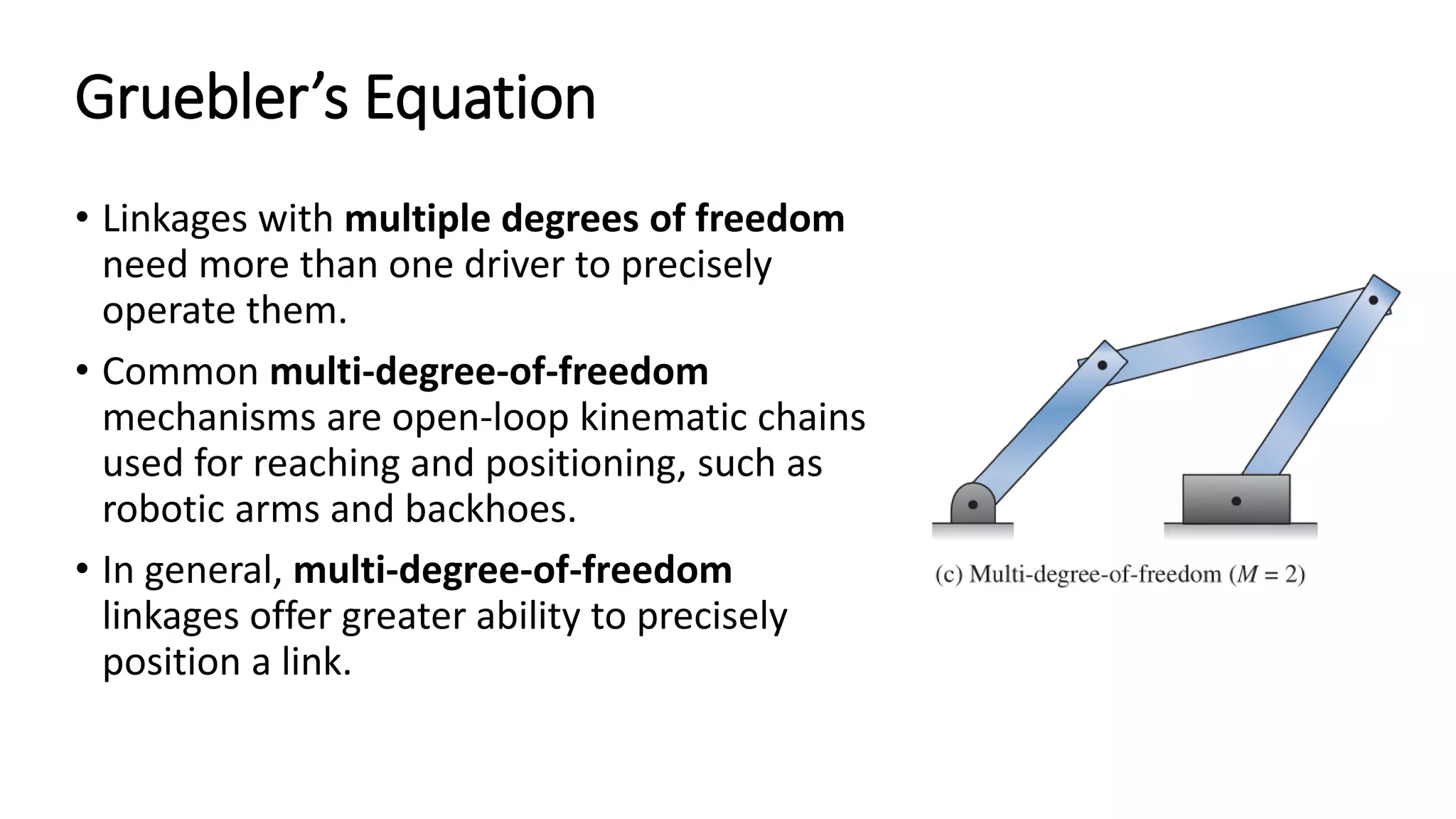

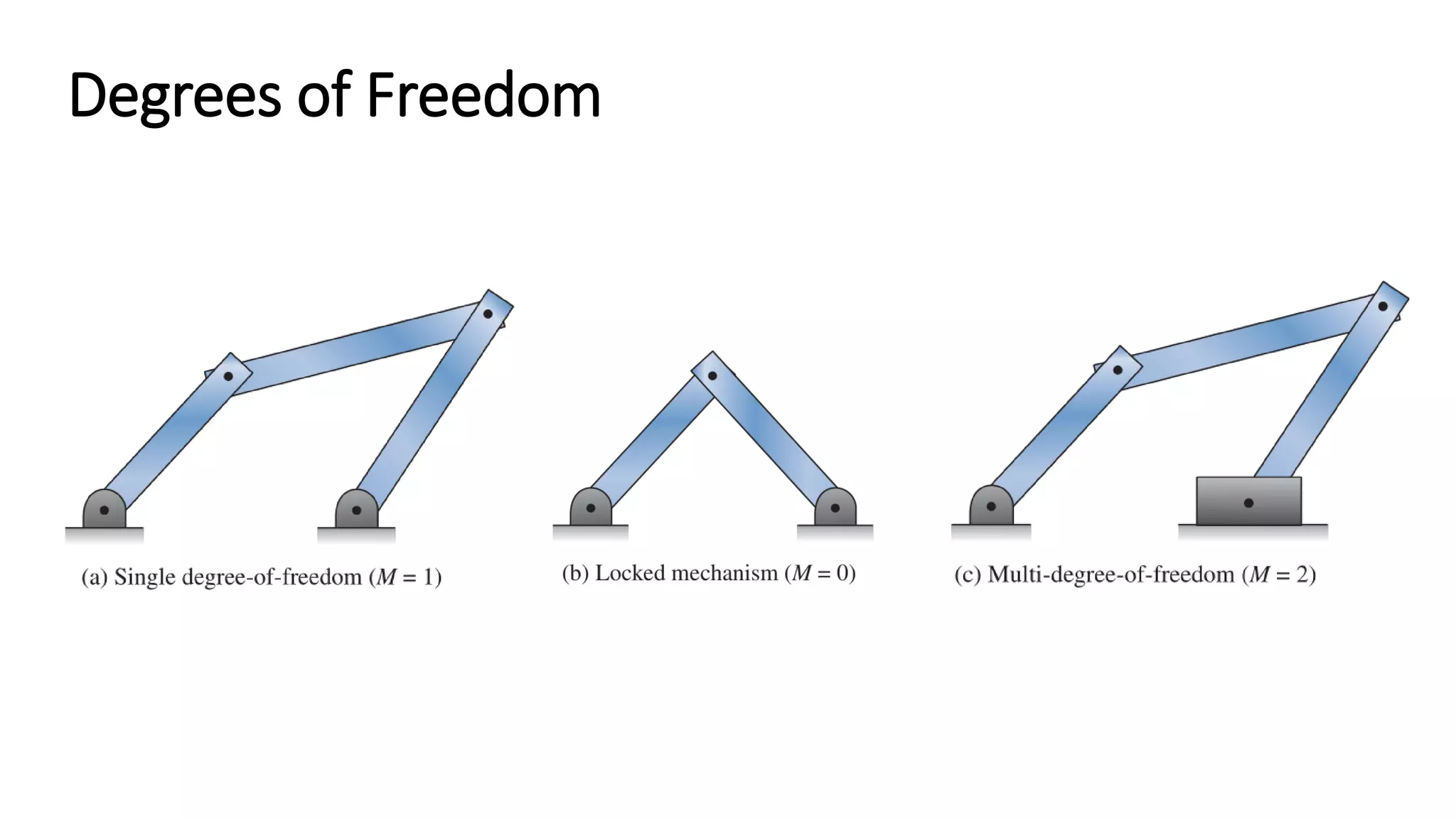

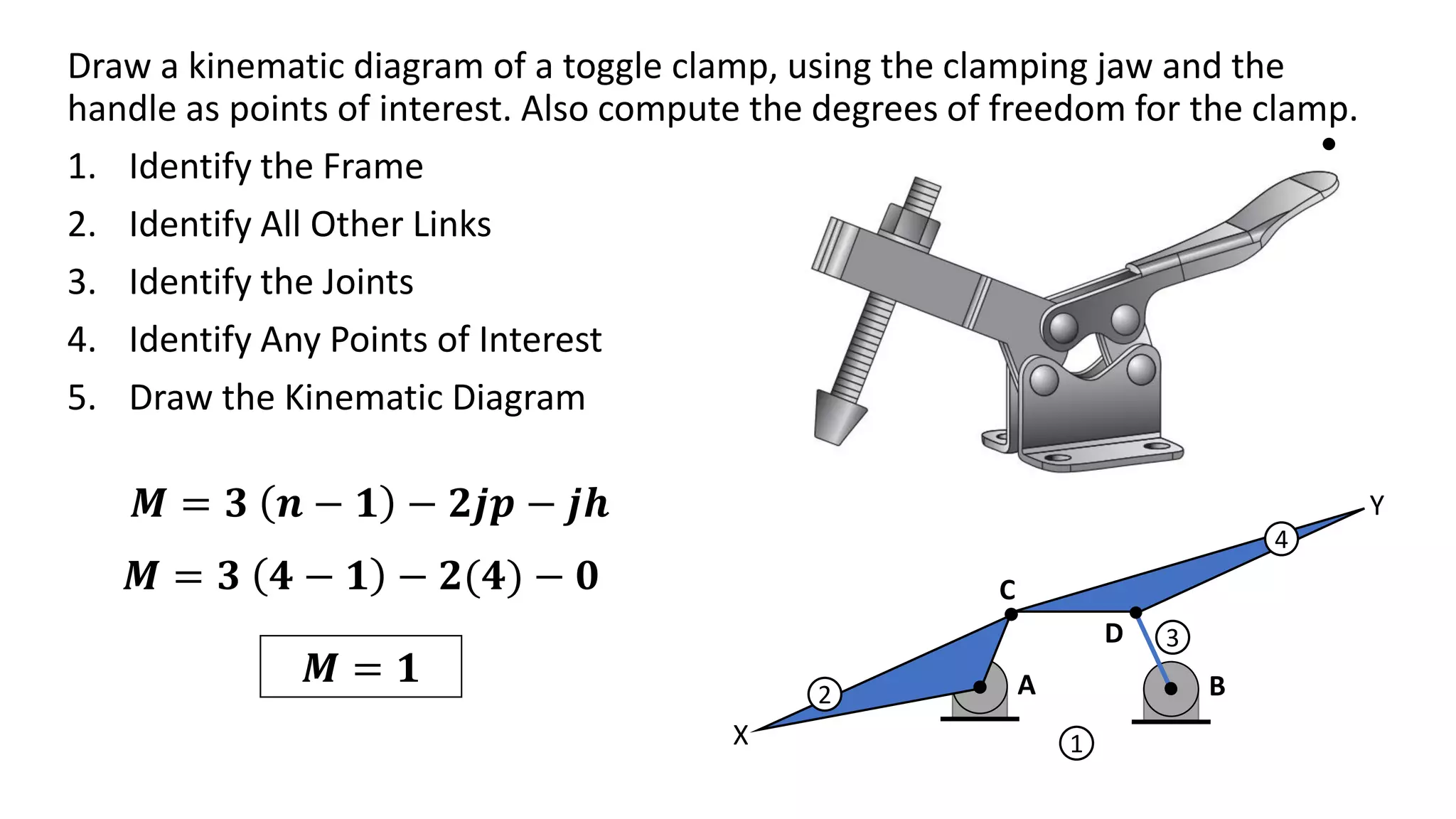

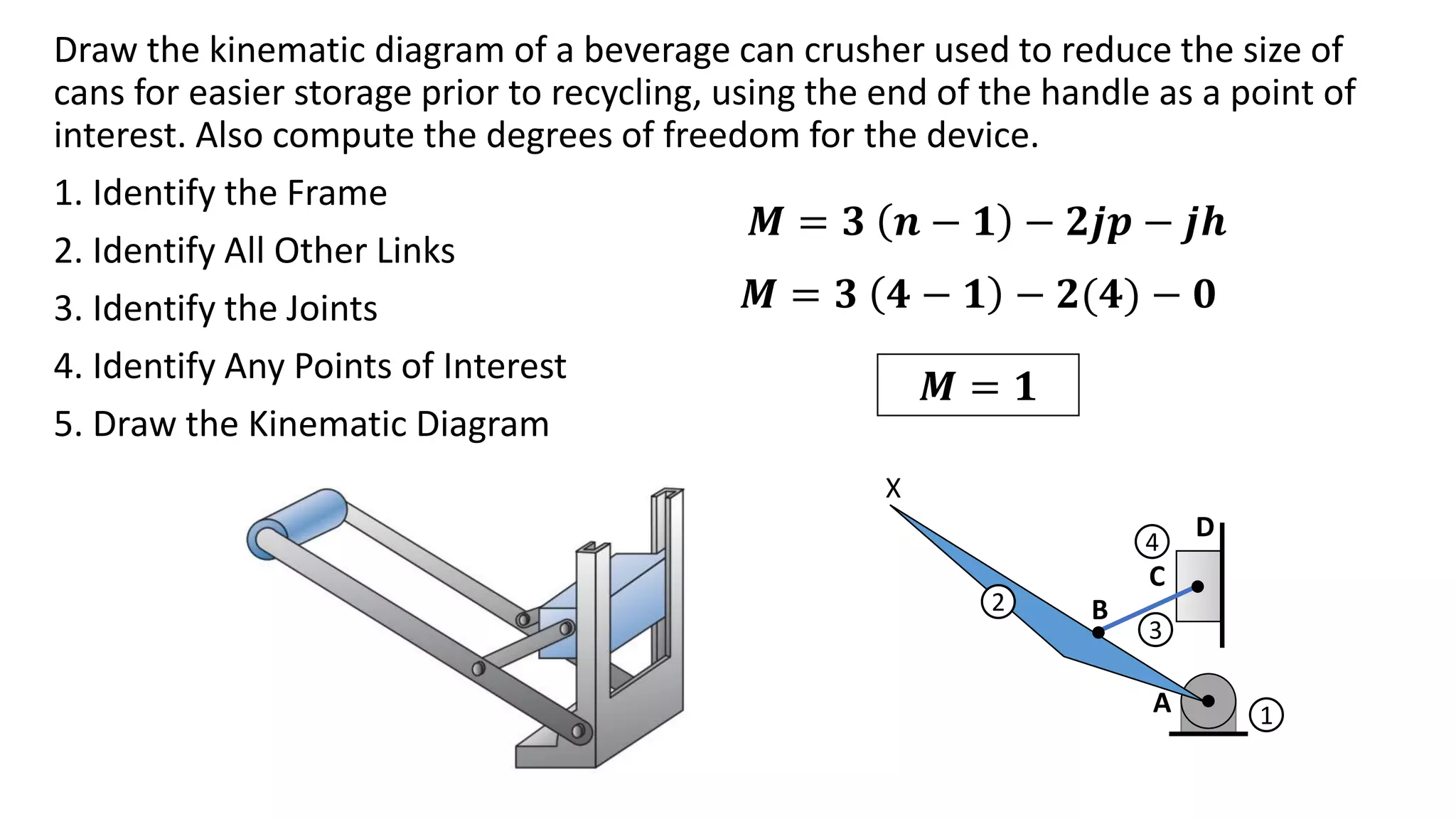

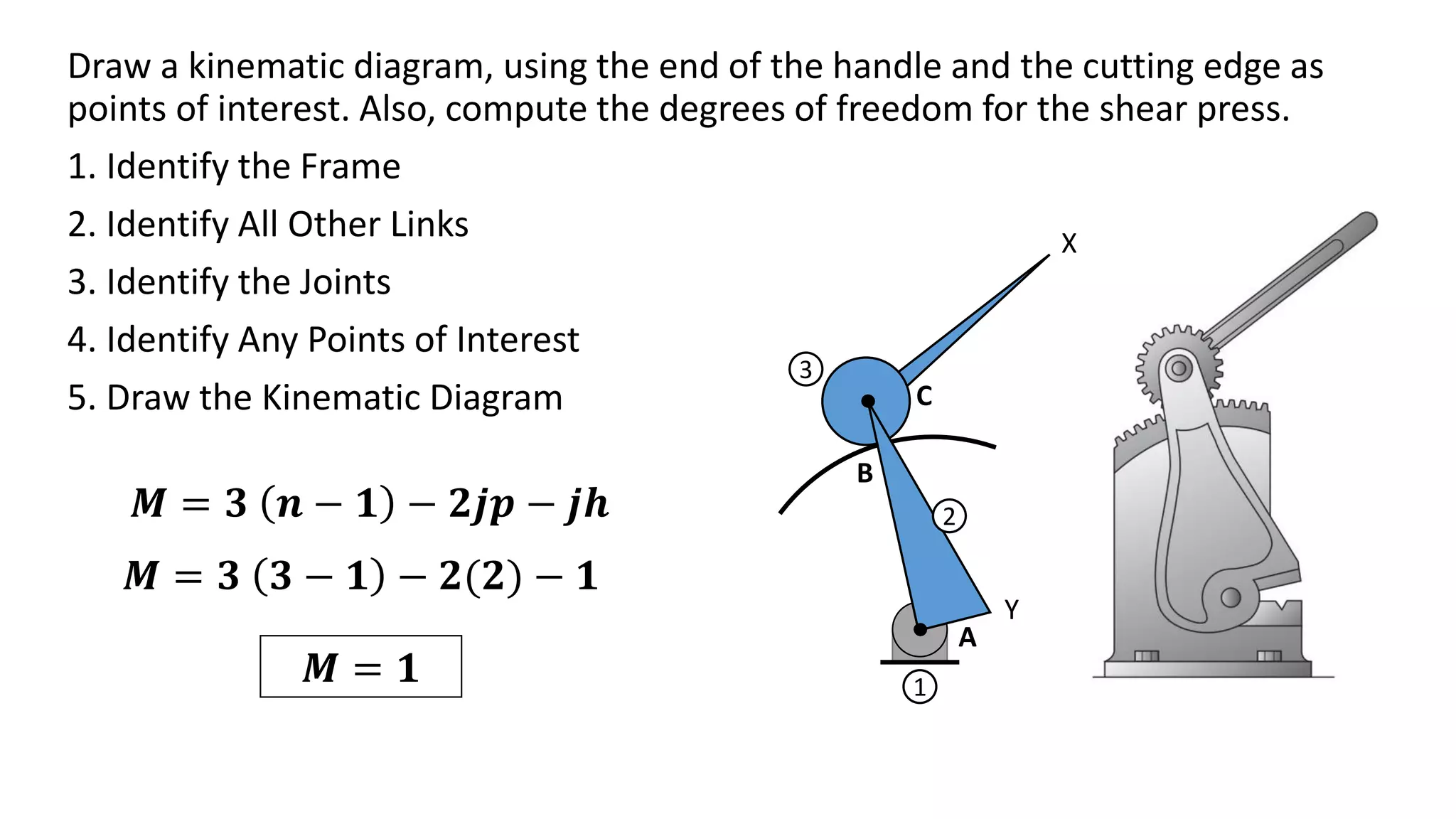

This document discusses kinematic diagrams and their use in analyzing machine motion. Kinematic diagrams represent mechanisms using a "stripped down" skeletal form showing only dimensions that influence motion. They are used to visualize relative motion of parts. Degrees of freedom refer to the number of independent inputs needed to precisely position all links and can be calculated using Gruebler's equation. The document provides examples of drawing kinematic diagrams and computing degrees of freedom for different mechanisms.