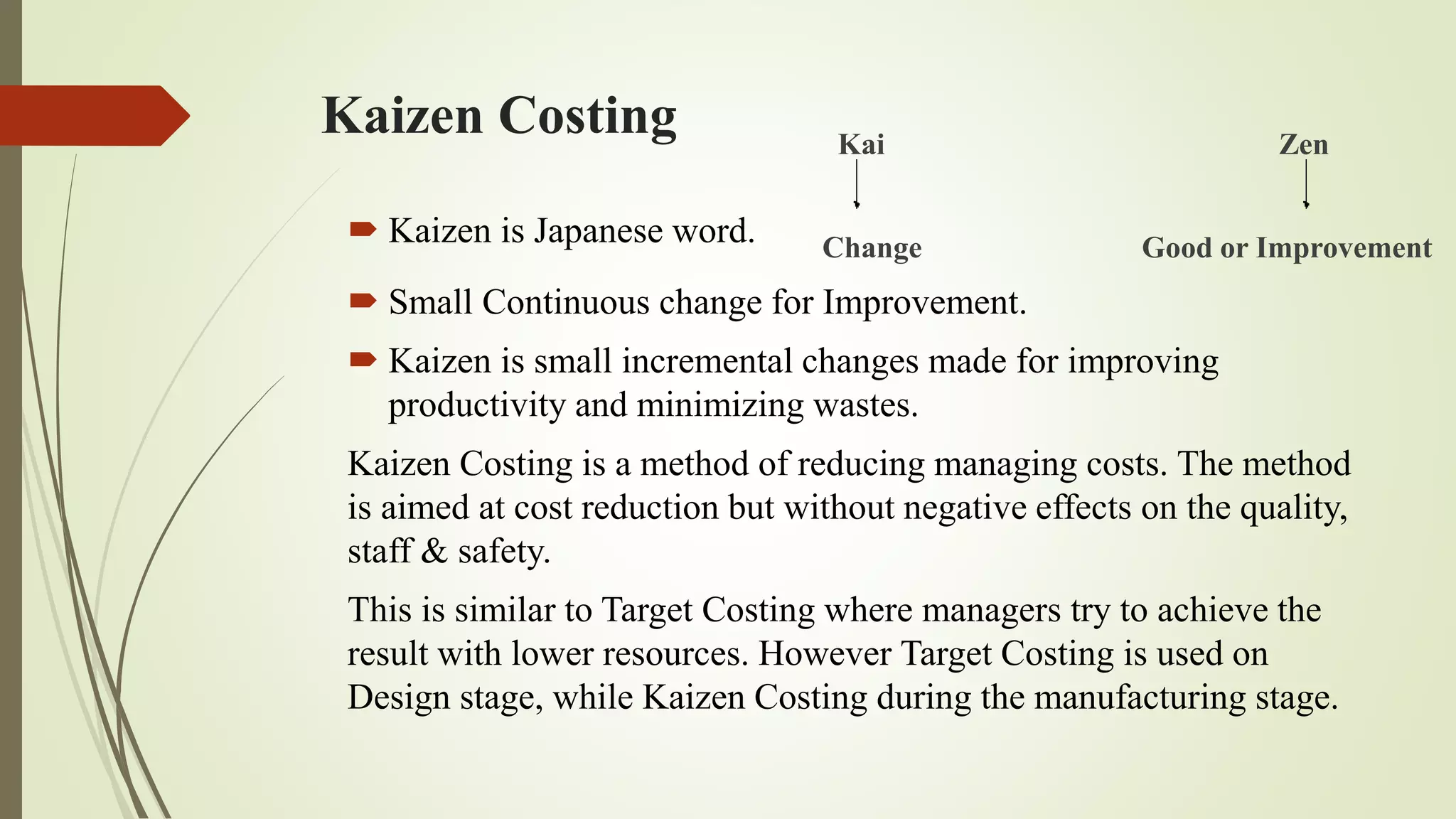

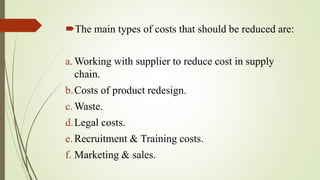

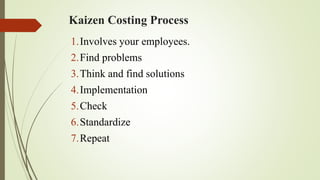

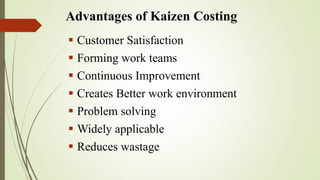

Kaizen costing is a method for continuously improving productivity and reducing costs through small, incremental changes. It focuses on minimizing waste and involves employees in an ongoing process of finding problems, developing solutions, implementing changes, and standardizing successful improvements. There are two approaches to kaizen costing - organization-specific and product-specific. Key advantages include improved customer satisfaction, continuous improvement, and a better work environment through collaborative problem-solving.