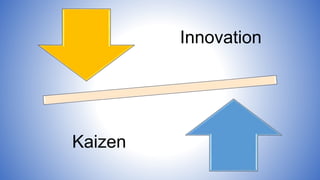

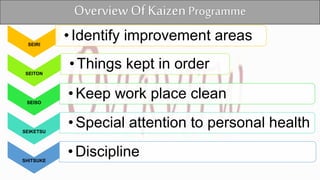

This document provides an overview of the concept of Kaizen. It discusses that Kaizen is a Japanese word meaning "continuous improvement" with the goal of generating customer satisfaction through small, incremental improvements involving everyone in an organization. The document outlines some of the key beliefs and views of Kaizen, including that there should be no day without some improvement. It also discusses how Kaizen can lead to better quality, faster work cycles, flexibility and low costs/waste. The document compares Kaizen to innovation and highlights some of the differences. Finally, it provides an overview of the steps in a typical Kaizen program and includes a case study on how Toyota has implemented Kaizen.