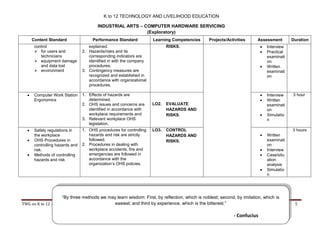

The document provides a curriculum guide for an exploratory course on computer hardware servicing. It outlines 4 lessons that cover key competencies including: using hand tools, performing mensuration and calculation, preparing and interpreting technical drawings, and practicing occupational health and safety procedures. For each lesson, learning competencies, projects/activities, assessment methods and durations are specified. The overarching goal is for students to develop an understanding of computer hardware servicing and safely apply key techniques involved in the field.