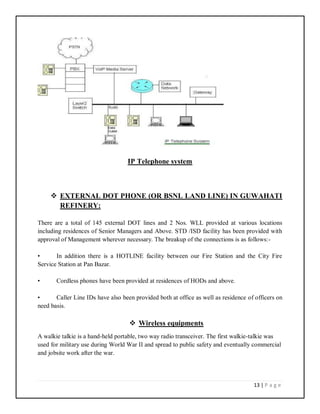

The document provides information on the communication systems at the Guwahati Refinery, including the EPABX telephone system, WINTAP/ARP system for call monitoring and emergency alerts, network termination units, external telephone lines, and walkie talkie systems. It describes the different types of communication facilities available and provides details on the EPABX system and software used for call monitoring and emergency alerts.