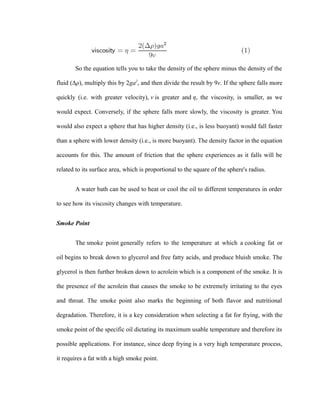

This document is an investigatory project report that studied the physical properties of oil extracted from talisay (Terminalia catappa) seeds. The researchers collected talisay fruits, removed the nuts, dried them, and extracted oil using a manual press. They tested the talisay oil for percent yield, color, clarity, smoke point, and viscosity and compared it to high and low quality palm oils. The results and discussion are in Chapter III, and conclusions and recommendations are in Chapters IV and V. The study found the talisay oil had properties similar to commercial oils and could be a viable and economic cooking oil alternative.