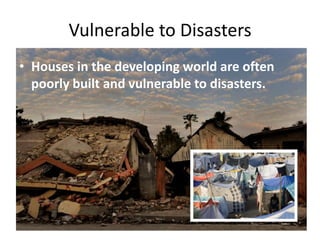

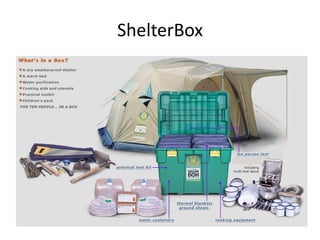

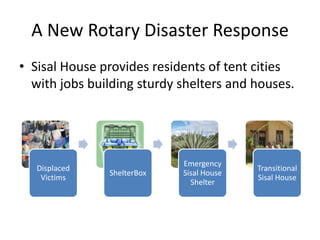

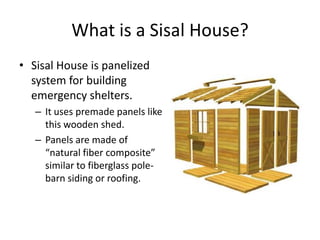

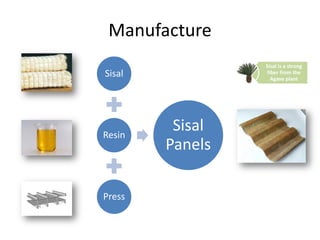

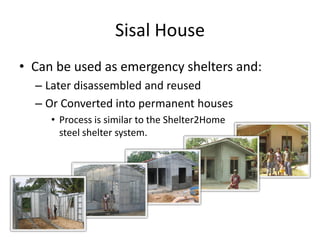

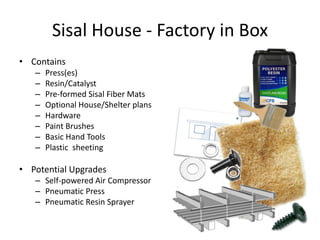

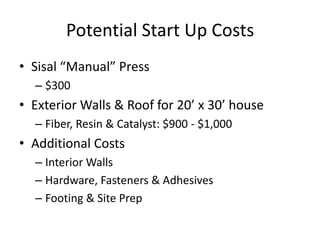

This document describes the Sisal House project, which aims to provide disaster victims with jobs building sturdy emergency shelters and transitional housing. Sisal House panels are made from natural fiber composite similar to fiberglass. A "Factory in a Box" would contain equipment and materials to produce the panels on-site, providing immediate economic benefits. The program seeks to move beyond temporary tent shelters by empowering locals to construct their own permanent homes. Initial steps outlined include creating a press, building sample structures, and developing partnerships with Rotary International.