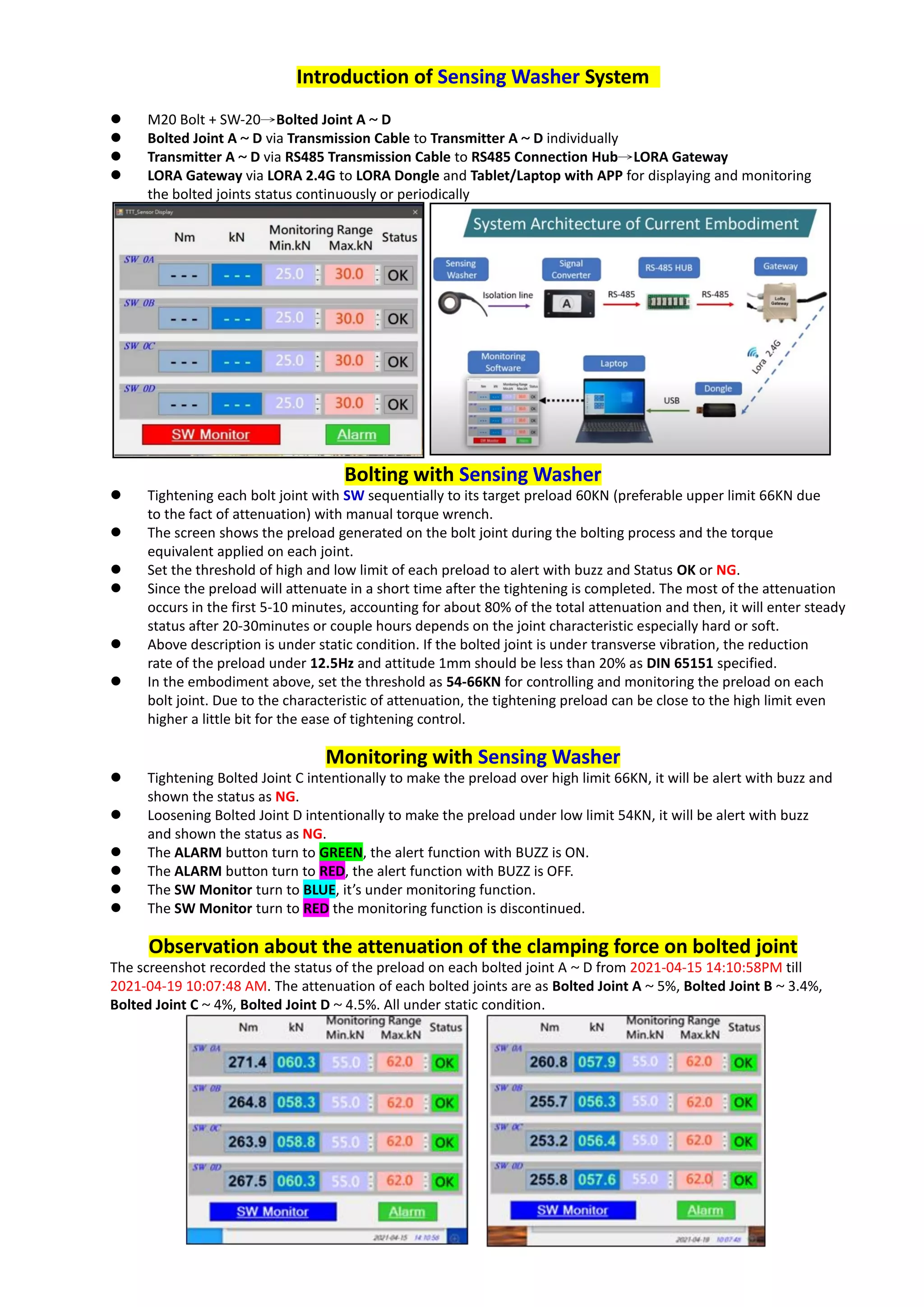

This document introduces a sensing washer system for monitoring bolted joints. The system uses sensing washers on each bolted joint connected via transmission cables to individual transmitters, which are connected via an RS485 cable to a LORA gateway and tablet. Each joint is tightened to a target preload of 60kN manually, and the system displays the preload and torque during tightening. It monitors for preload above or below thresholds of 54-66kN and alerts if out of range. Observations showed attenuation rates of around 5% for the bolted joints over several days under static conditions.