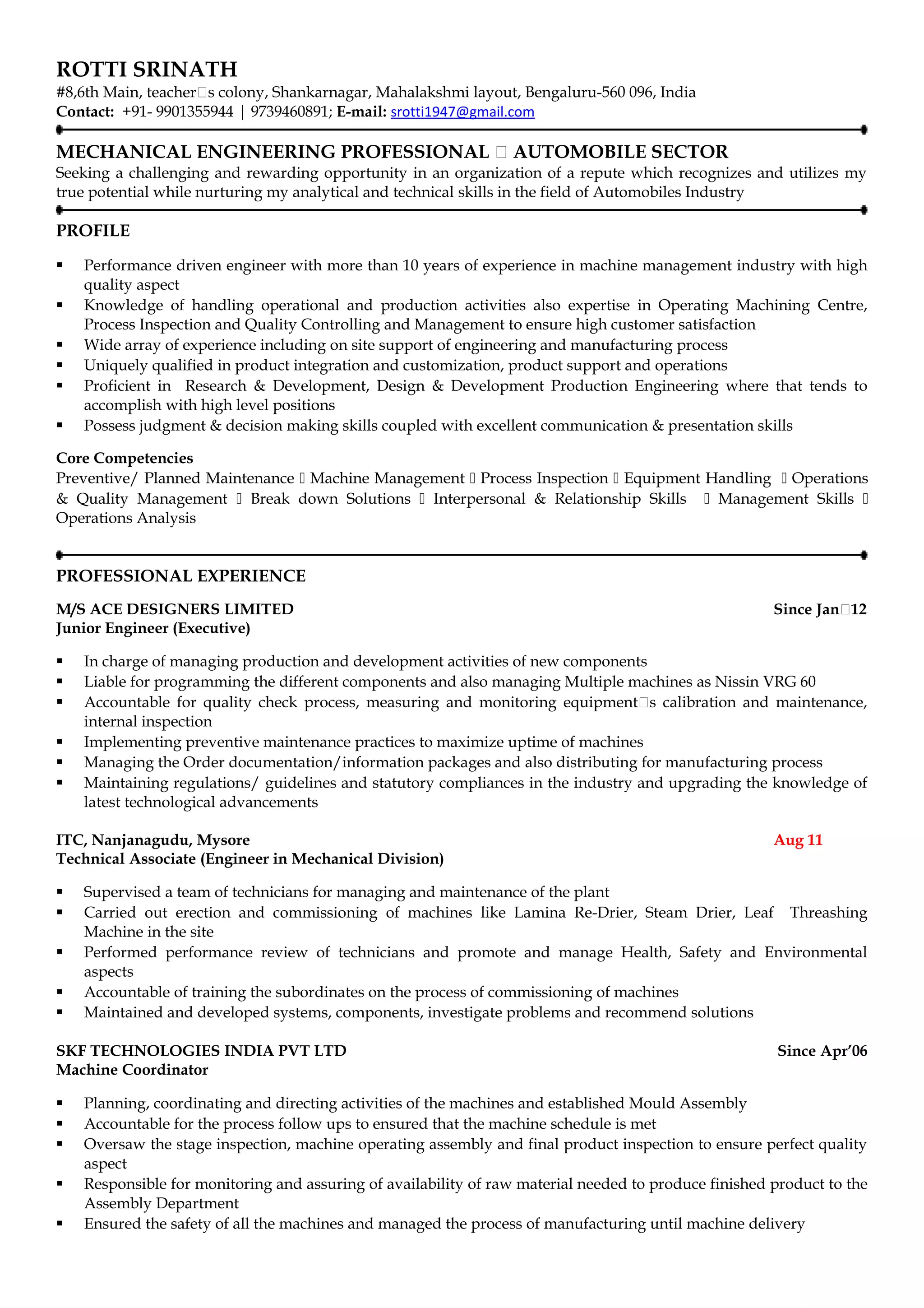

Rotti Srinath is a mechanical engineer with over 10 years of experience in machine management and the automobile industry. He is seeking a challenging position that utilizes his technical skills and experience. He has extensive experience managing production activities, quality control, and preventative maintenance. His career includes roles managing operations, training subordinates, and ensuring safety and regulatory compliance.