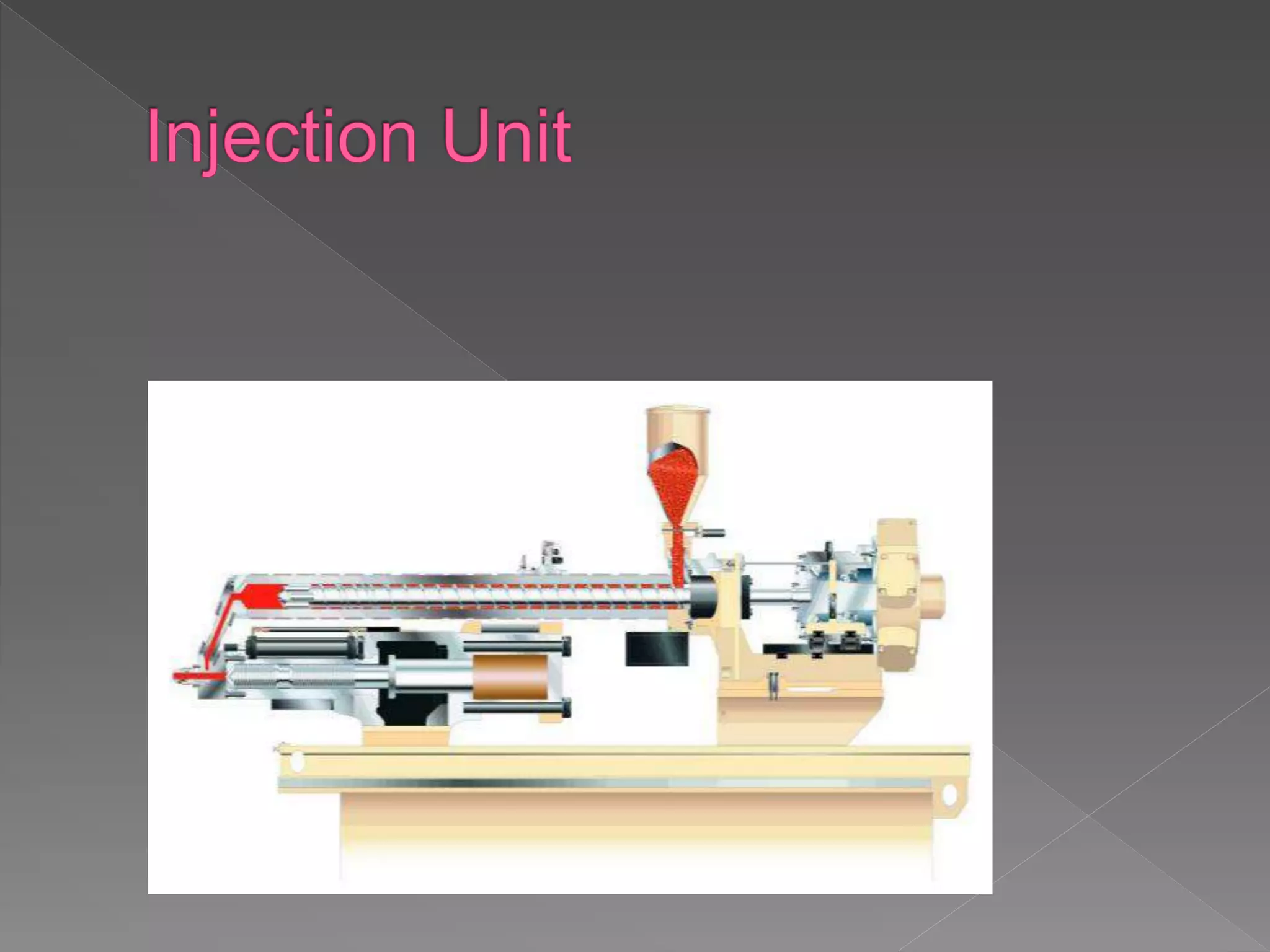

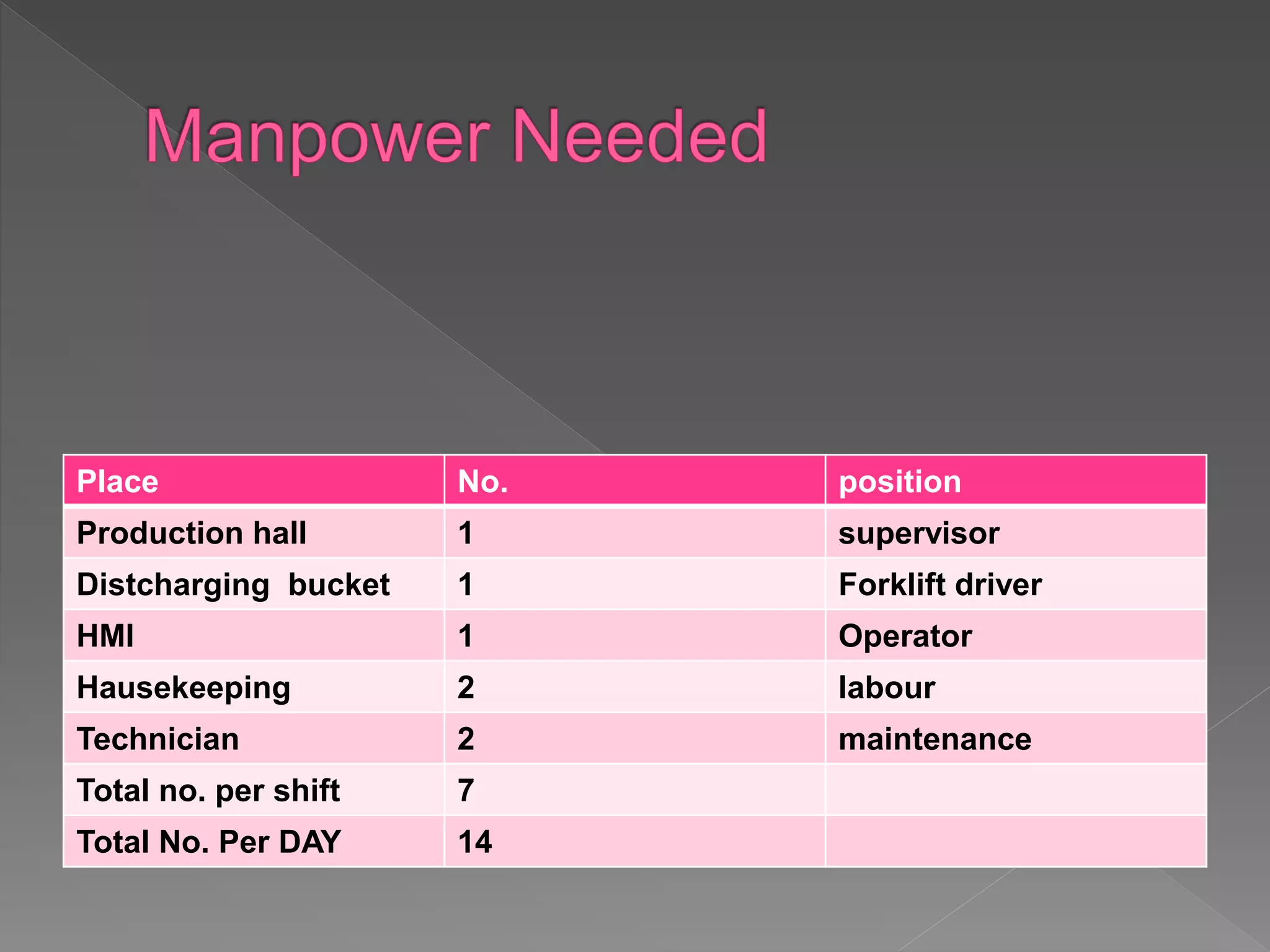

This document summarizes the key components and processes involved in plastic injection molding. It describes the hopper, barrel, ram, archimedes' screw, heaters, and mold and their functions. It provides details on the productivity and advantages of the recommended Krones machine, including lower power consumption, good control of temperature and AA percentage. It also lists the major equipment used, including a resin dryer, hoppers, hopper loader, operating air and chilled water systems. Finally, it specifies the number of staff required per shift and day.