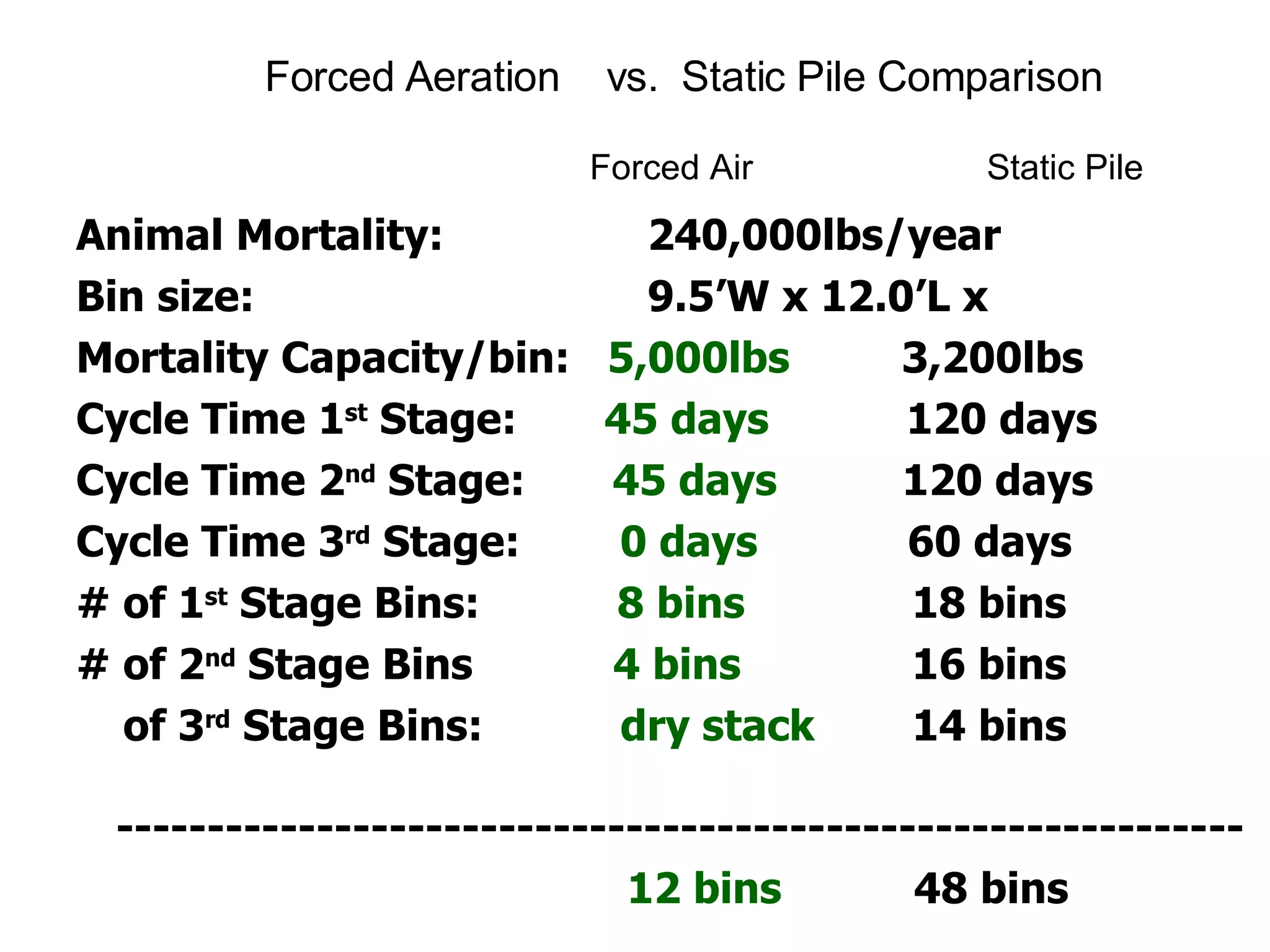

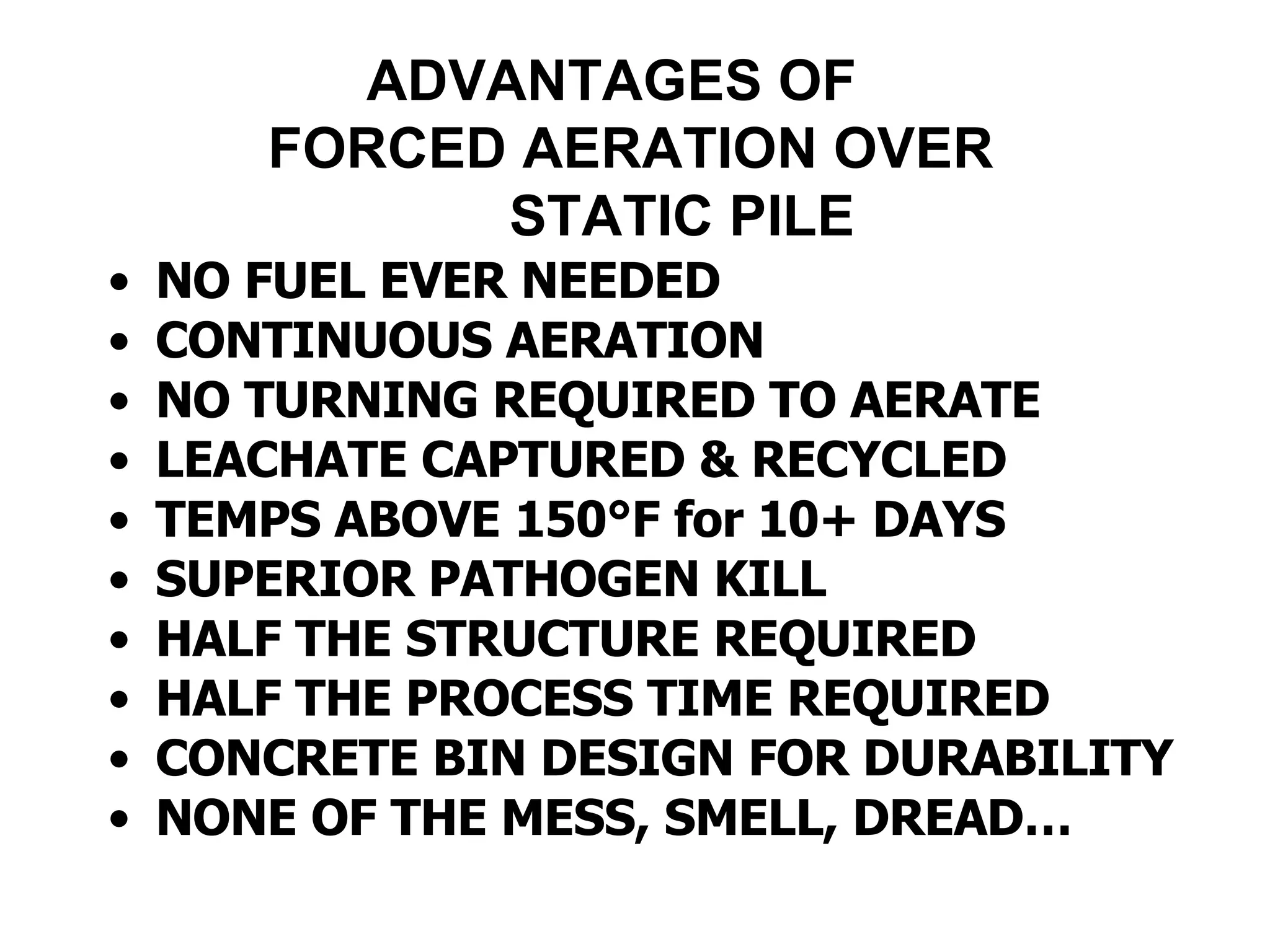

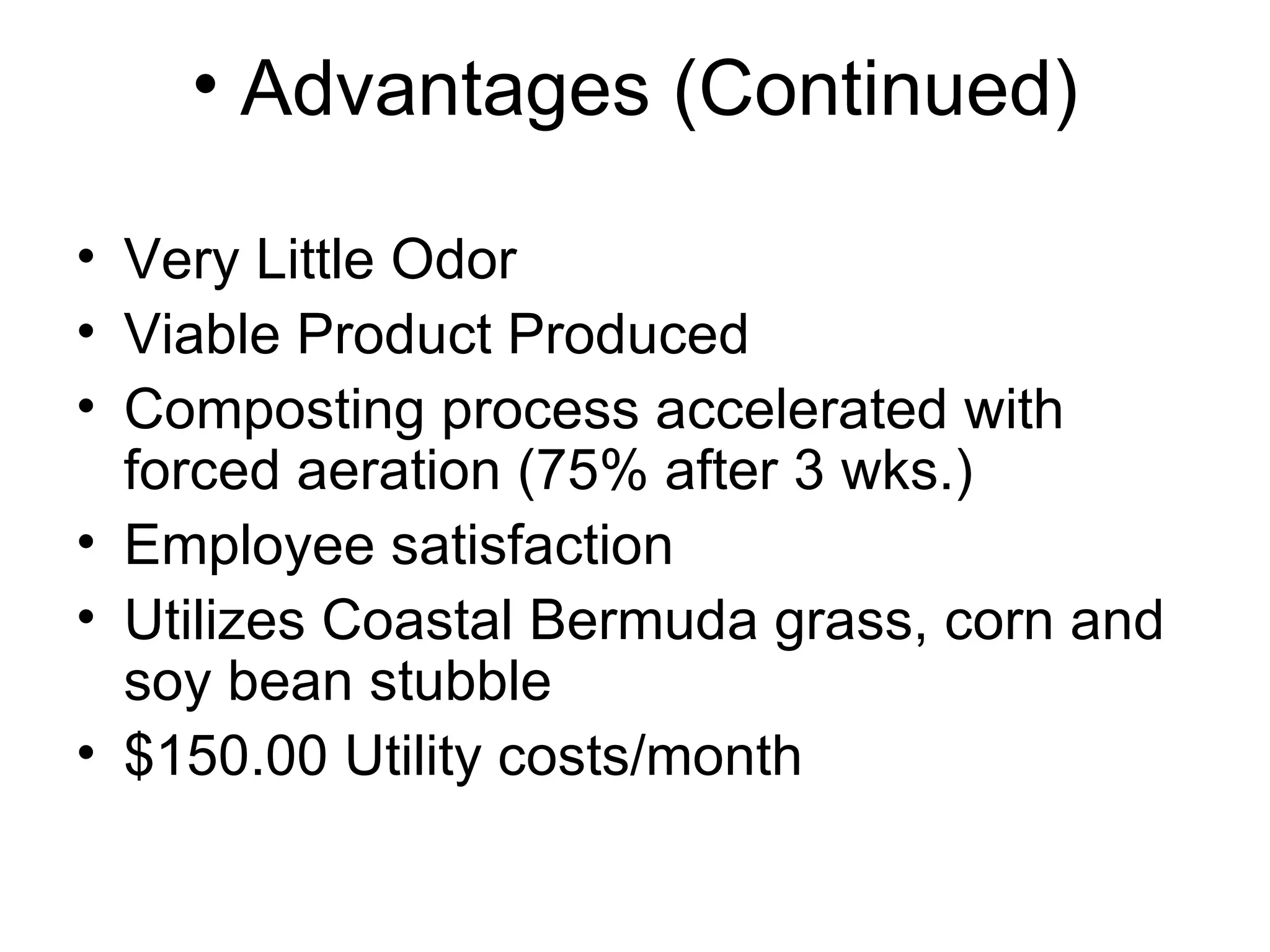

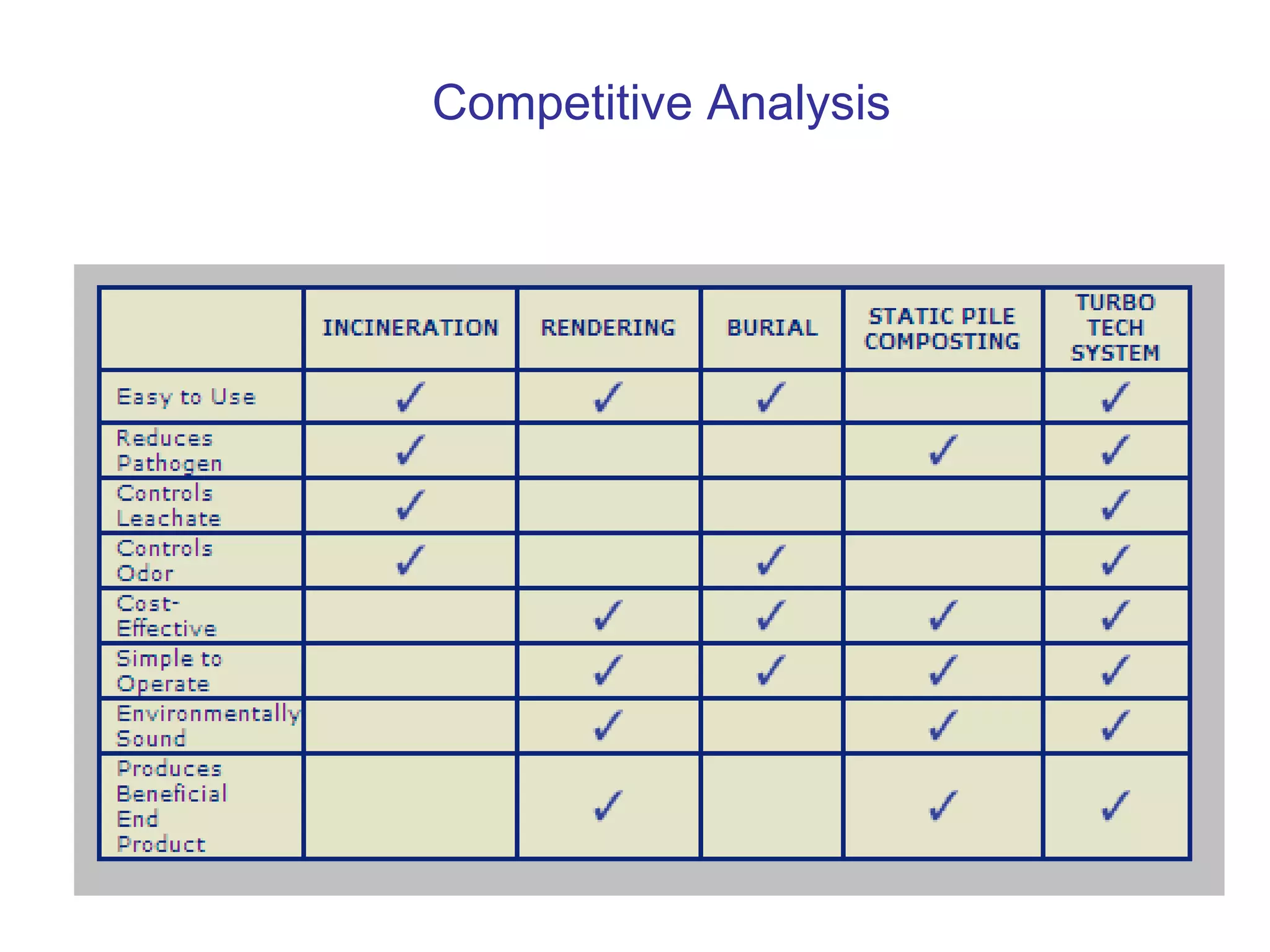

This document compares forced air composting to traditional static pile composting. Forced air composting uses fewer bins, has shorter cycle times, produces less odor, and results in a viable compost product faster than static pile composting. Some advantages of forced air composting are that it requires no fuel, allows continuous aeration without turning, captures and recycles leachate, reaches temperatures over 150 degrees Fahrenheit, requires half the structure and processing time, and produces much less mess and odor than static pile composting.

![Keith Warren 828-230-1729 [email_address] President](https://image.slidesharecdn.com/forced-air-vs-static-pile-1196717989672874-2/75/Forced-Air-Vs-Static-Pile-1-2048.jpg)