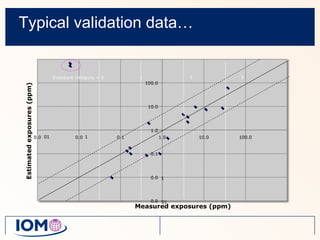

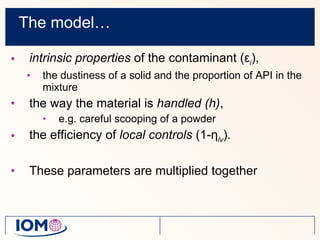

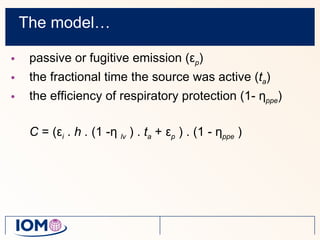

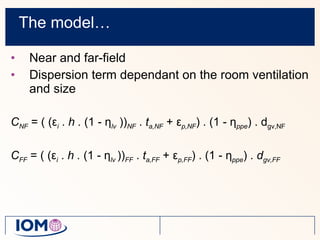

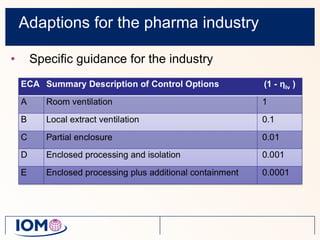

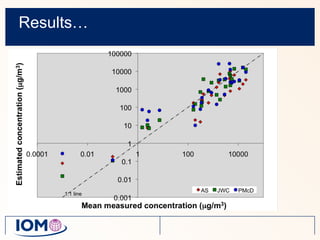

The document discusses a model developed to assess occupational exposure to pharmaceutical powders, which can pose health risks if inhaled. It highlights challenges in measuring exposure due to variability and proposes a validated model that factors in various parameters, such as dustiness and material handling. The model's application in the pharmaceutical industry can help manage risks effectively, although improved data on powder dustiness is needed.