Ingeinnova Automotive is working on several automotive projects:

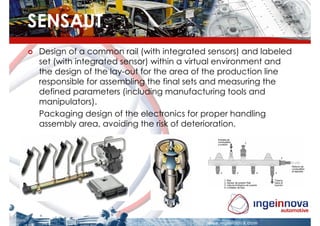

1) Preparing tire clearance and bending for three vehicle models and validating tools and processes.

2) Welding and assembly work for model J77 including validating tools and generating robot paths.

3) Adapting production lines for an new vehicle model J87 to be built alongside existing models.

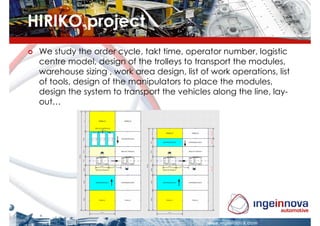

4) Developing the manufacturing line for an electric vehicle to assemble modules for two production rates.