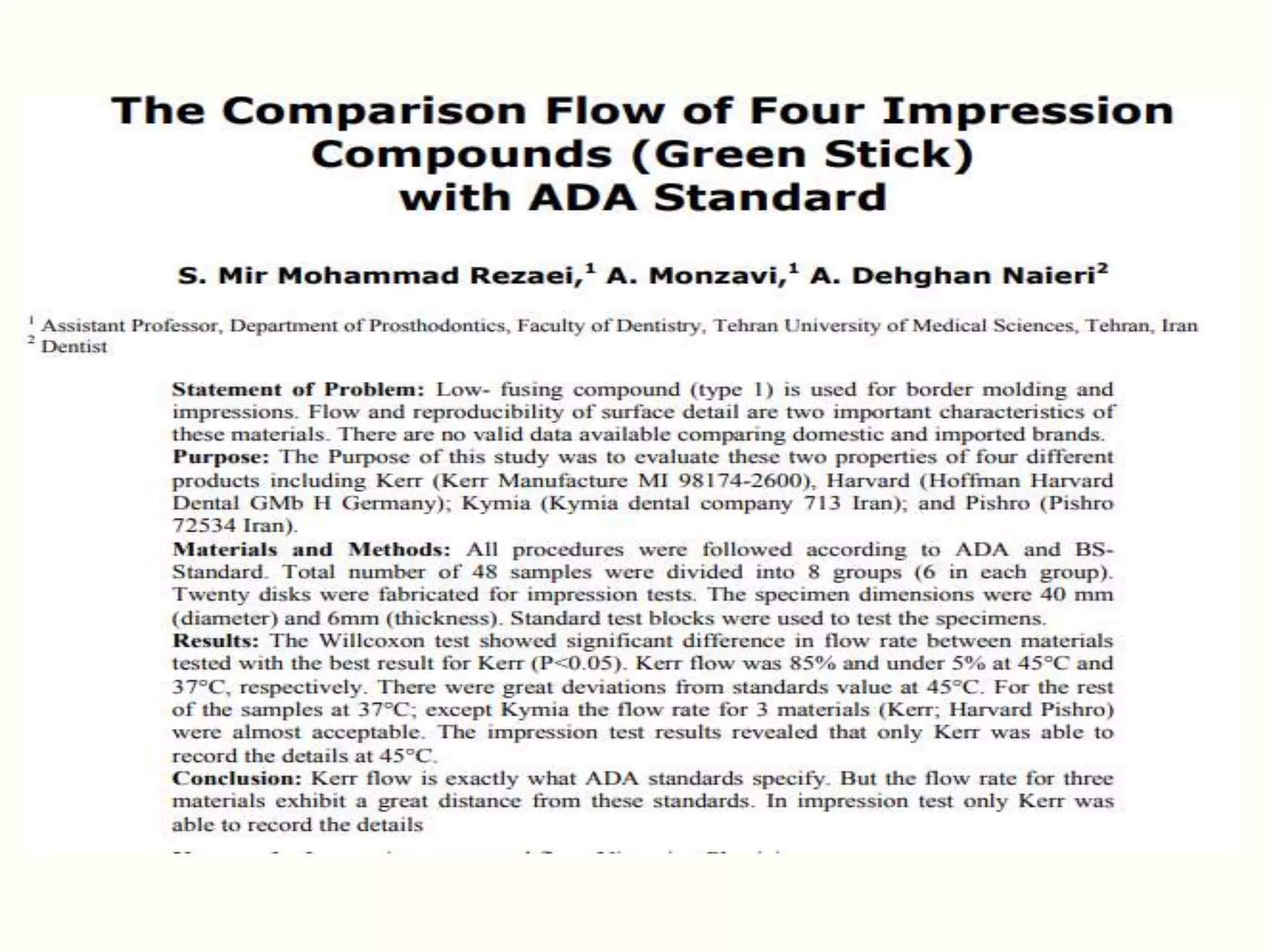

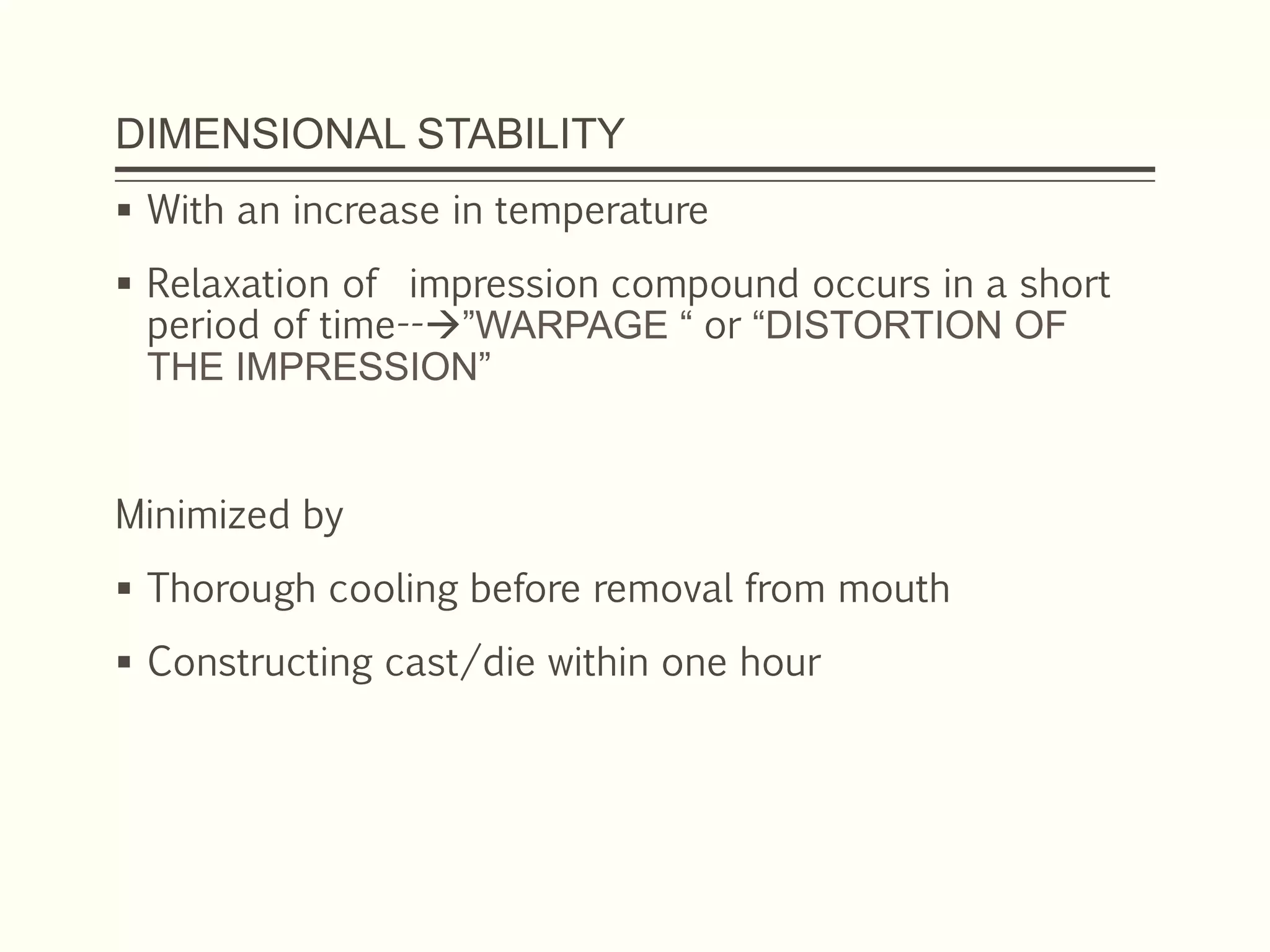

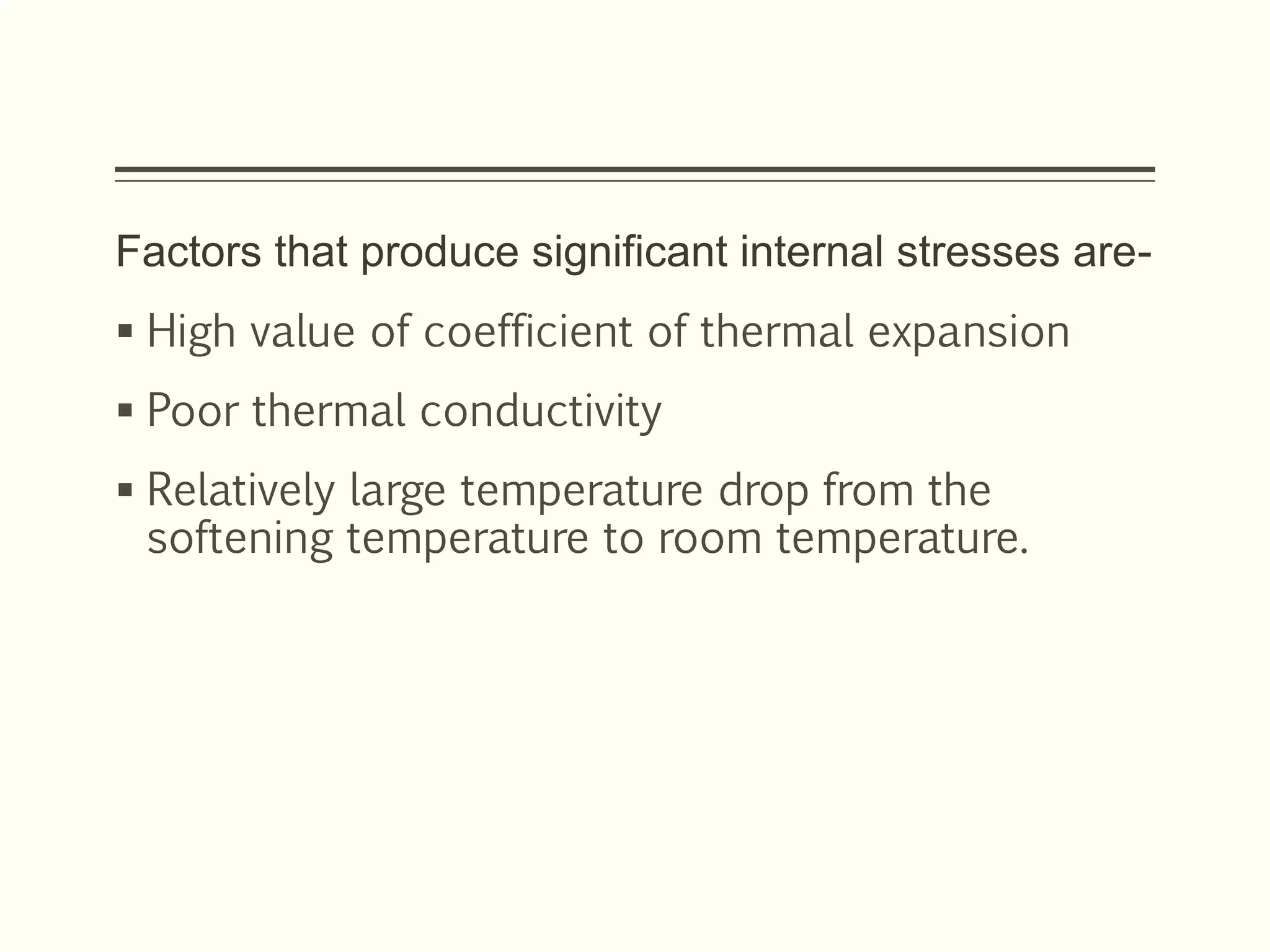

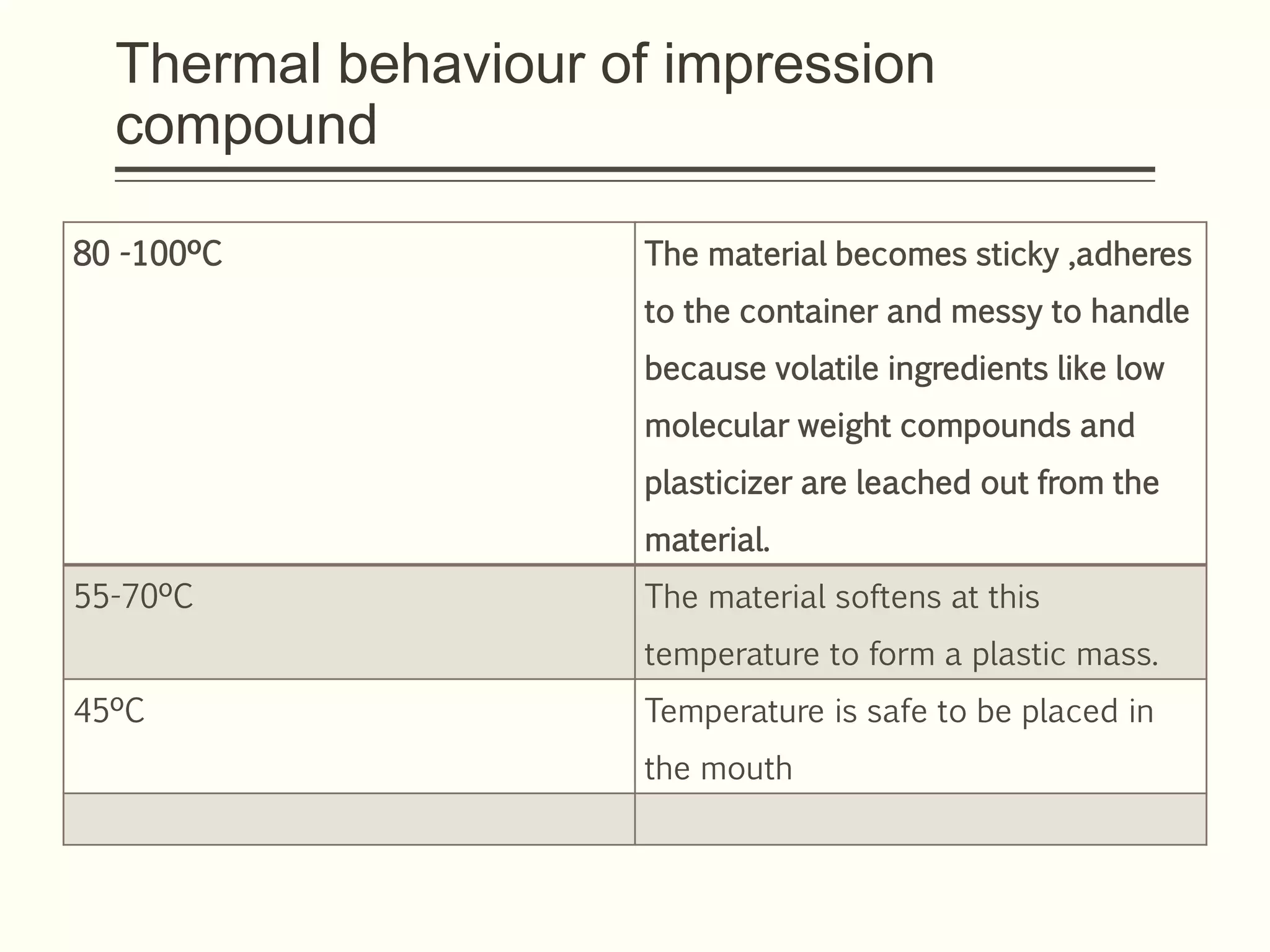

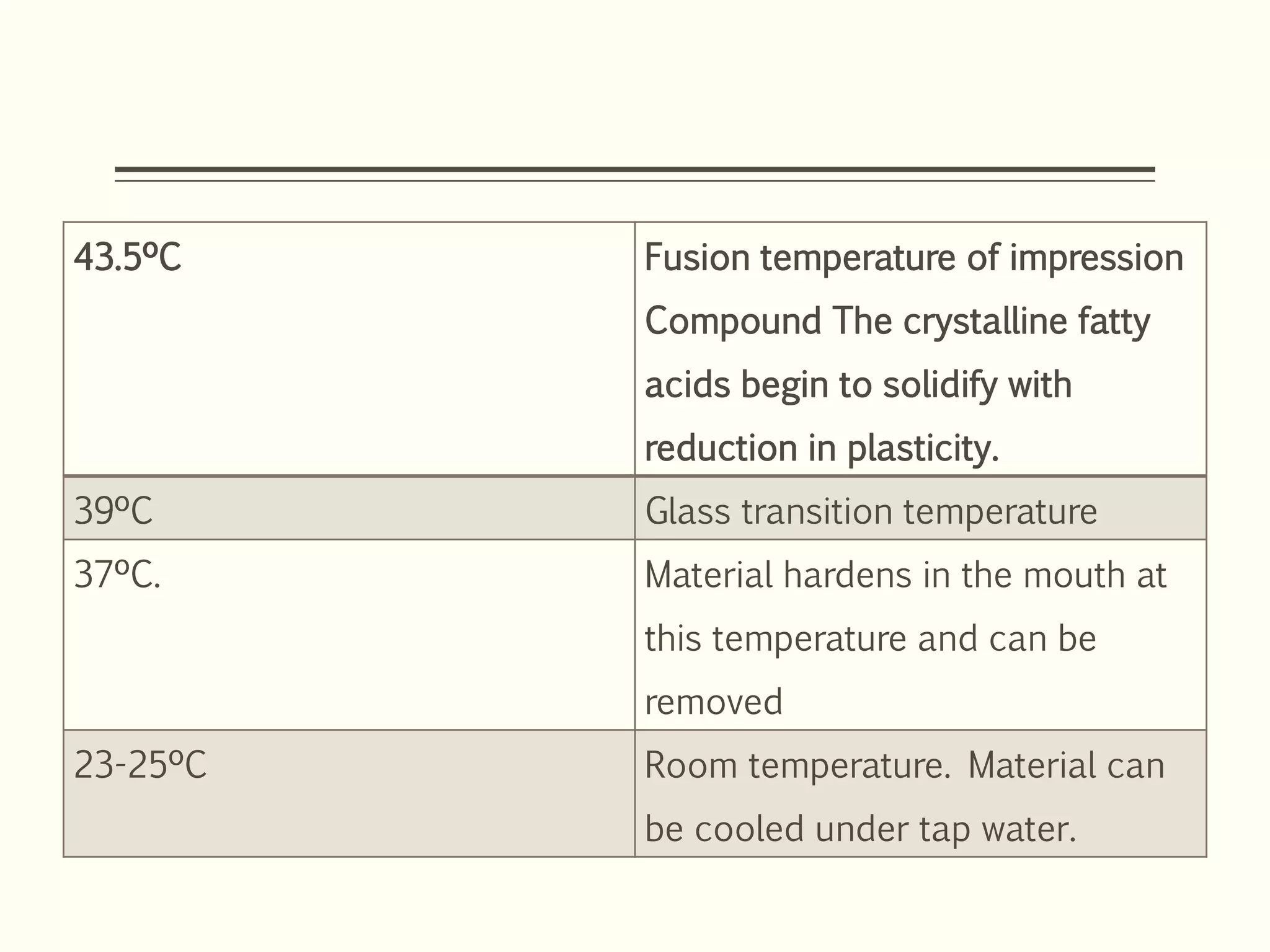

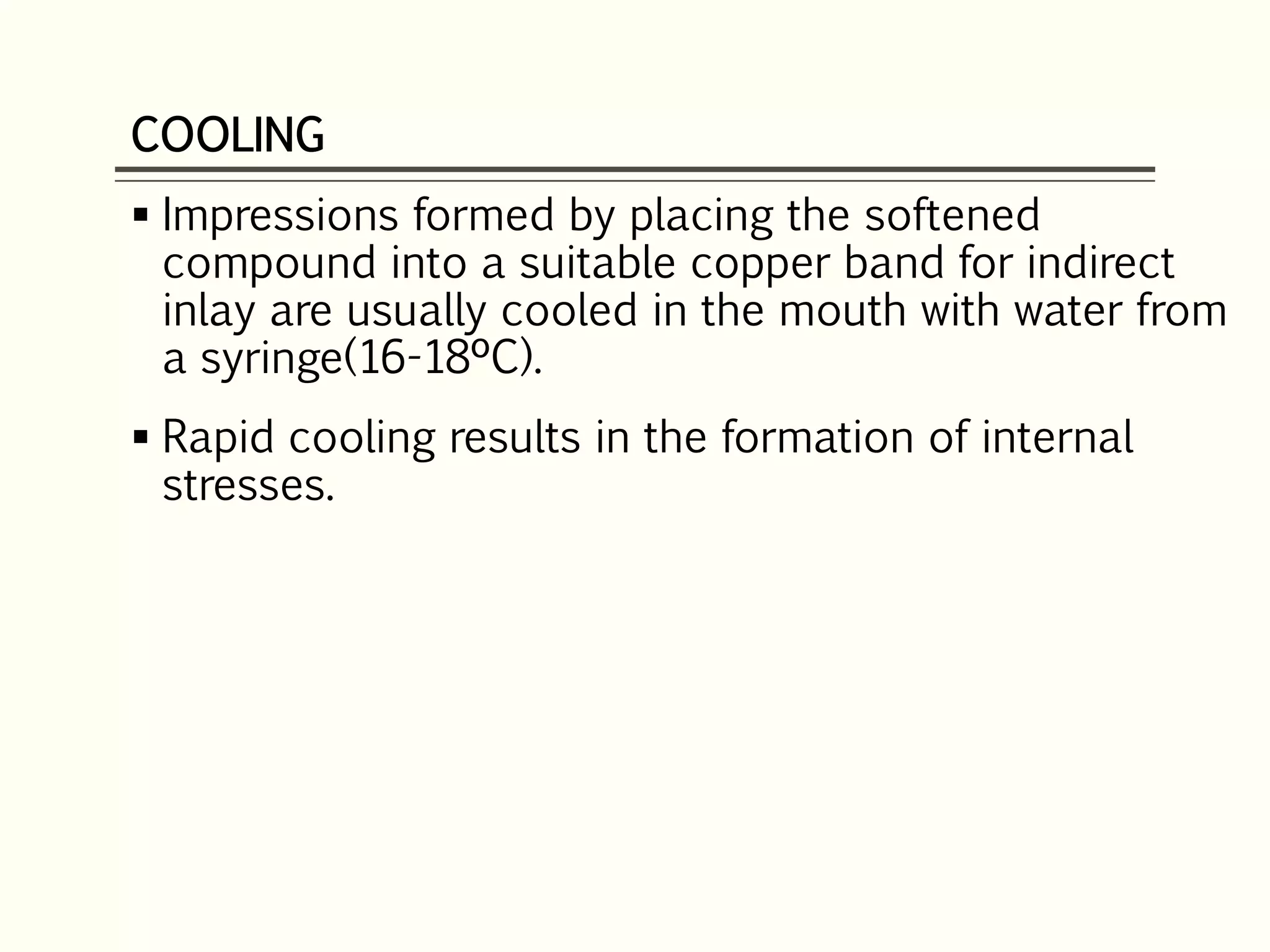

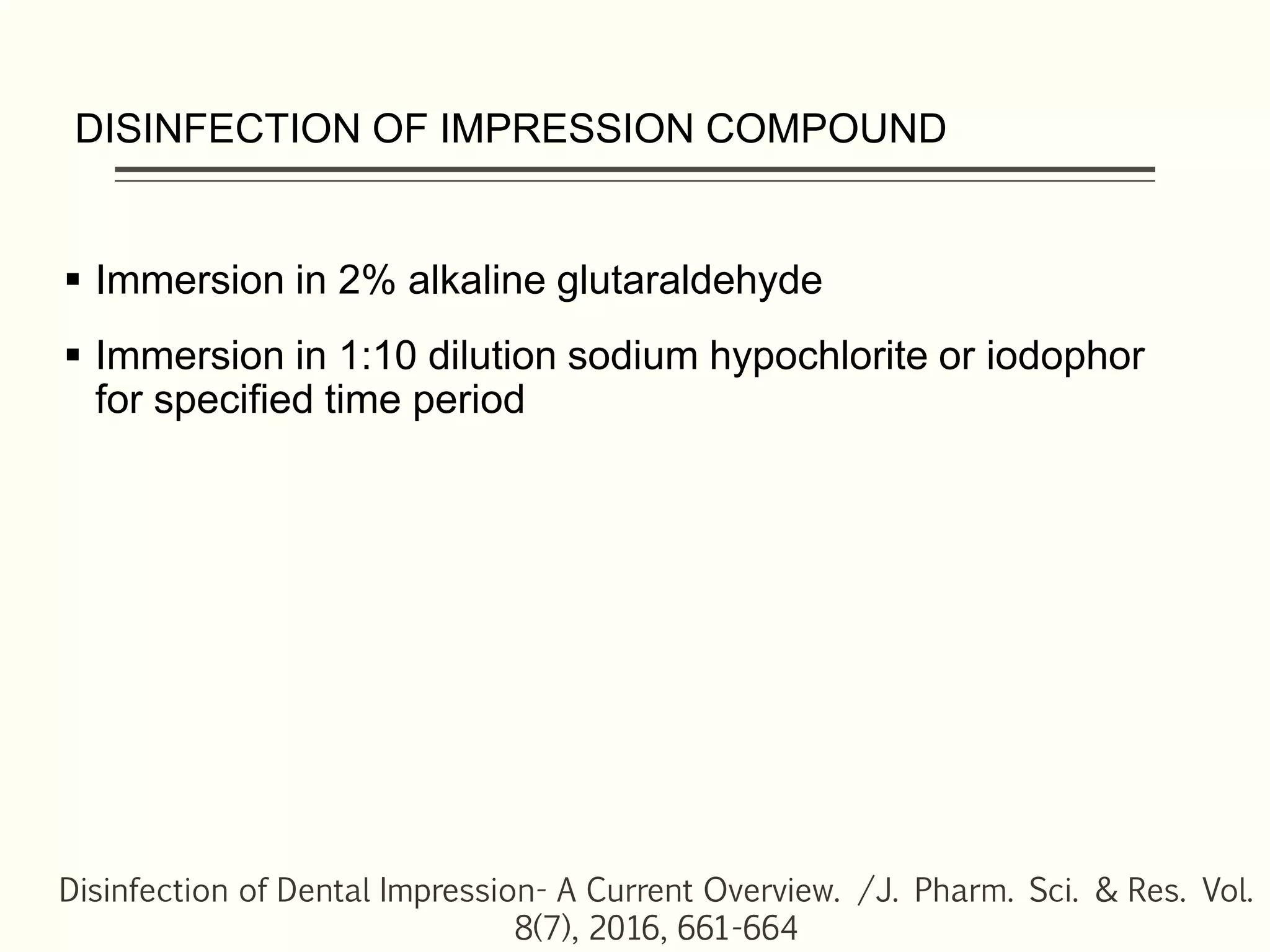

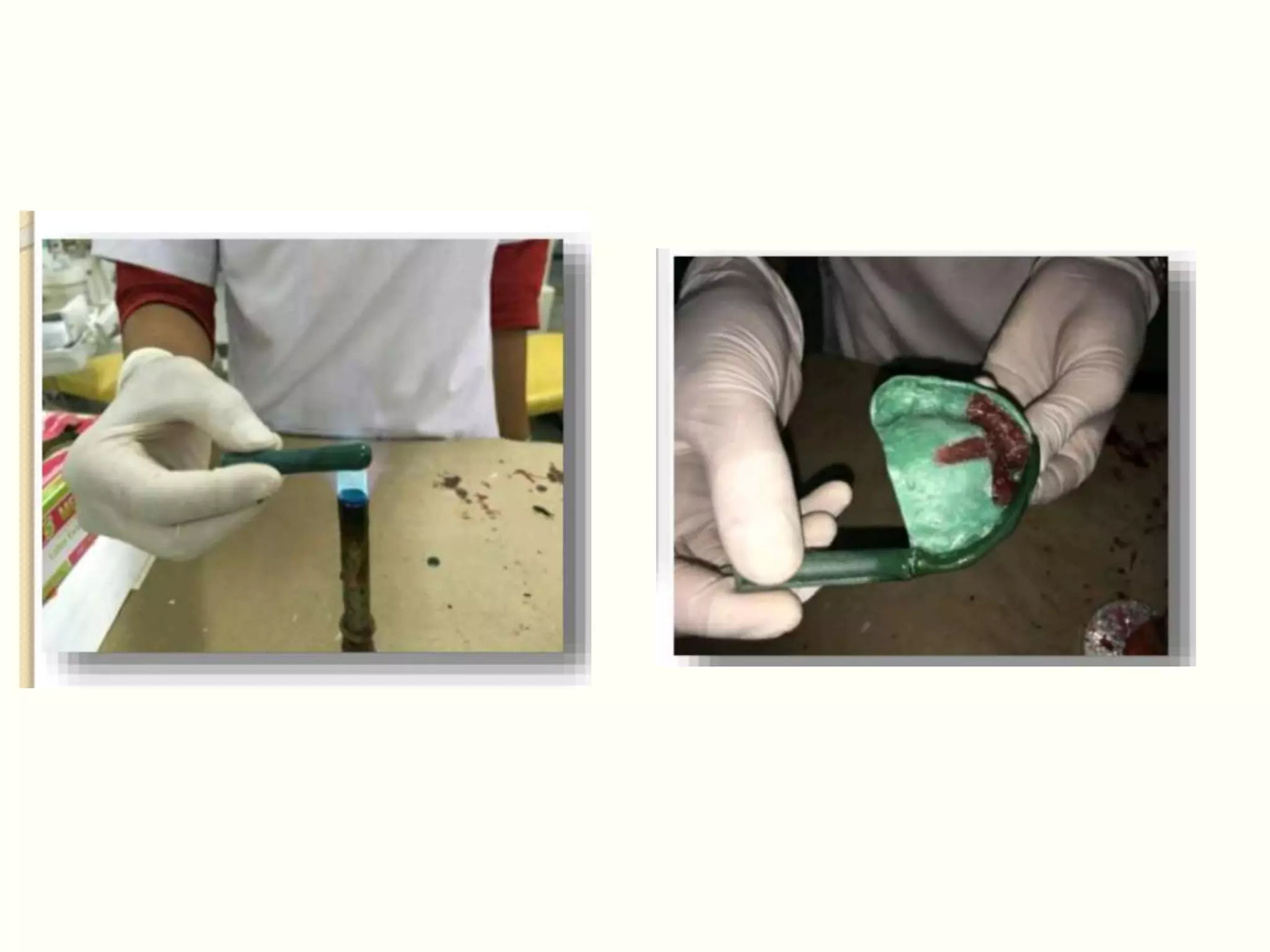

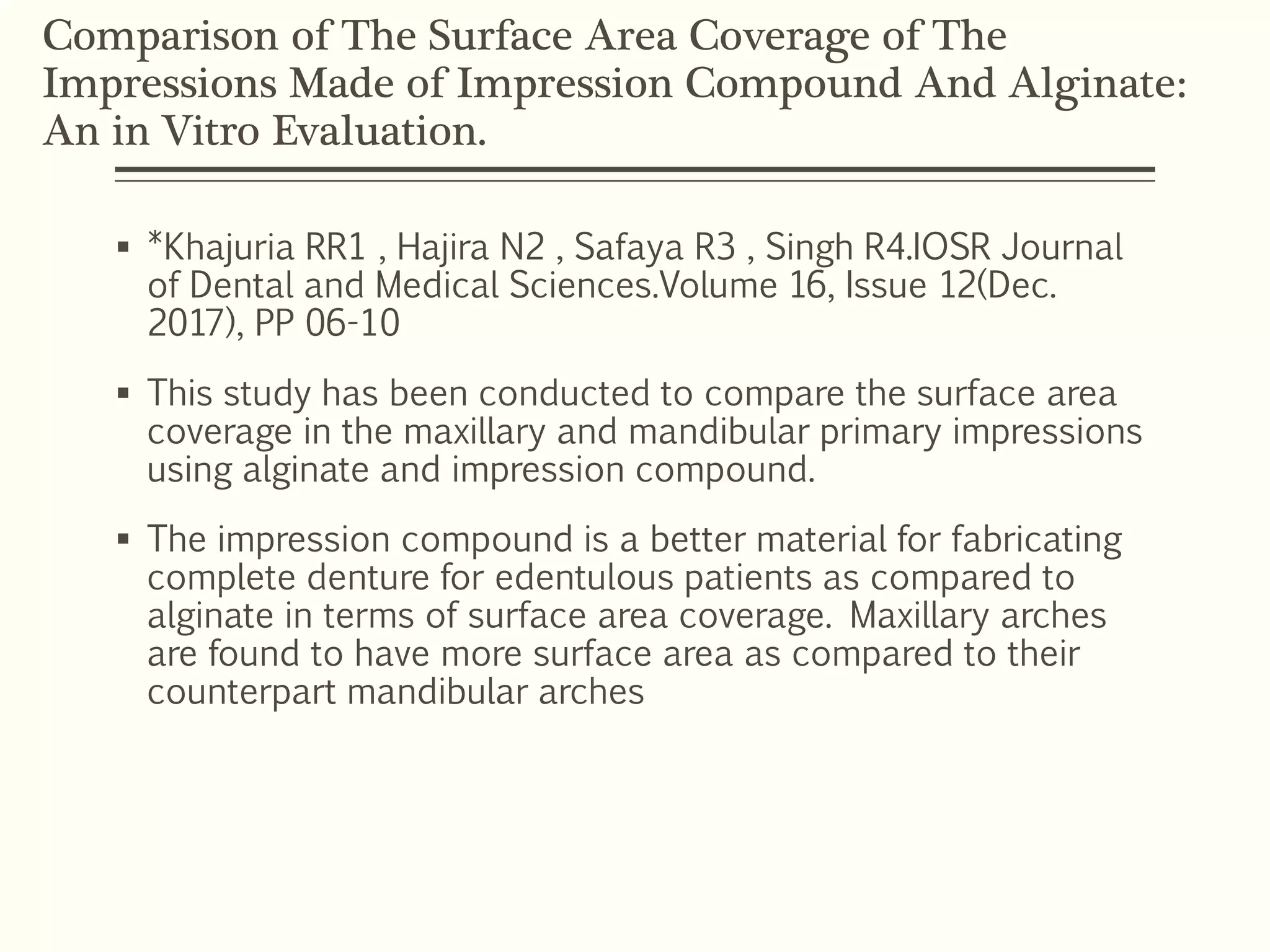

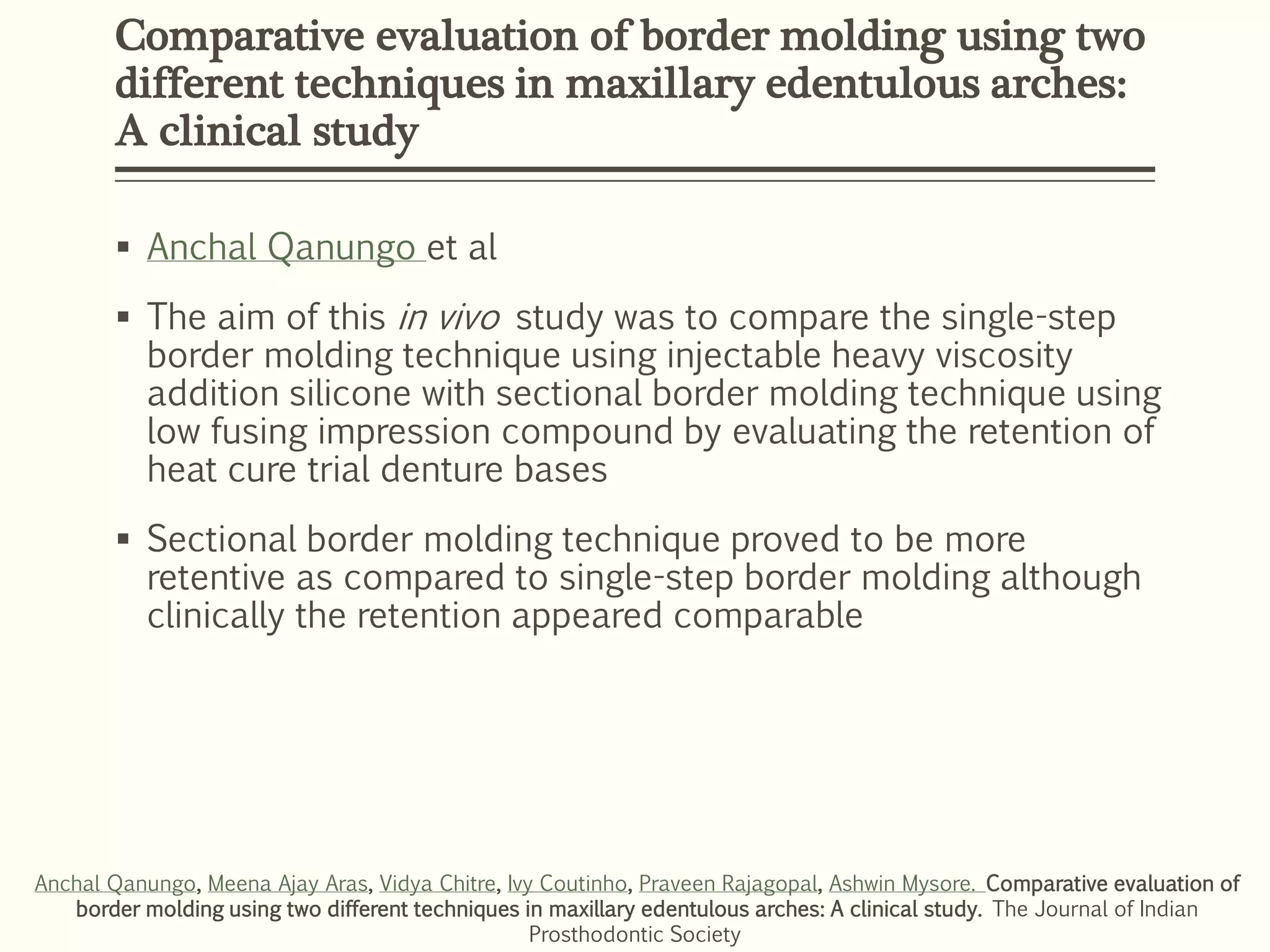

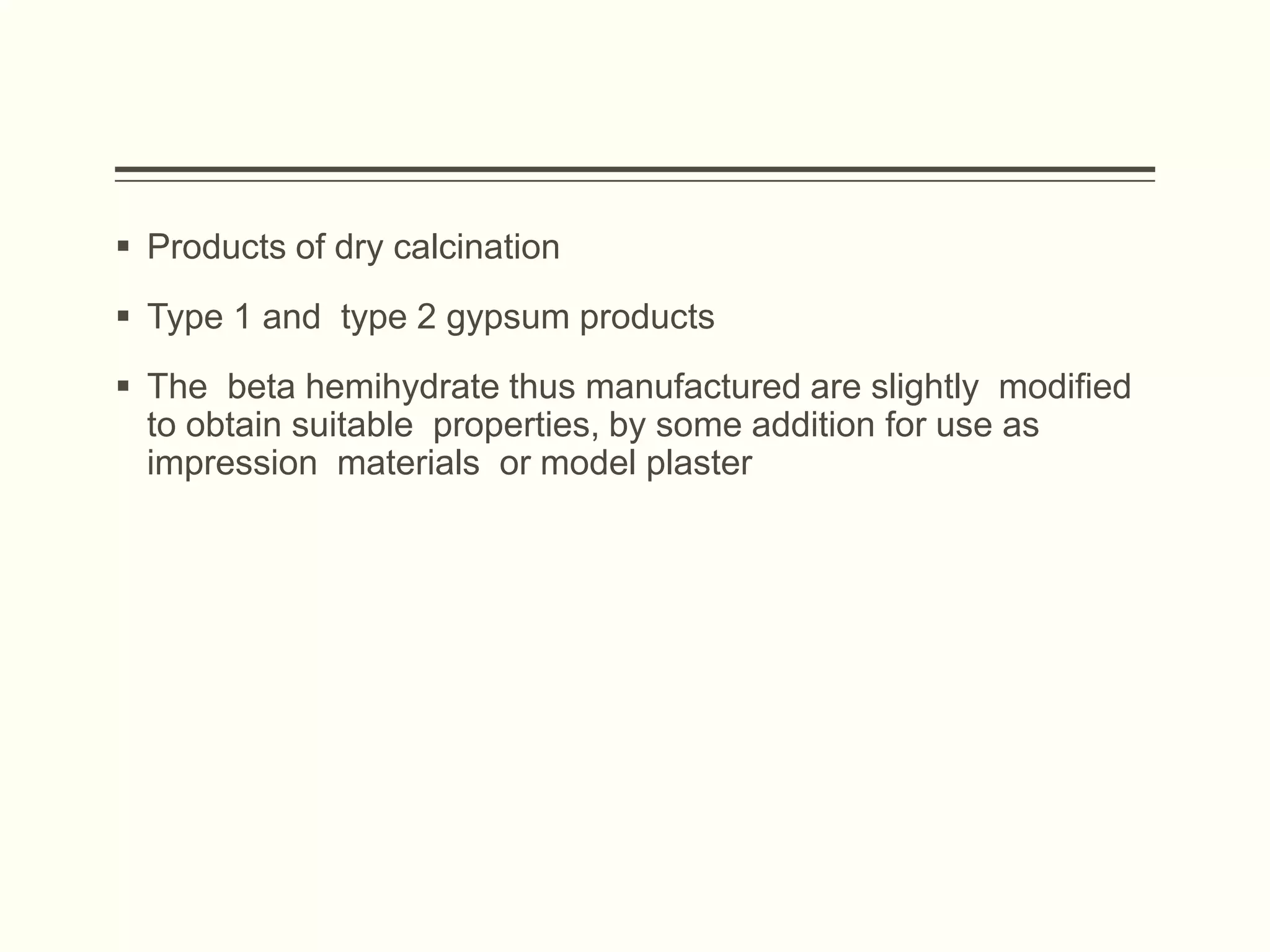

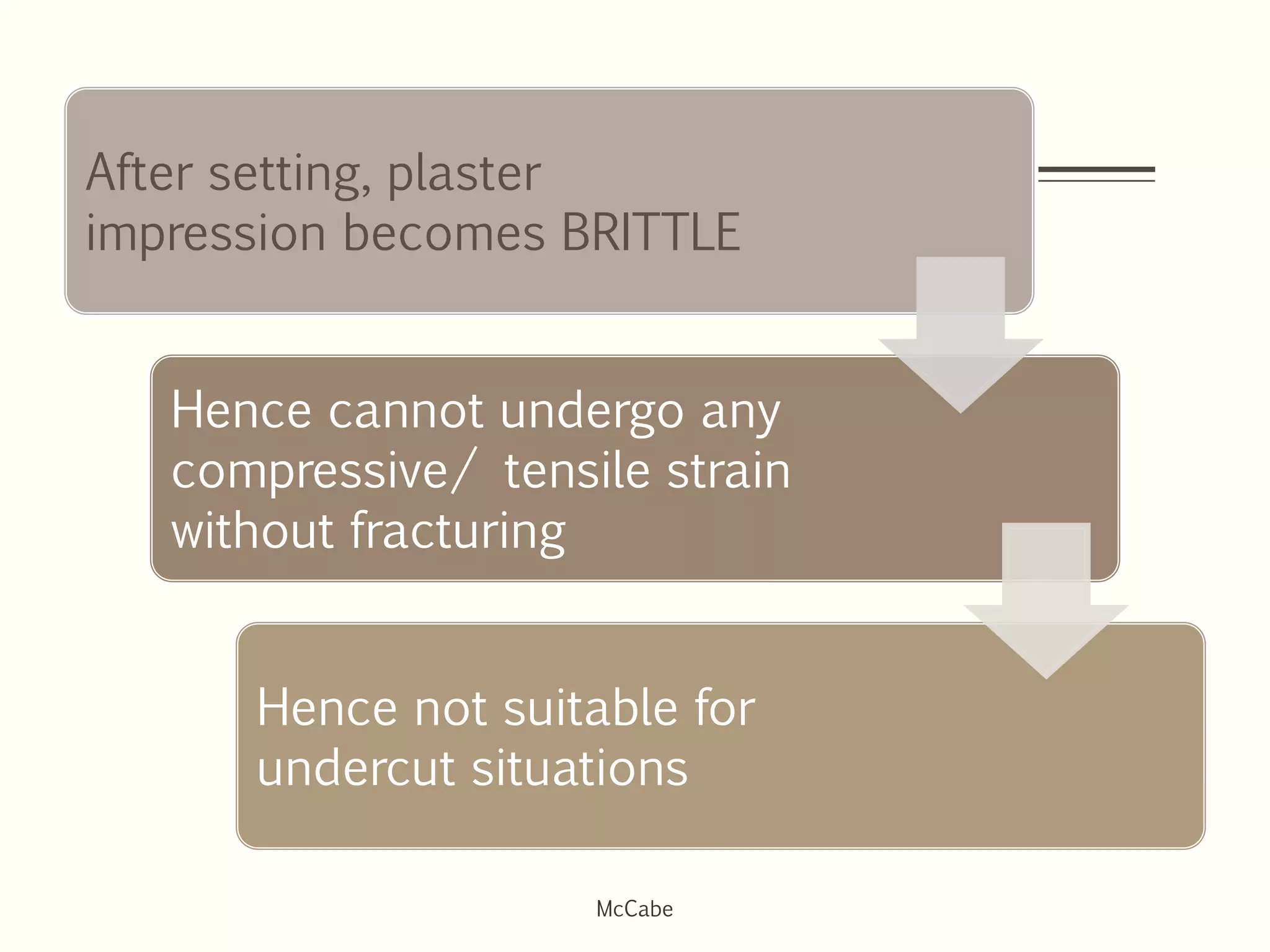

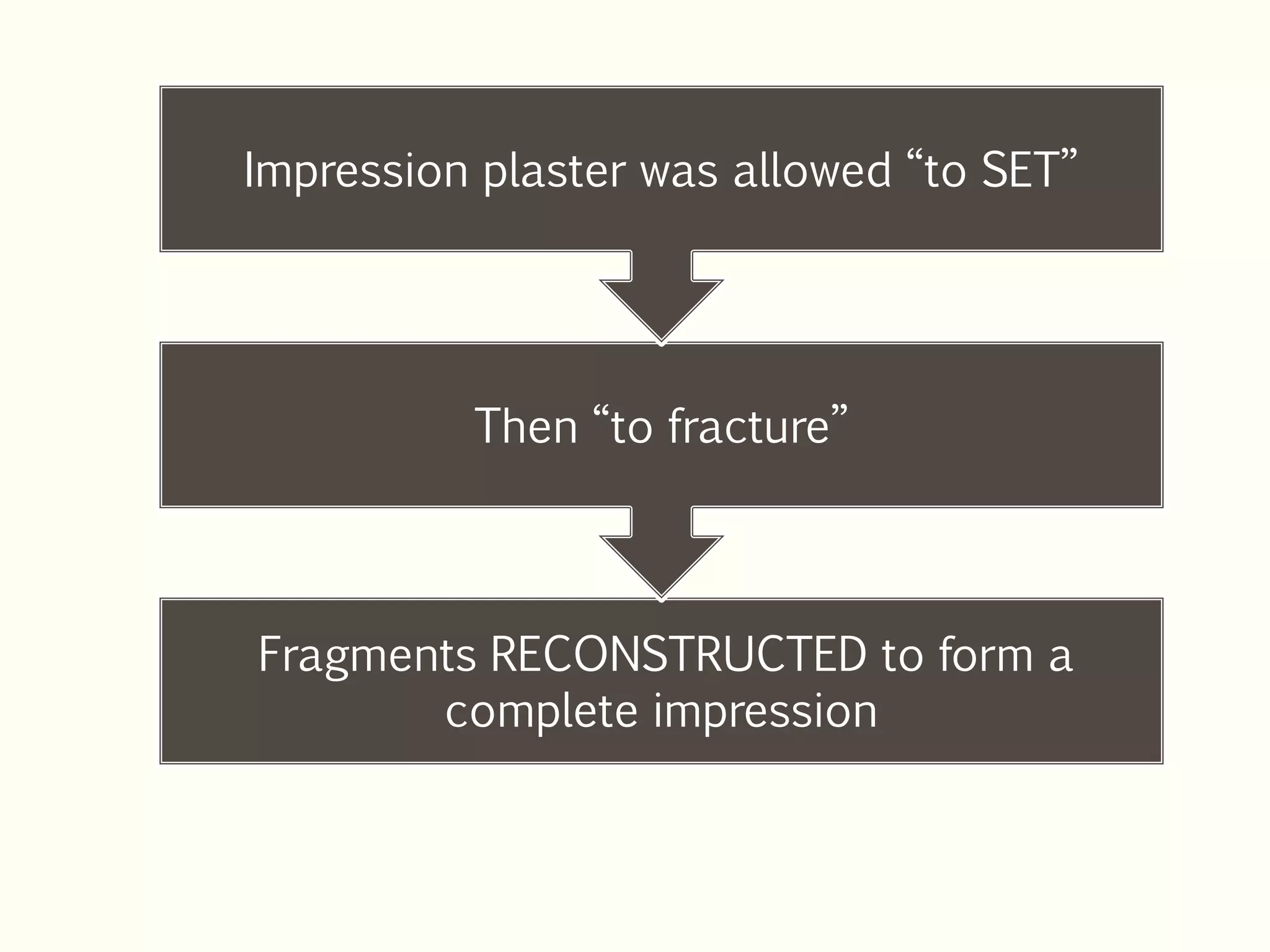

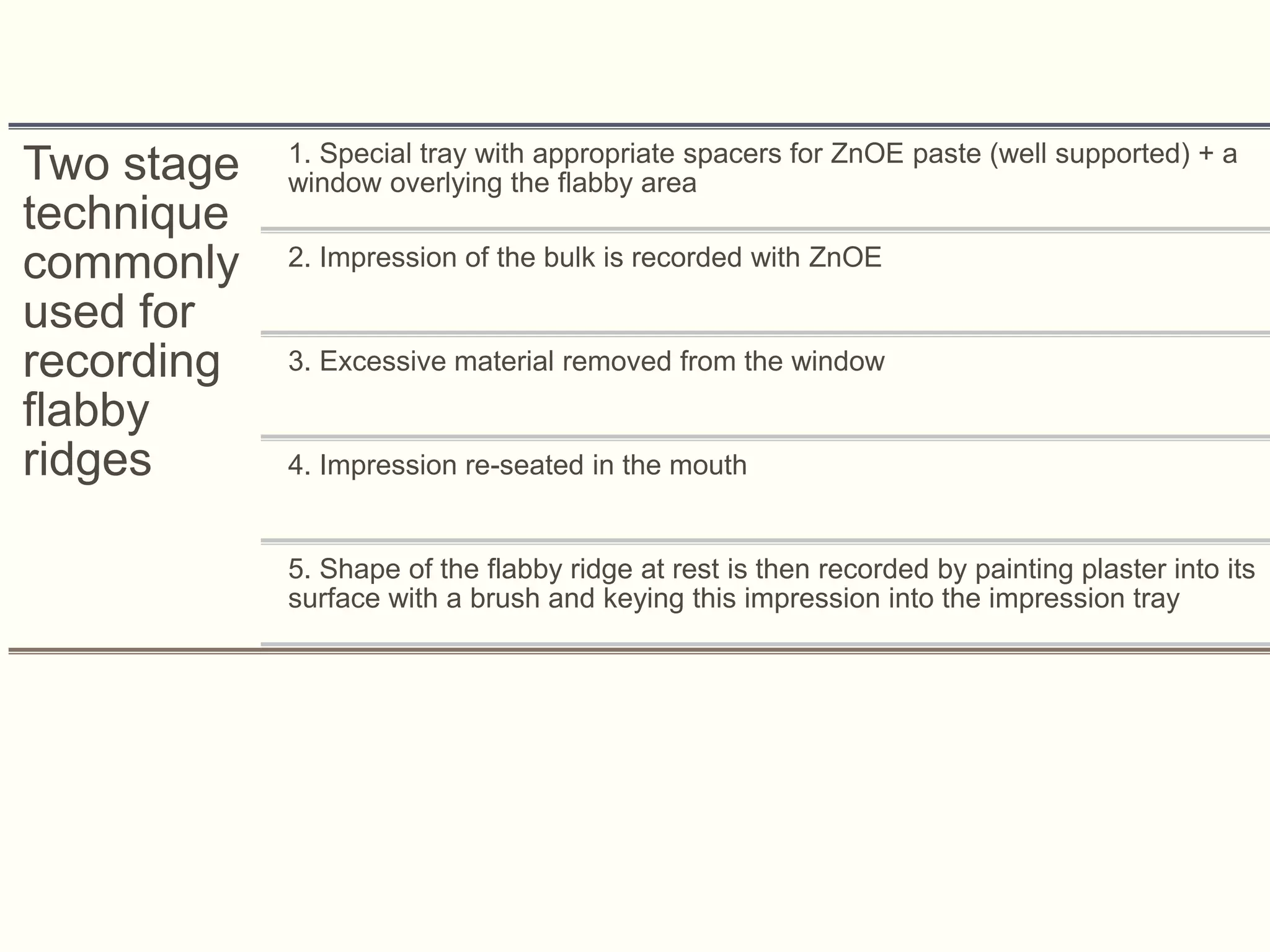

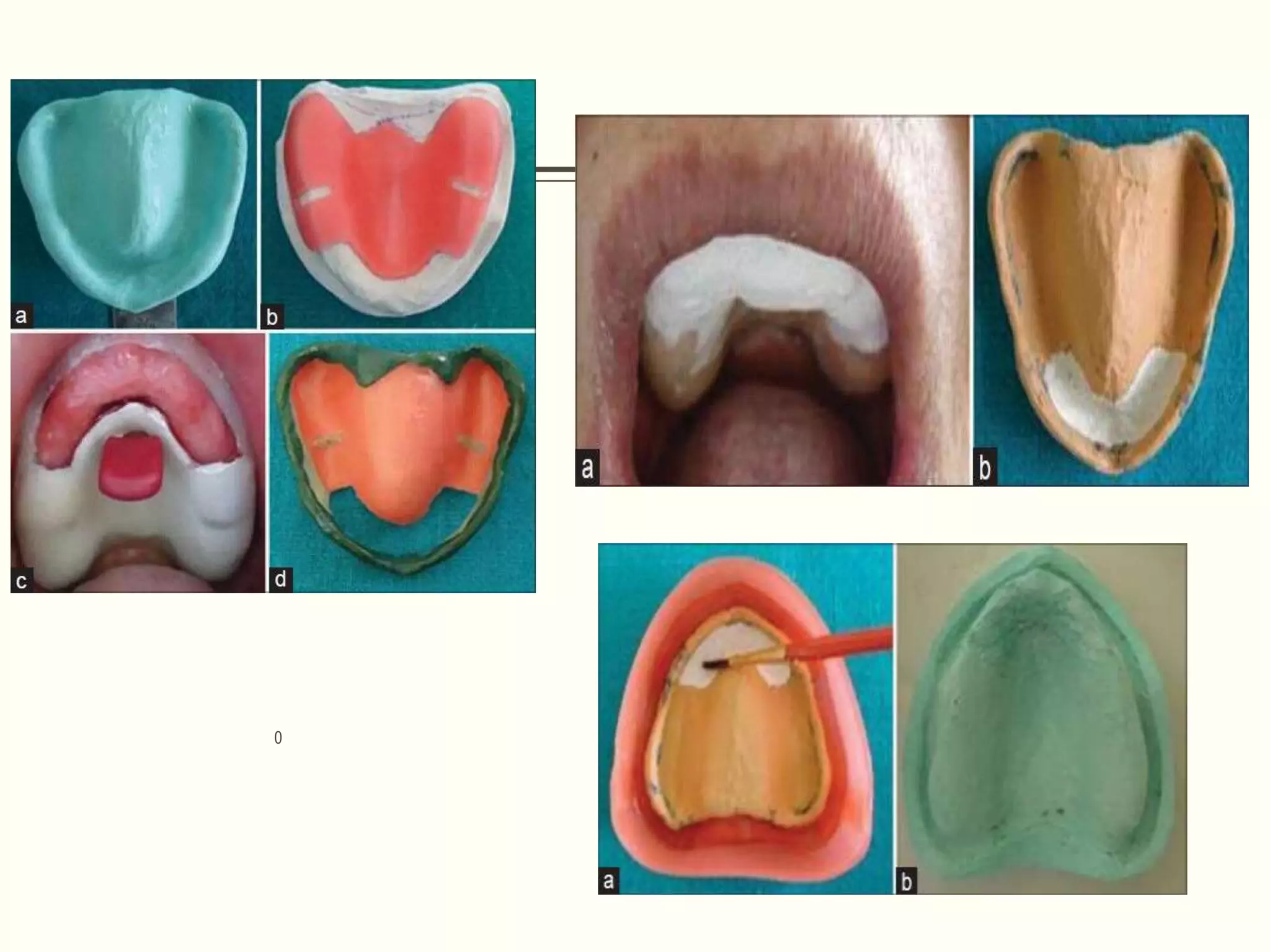

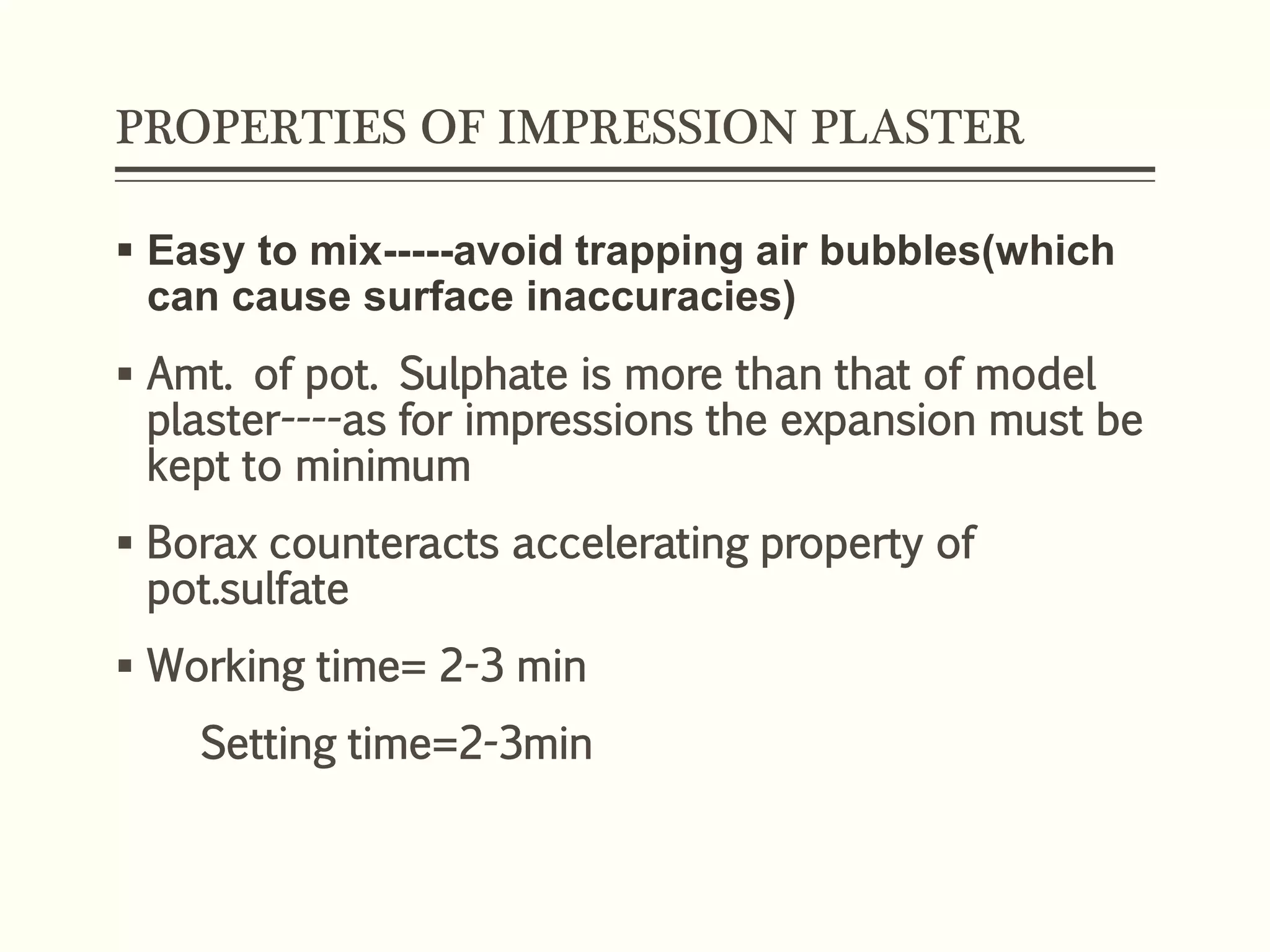

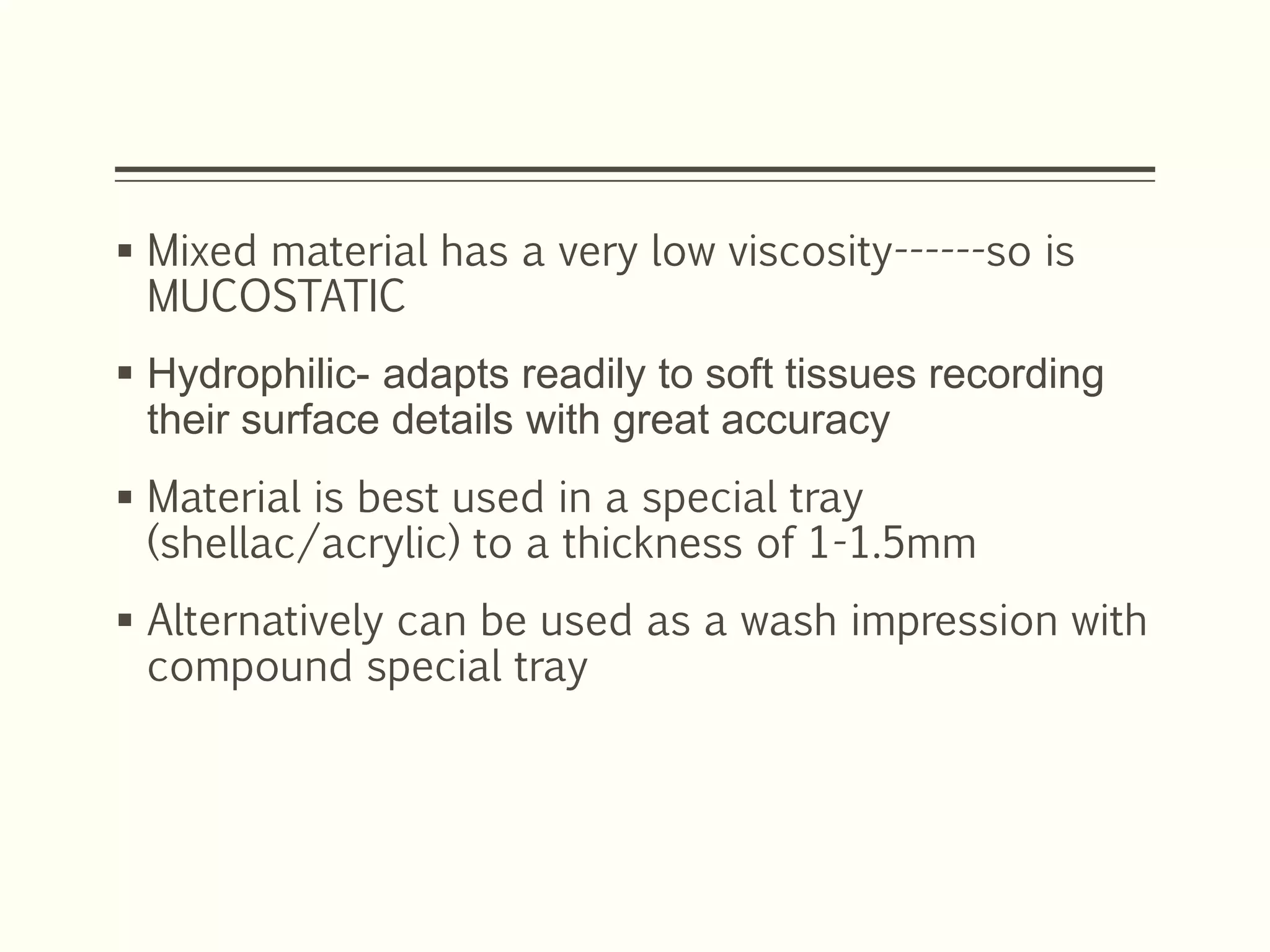

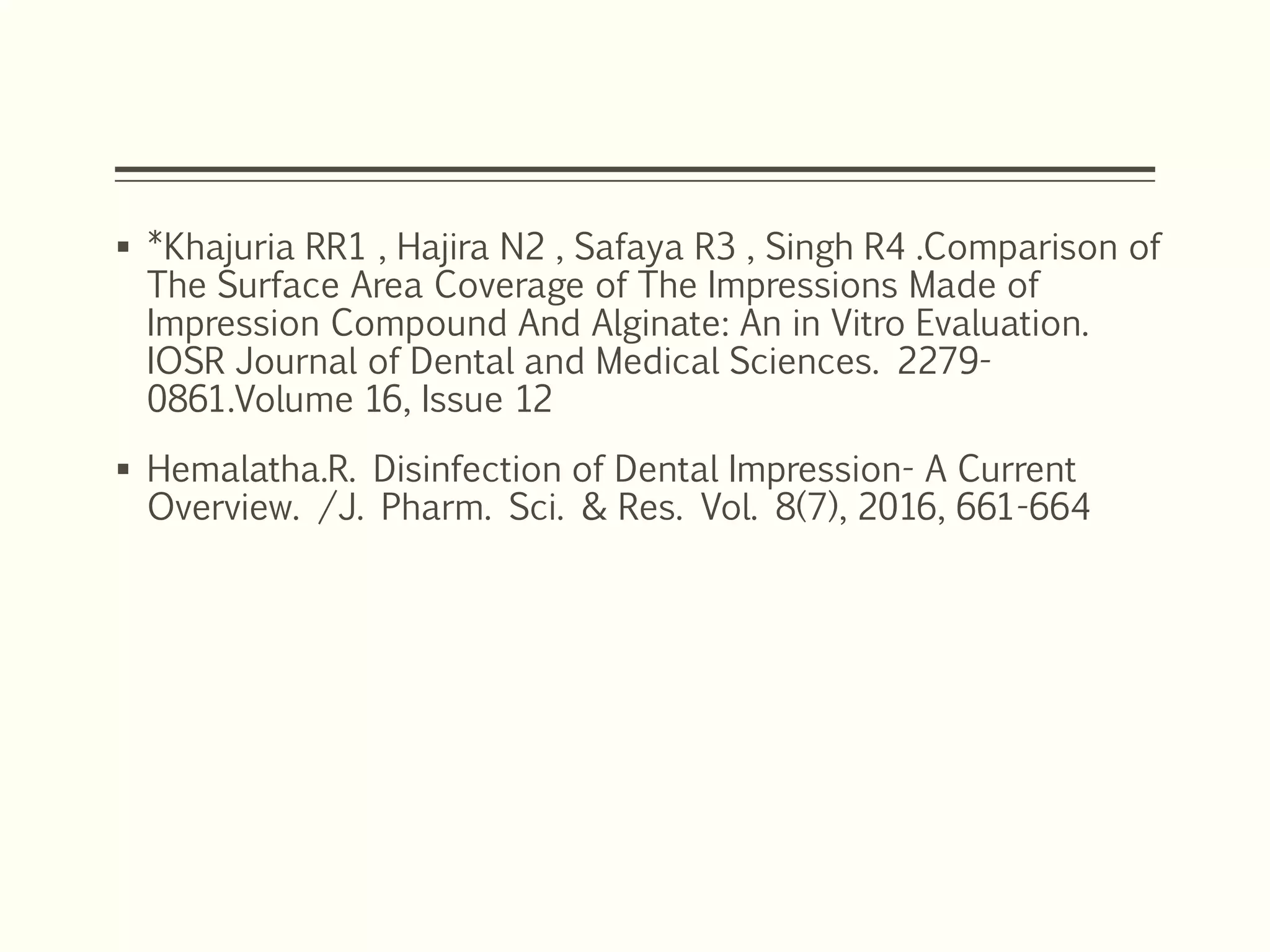

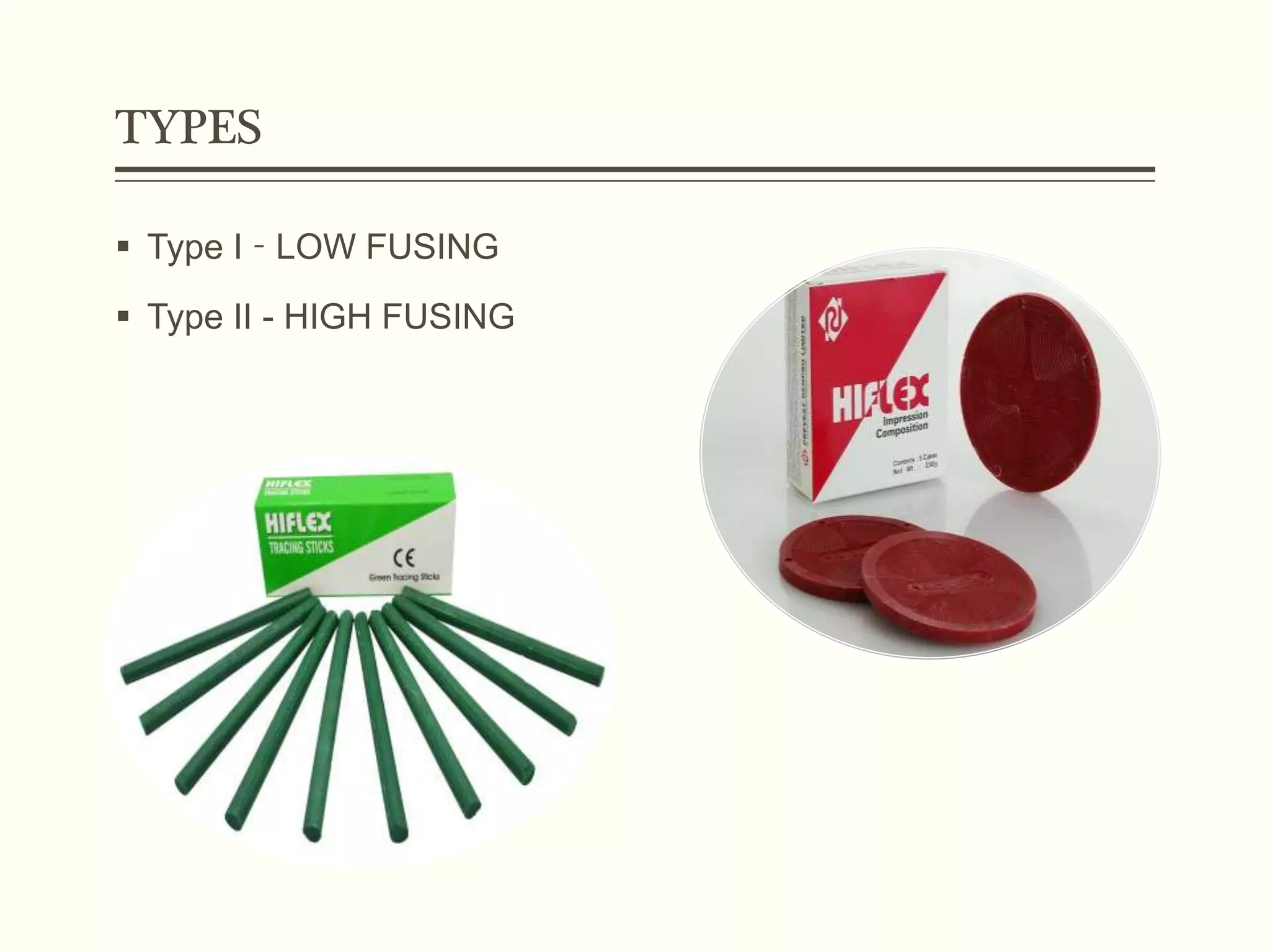

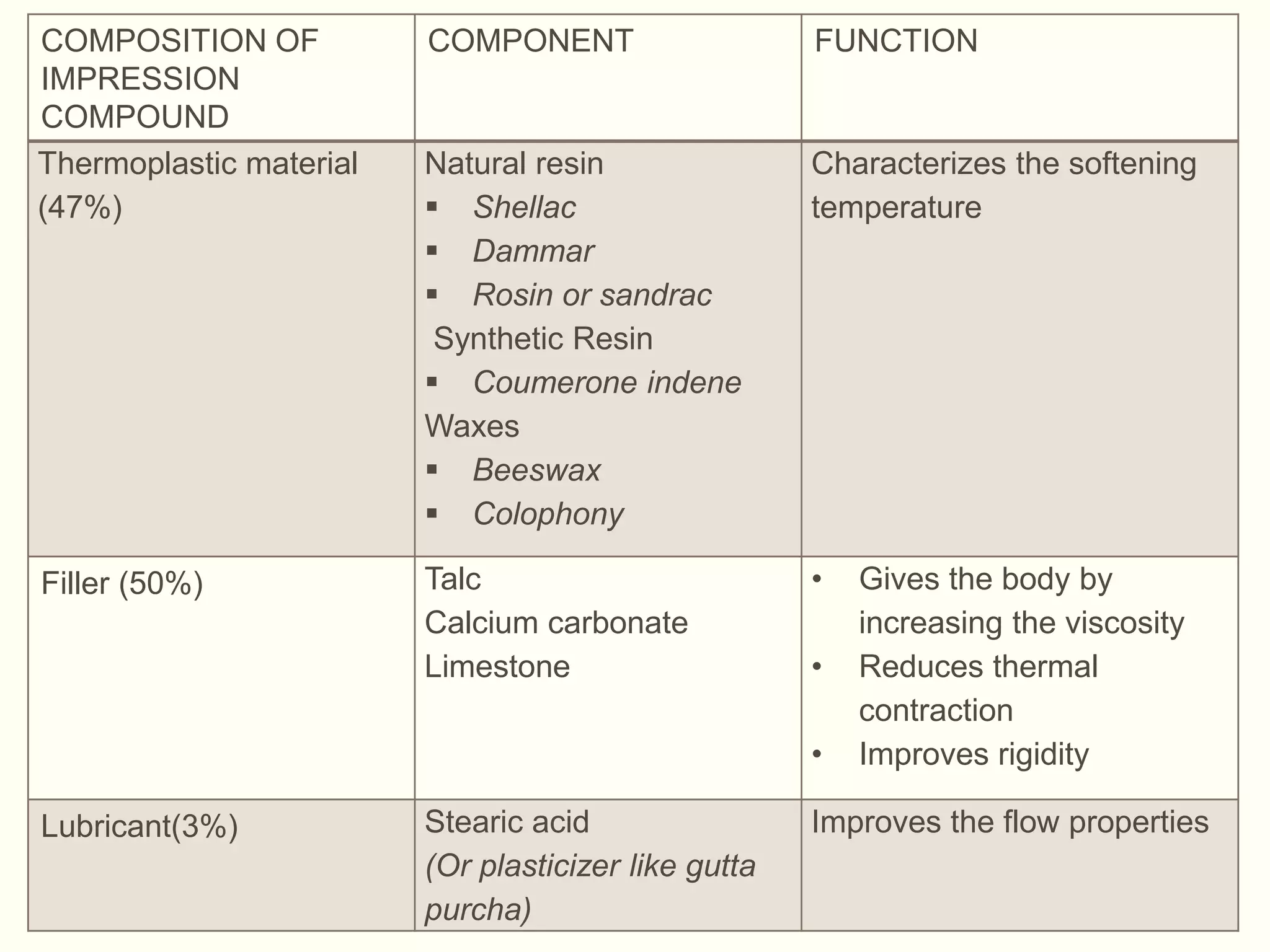

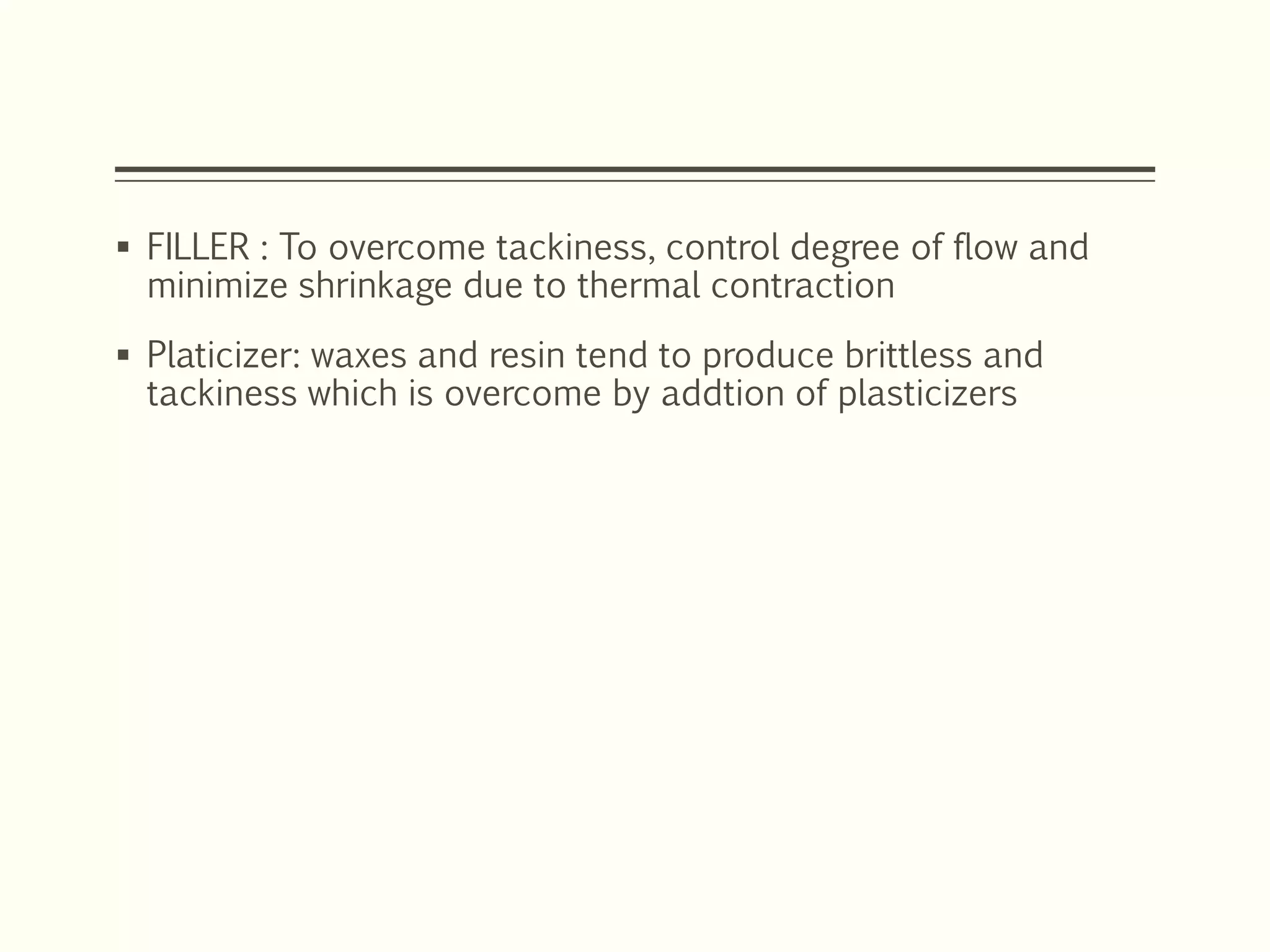

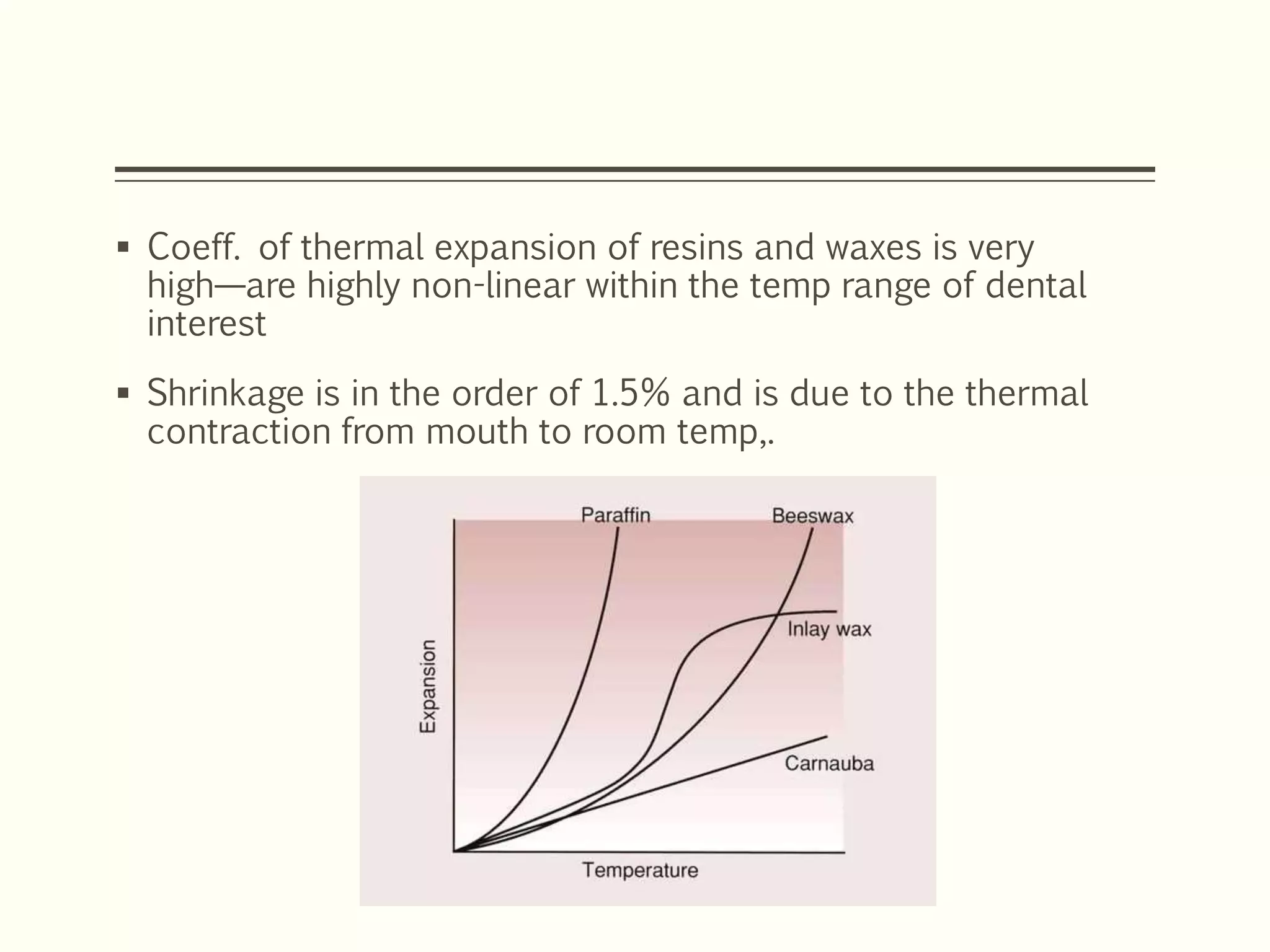

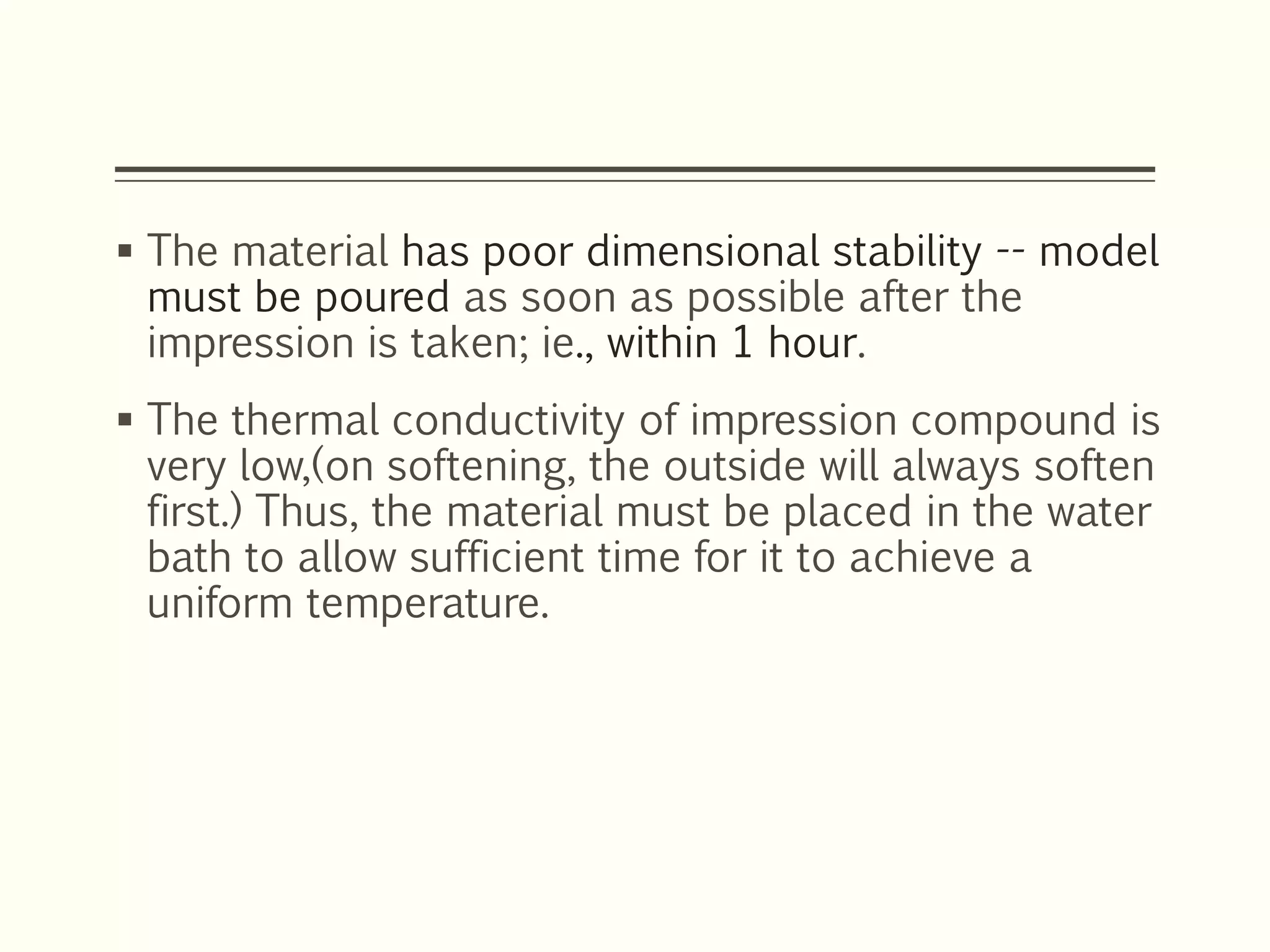

This document discusses impression compound, which is a non-elastic, thermoplastic impression material. It comes in various colors (red, green, gray) which indicate different working temperatures. Red compound has a lower melting temperature. Impression compound is composed of thermoplastic resins, waxes, filler, and lubricants. It has high viscosity and mucocompressive properties. It is commonly used to make preliminary impressions for edentulous ridges and single crowns. Some techniques described are border molding, copper ring technique, and using impression plaster. Impression compound has advantages of being economical and easy to use but also has disadvantages like poor dimensional stability and difficulty recording fine details due to high viscosity.

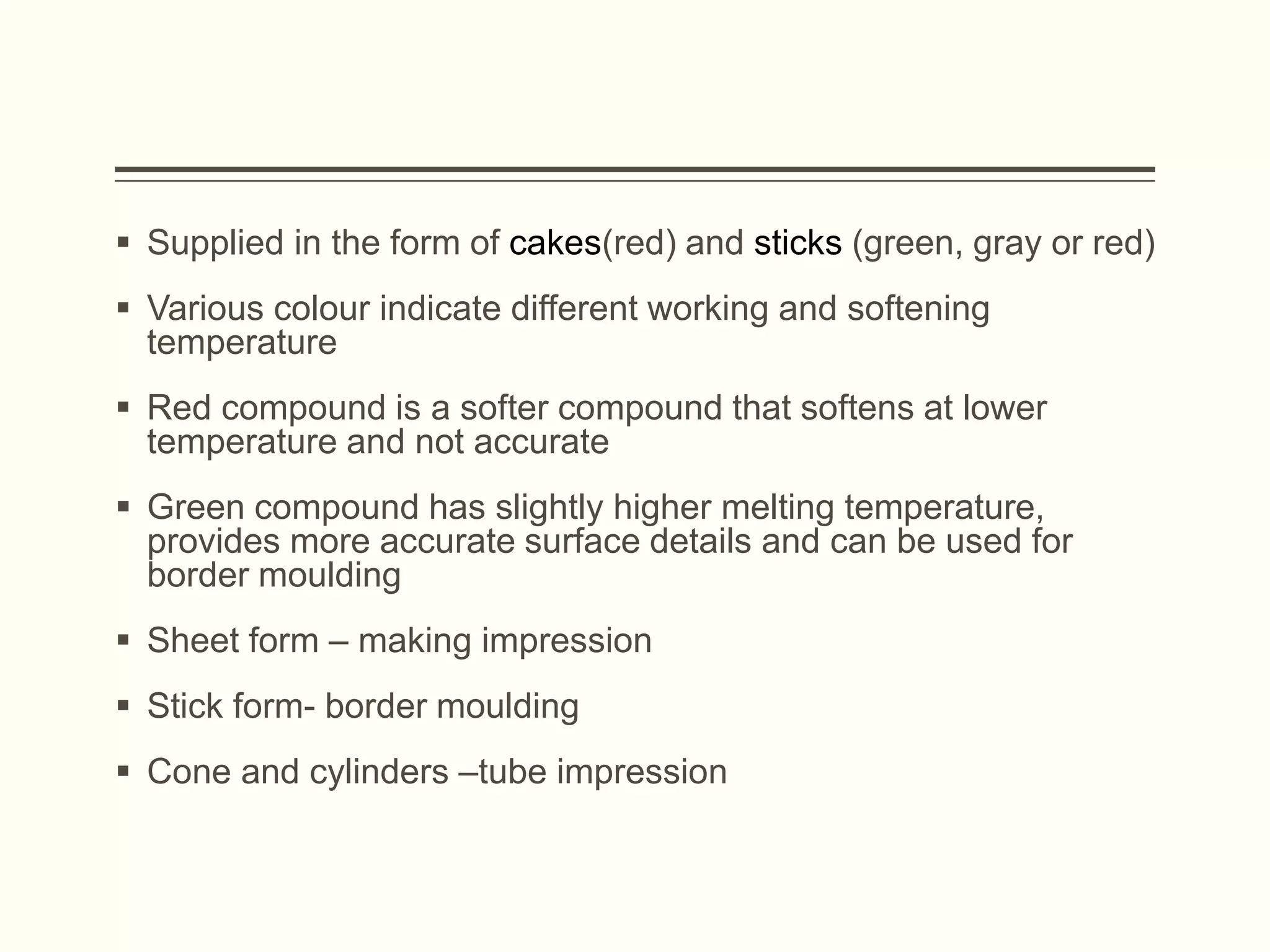

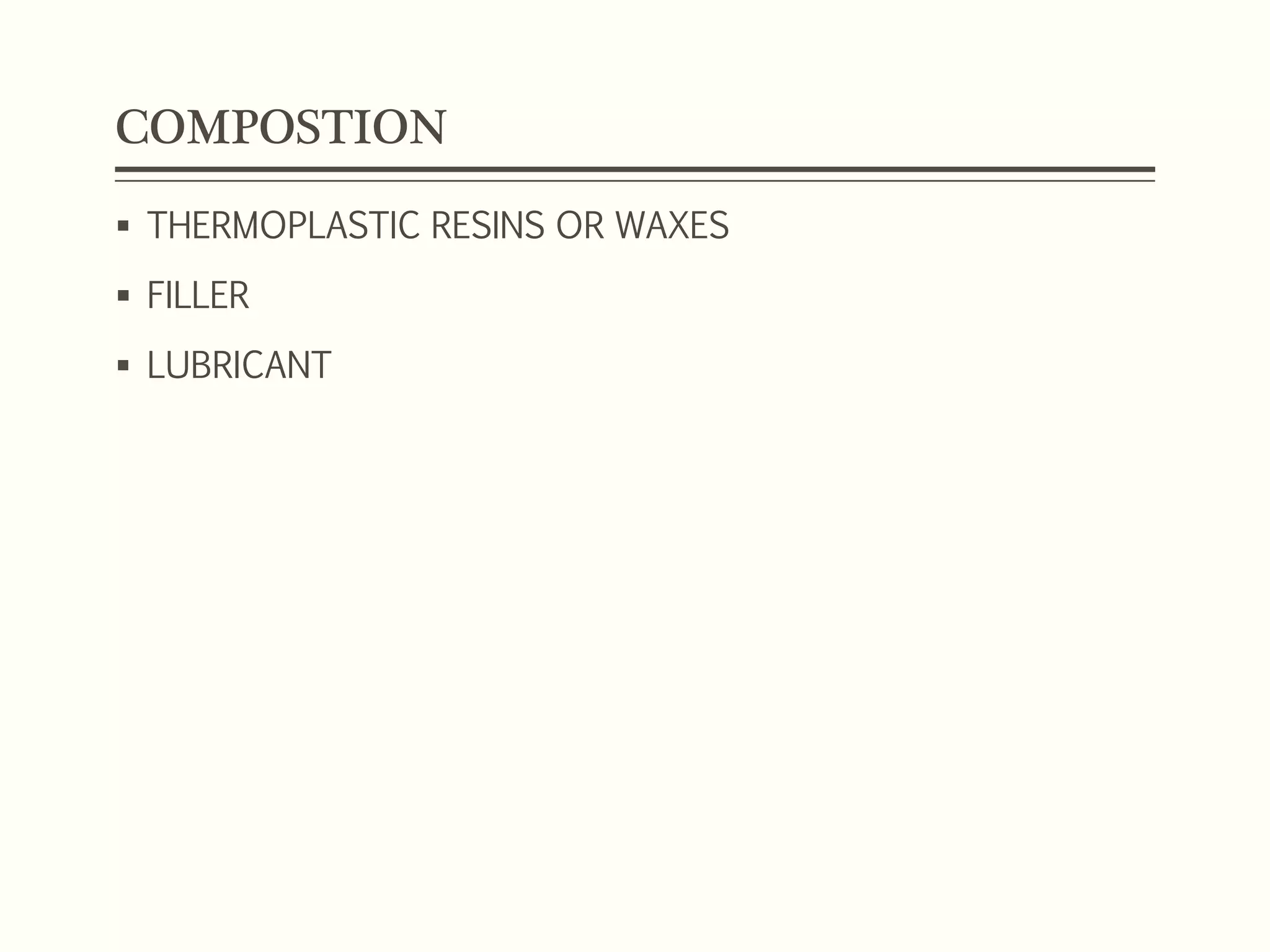

![PROPERTIES OF IMPRESSION COMPOUNDS

Flow

AT 37 DEGREE

CELSIUS(ON REMOVAL

OF IMPRESSION)

AT 45 DEGREE

CELSIUS

(INTRODUCTION OF

IMPRESSION)

I

[IMPRESSION

COMPOUND-LOW

FUSING]

</= 6% >/= 85%

II

TRAY COMPOUND[HIGH

FUSING]

</= 2% 70-85%](https://image.slidesharecdn.com/inelasticimpressionmaterial-ii-200610131731/75/Inelastic-impression-material-14-2048.jpg)