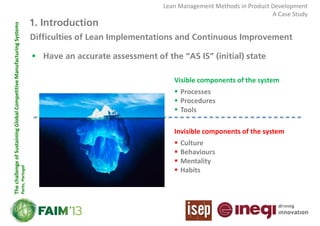

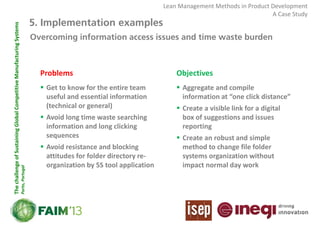

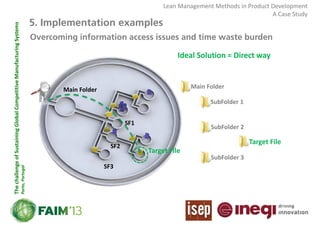

The document explores lean management methods in product development and contrasts these with lean manufacturing, emphasizing challenges in implementation and the need for top management commitment. It presents a reference model and examples of successful strategies to overcome common barriers like human resistance and information access issues. The study concludes with the development of a tailored model for lean implementation that resulted in significant time savings and increased team motivation through better information management and recognition of individual talents.

![ThechallengeofSustainingGlobalCompetitiveManufacturingSystems

Daniel Soares1, João Bastos2,3, Diana Gavazzo1, João Paulo

Pereira1 and A.J. Baptista1 [abaptista@inegi.up.pt]

Lean Management Methods in

Product Development – A Case Study](https://image.slidesharecdn.com/inegileanproductdevelopmentfaim27jun2013v02-130908165906-/85/Lean-Management-Methods-in-Product-Development-A-Case-Study-19-320.jpg)