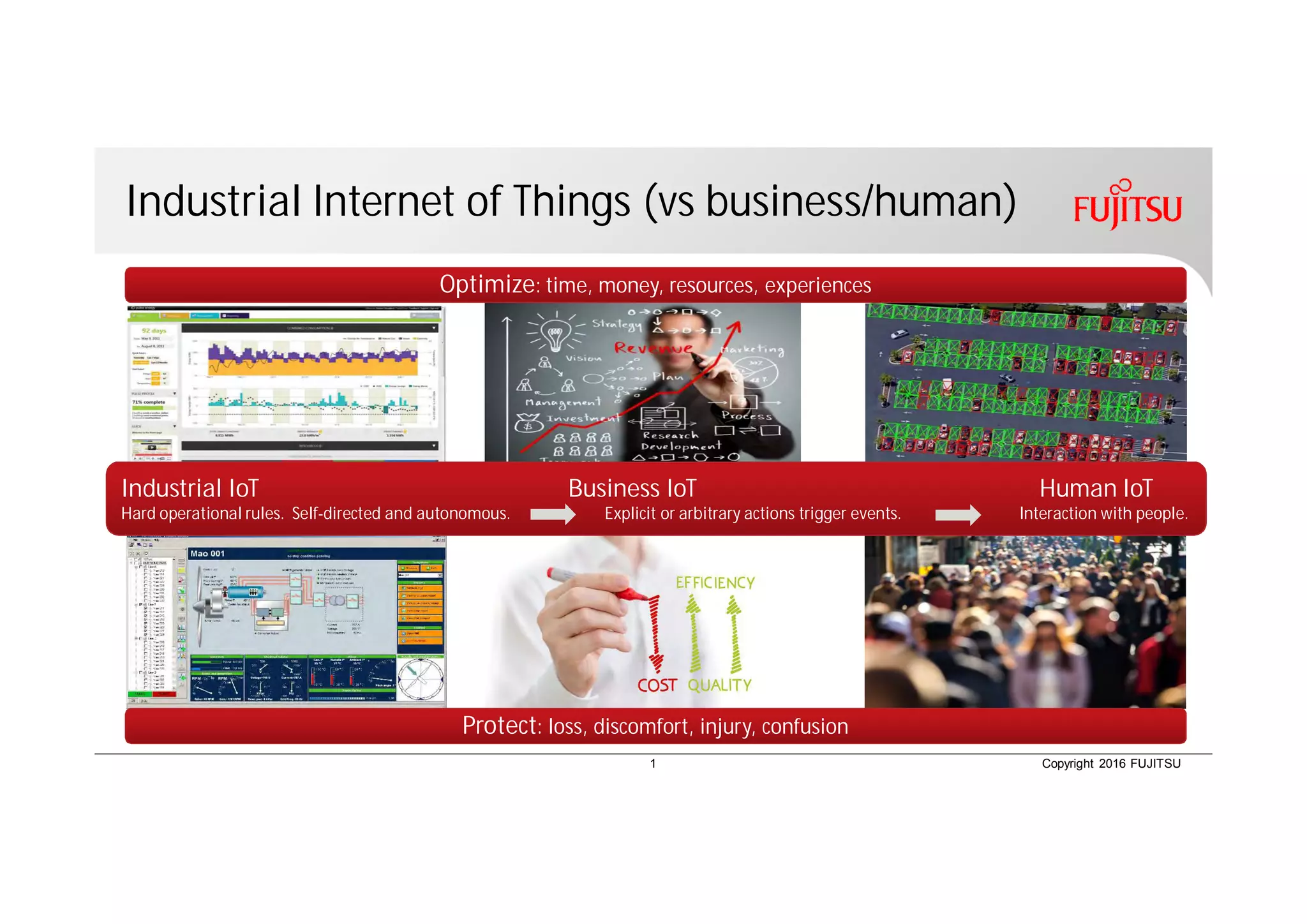

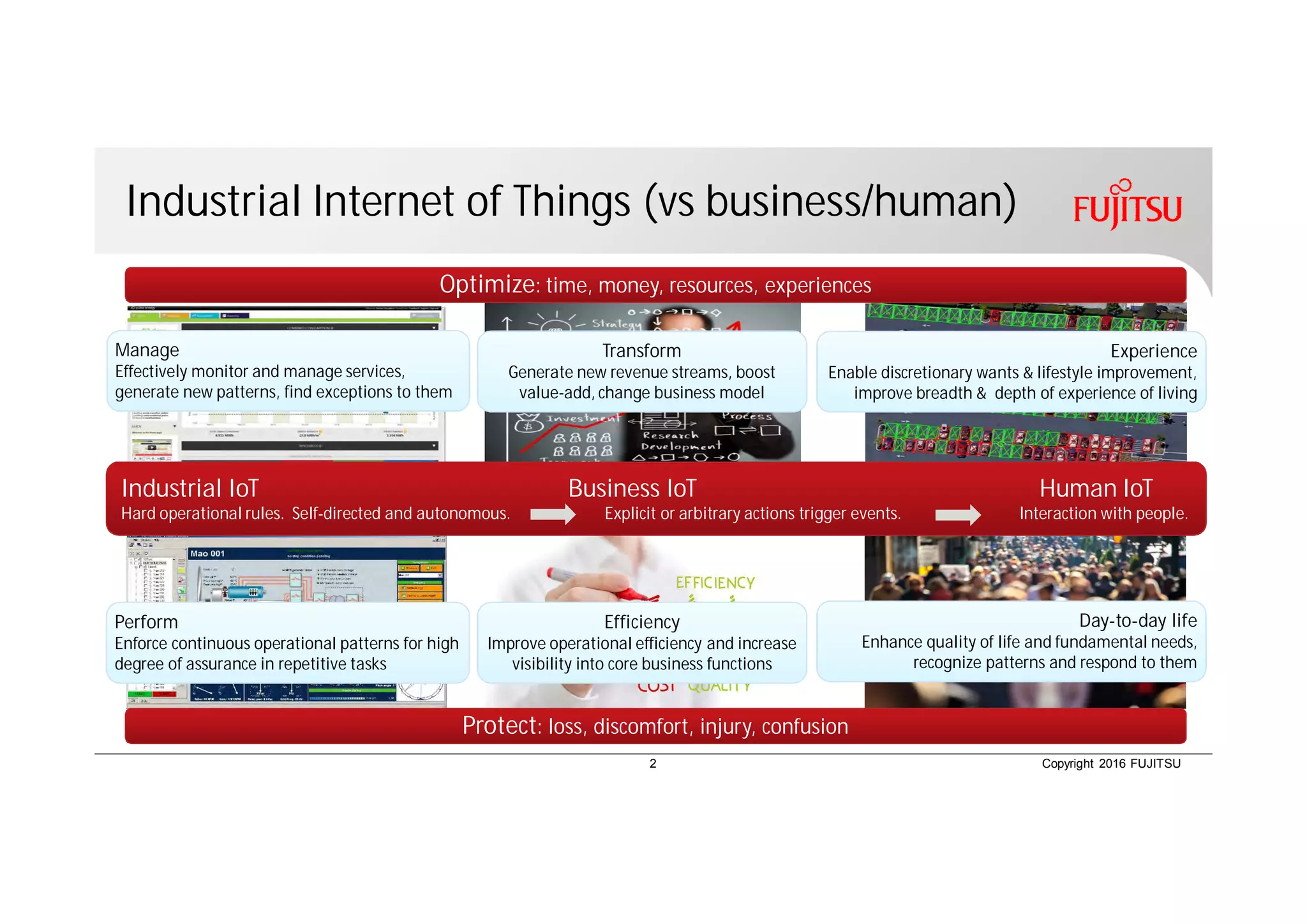

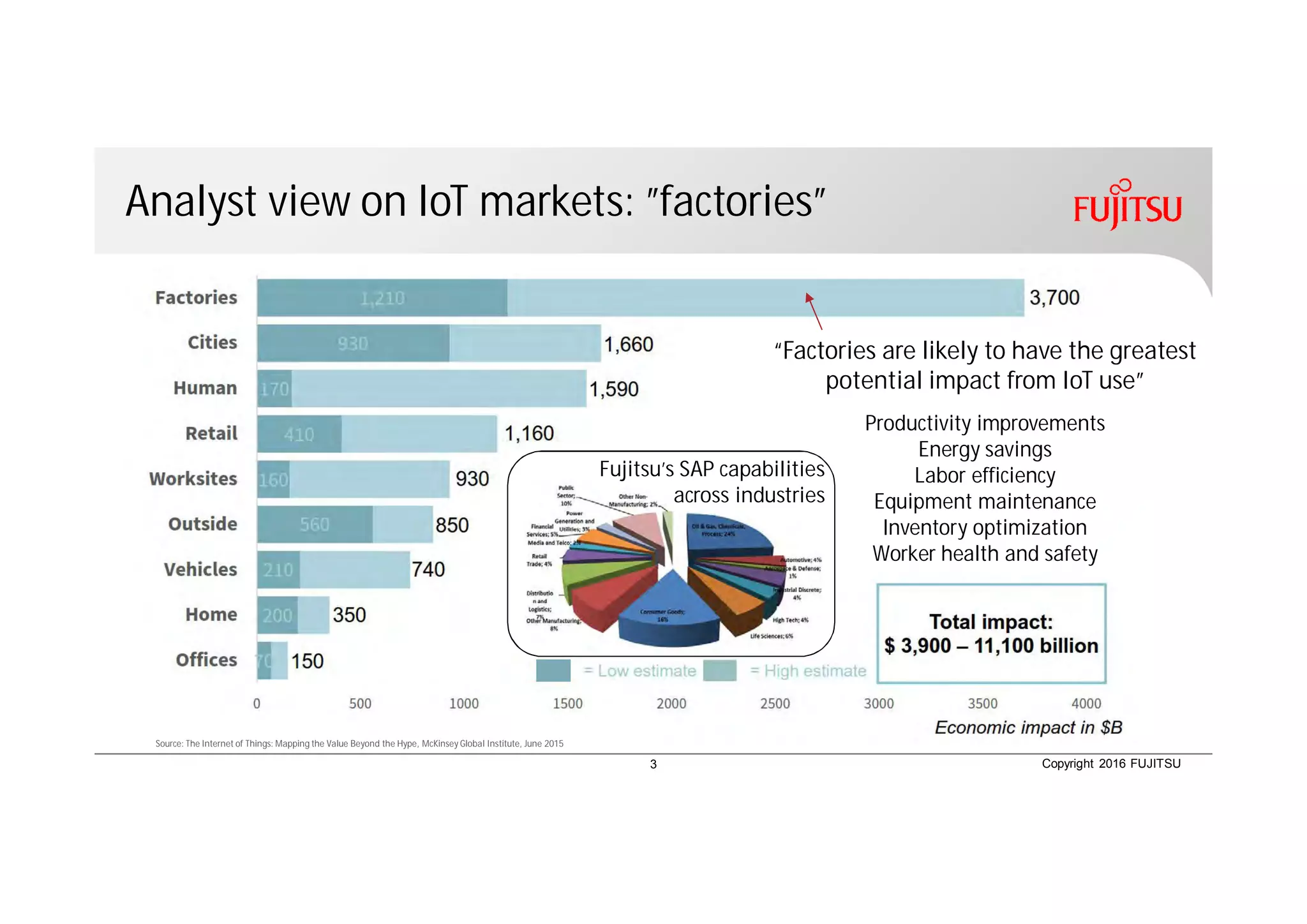

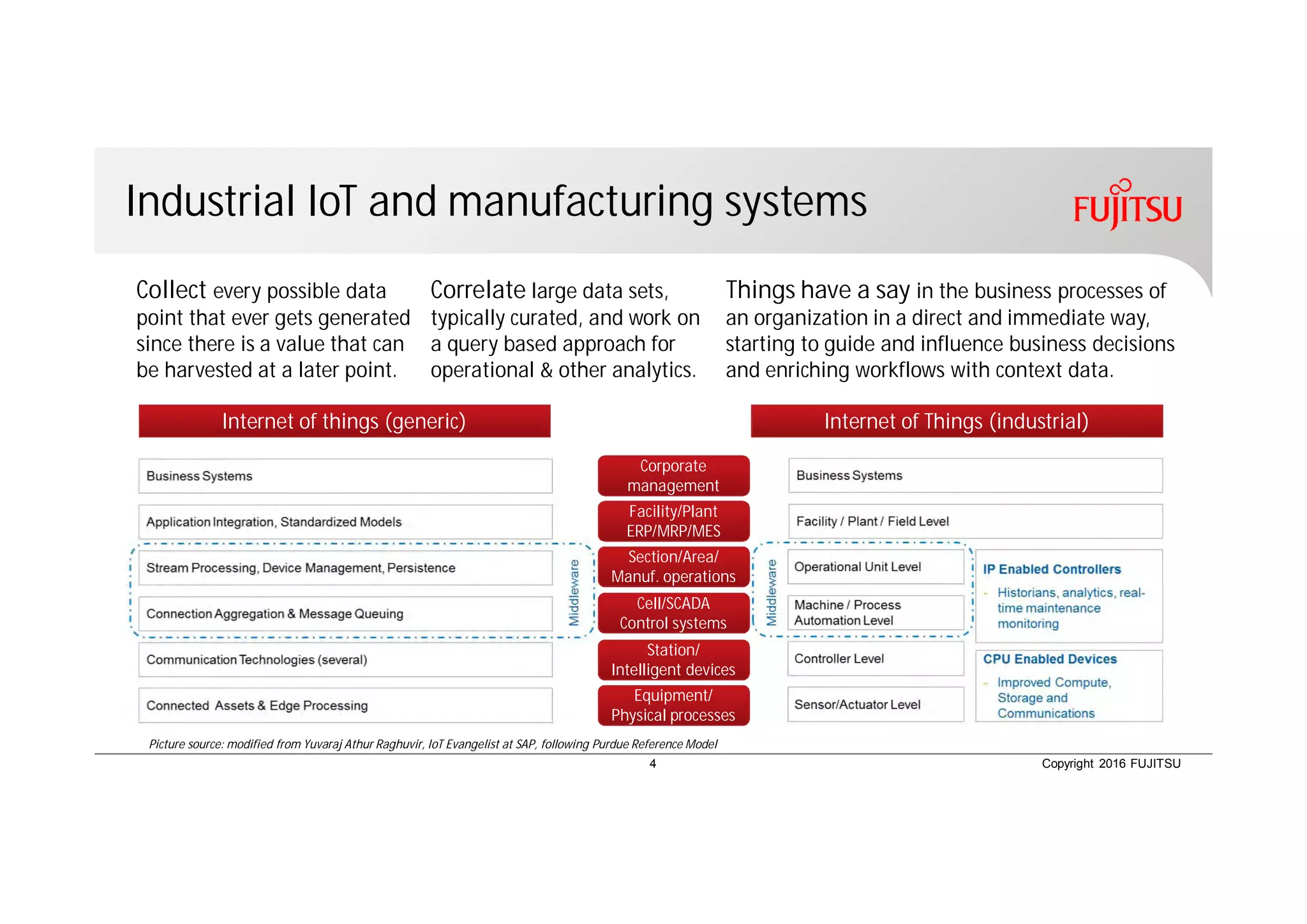

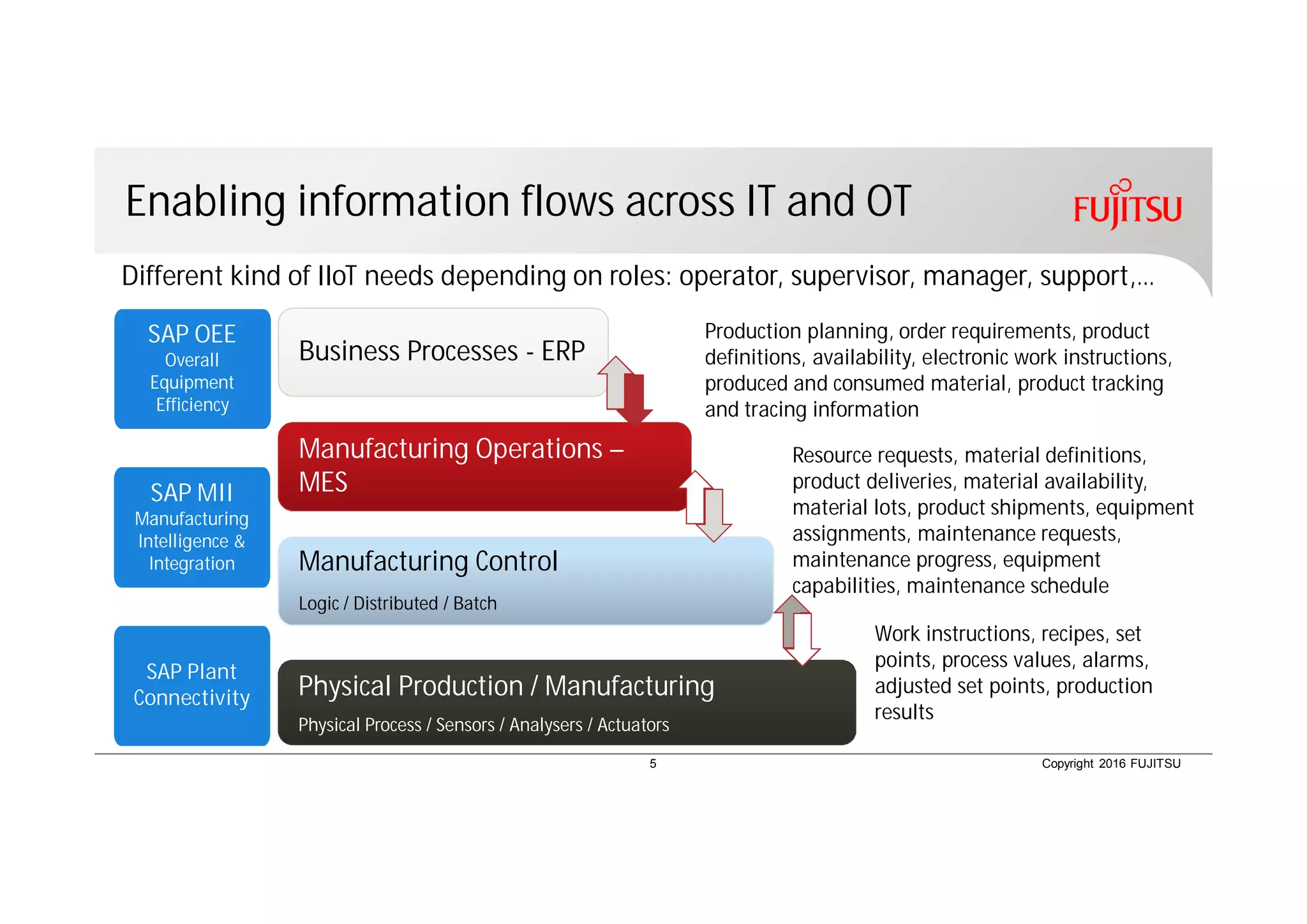

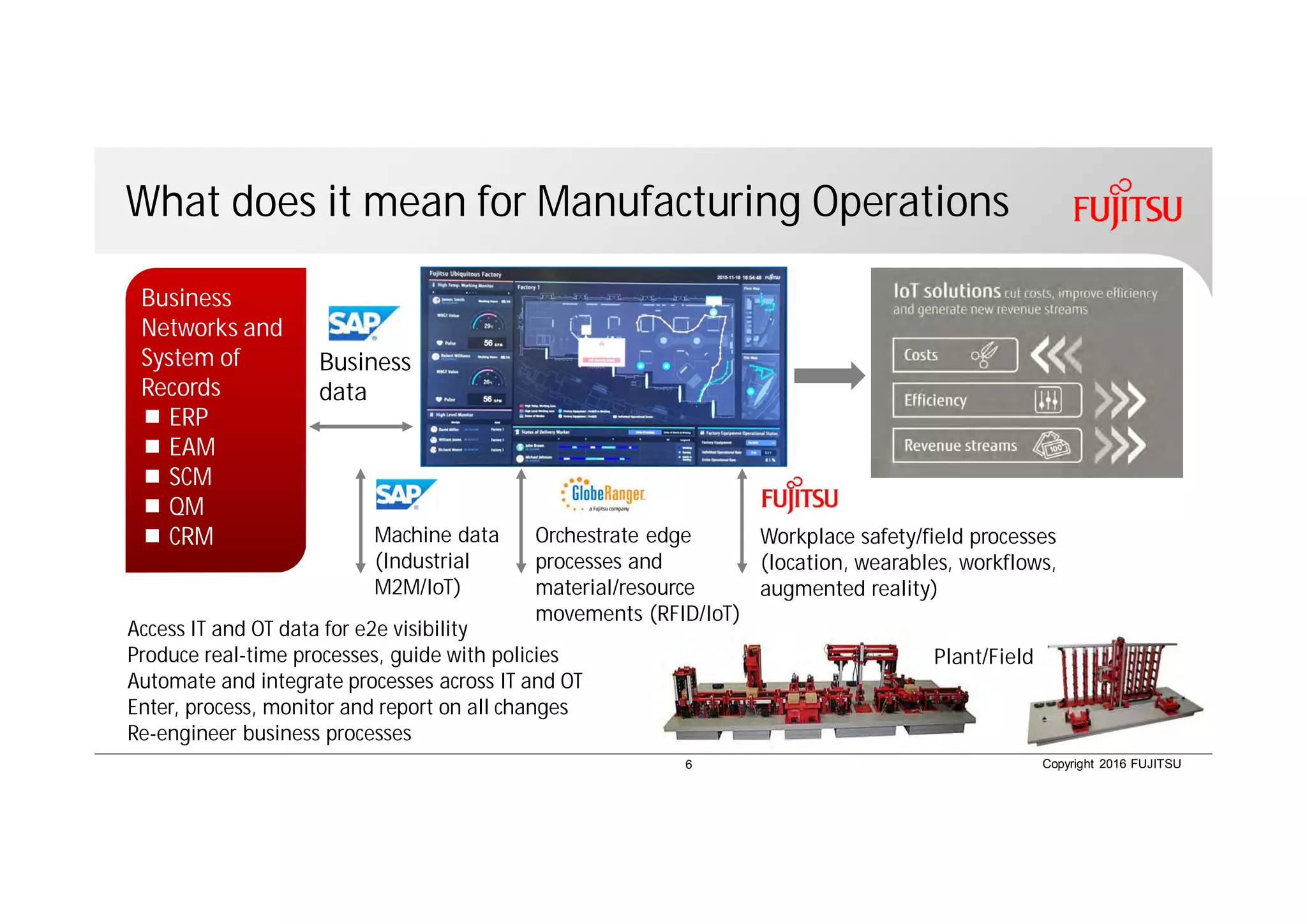

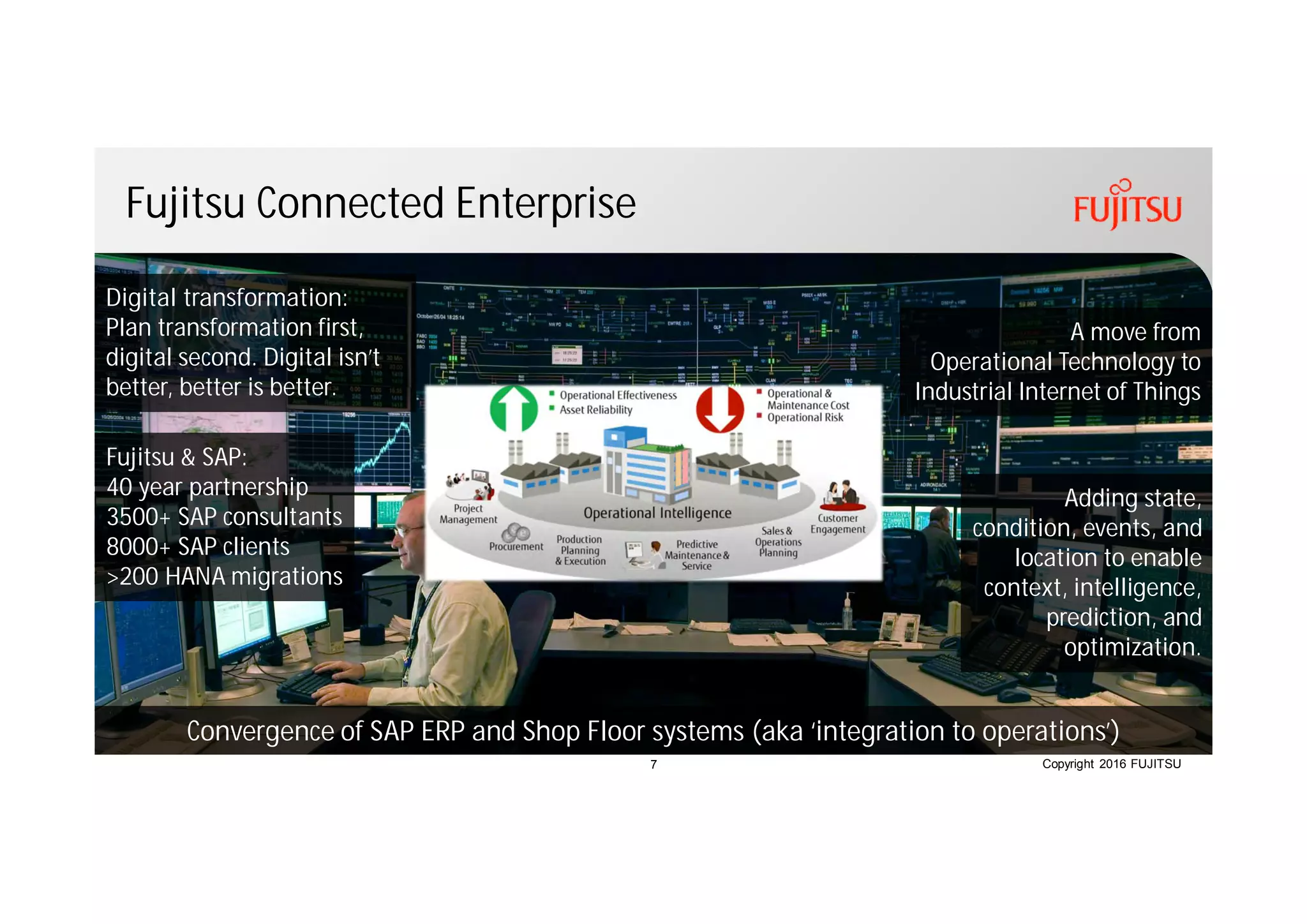

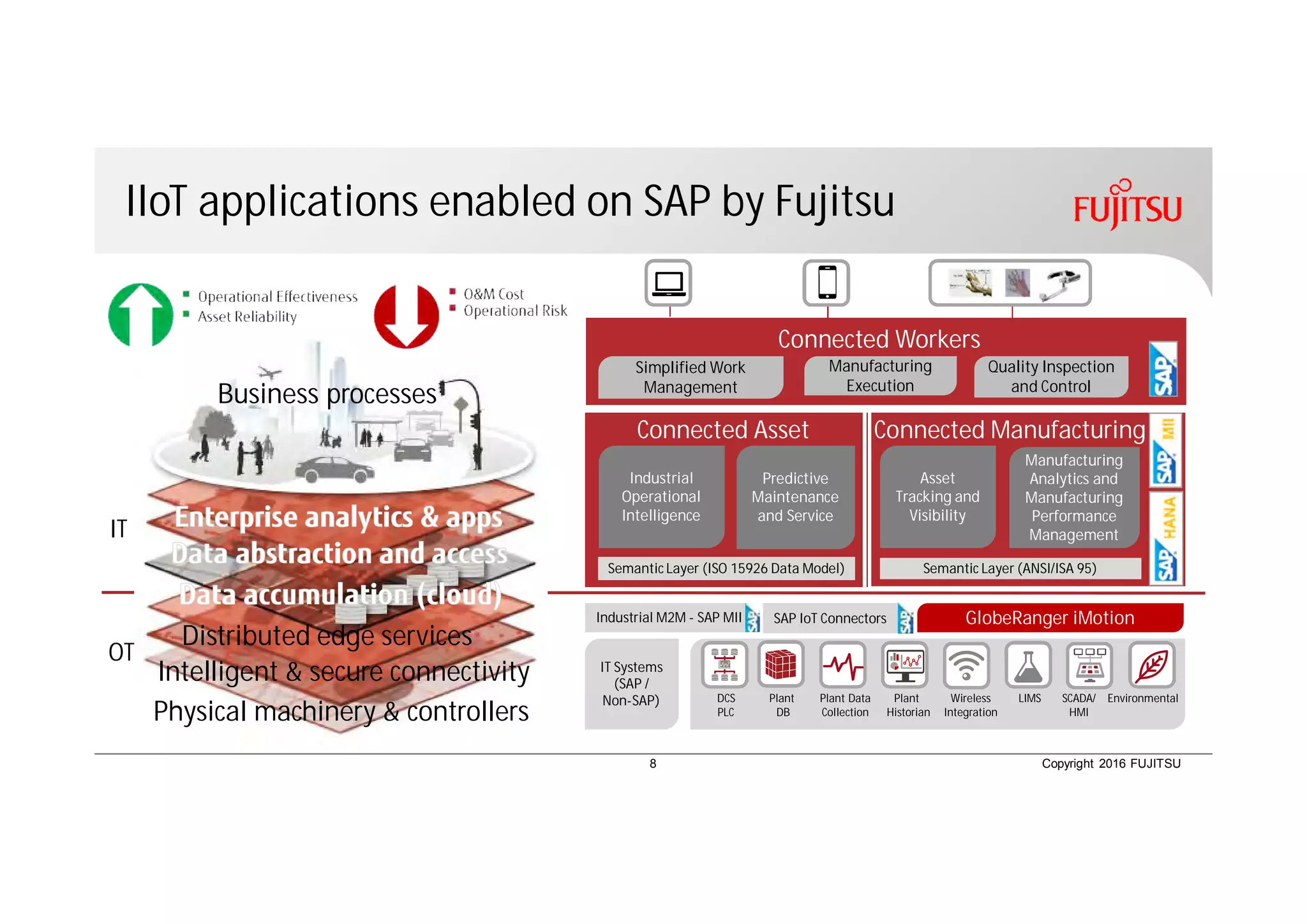

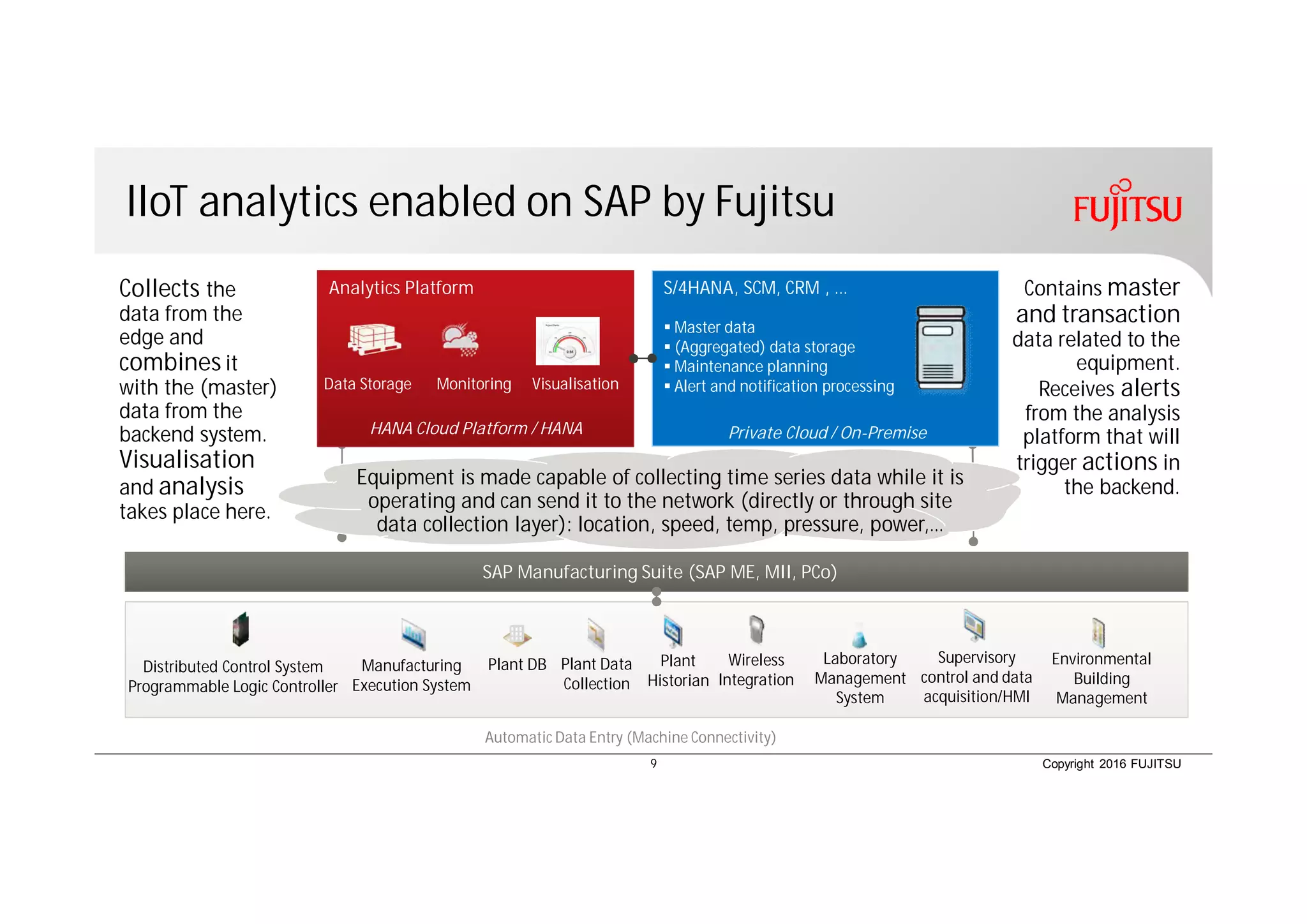

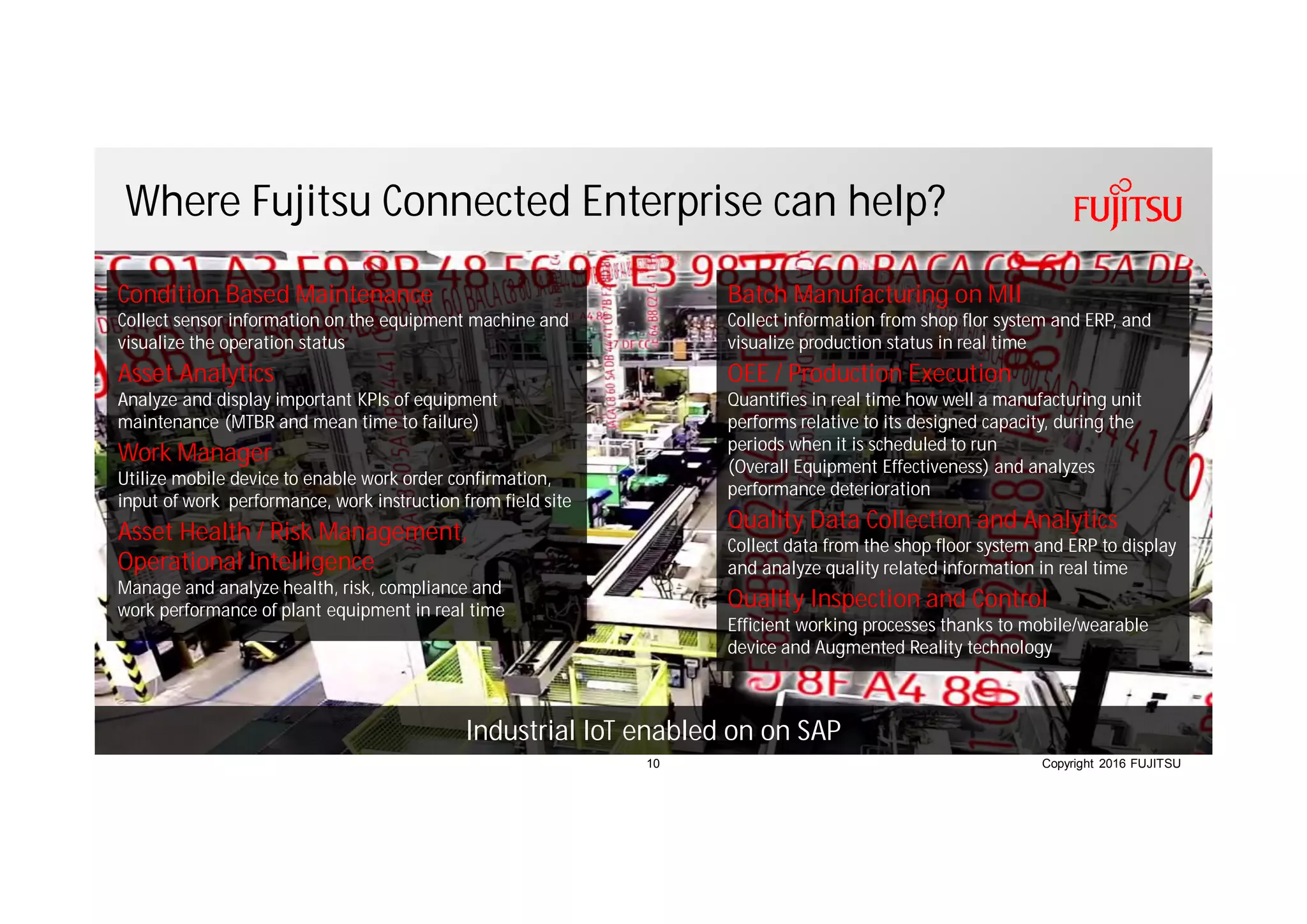

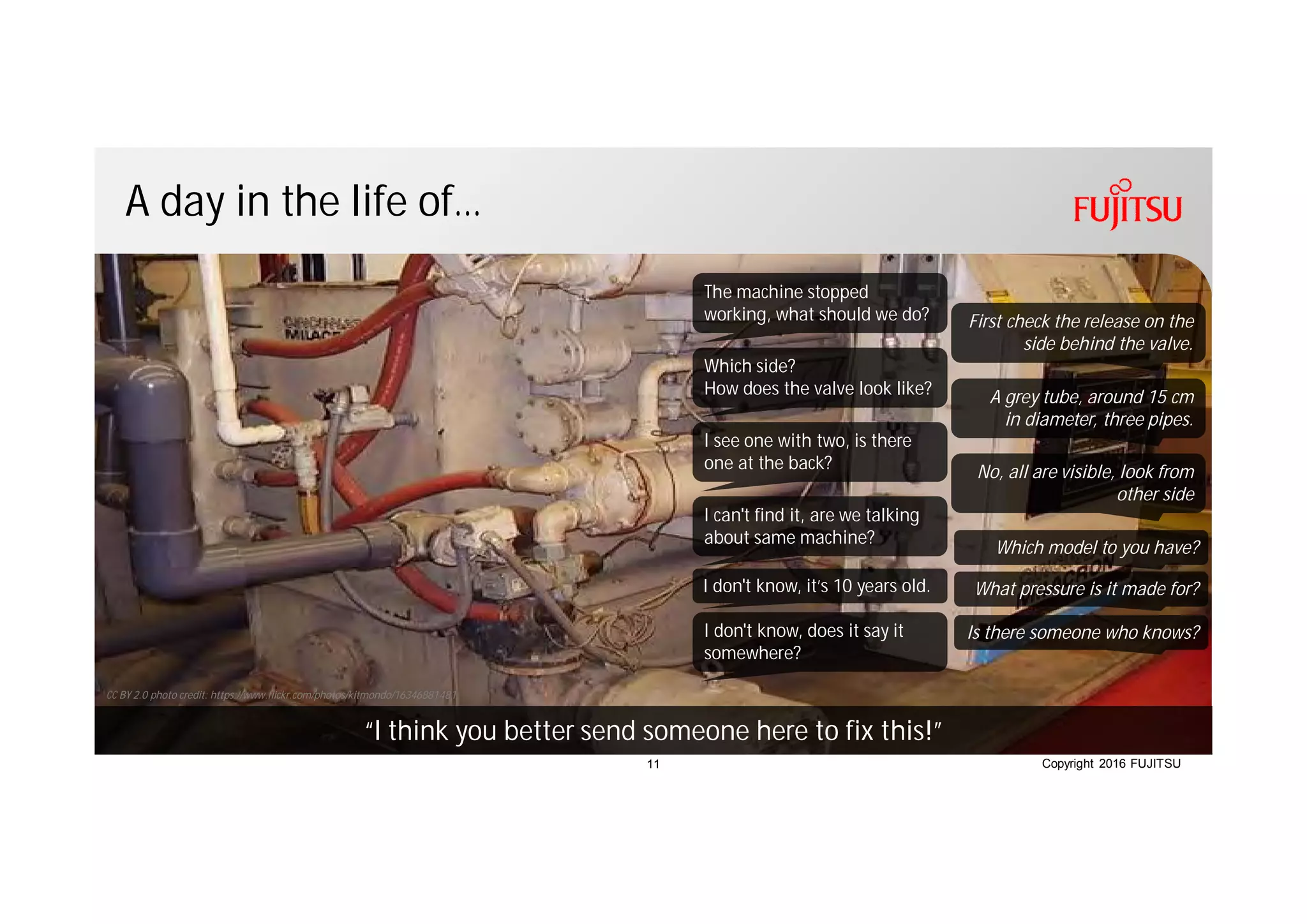

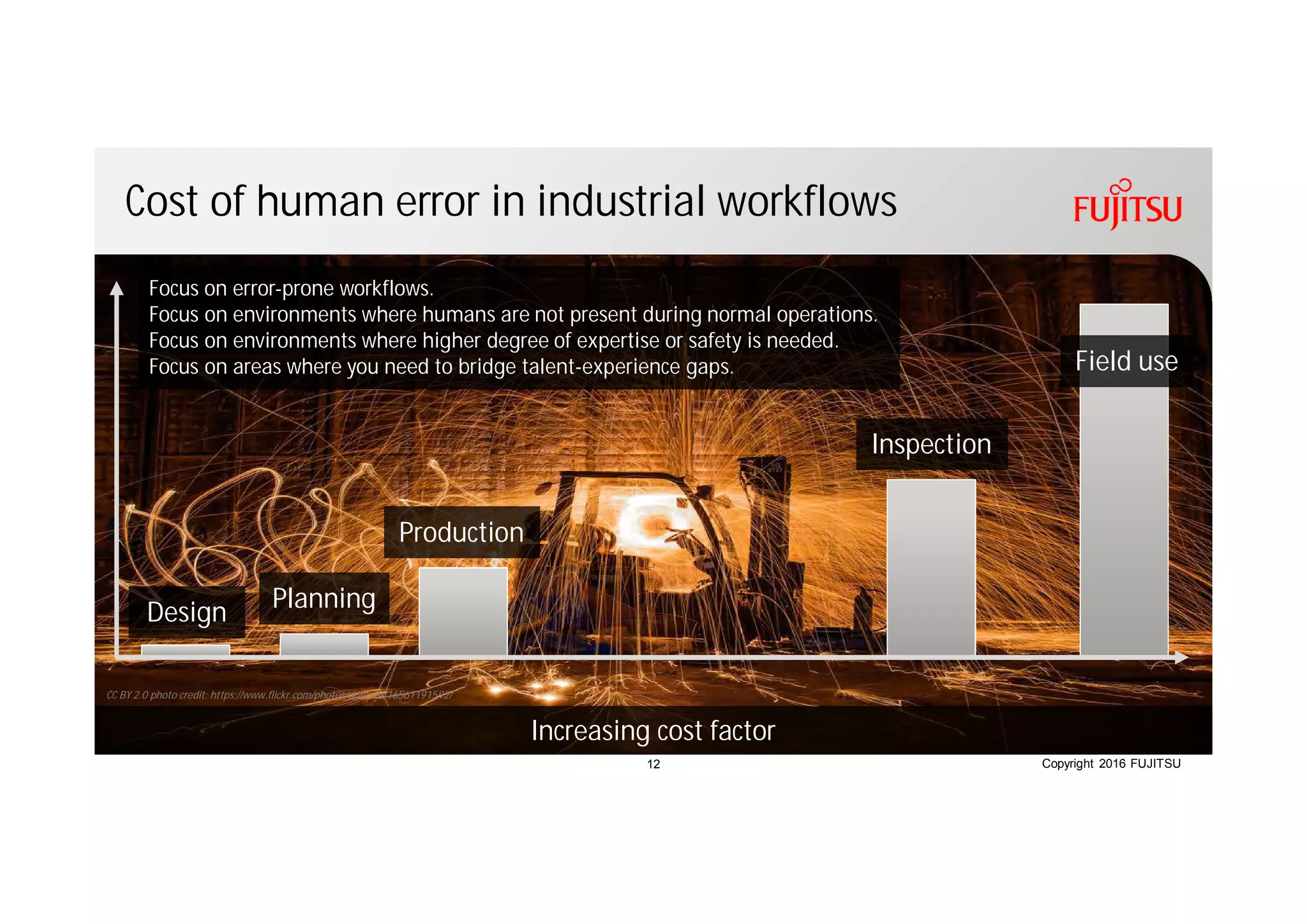

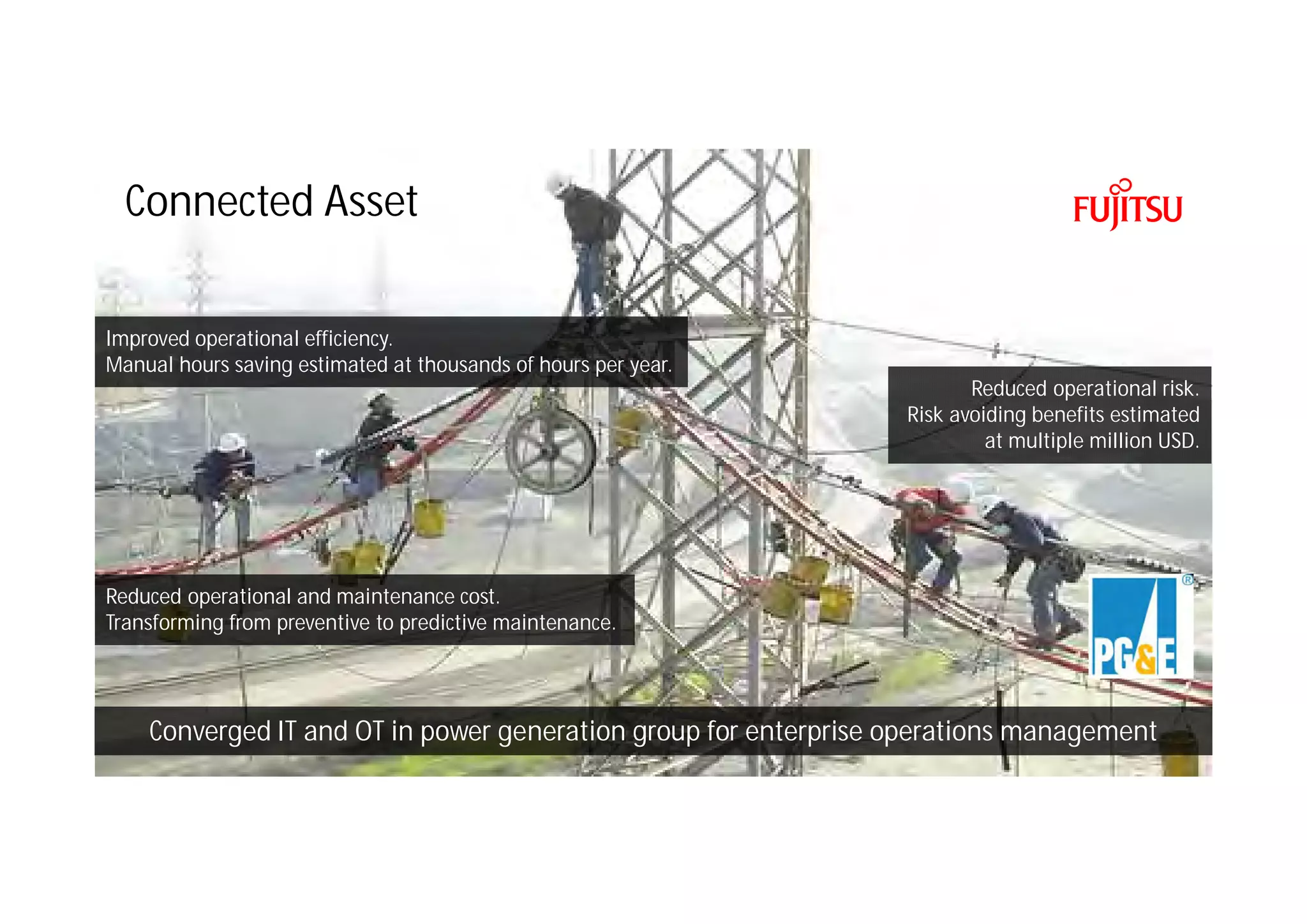

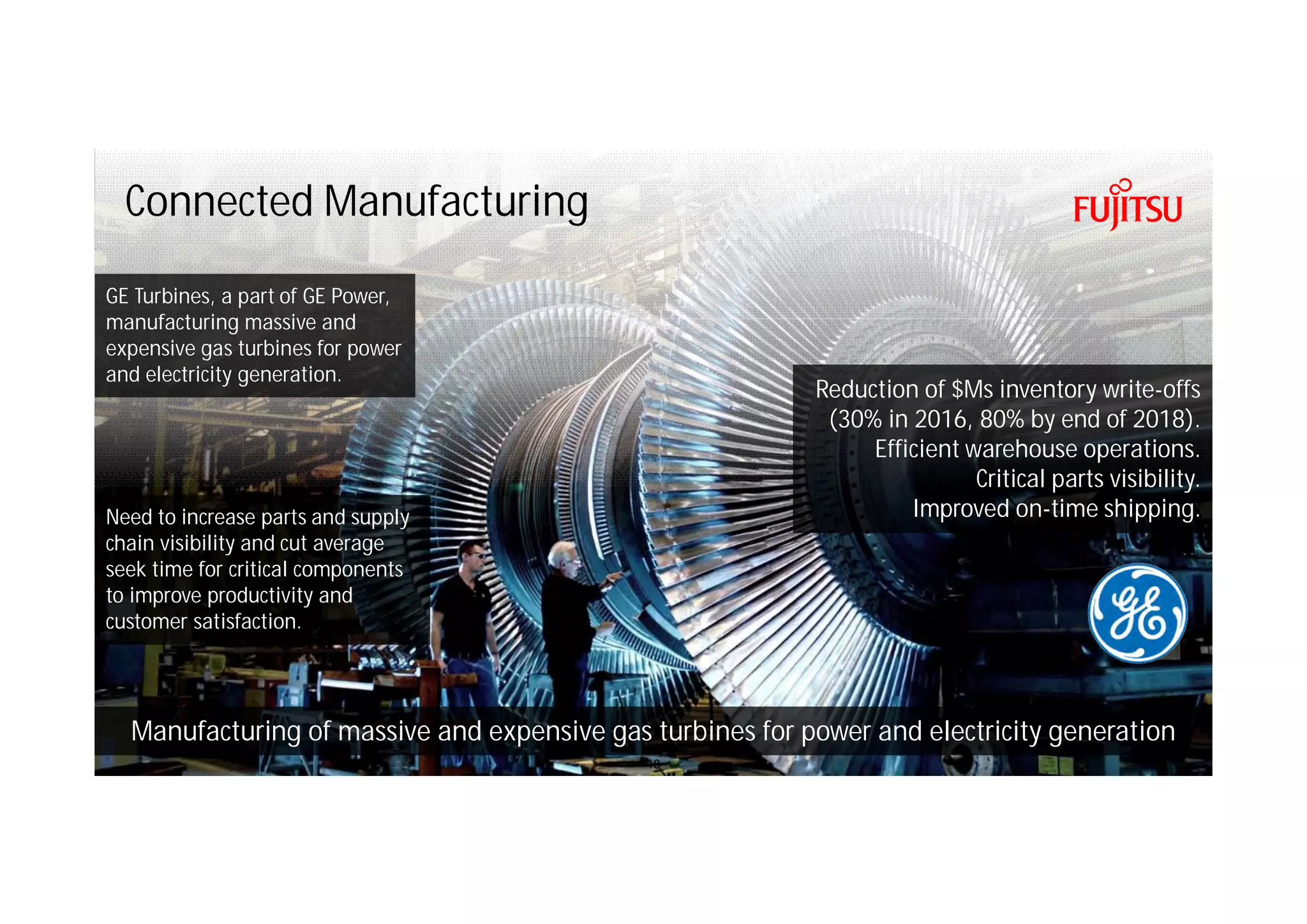

This document discusses industrial IoT and how it can optimize operations through technologies like predictive maintenance, asset tracking, and manufacturing analytics. It provides examples of how Fujitsu uses SAP technologies to enable IIoT applications across industries. These include condition-based maintenance using sensors to monitor equipment health, mobile work management apps for technicians, and remote expert support using augmented reality. The goal is to improve efficiency, reduce costs from errors and downtime, and transform processes by integrating IT and operational systems.