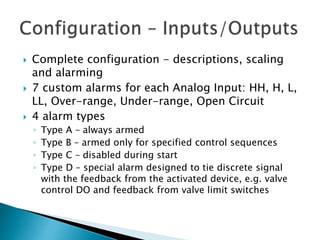

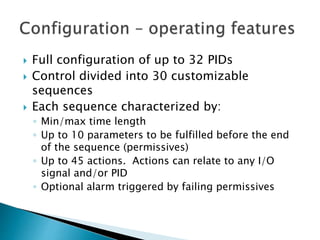

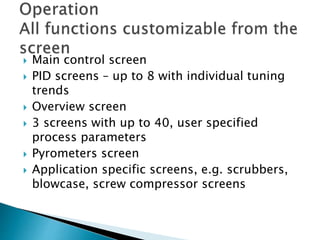

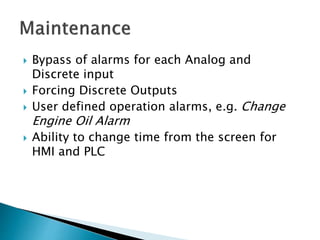

This document describes a compressor control solution that provides configurable control sequences, logging, alarming, reporting and security features. It allows optimization of energy use, increased uptime and performance, and reduction of emissions. The control solution is highly configurable and customizable through its interface to eliminate the need for on-site service visits.