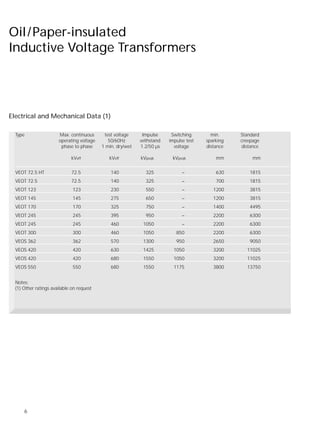

This document provides information on Trench's inductive voltage transformers, models VEOT and VEOS. It summarizes their key features, which include oil/paper insulation for reliability; optimized designs for low weight and stresses; and over 30 years of successful field experience. The VEOT is for voltages up to 300kV, while the VEOS for above 300kV has a mid-point primary winding to reduce stresses. Electrical and mechanical specifications are provided for standard models.