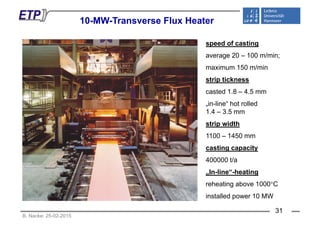

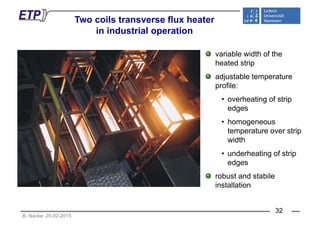

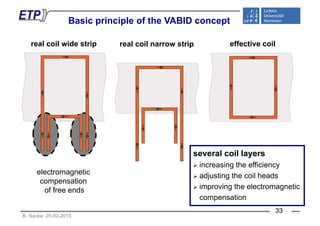

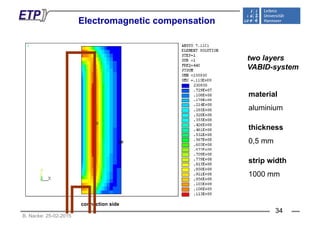

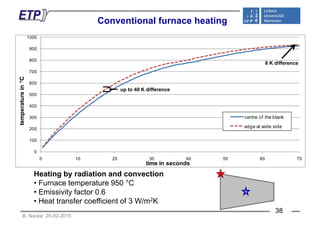

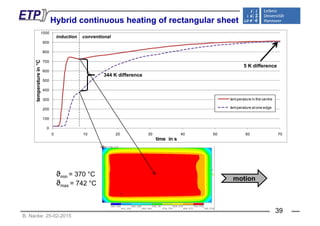

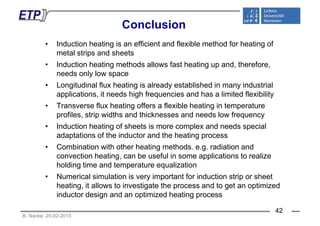

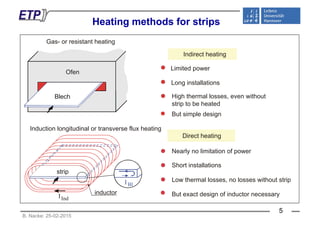

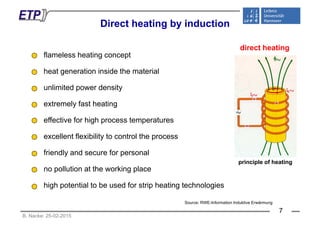

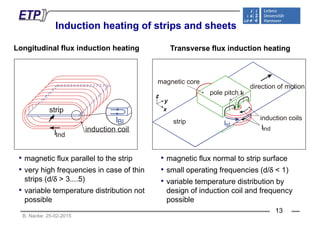

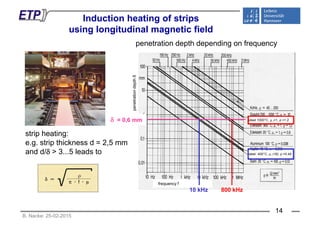

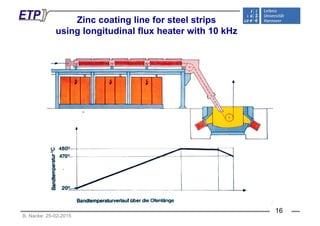

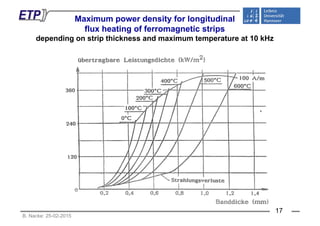

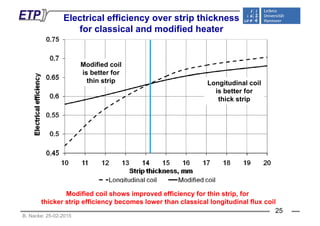

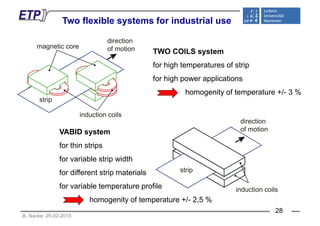

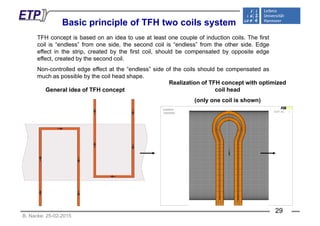

The document presents a comprehensive overview of induction heating methods for strips and sheets, detailing various heating techniques, applications, and requirements for efficient heating systems. It emphasizes the advantages of direct induction heating over traditional methods, highlighting its flexibility, speed, and energy efficiency while discussing limitations and complexities involved in heating sheets. The conclusion suggests that while longitudinal flux heating is widely used, transverse flux heating offers greater flexibility, and numerical simulations are vital for optimizing heating processes.

![Integrated Joule heat of TFH two coilsg

concept with optimized coil shape

1.4E+06

1.2E+06

1.0E+06

m]

6 0E+05

8.0E+05

cificpower[W/m

4.0E+05

6.0E+05

Spec

2.0E+05

0.0E+00

-700 -600 -500 -400 -300 -200 -100 0 100 200 300 400 500 600 700

Strip width [mm]

B. Nacke: 25-02-2015

JH1 JH2 JHsum

30](https://image.slidesharecdn.com/nacke-epm-webinar-190618164505/85/Induction-heating-of-strips-and-sheets-30-320.jpg)