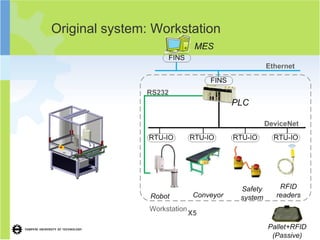

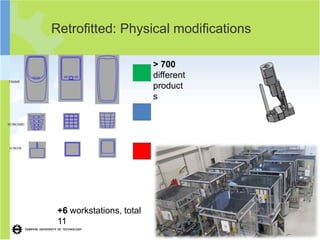

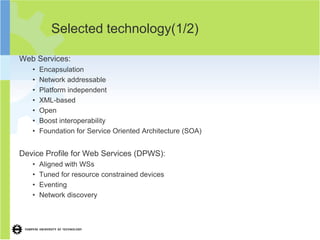

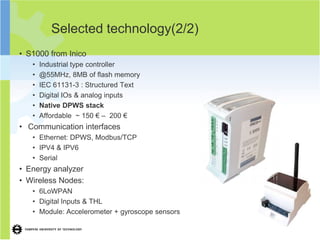

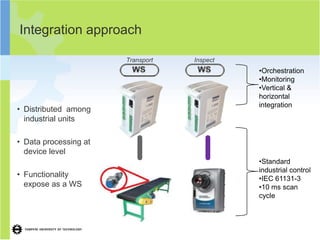

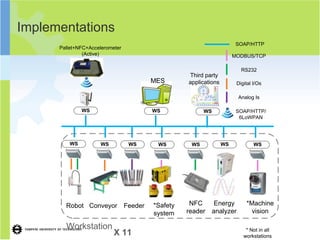

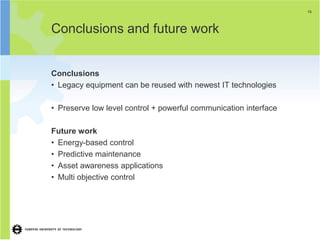

The document discusses a paper presented at the IEEE conference about retrofitting factory automation systems to meet market and societal demands, focusing on enhancing flexibility, reconfigurability, and interoperability using modern IT technologies. Key achievements include the creation of a flexible and reconfigurable automation system that integrates various industrial units and replaces legacy equipment while ensuring improved efficiency. The authors propose future work on energy-based control, predictive maintenance, and multi-objective control applications.