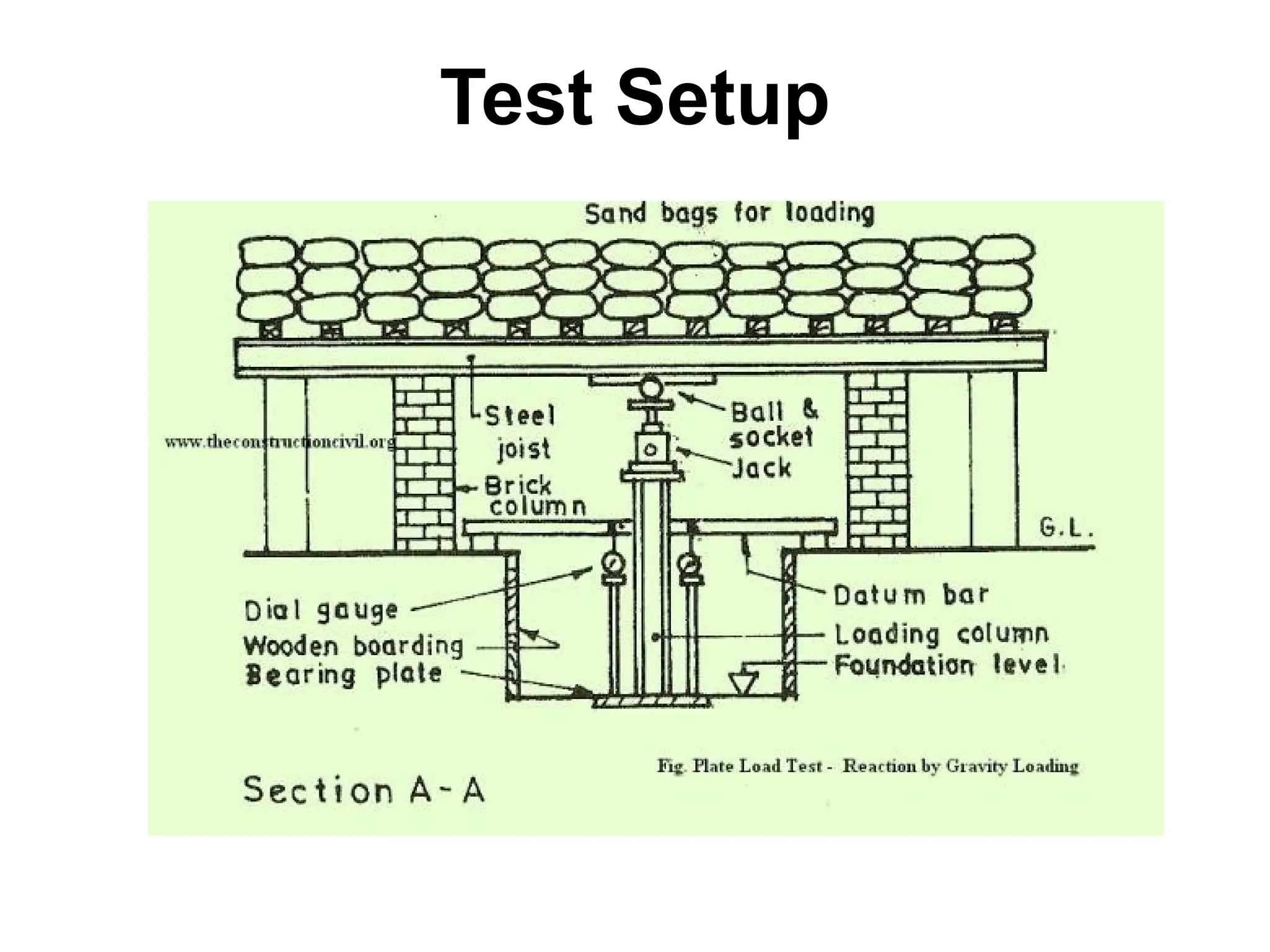

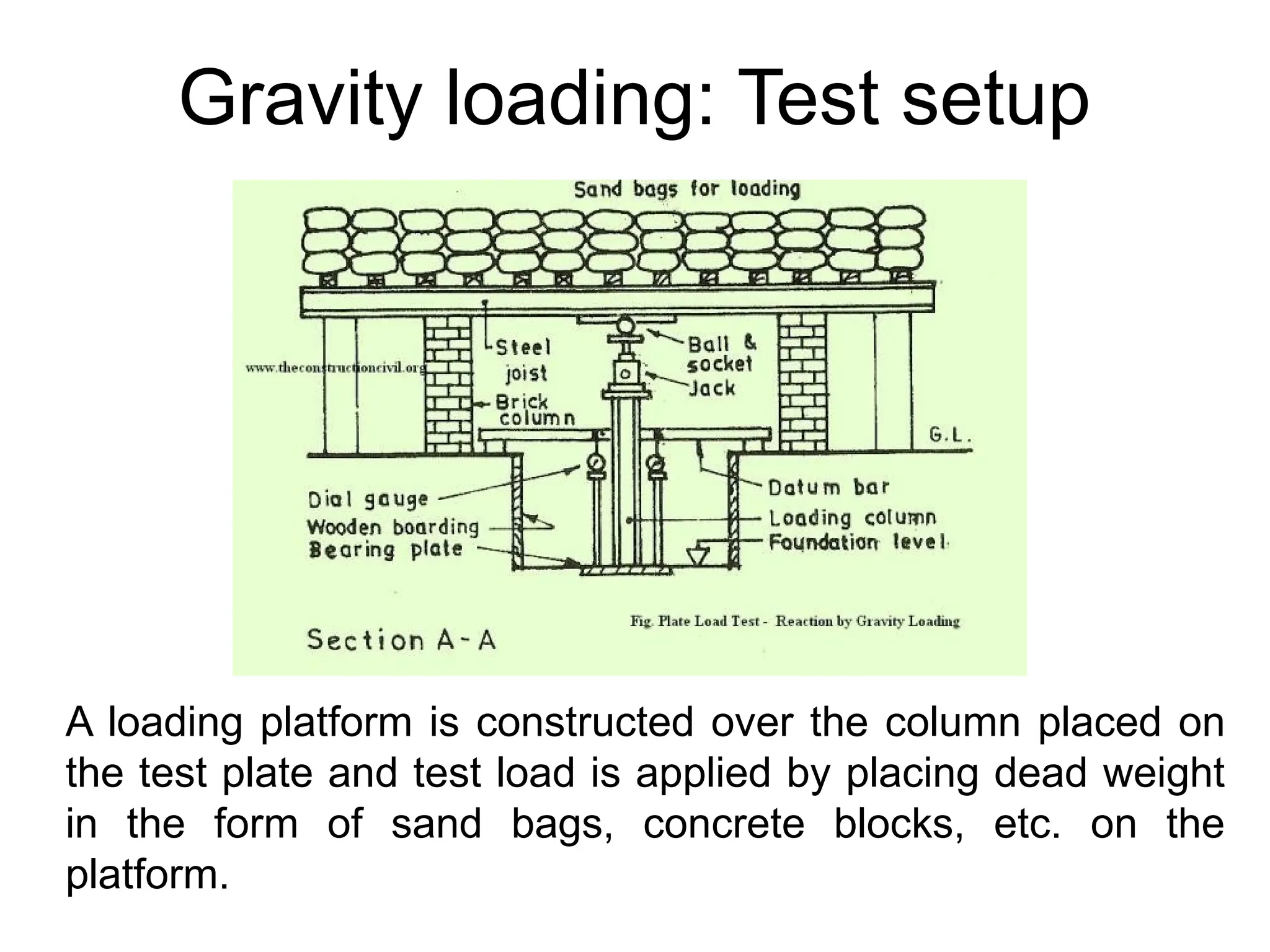

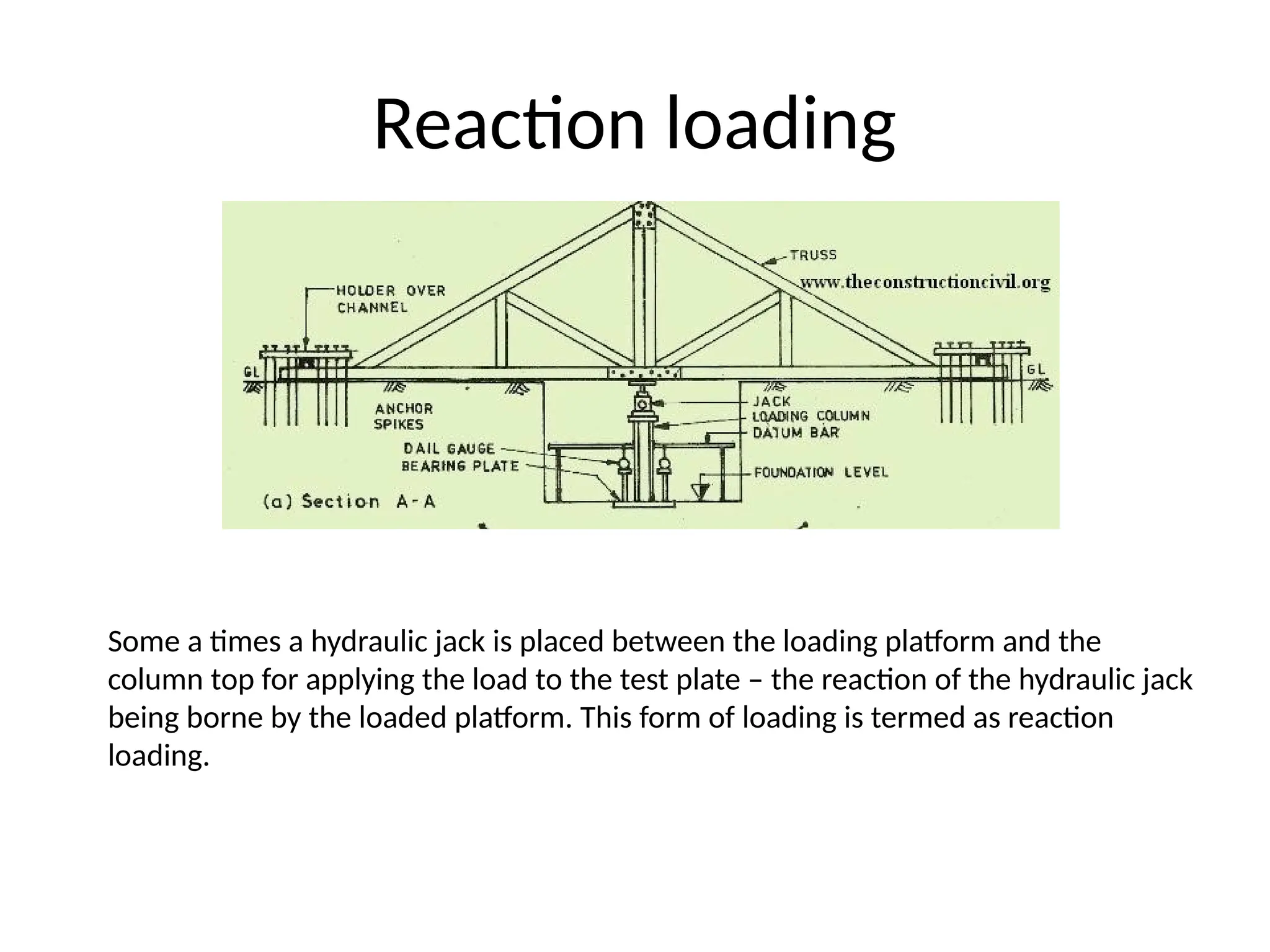

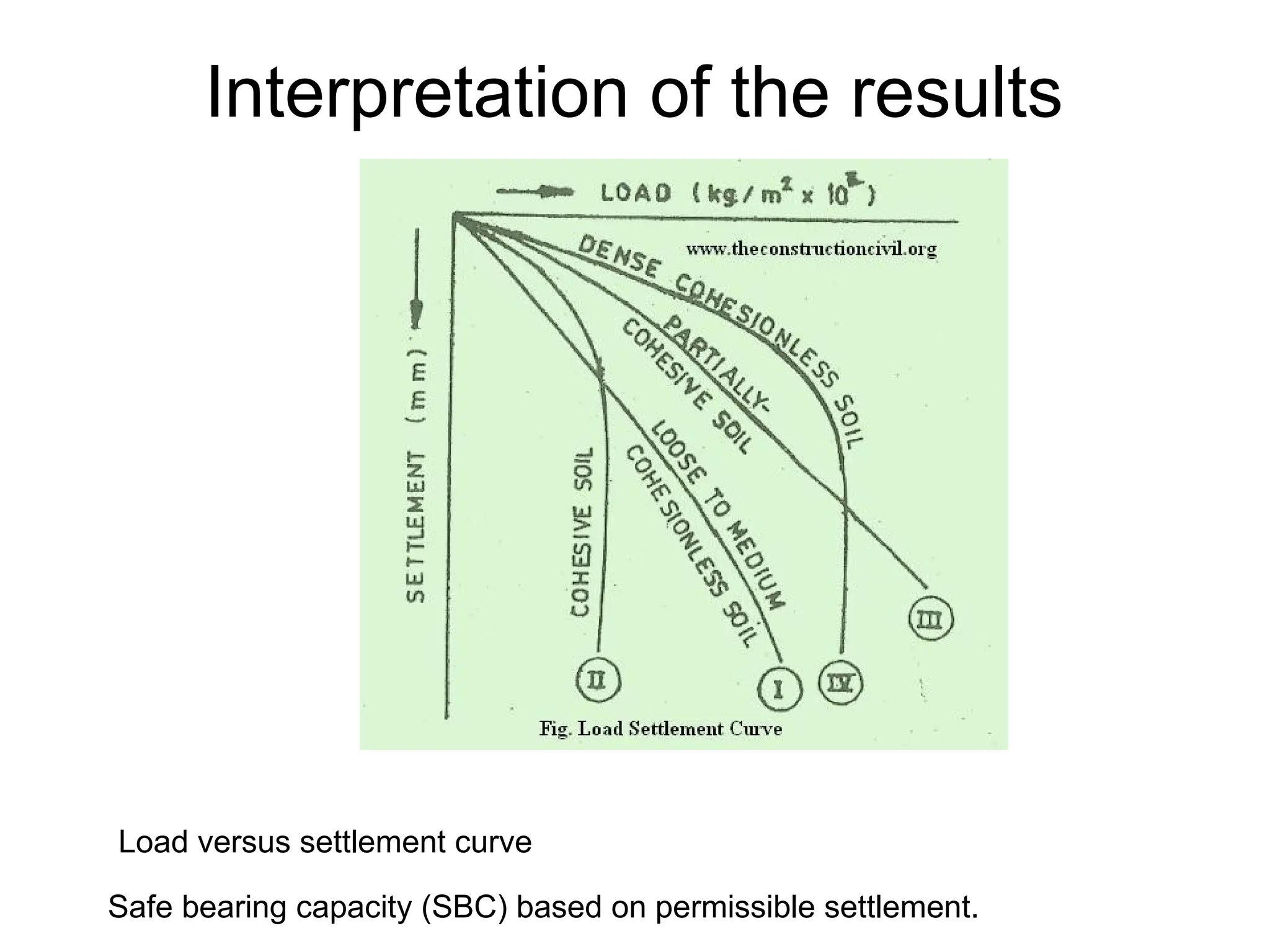

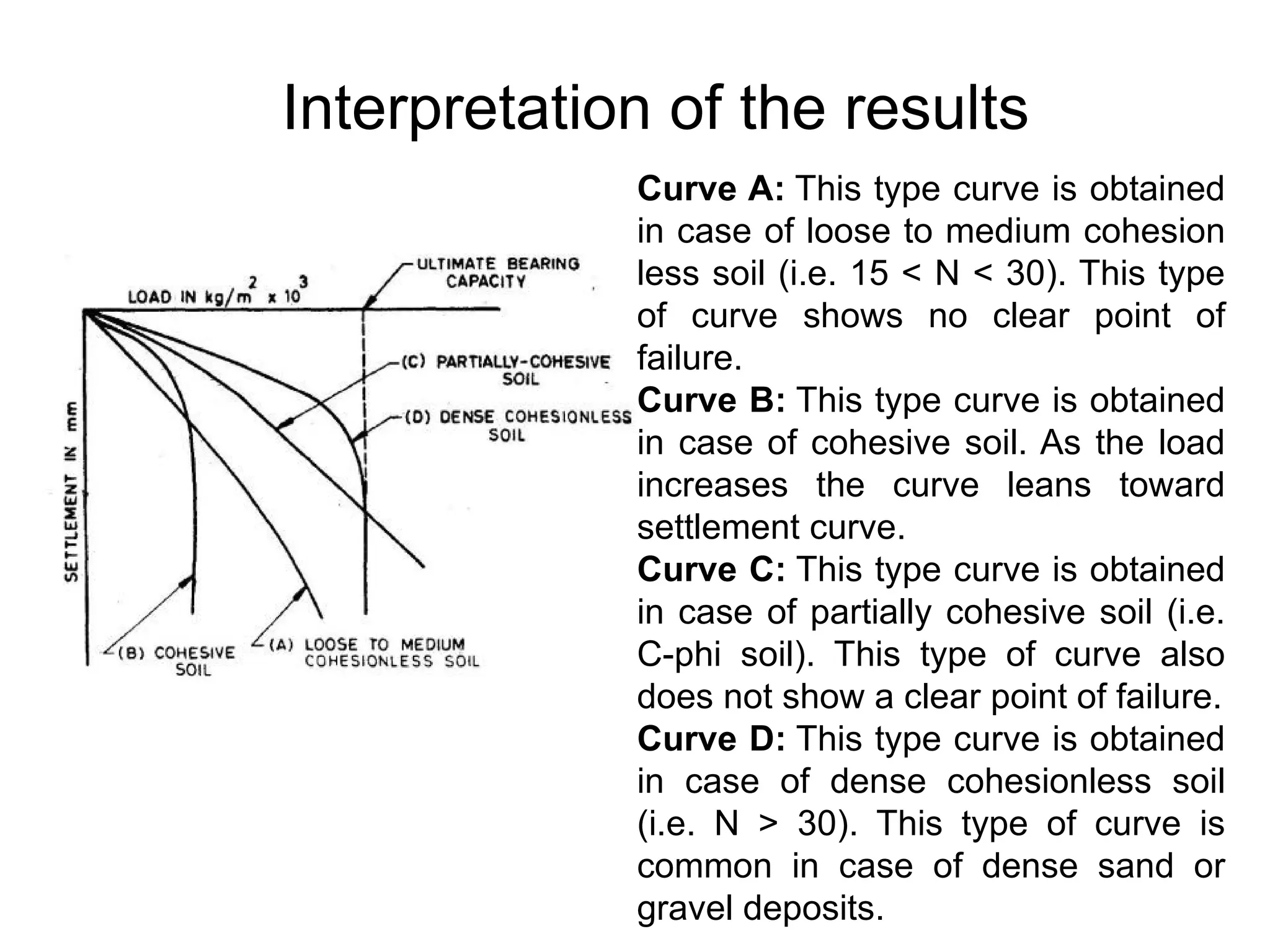

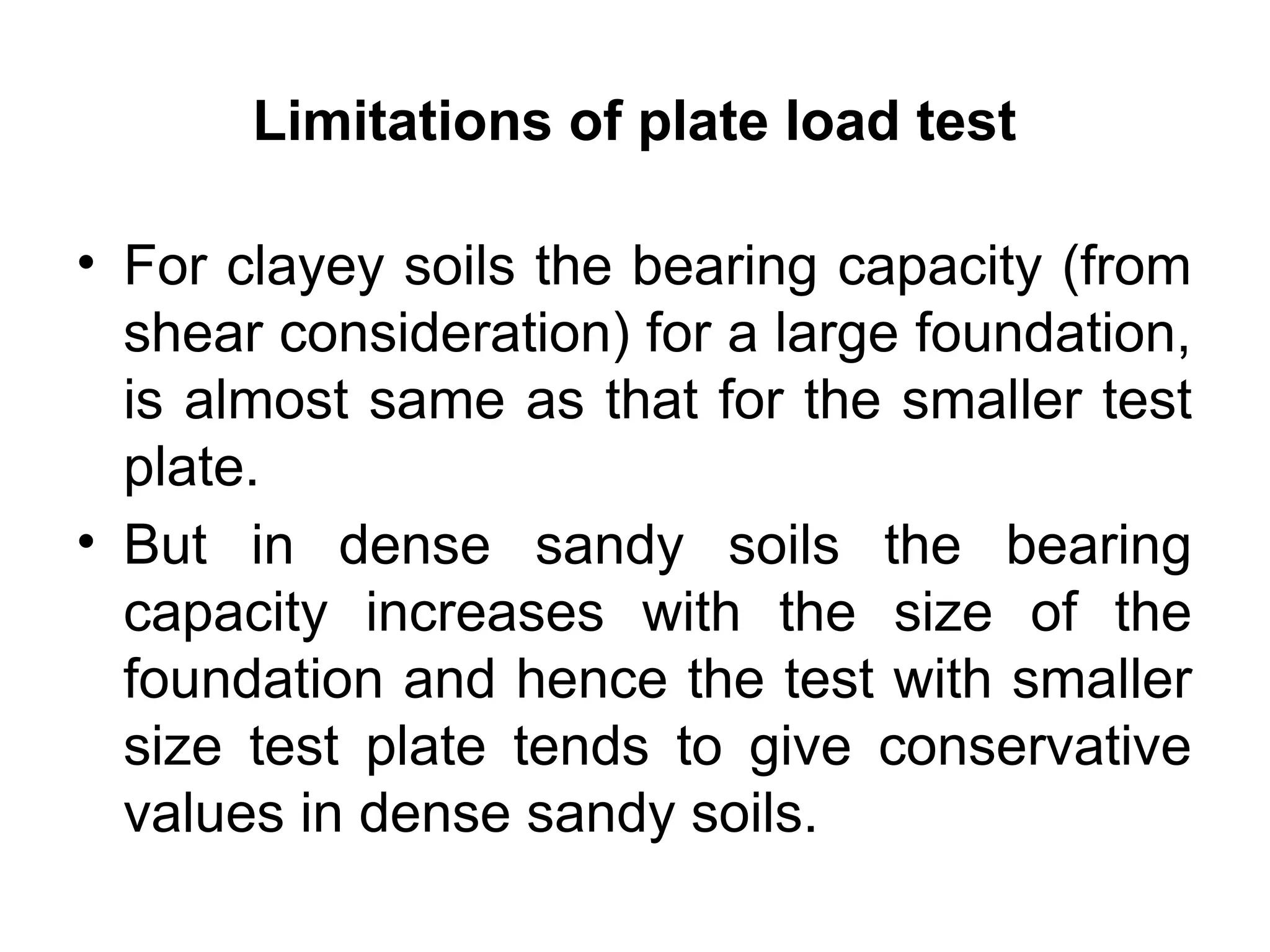

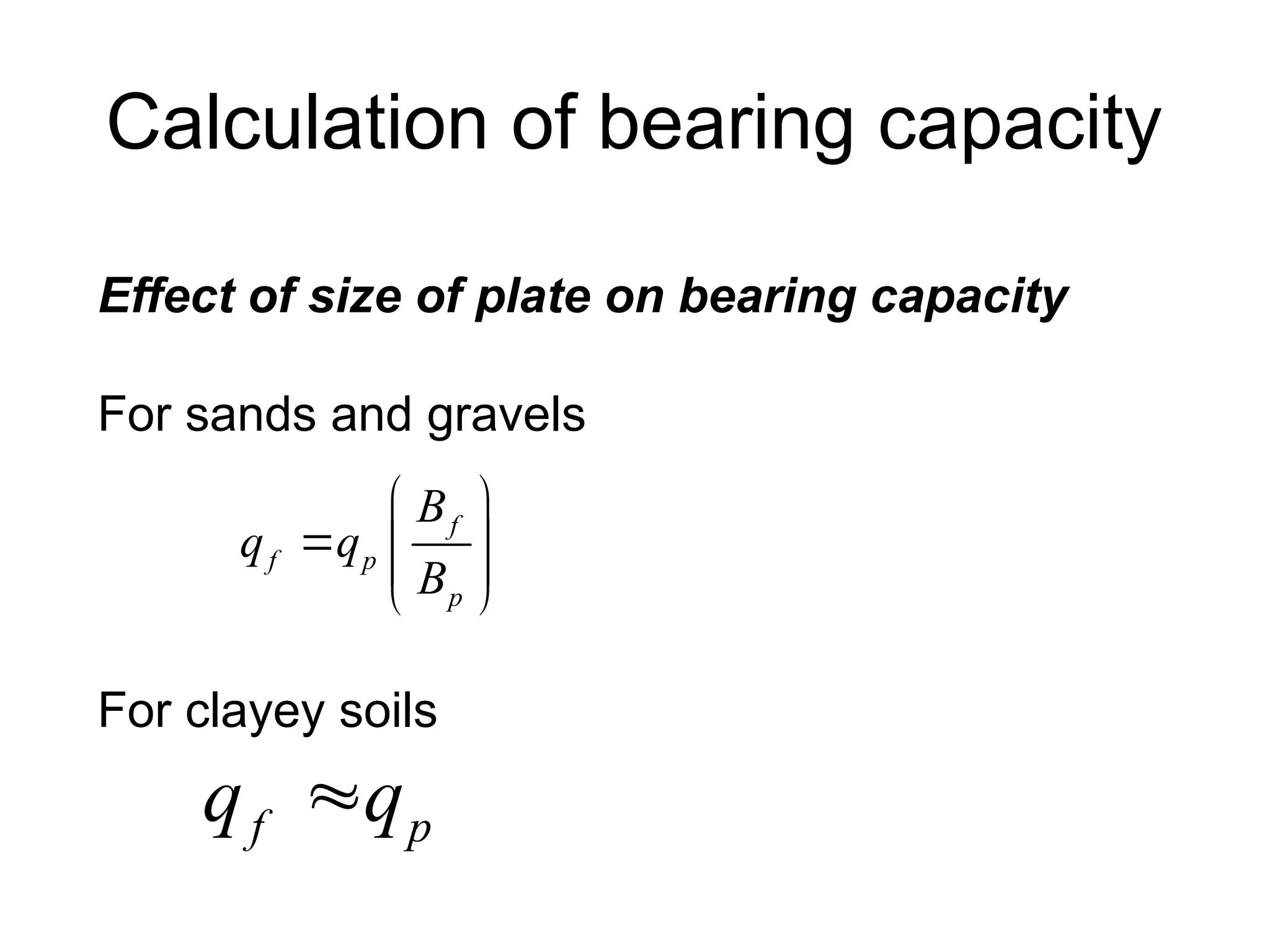

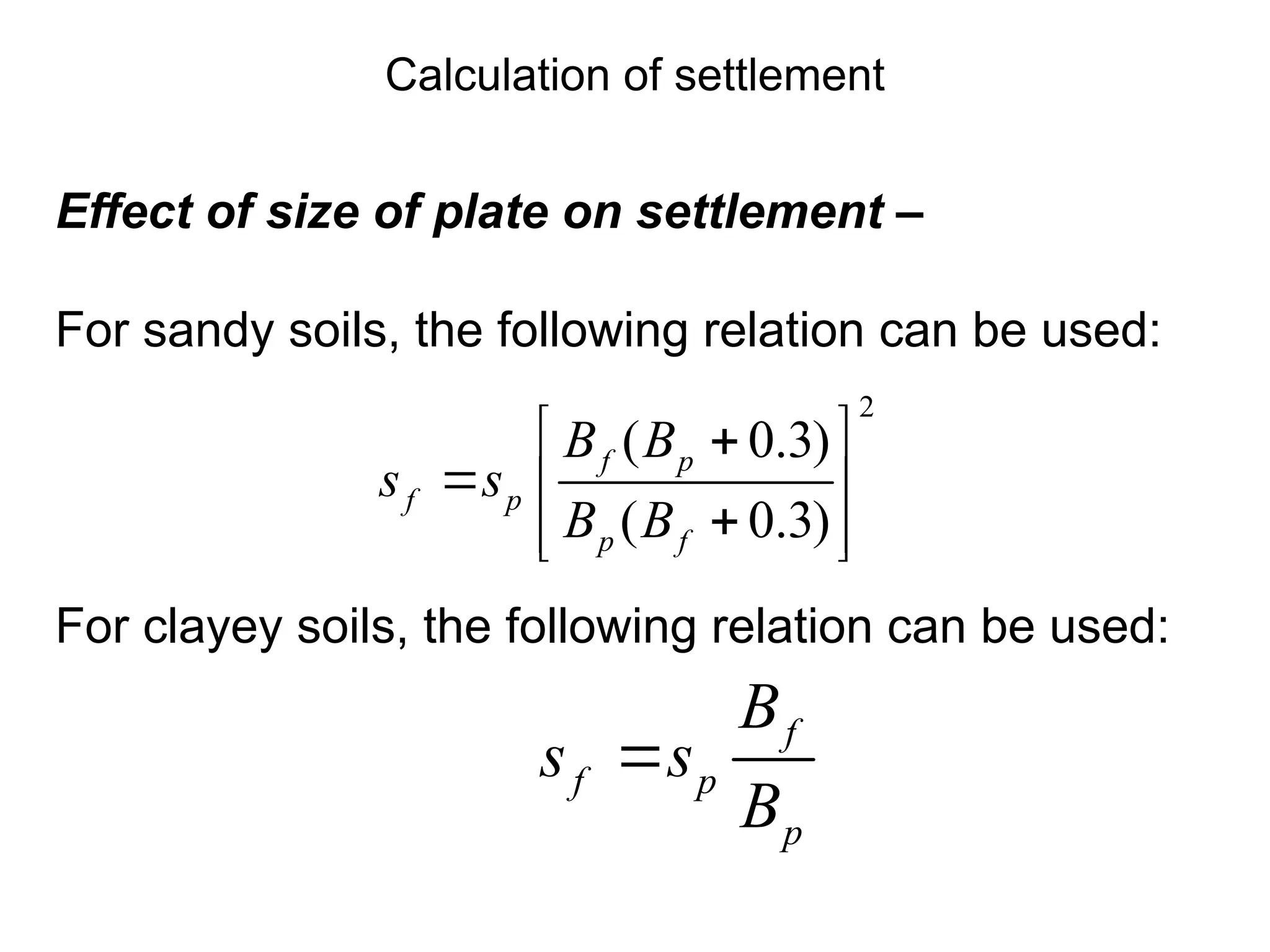

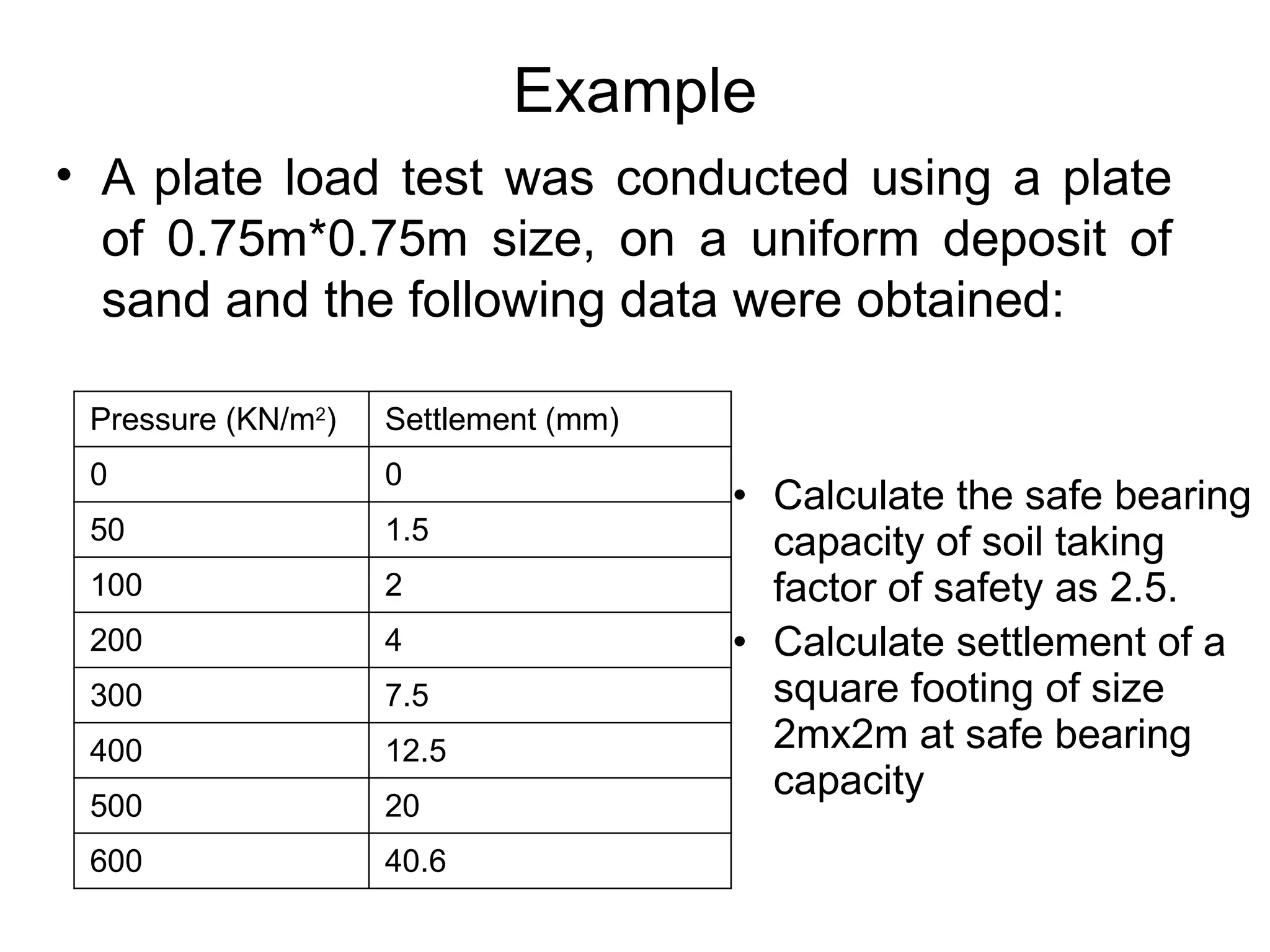

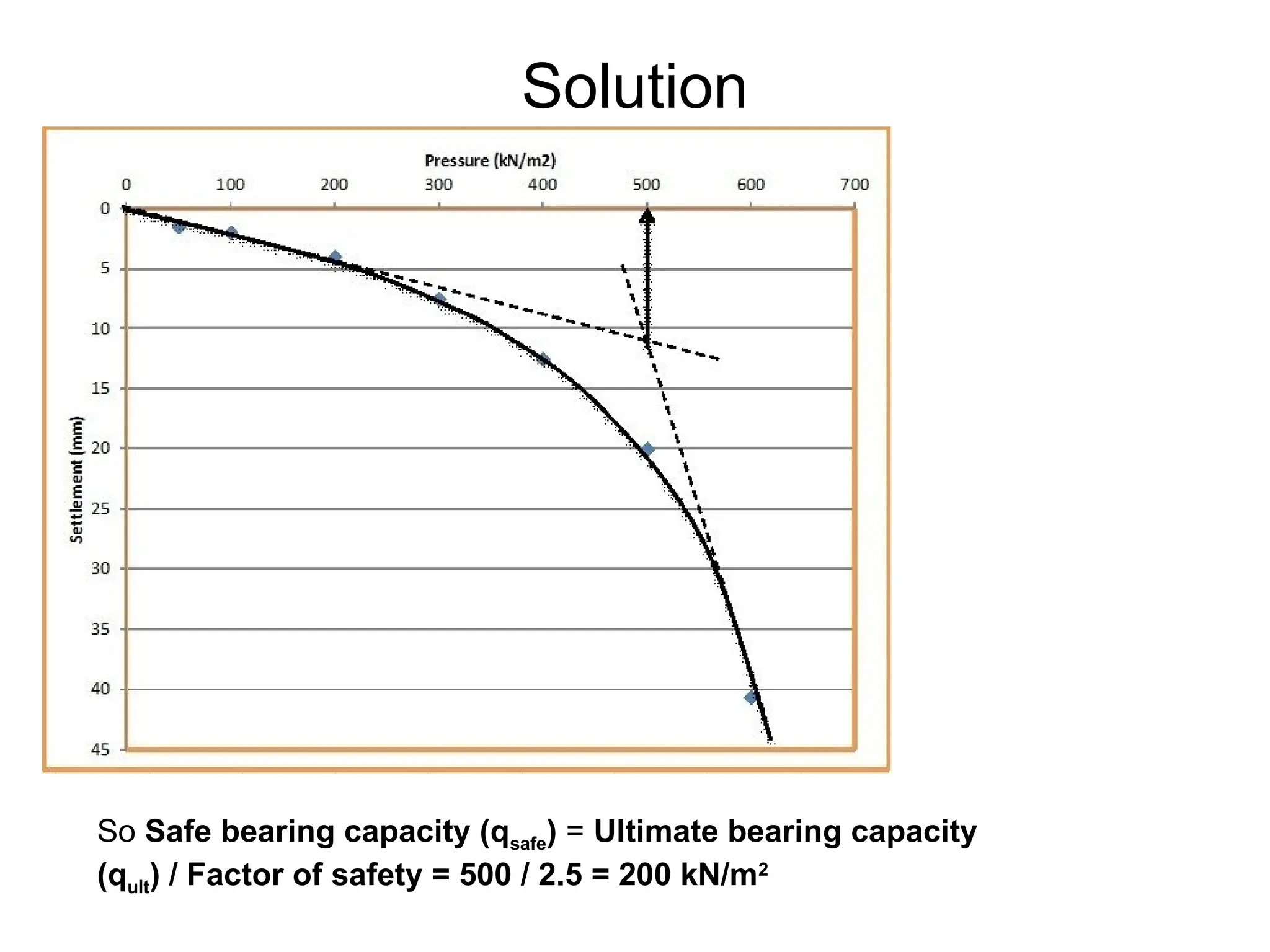

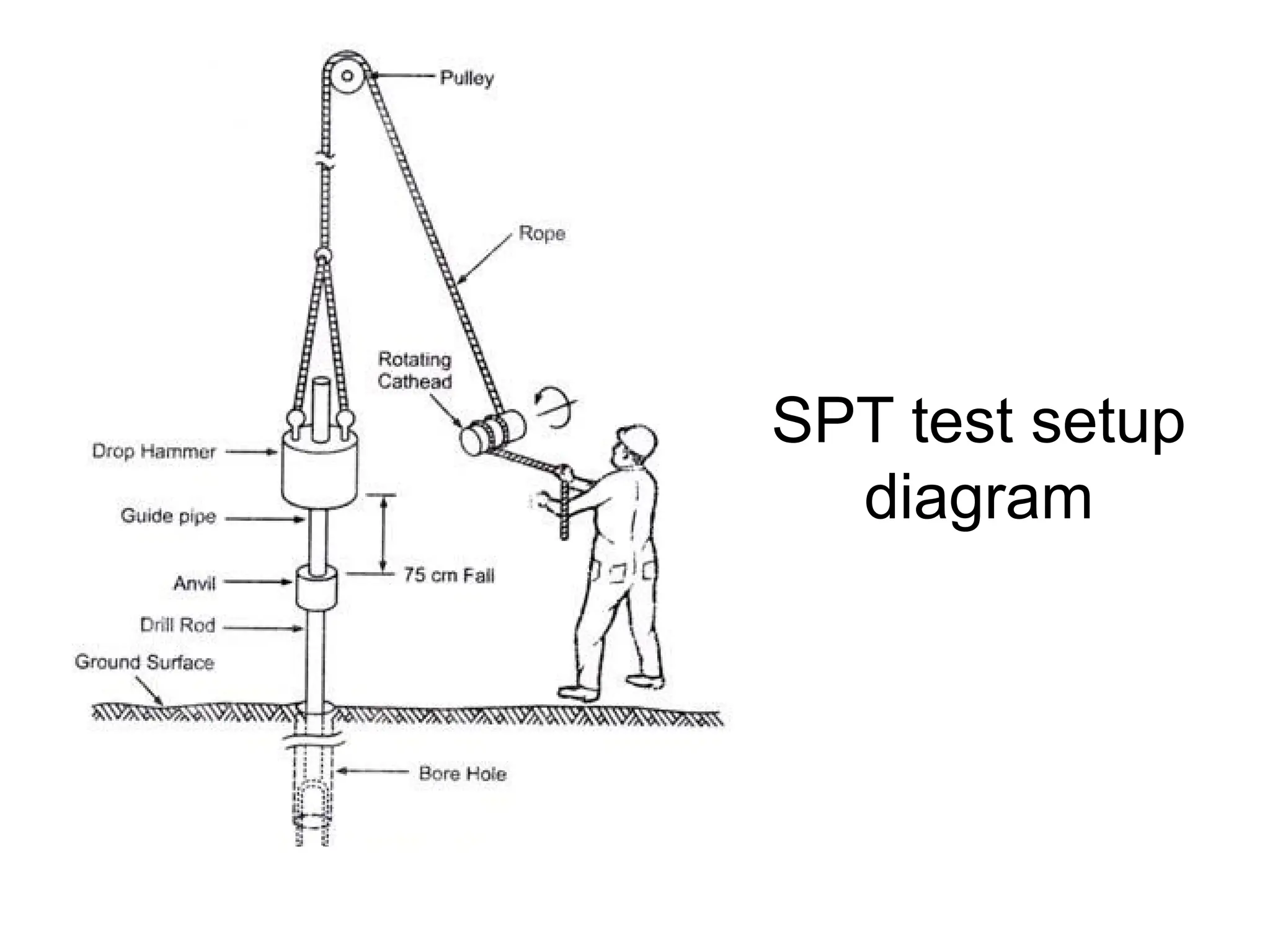

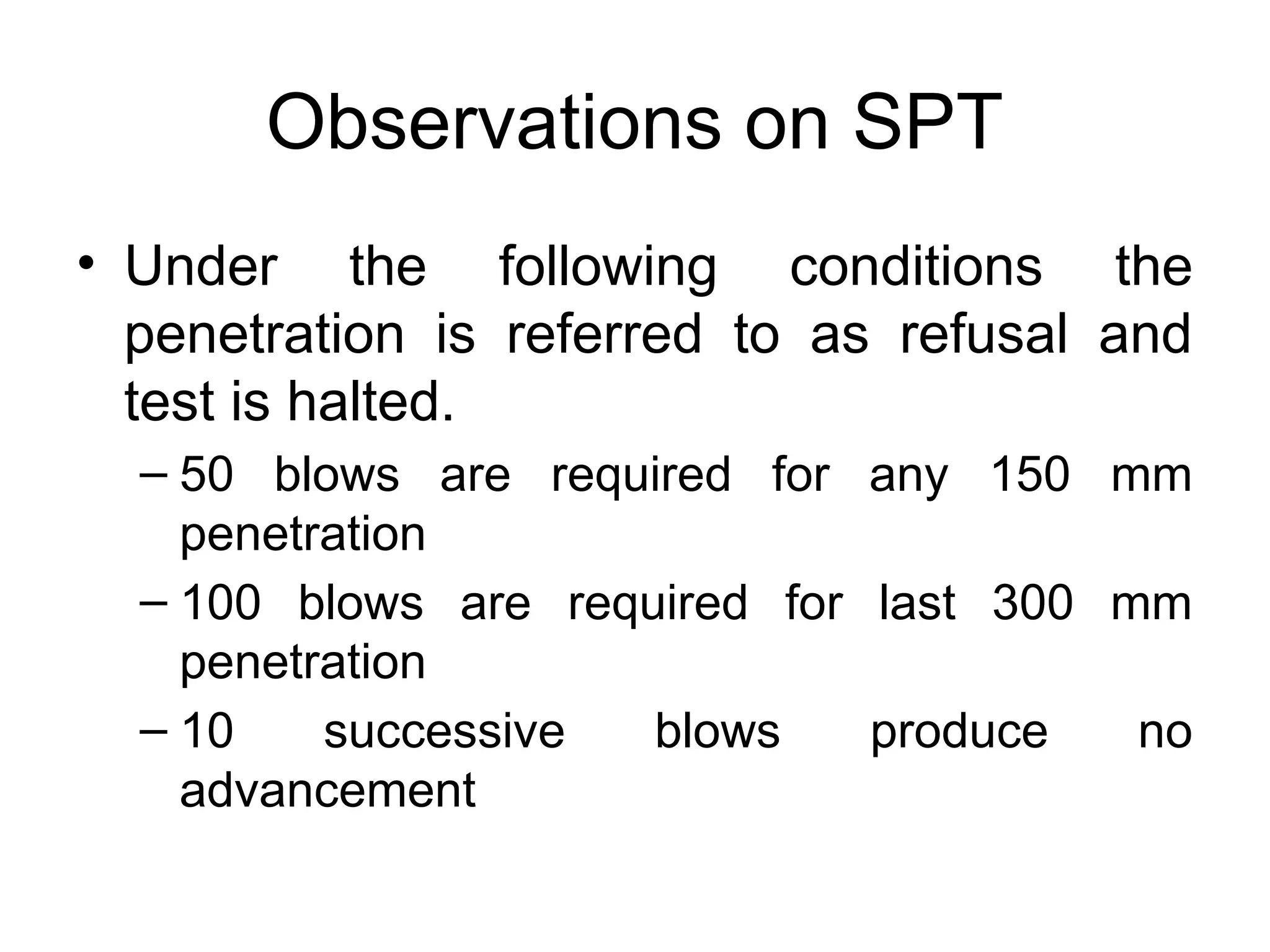

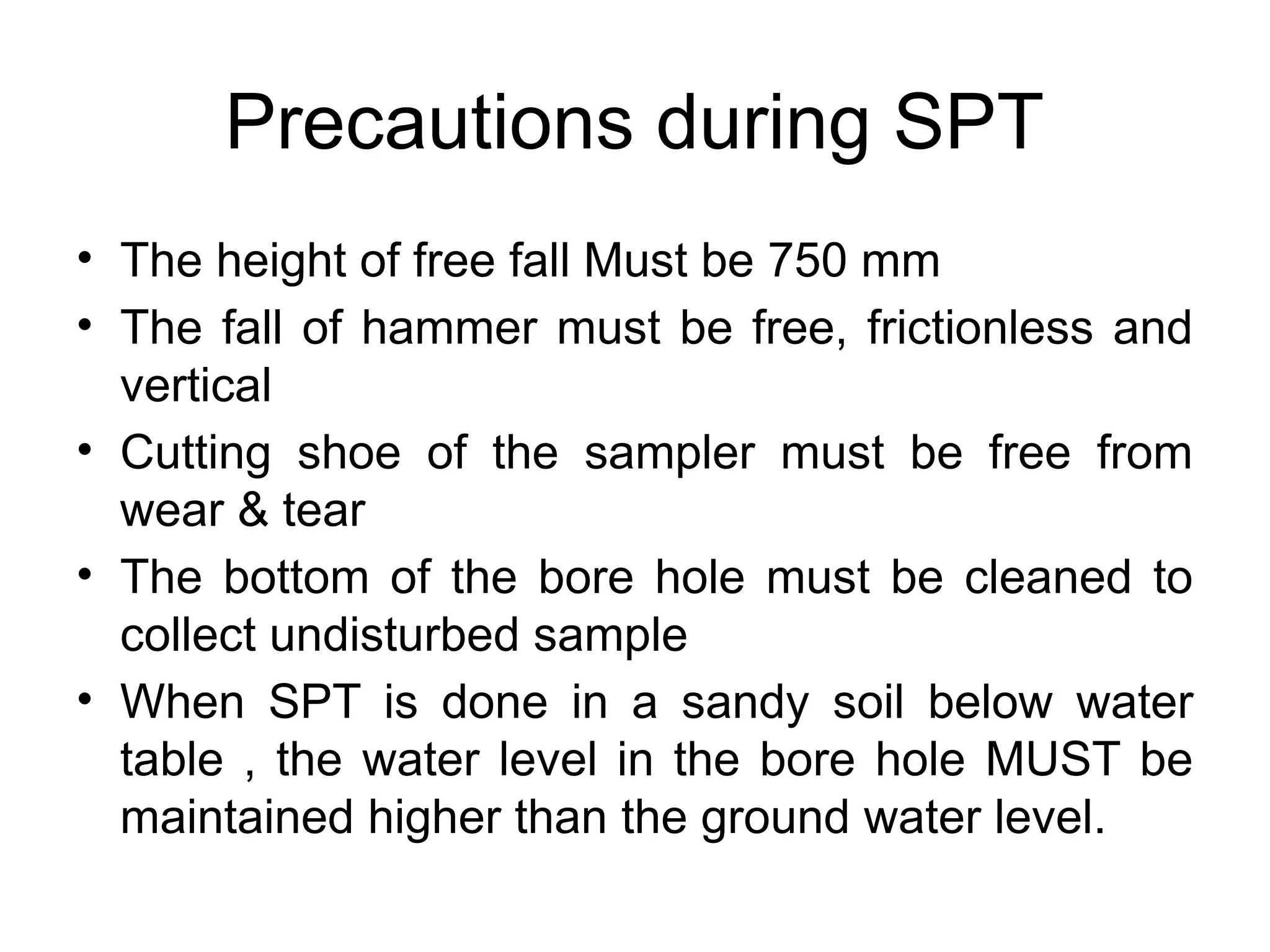

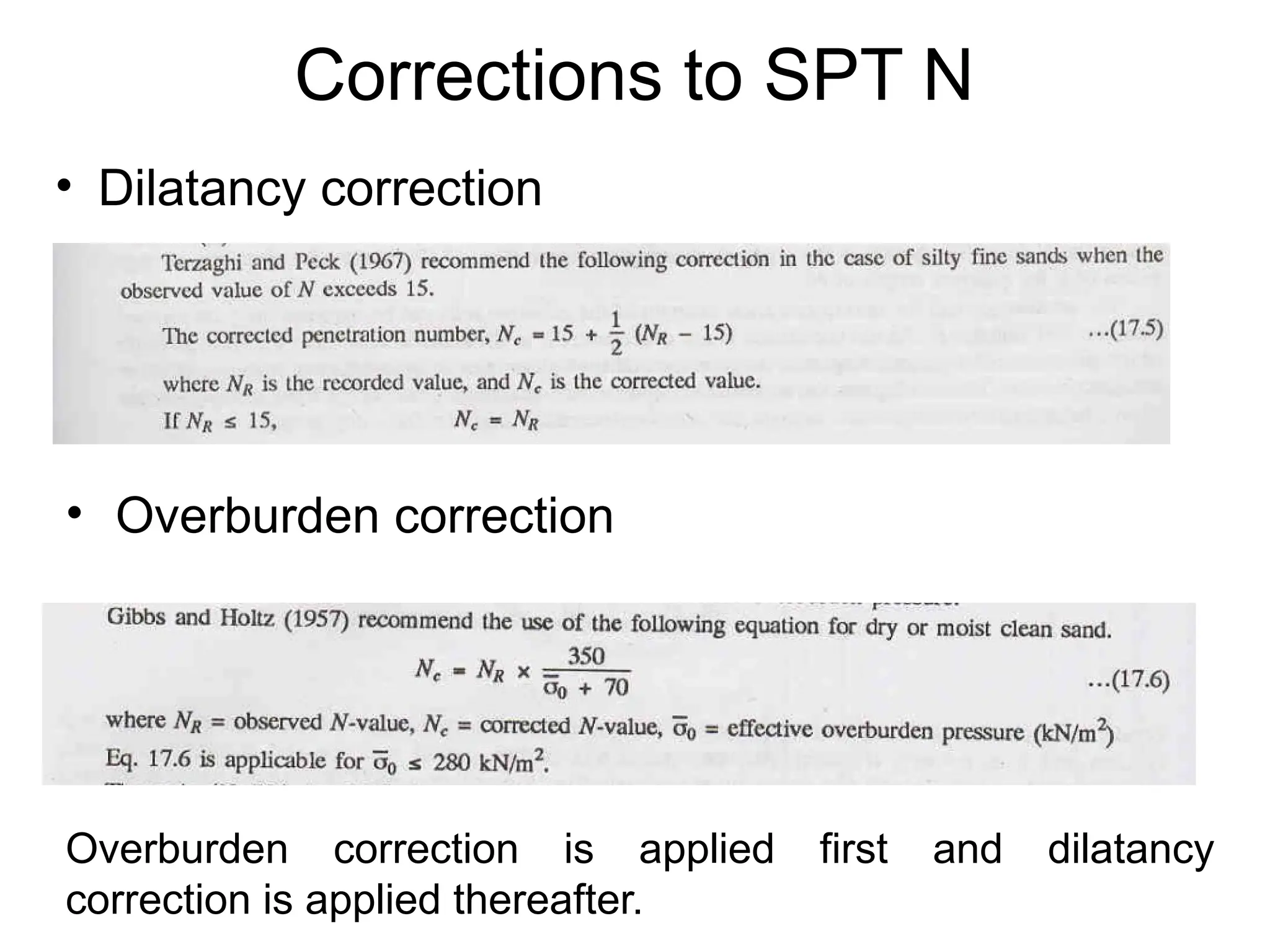

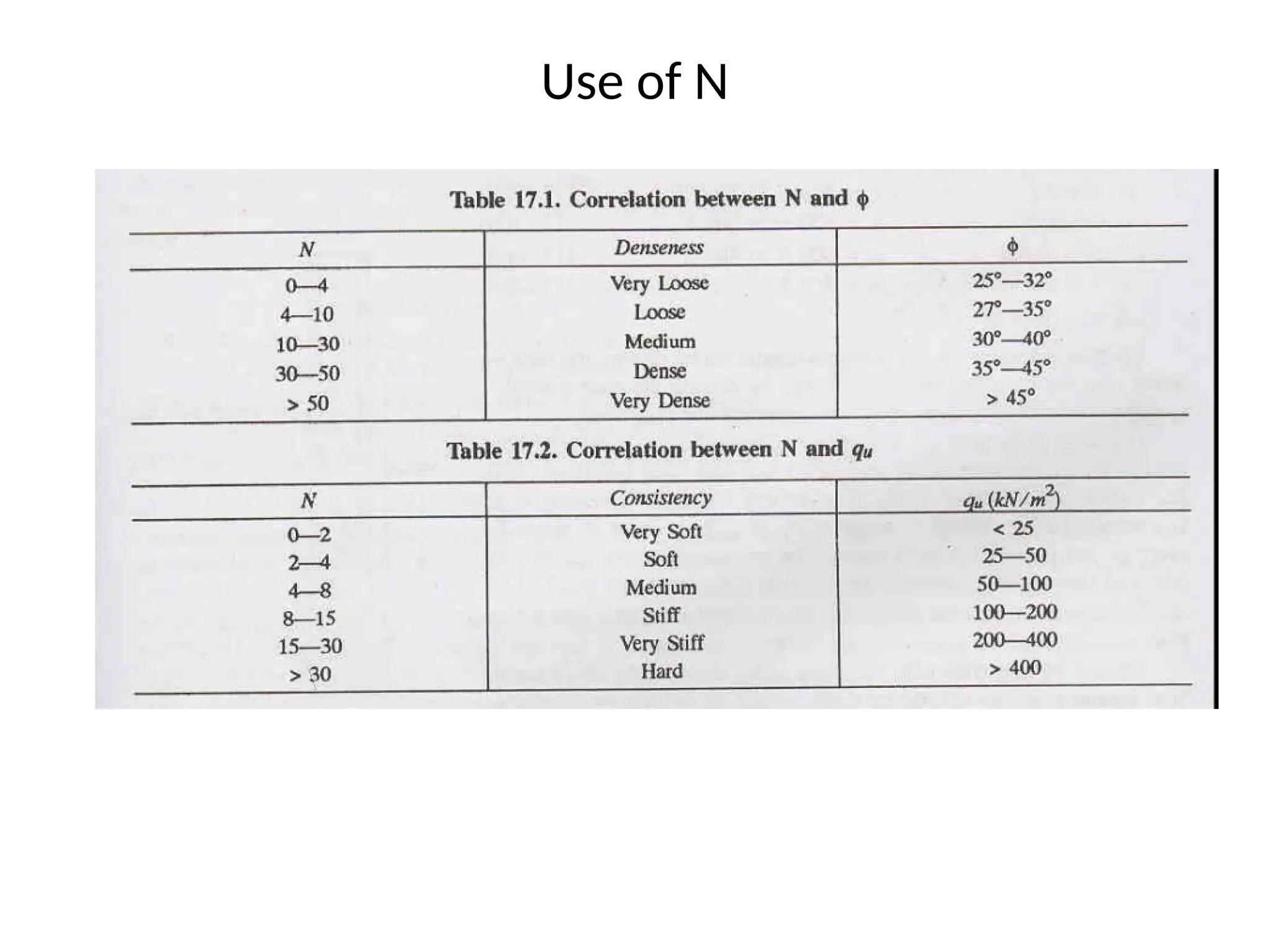

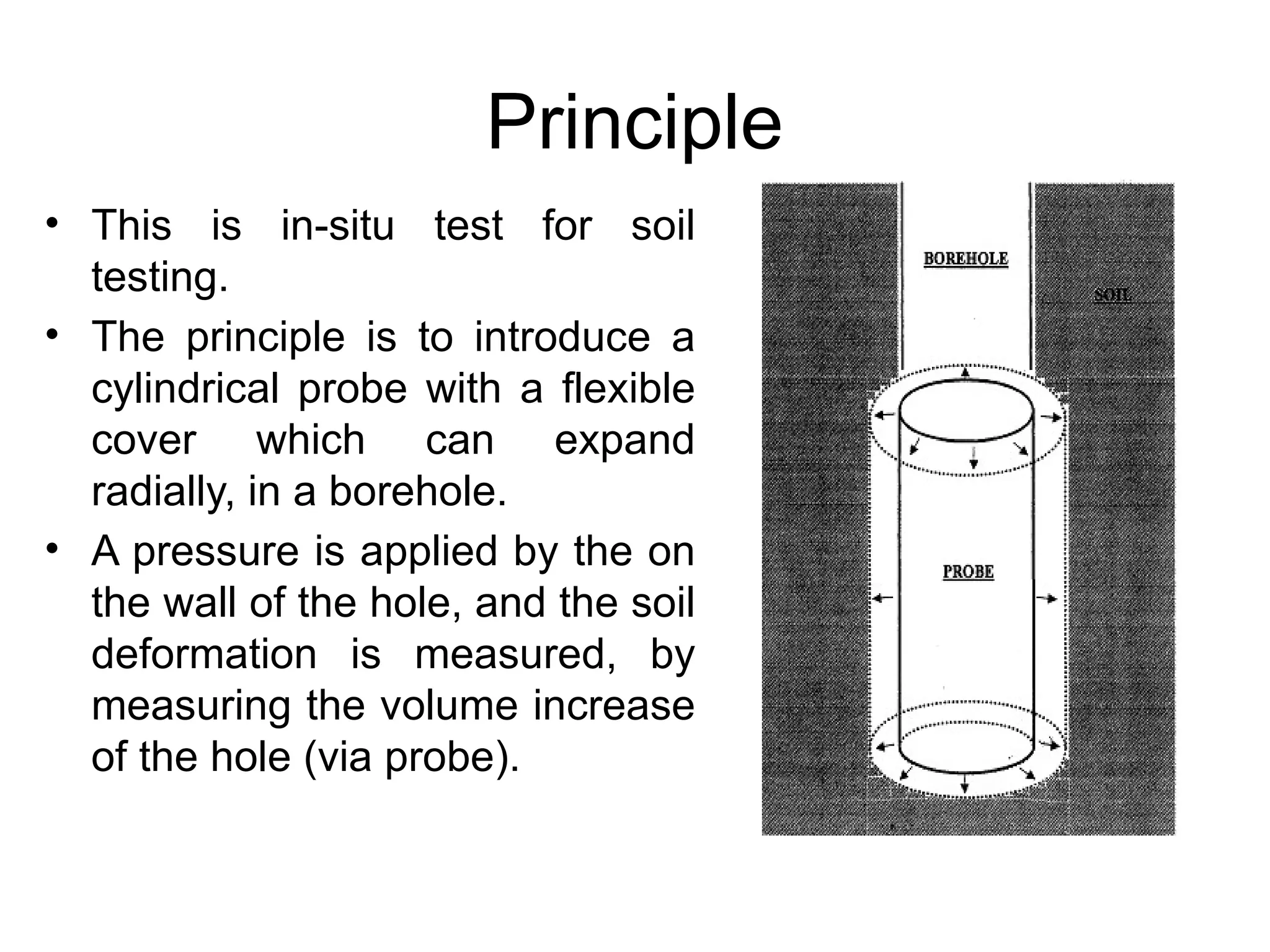

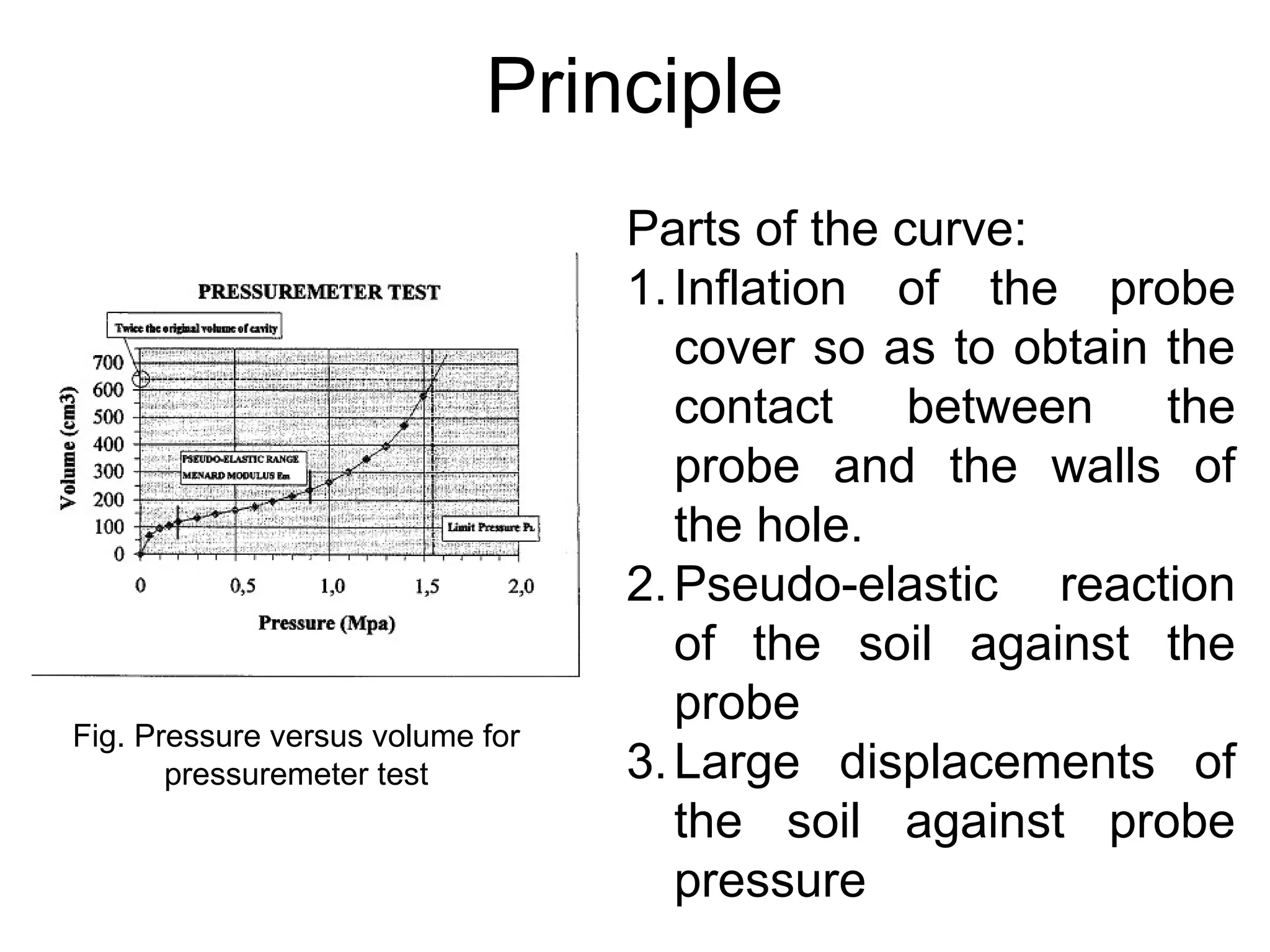

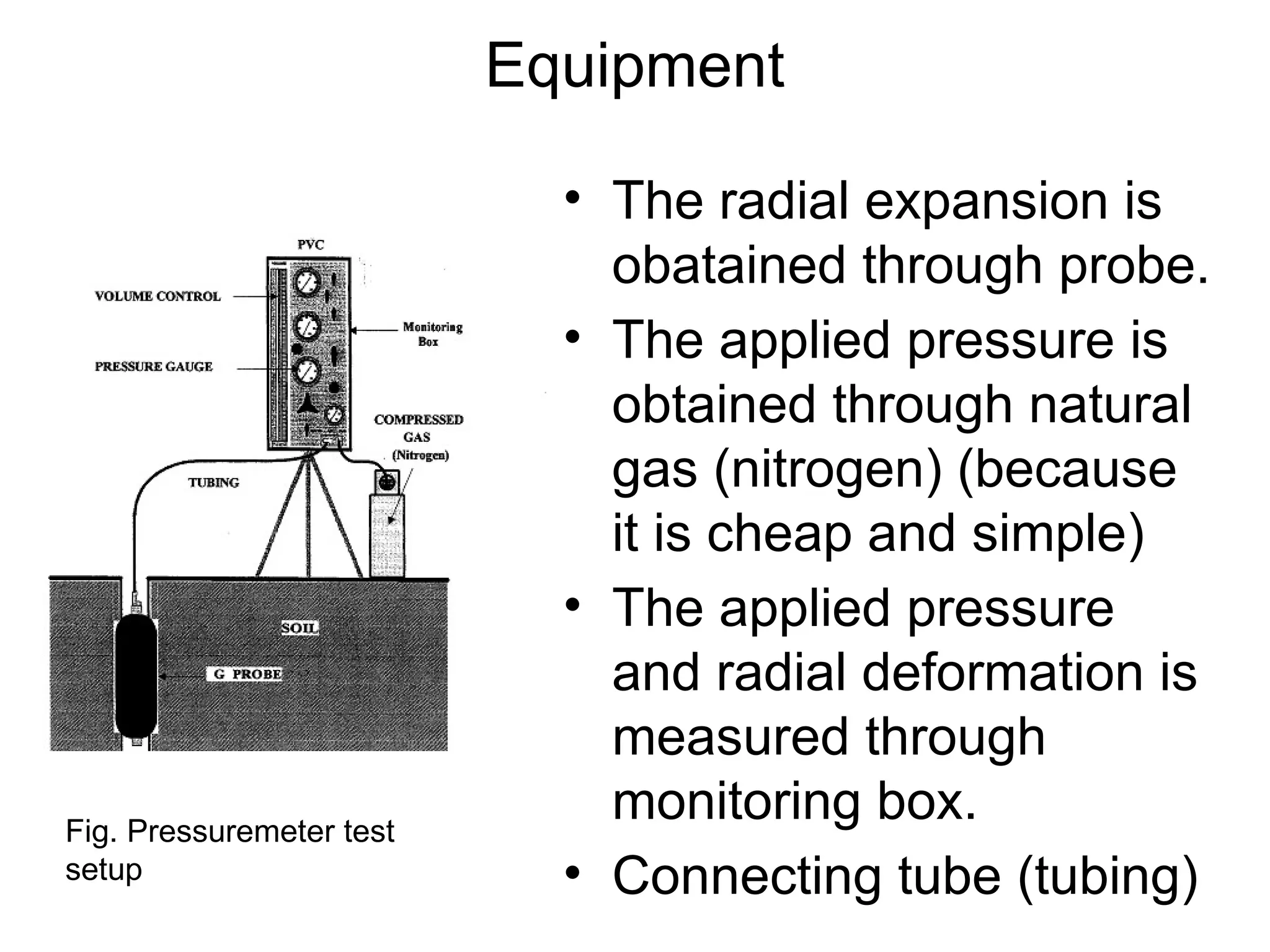

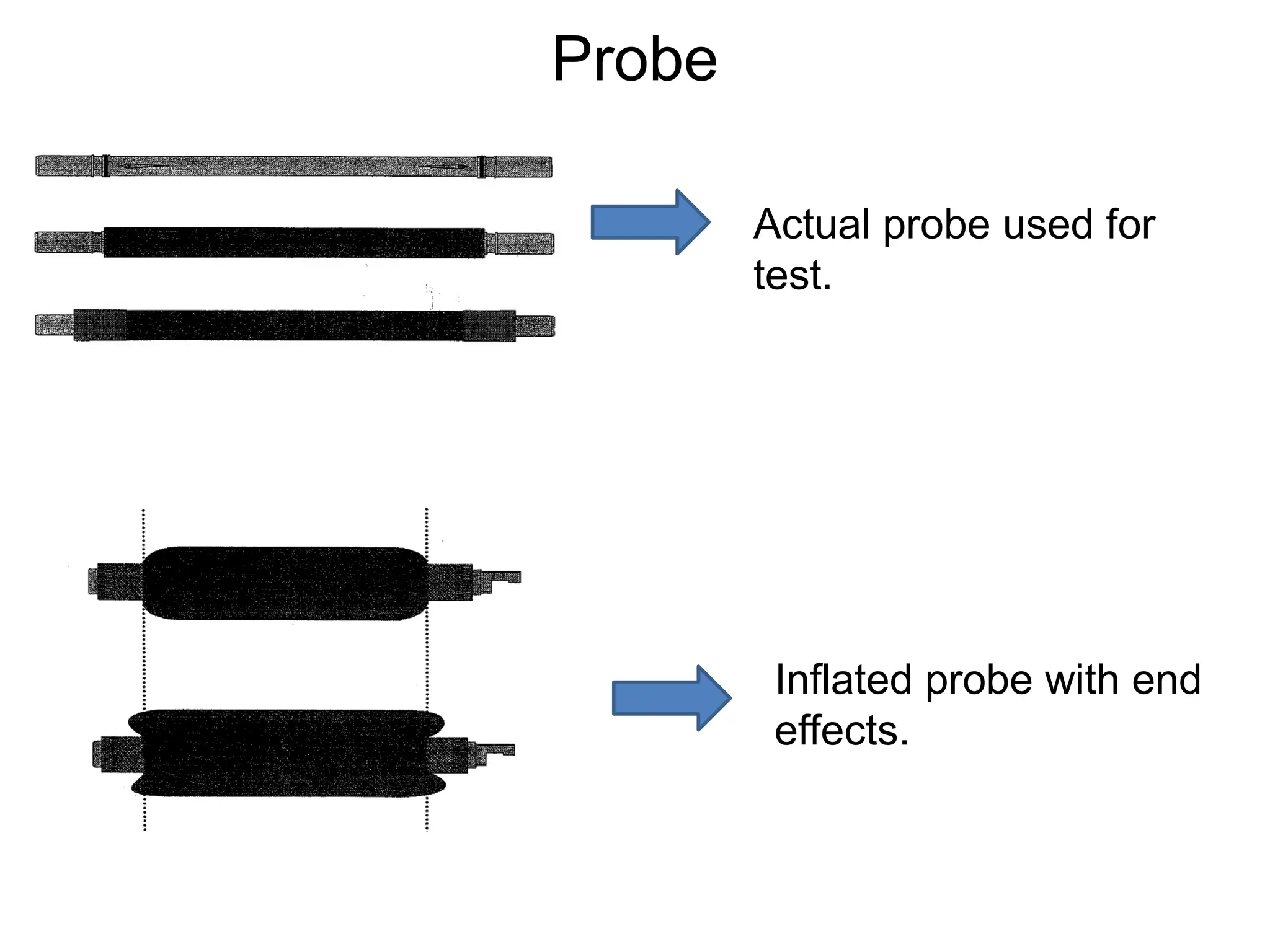

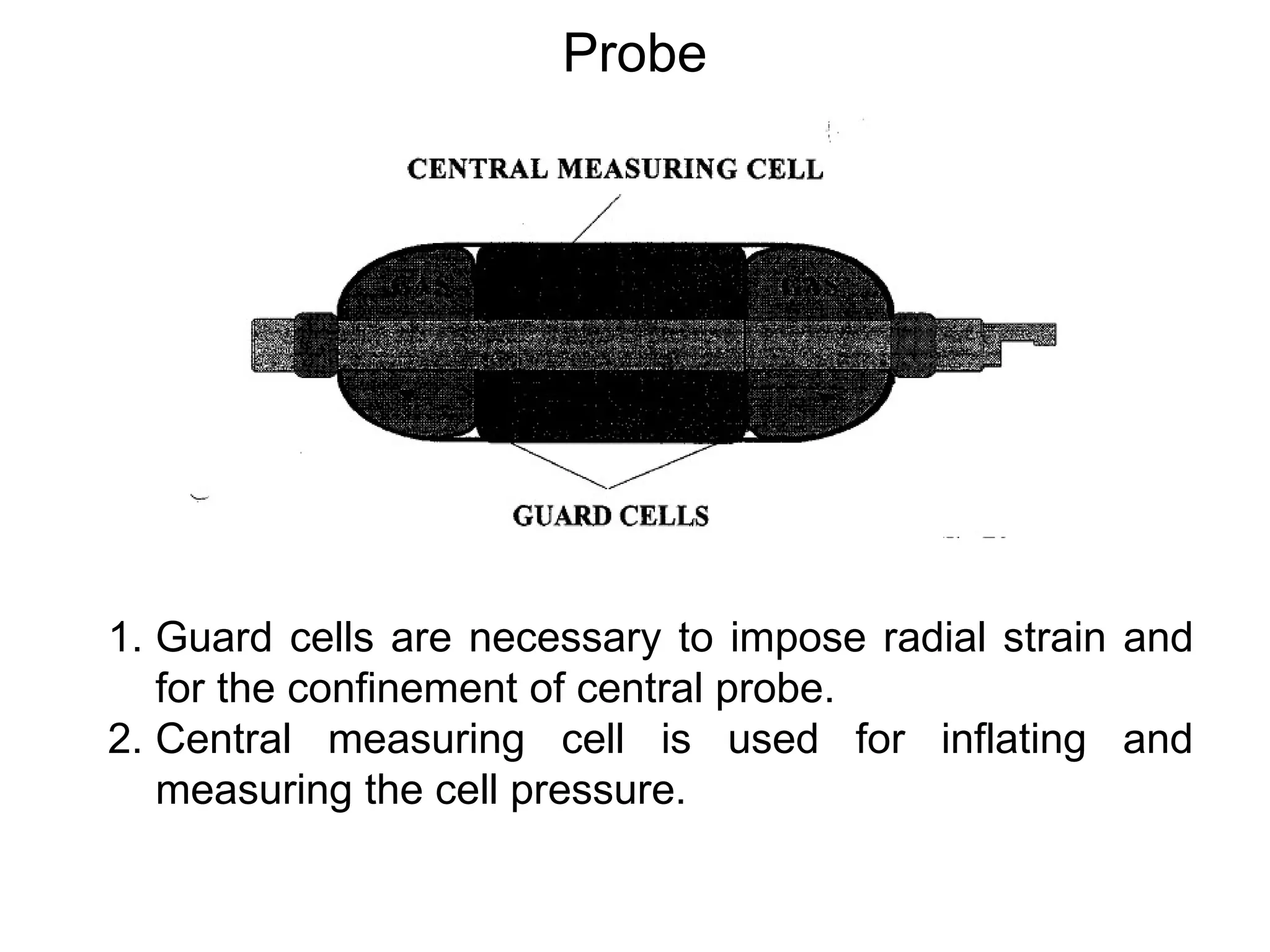

The document outlines methods for assessing the load-bearing capacity of foundations, particularly through the plate load test and the standard penetration test (SPT). It details the test setup, procedures, interpretation of results, and limitations of these tests, while also providing insights on the pressuremeter test used for soil parameter calculations. The material includes examples, calculations, and assignments related to geotechnical engineering practices.