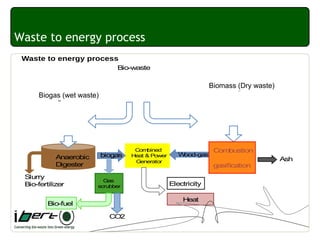

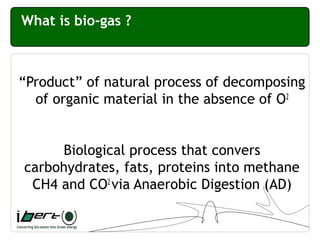

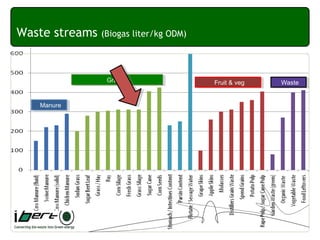

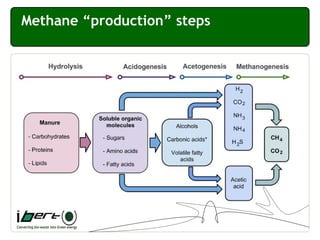

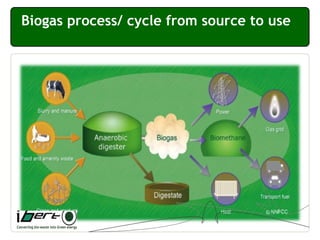

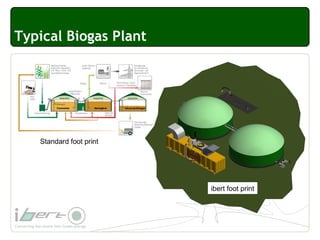

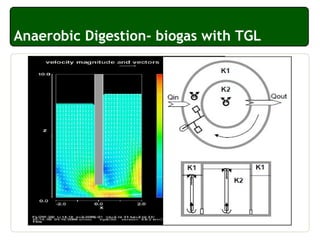

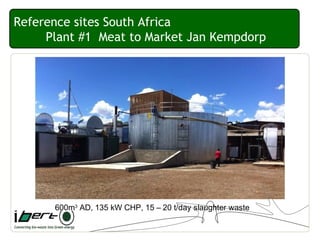

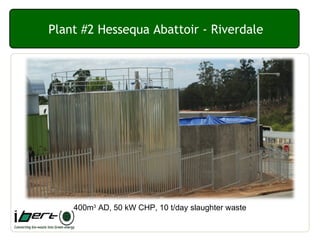

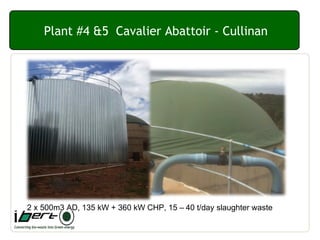

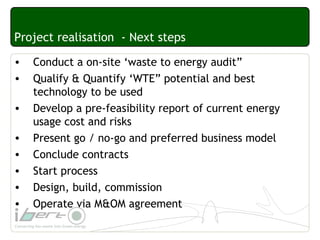

This document discusses waste-to-energy processes using biogas technology. It introduces Horst Unterlechner, a biomass energy specialist, and describes several pilot waste-to-energy projects in South Africa since 2012. The document outlines the waste-to-energy process which involves anaerobic digestion of organic waste to produce biogas, followed by combustion in a generator to produce electricity and heat. It provides details on six existing biogas plants in South Africa processing various waste streams. The technology developed by Ibert can process both organic and non-organic waste on-site to produce biogas with outputs over 12kW of electricity and 20kW of thermal energy. The final sections discuss next steps to conduct waste aud