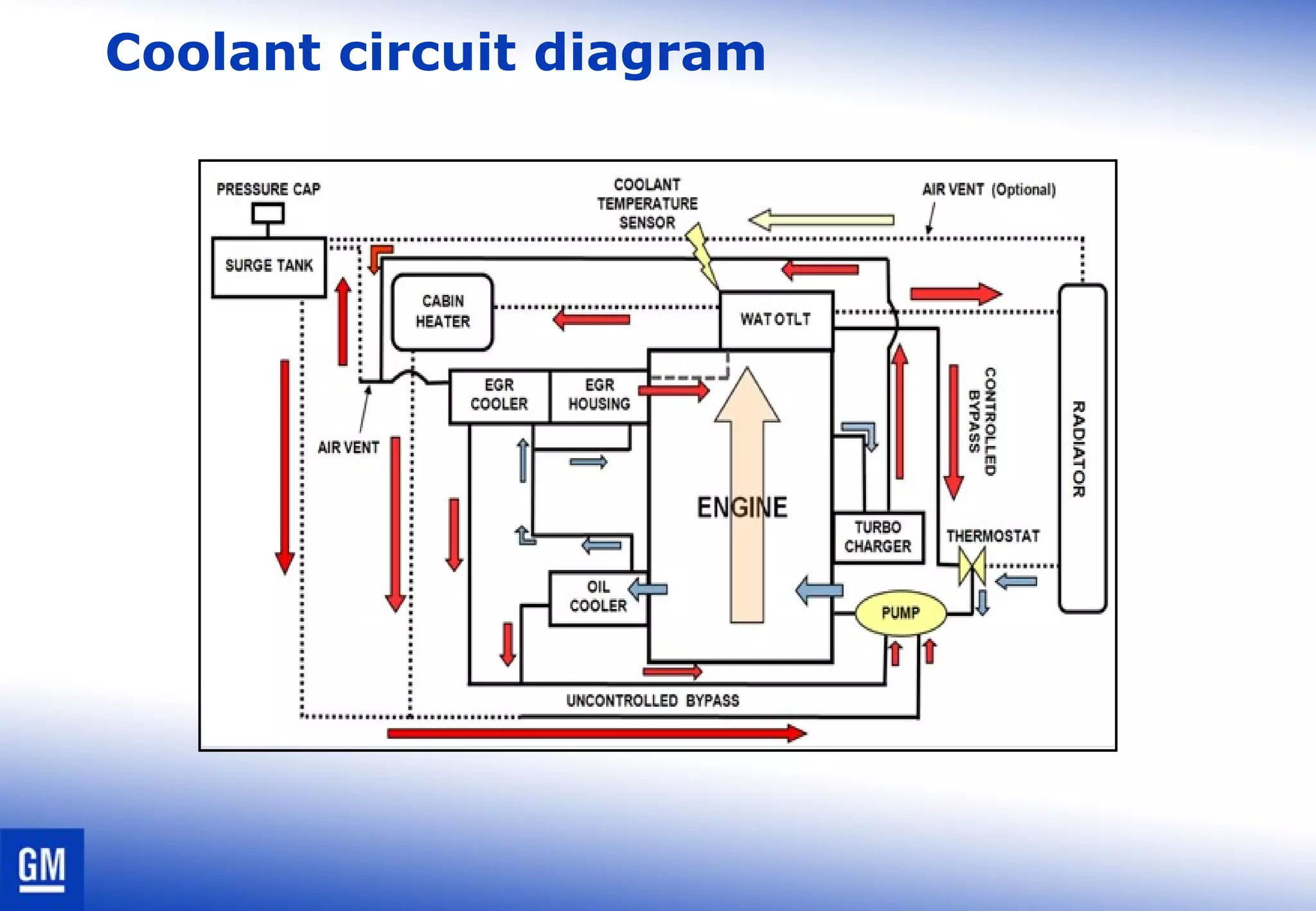

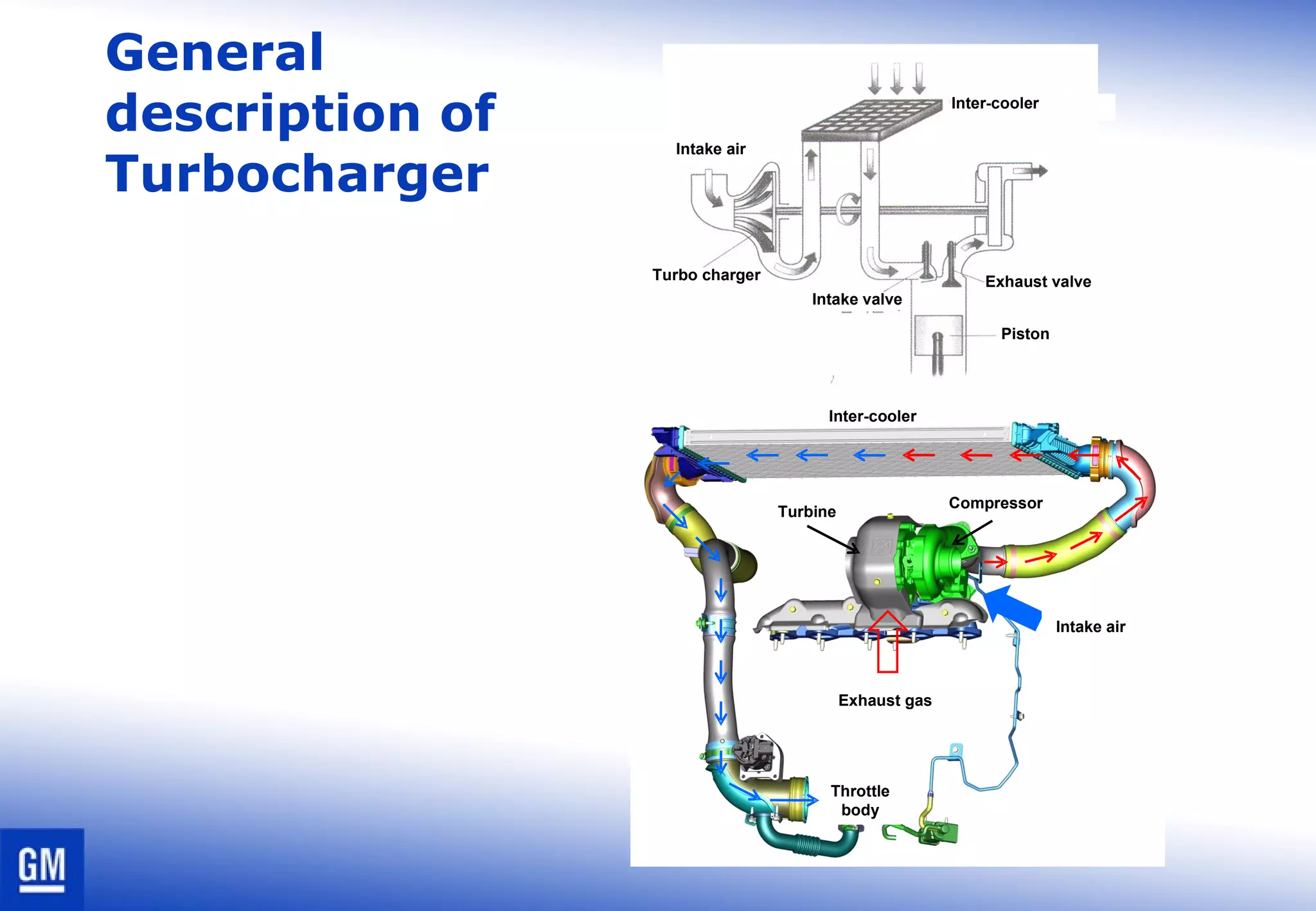

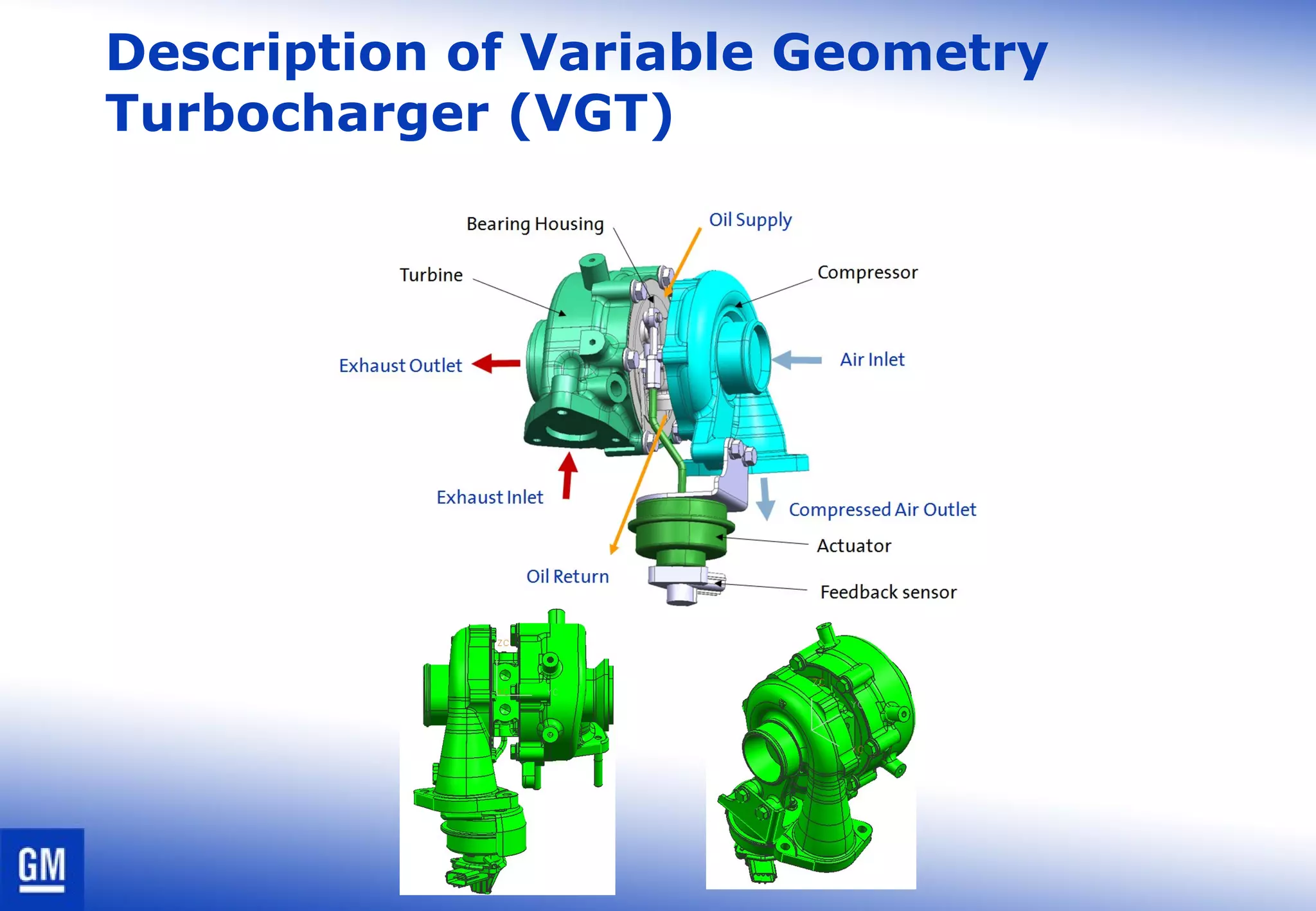

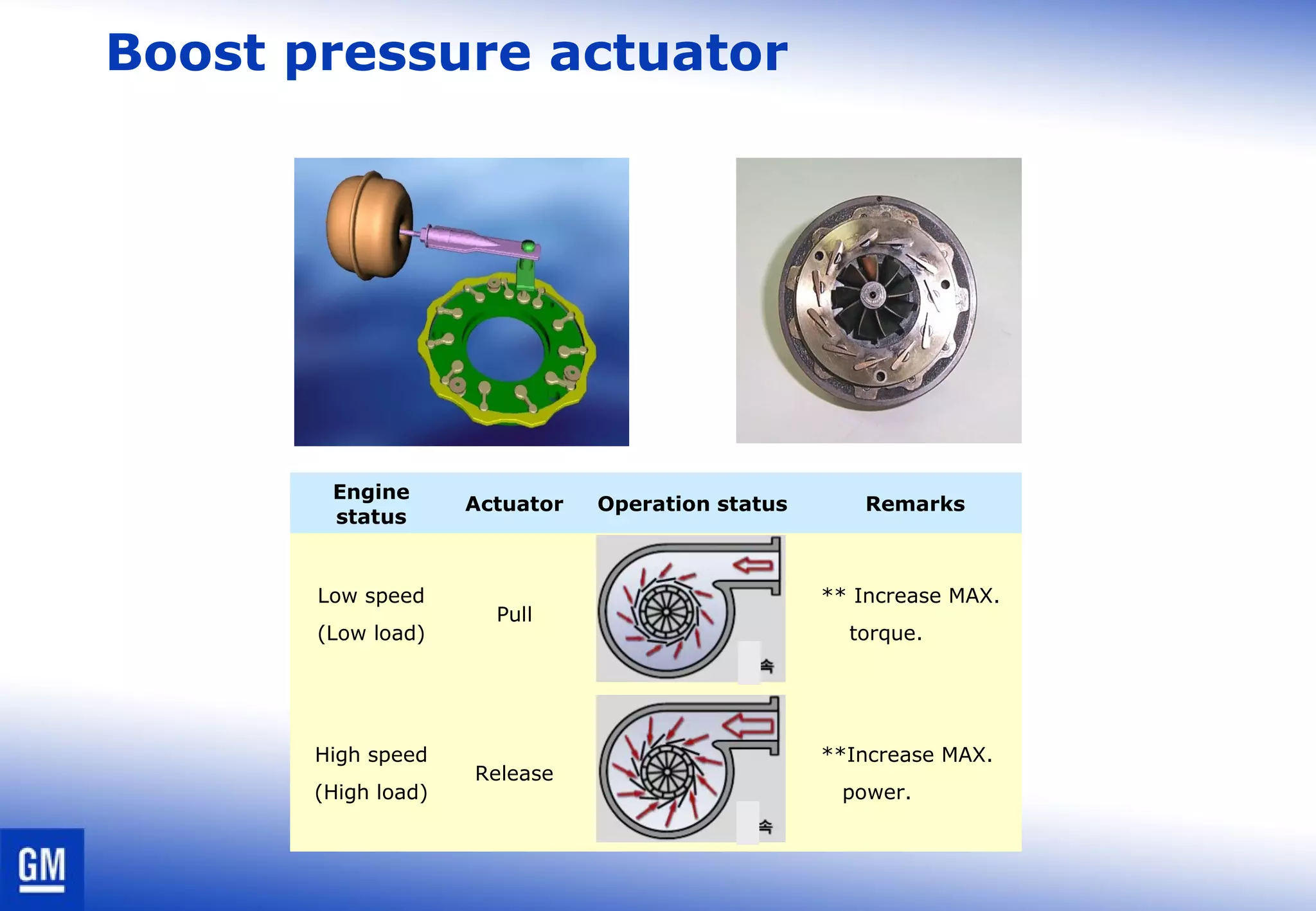

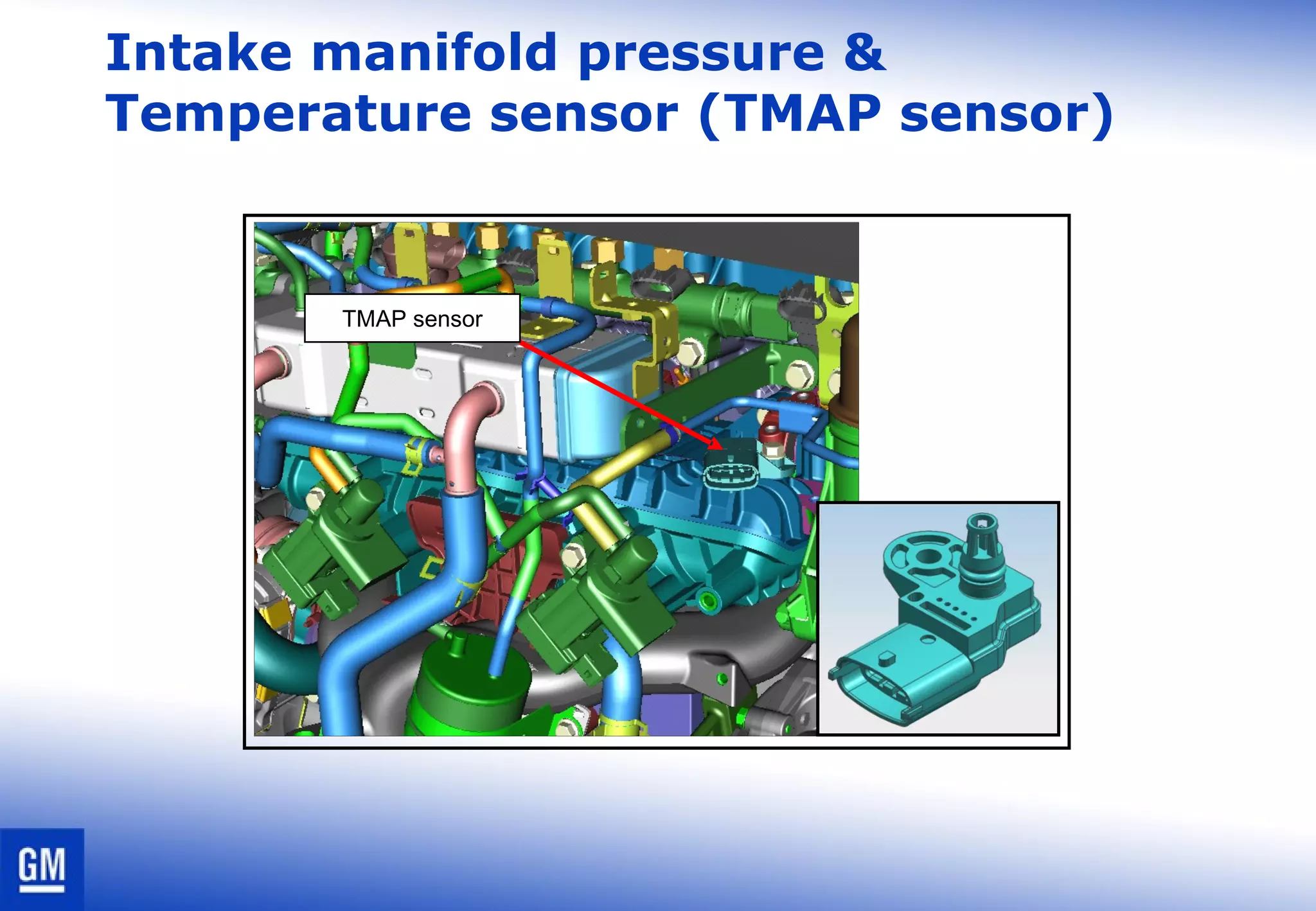

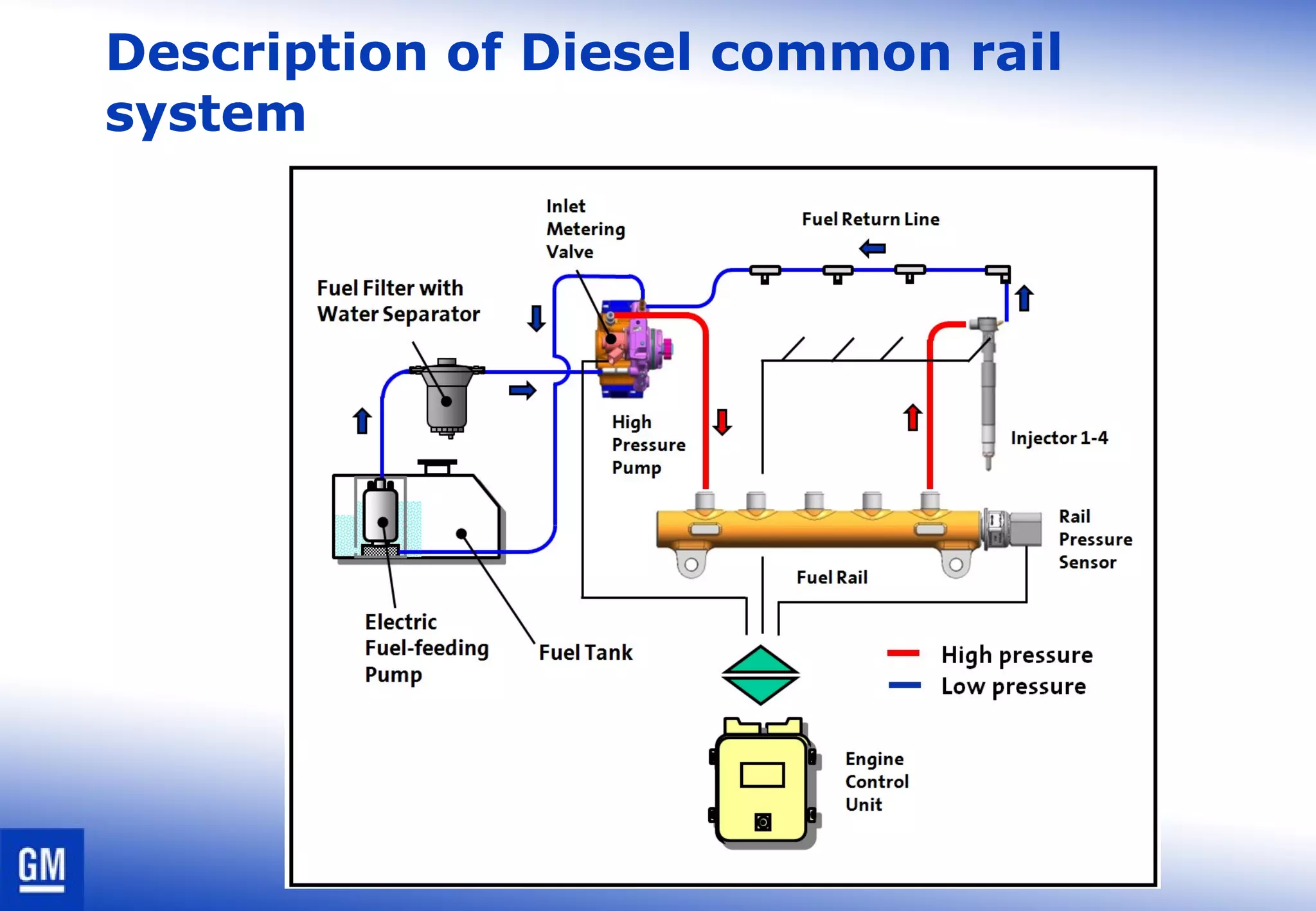

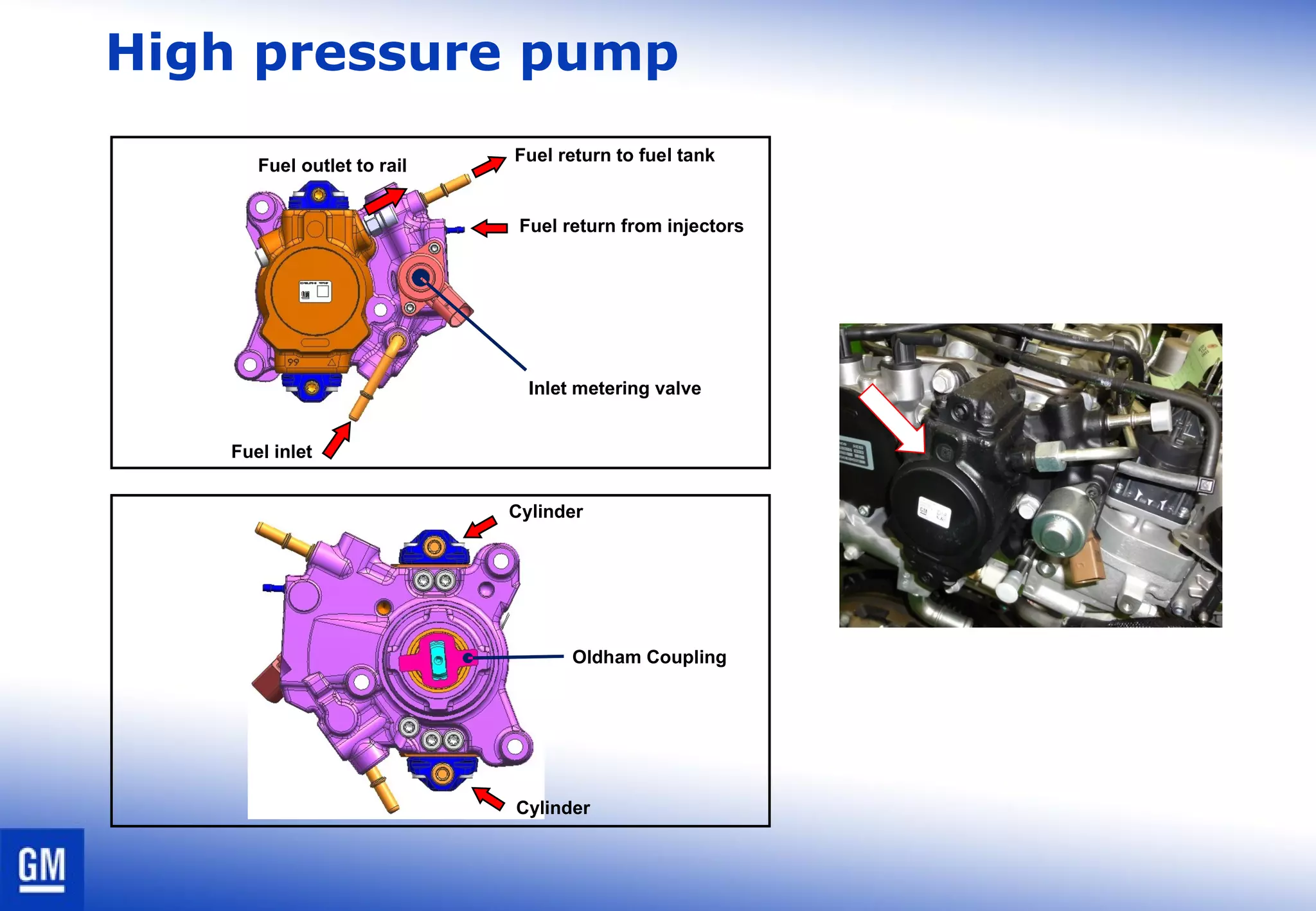

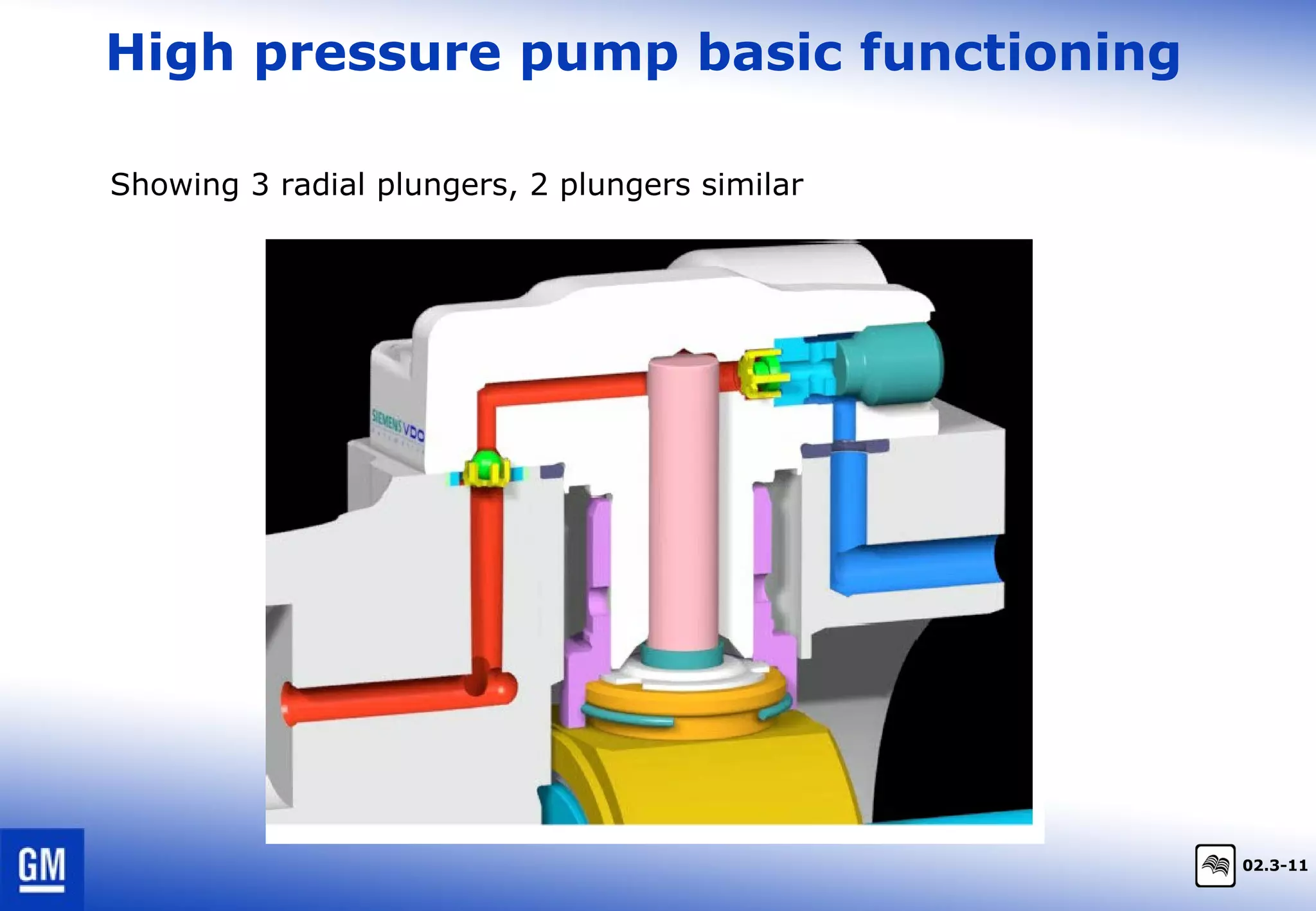

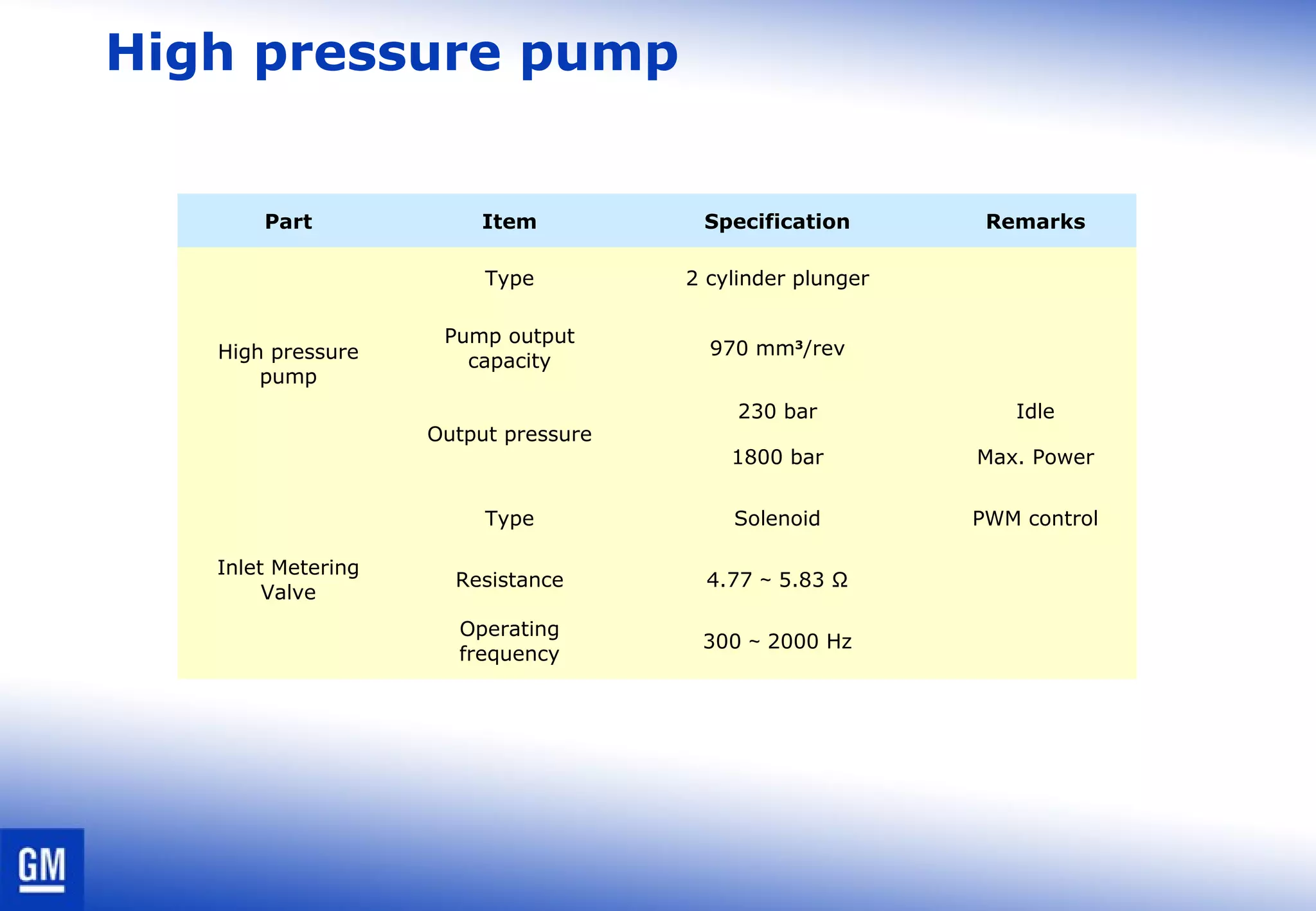

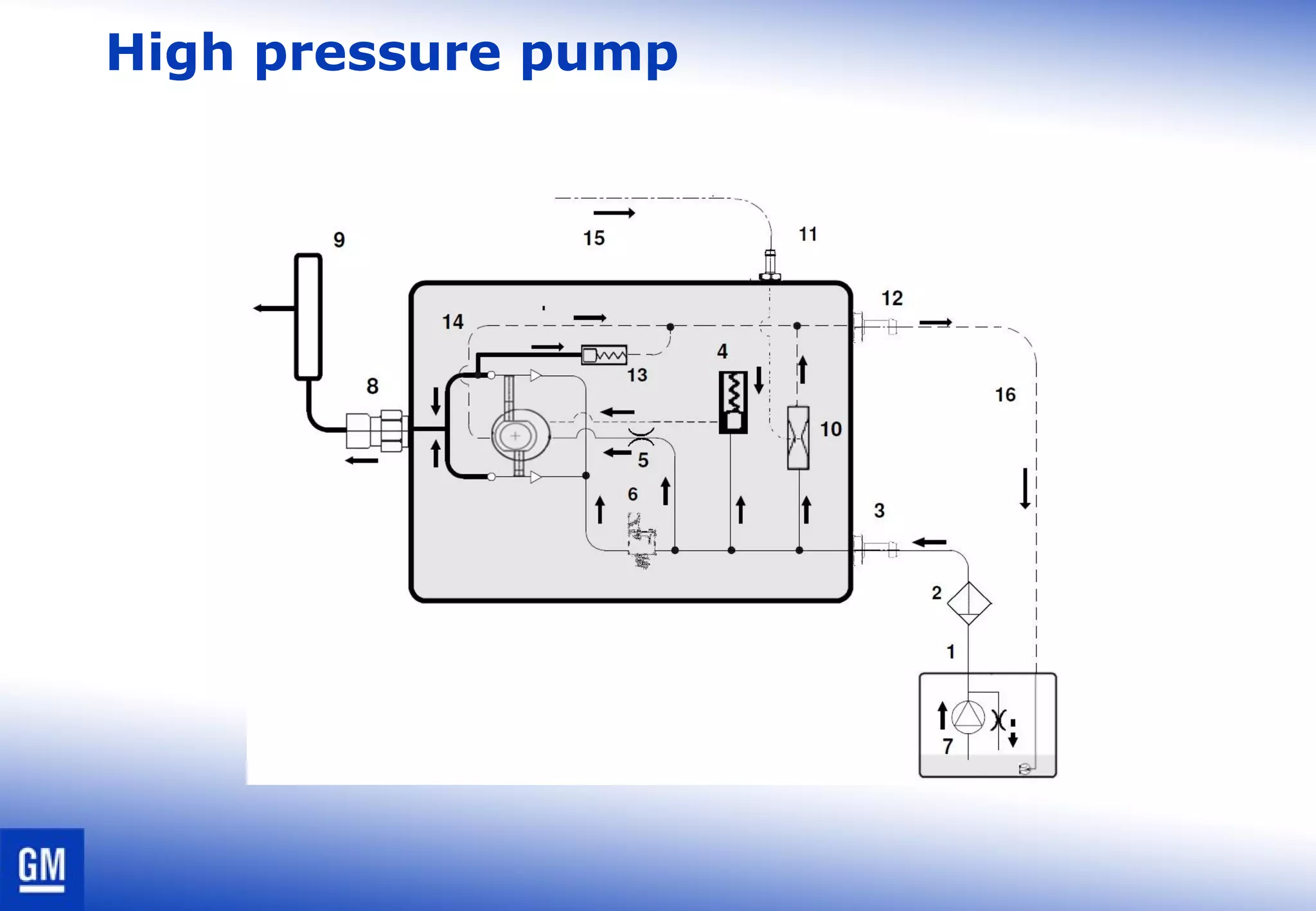

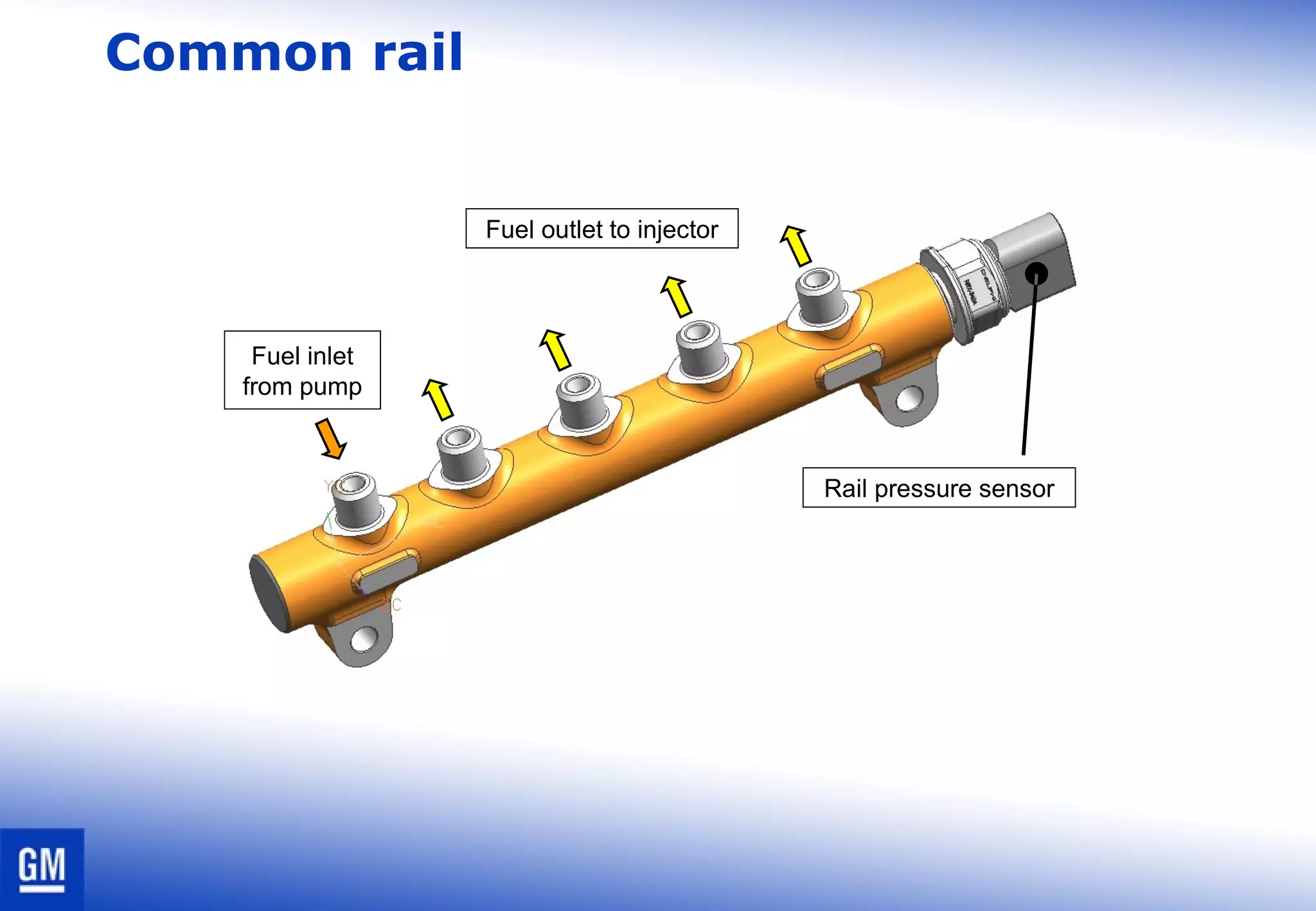

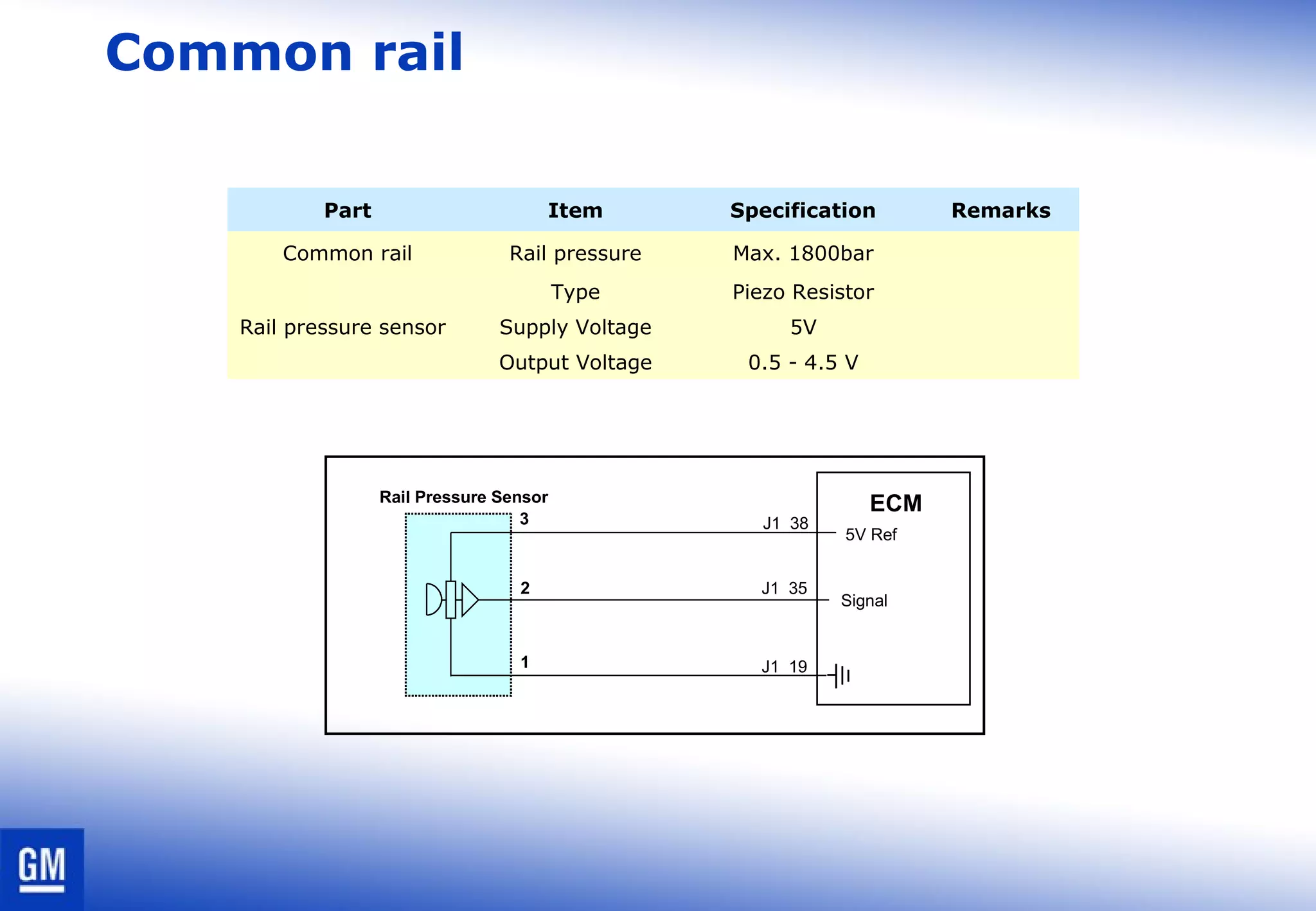

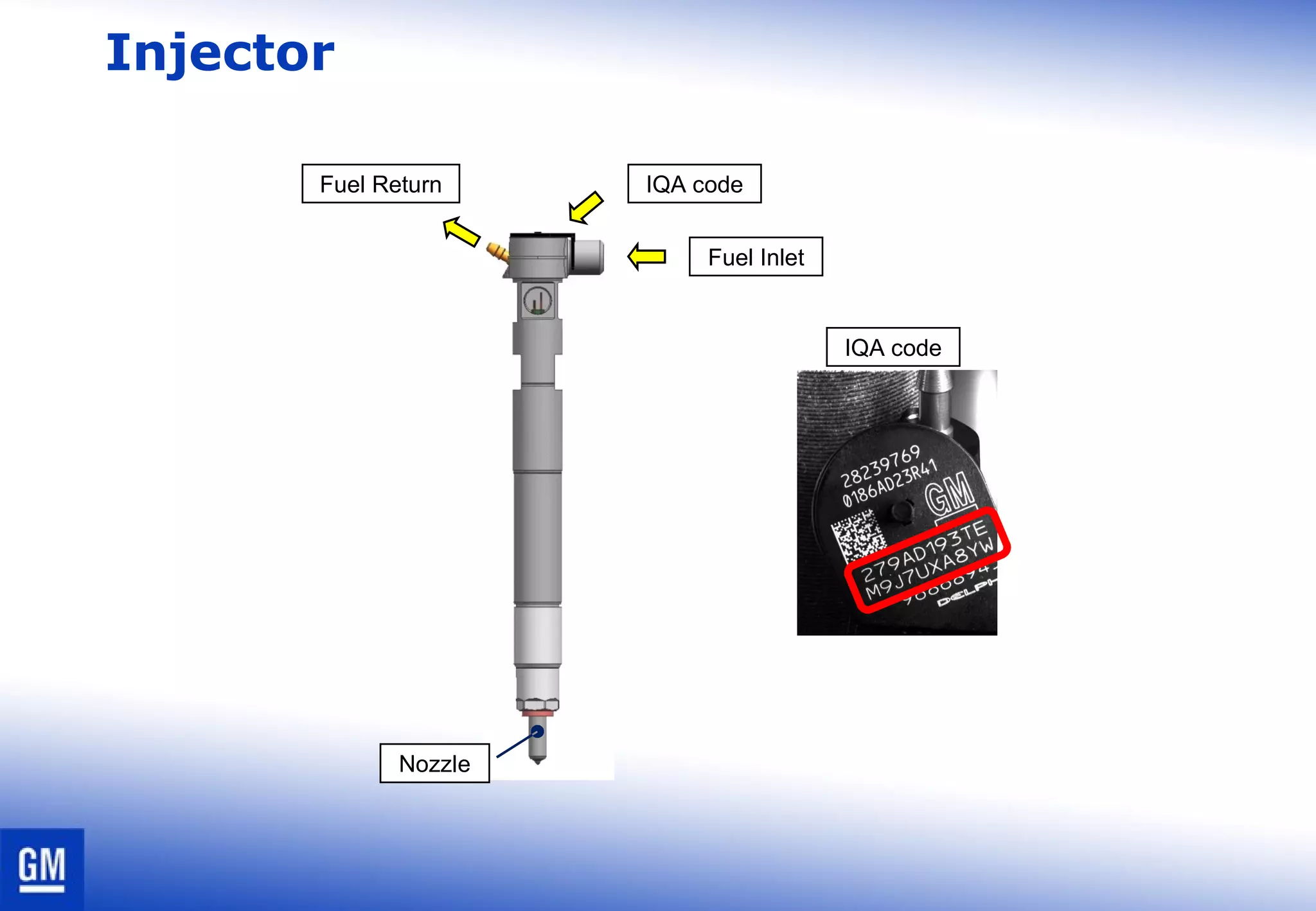

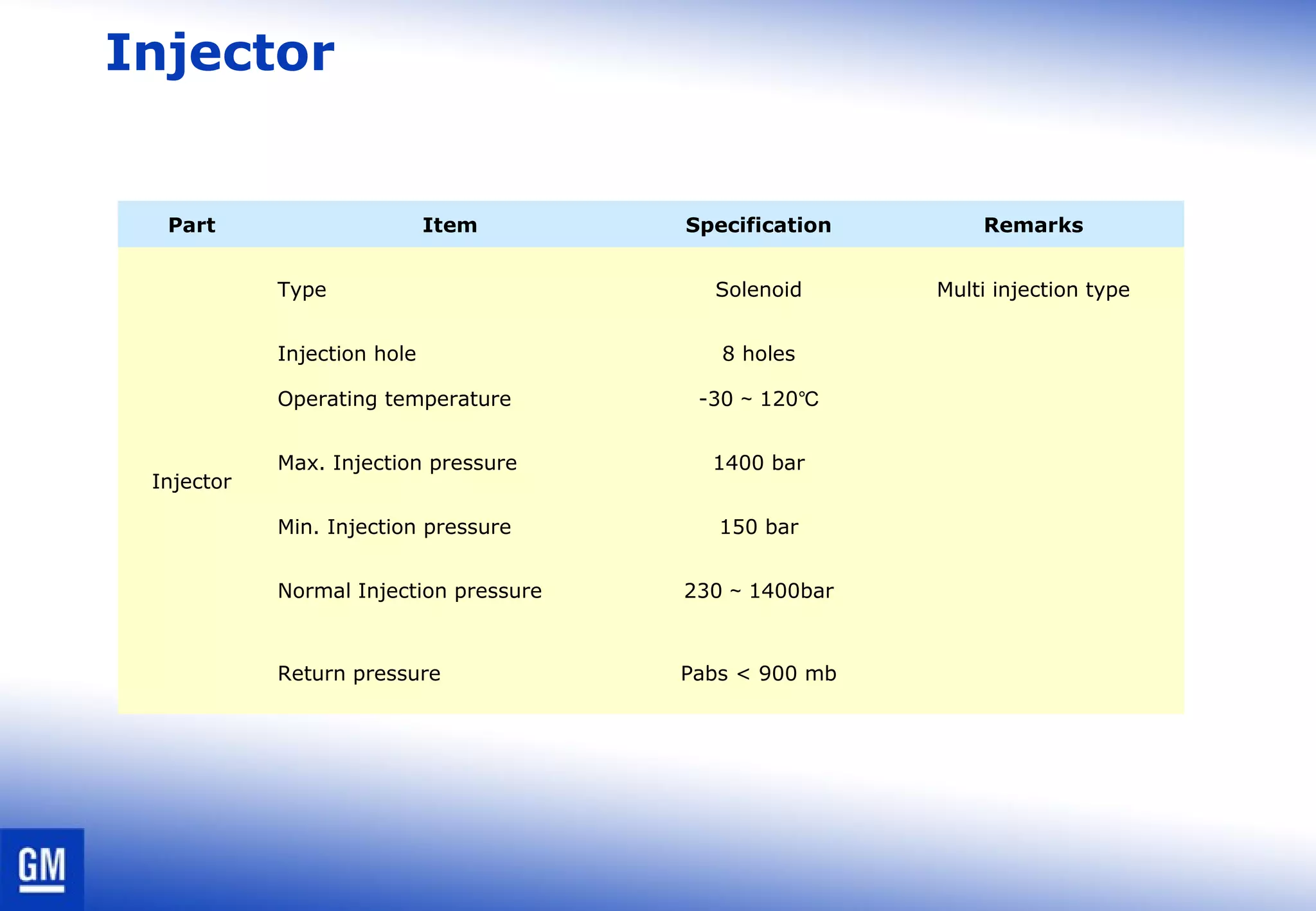

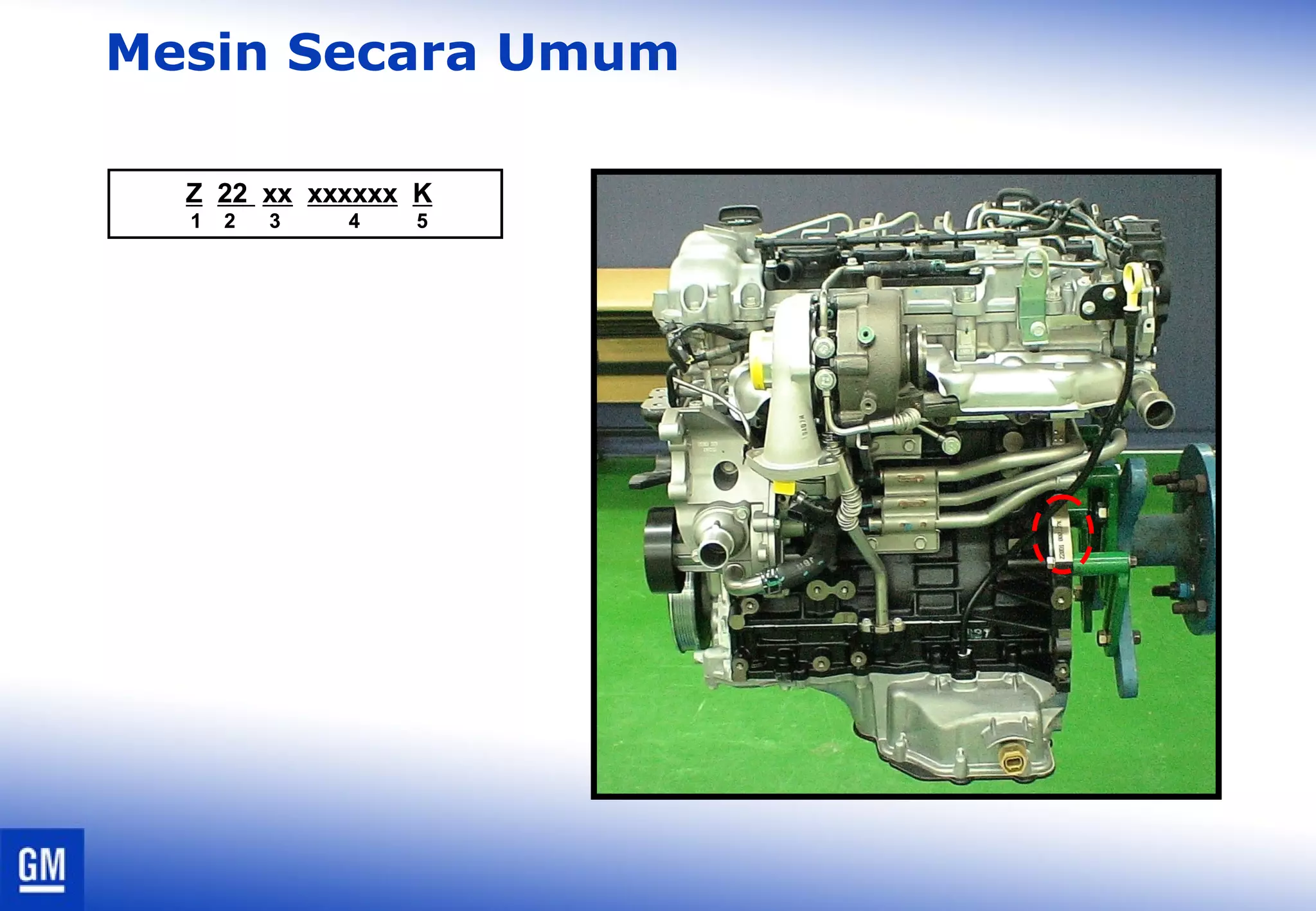

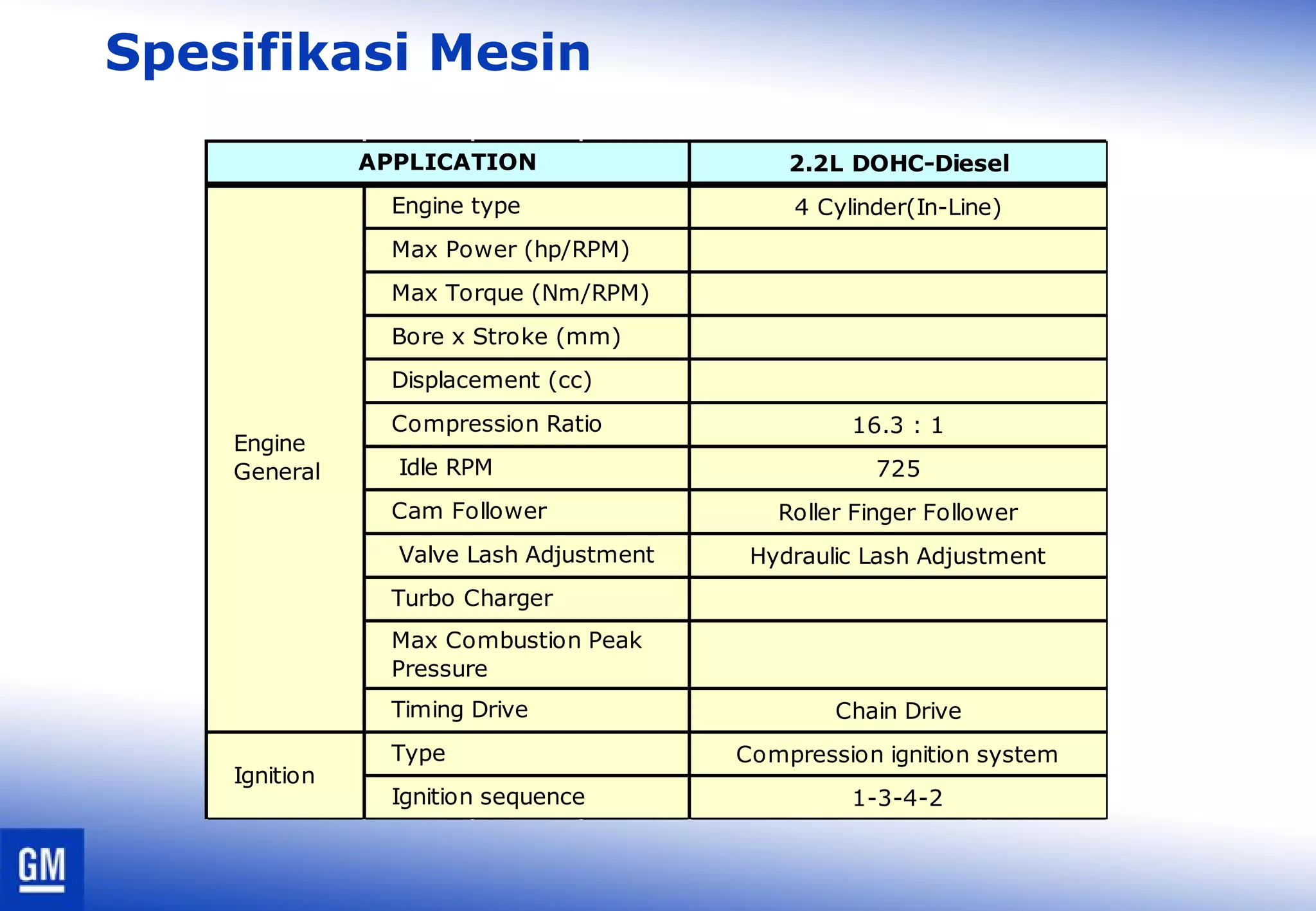

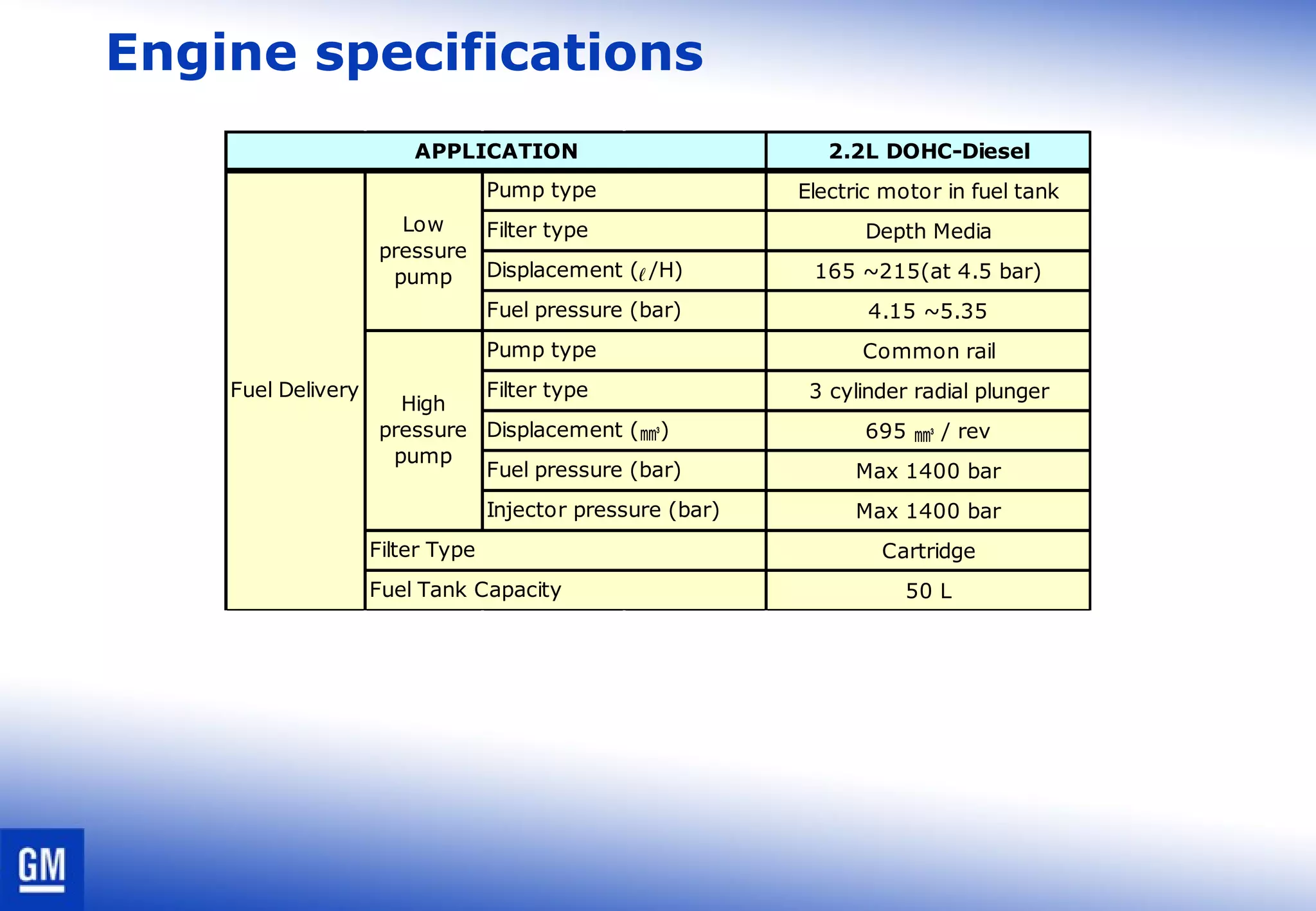

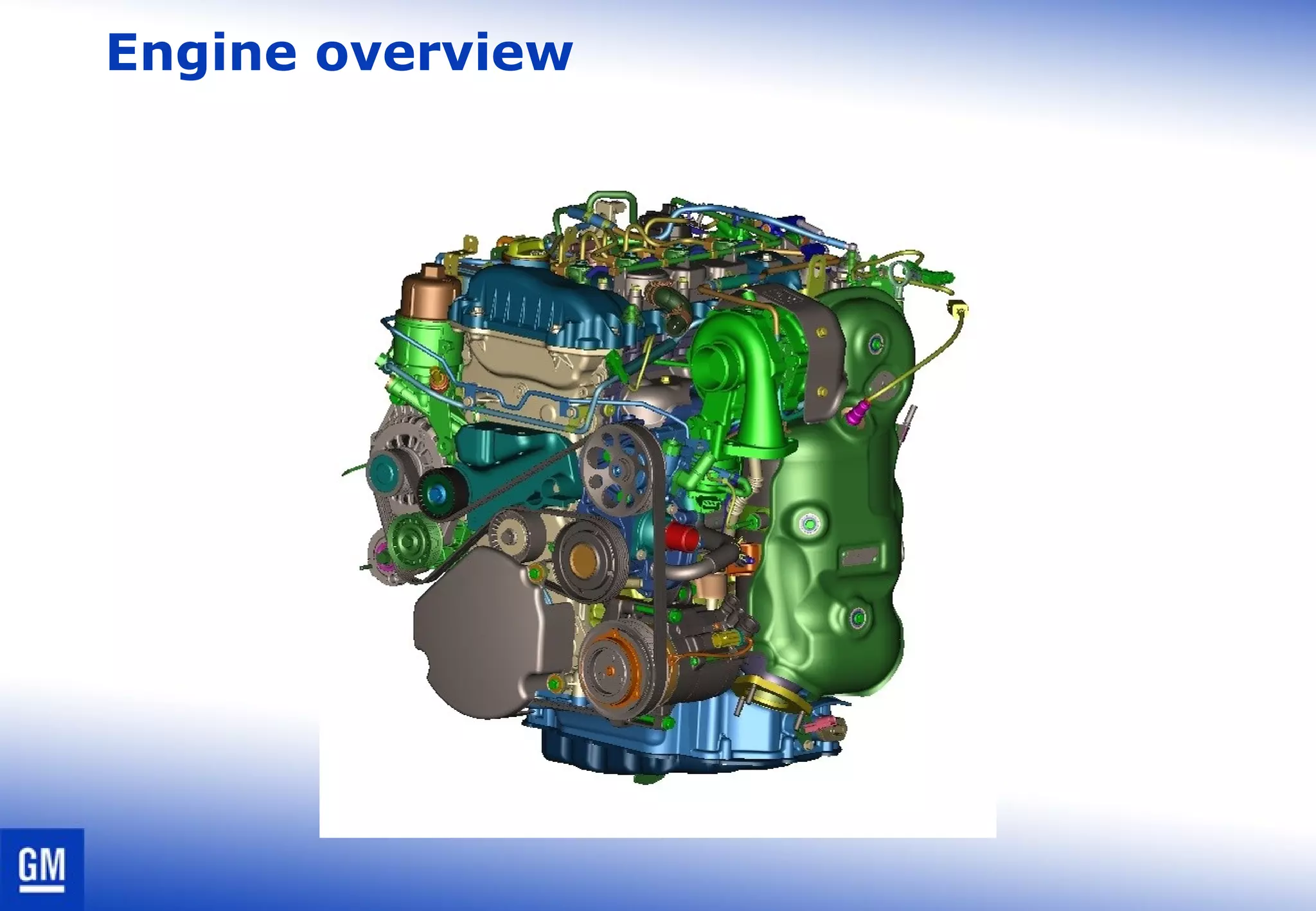

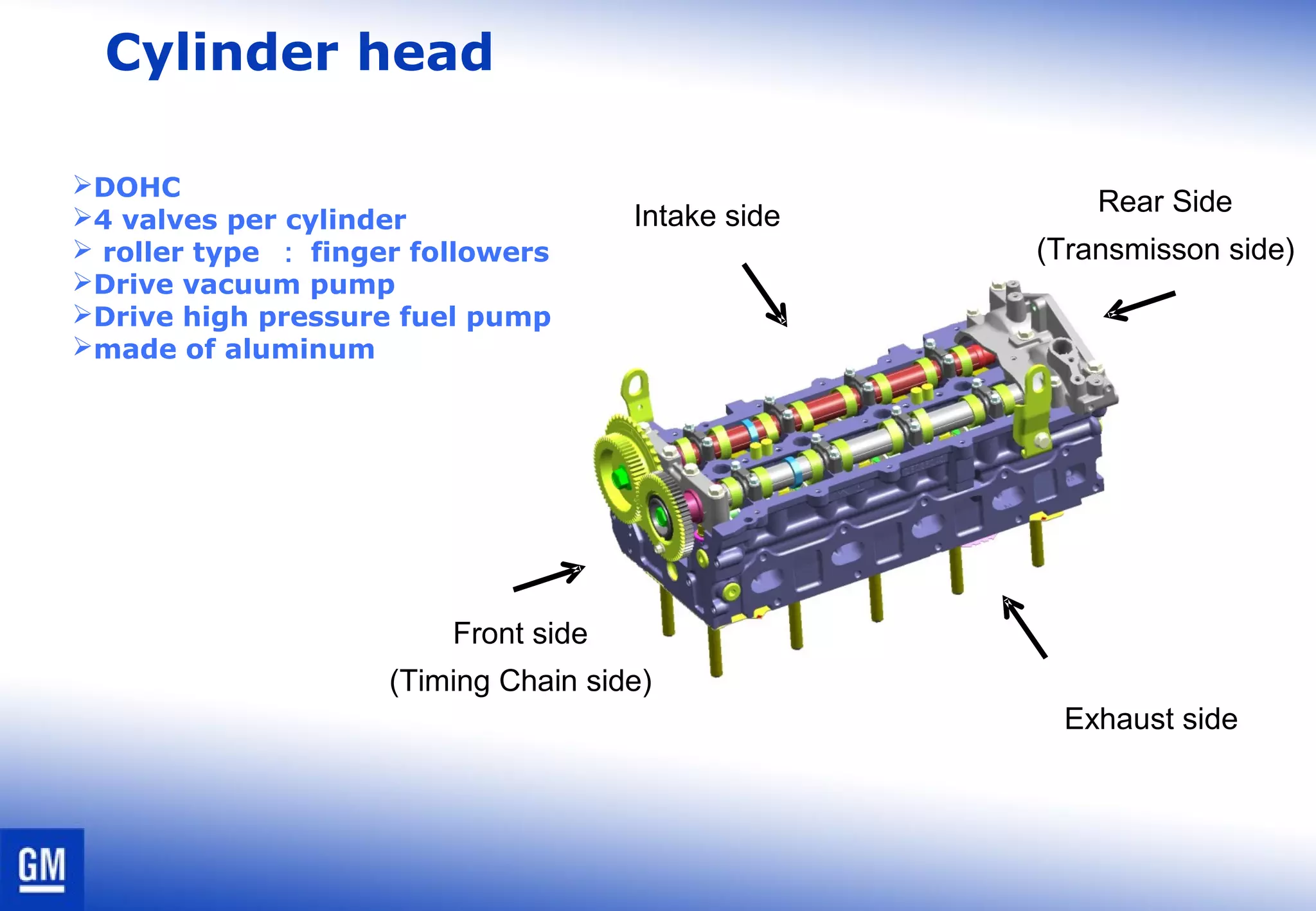

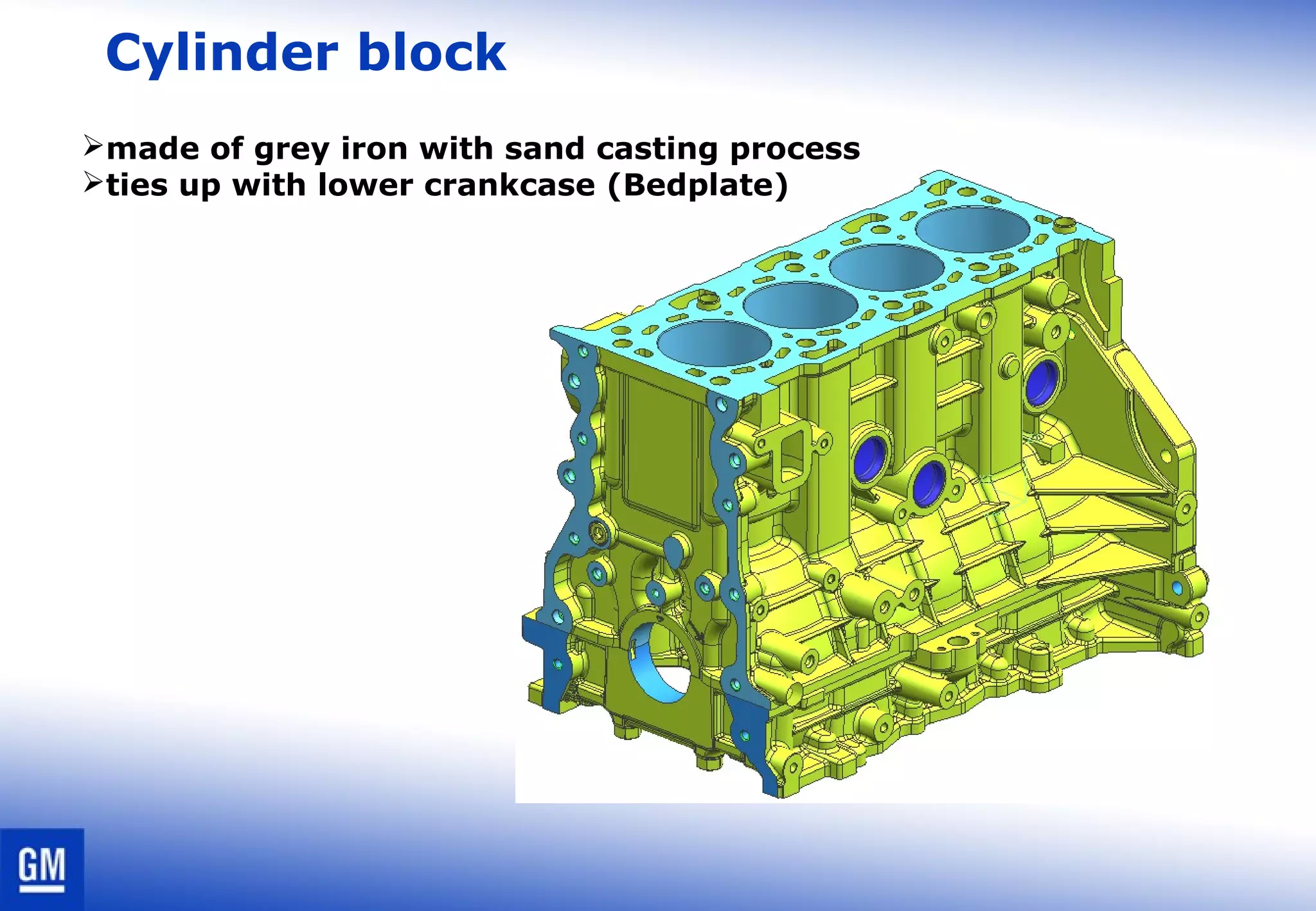

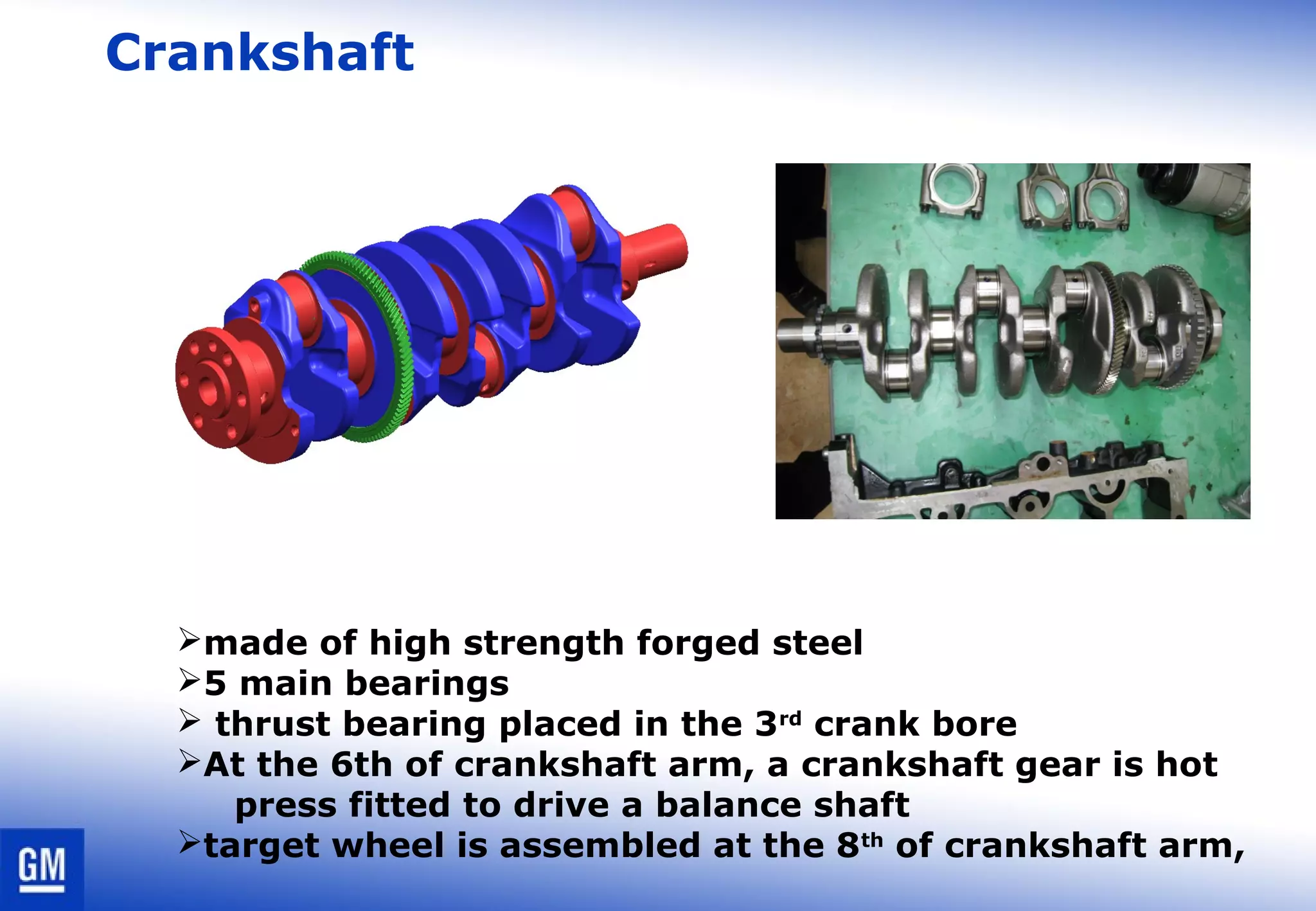

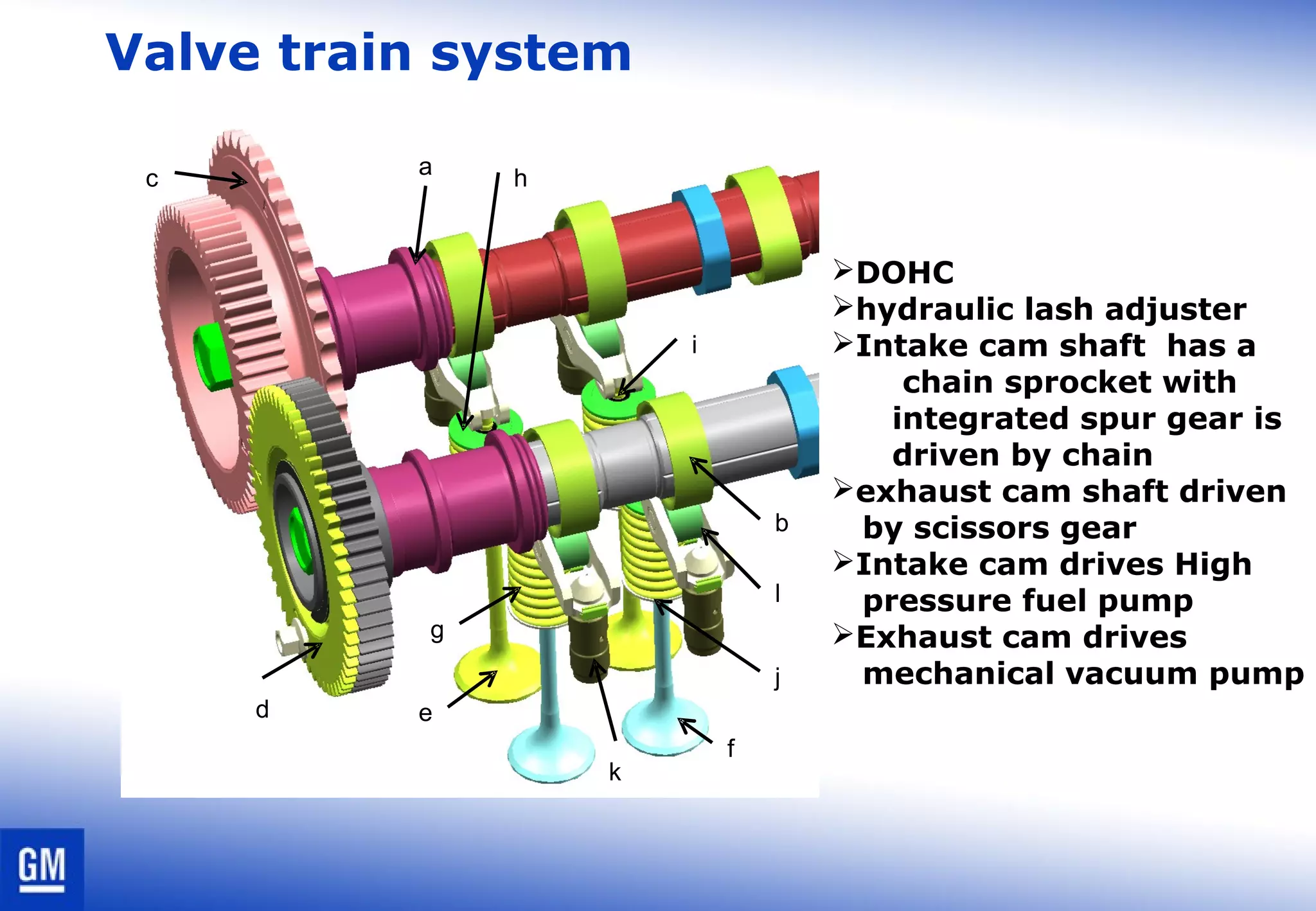

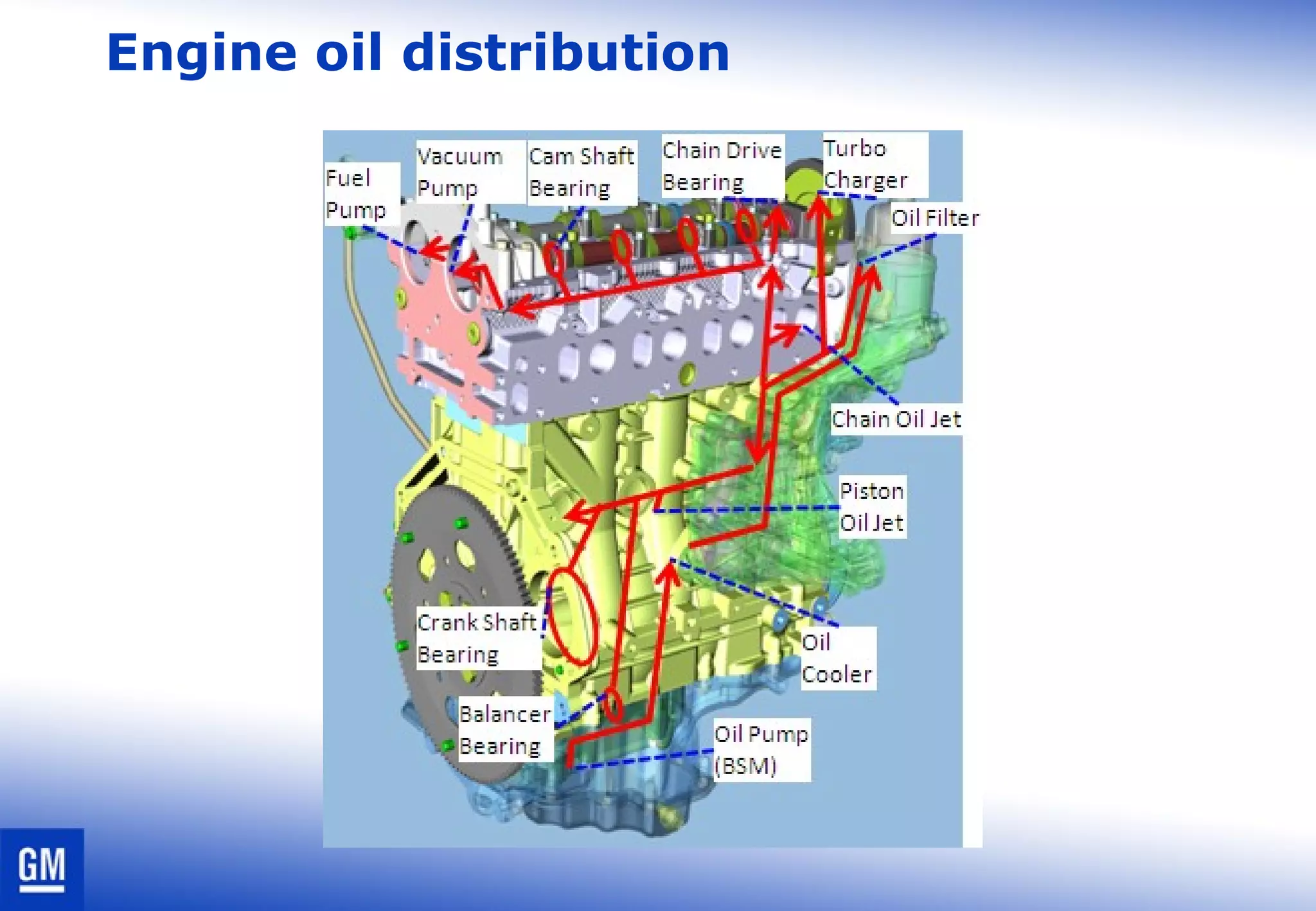

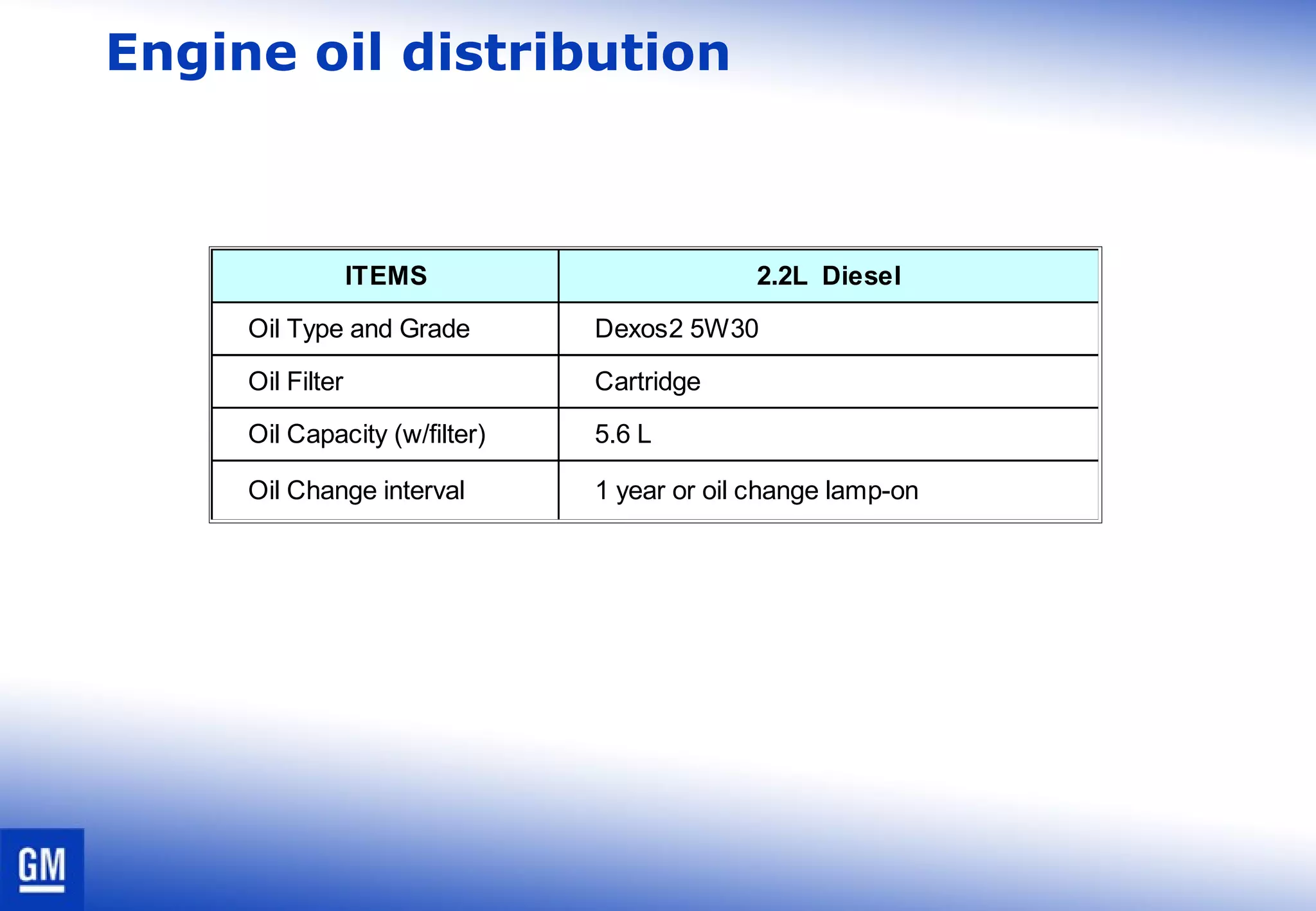

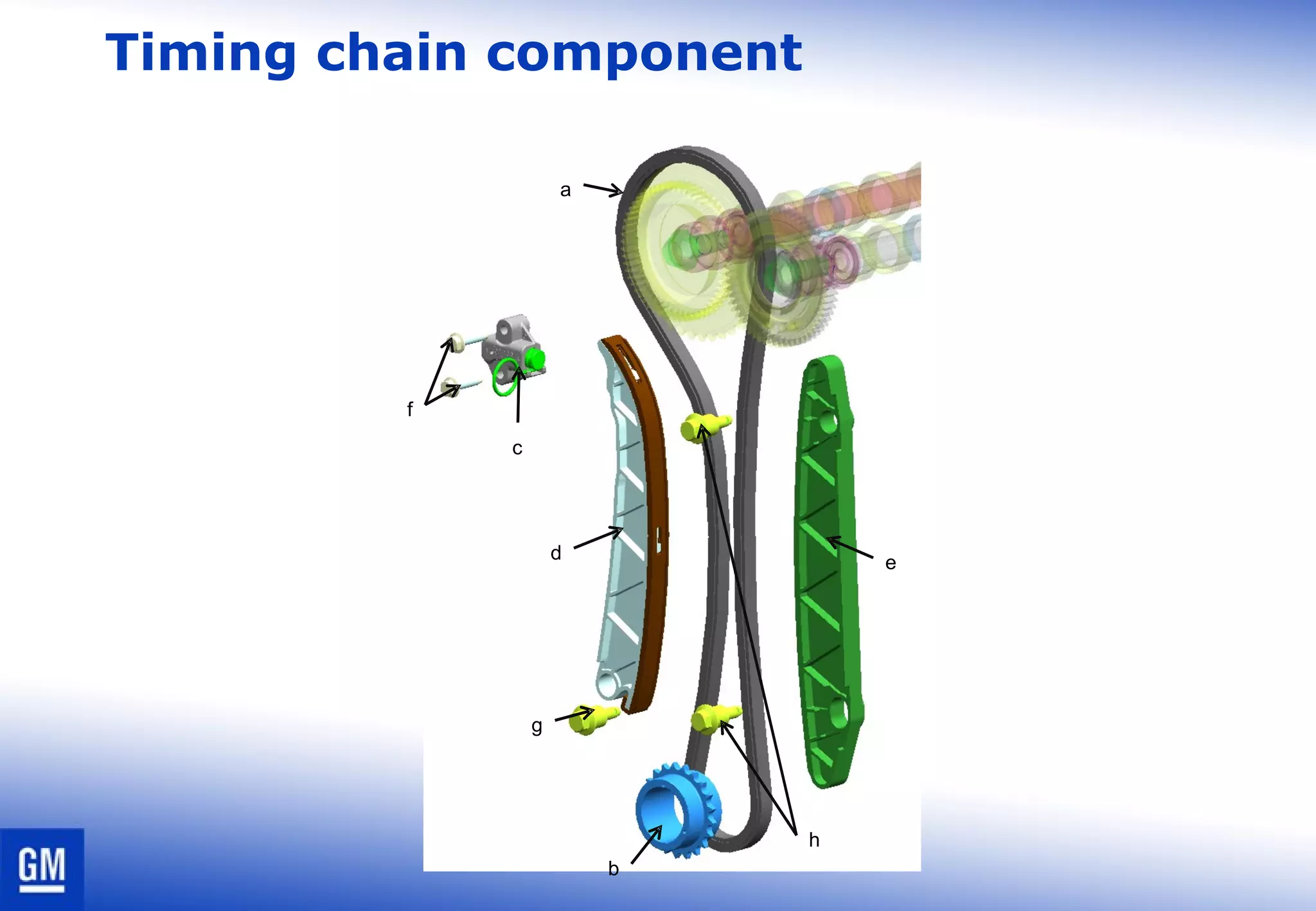

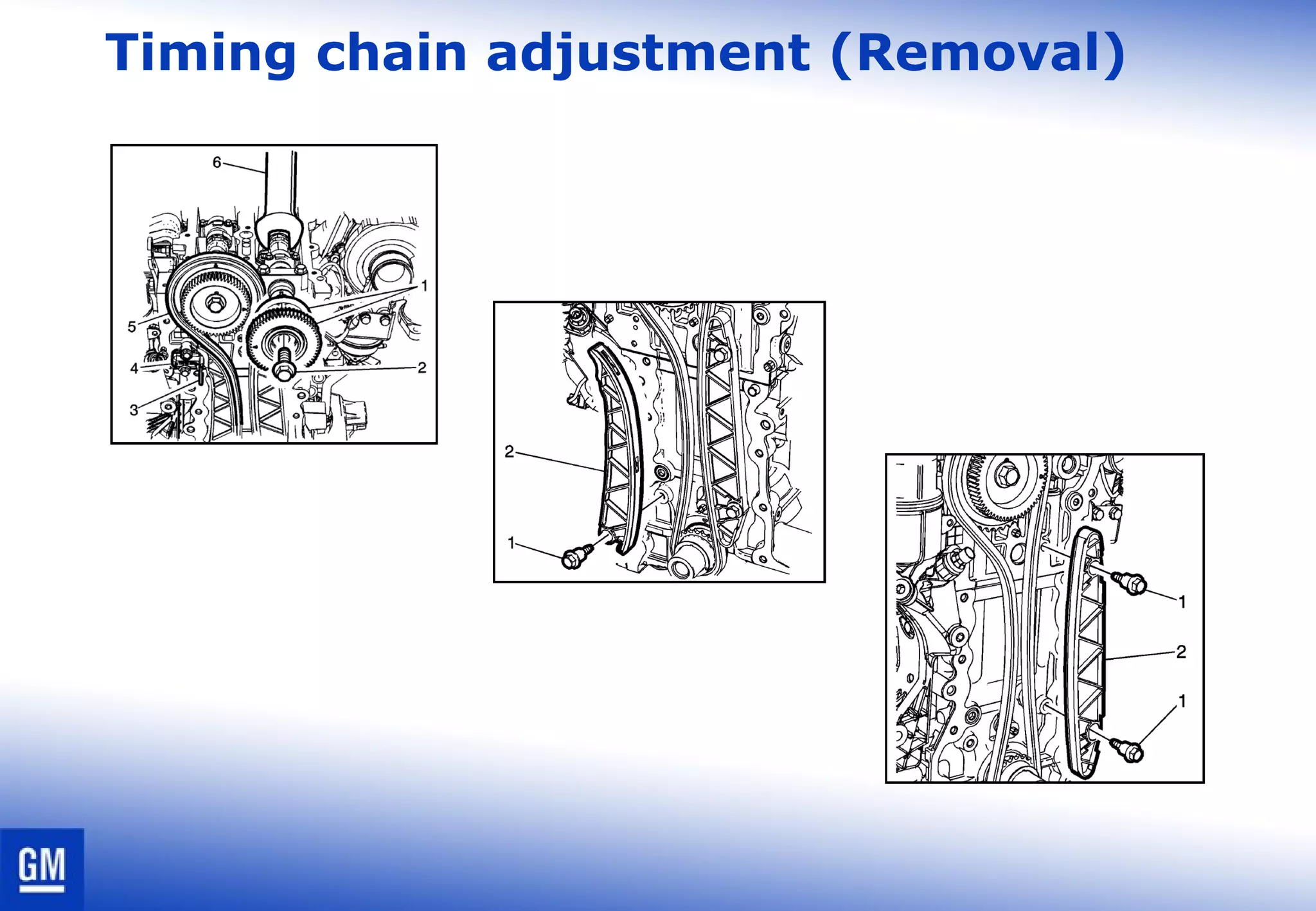

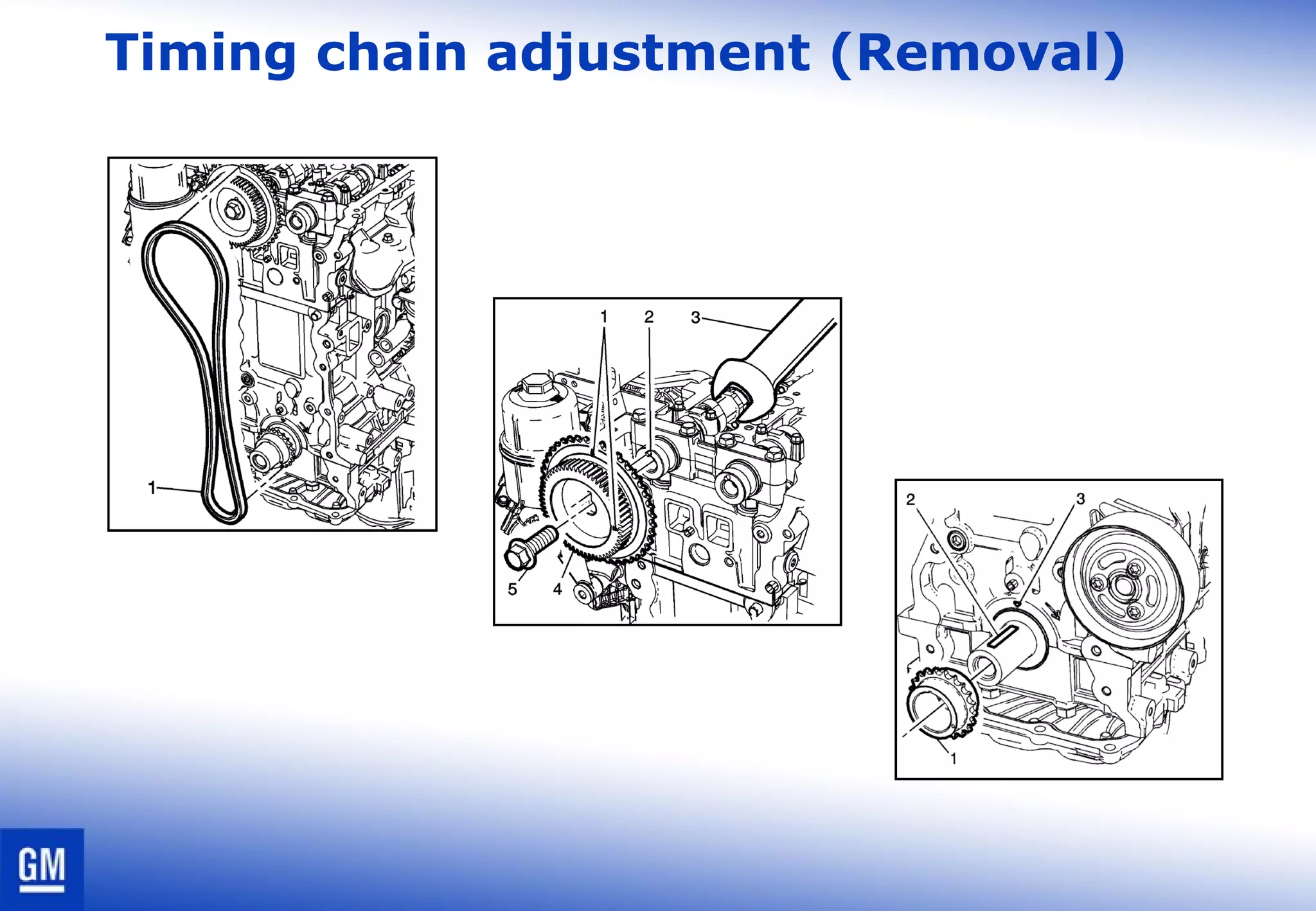

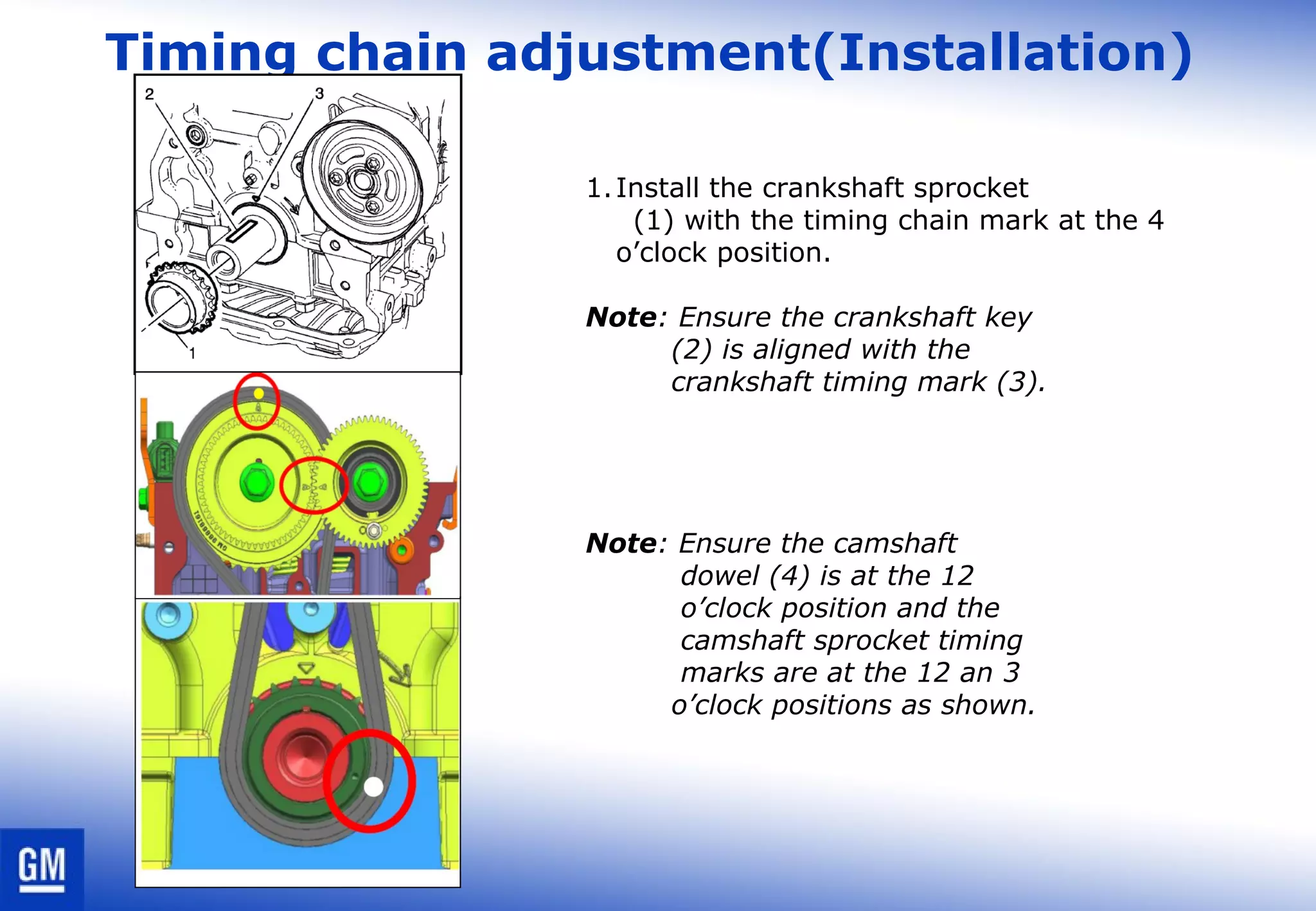

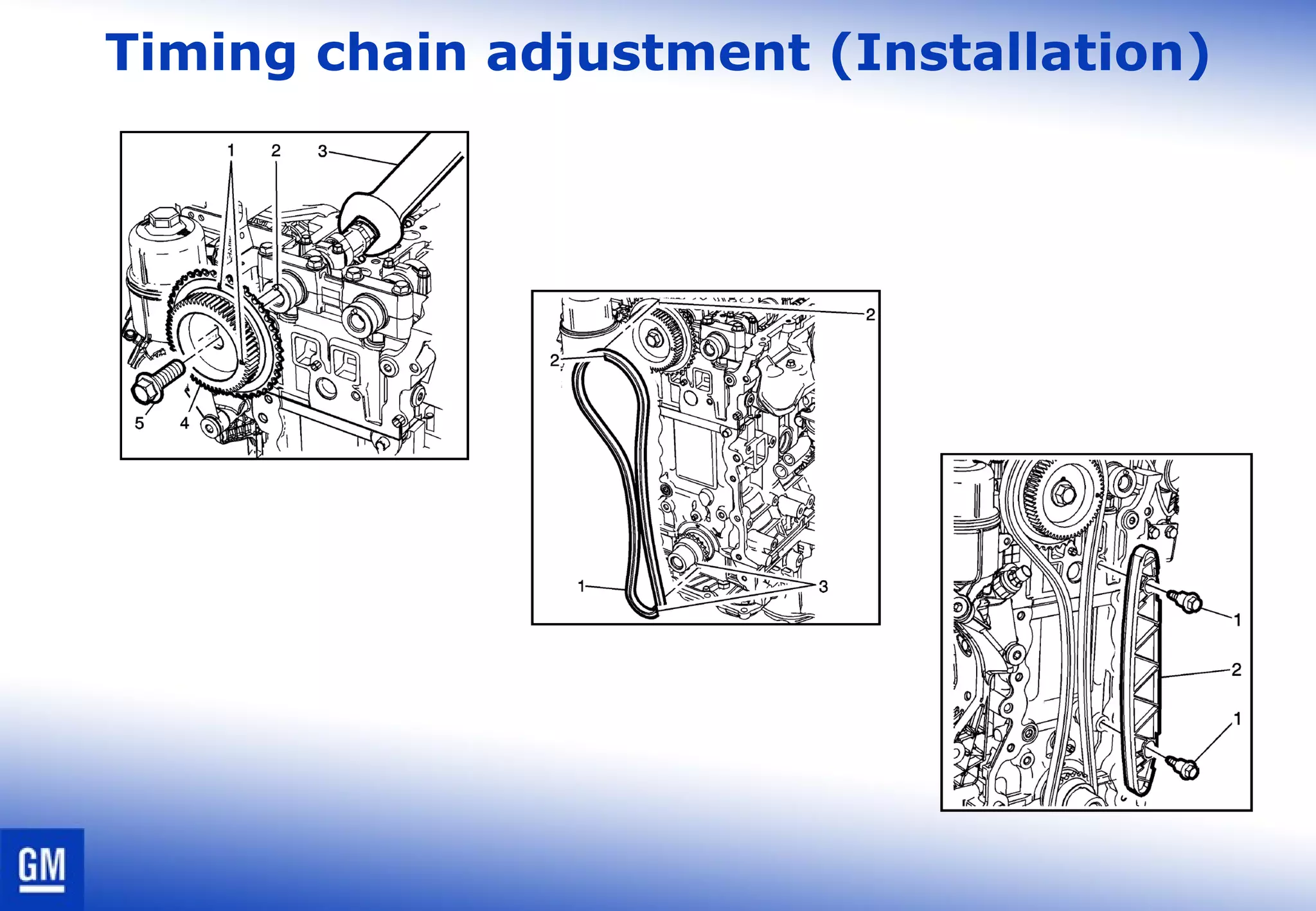

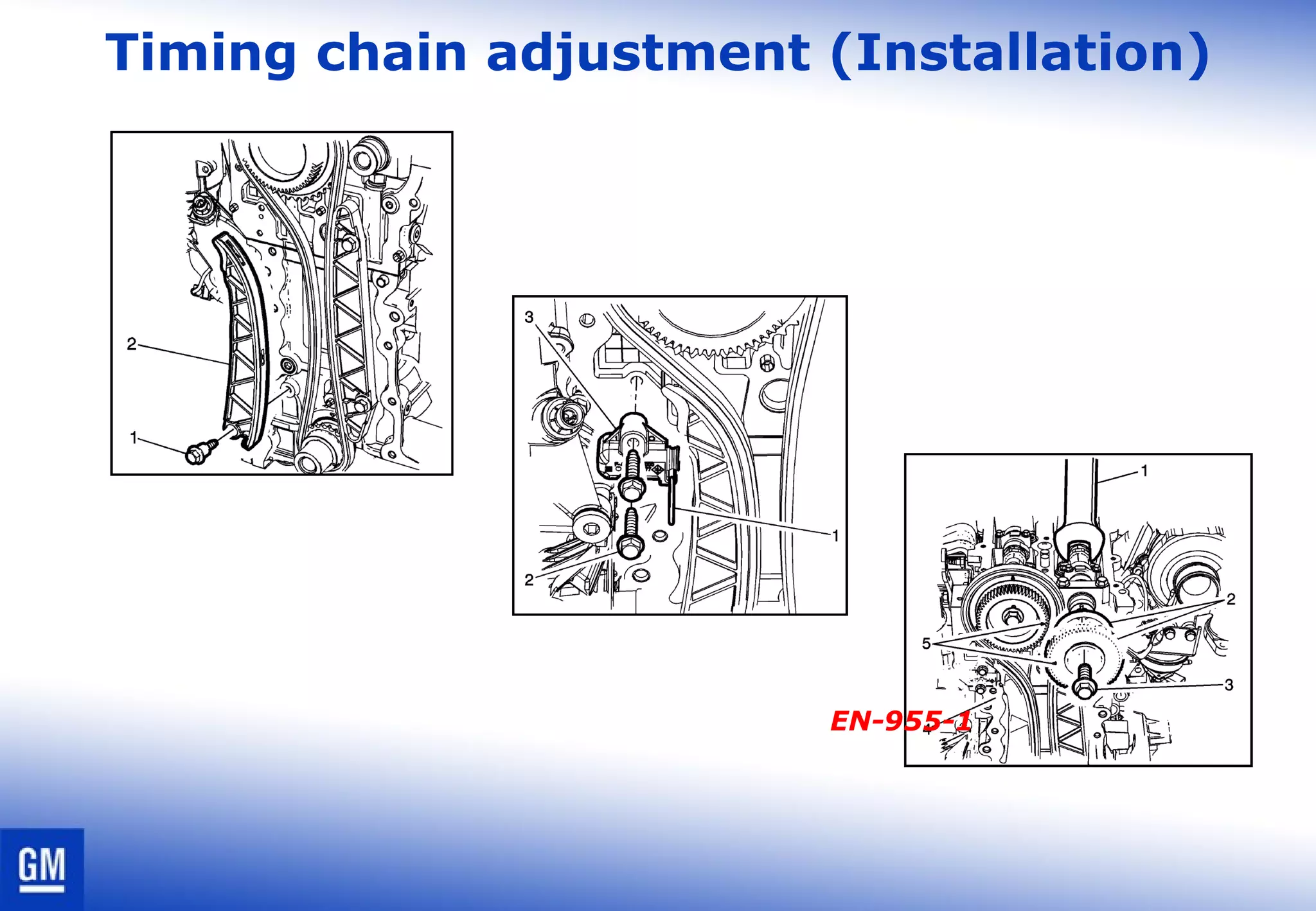

This document provides specifications for a 2.2L DOHC diesel engine. It includes details on the engine components like the cylinder head, block, pistons, crankshaft and camshaft. It also describes the engine systems including the timing chain, fuel delivery common rail system, turbocharger and variable geometry components, cooling system and lubrication system.

![Crankshaft pulley with drive belt

[Crank pulley] [Section View]

Damper rubber

Isolation rubber](https://image.slidesharecdn.com/dieselcommonrailbasic-150111003827-conversion-gate02/75/Diesel-common-rail-basic-25-2048.jpg)