The document discusses the electrolytic recovery of antimony from a natural stibnite ore sample located in Egypt. It describes analyzing the ore's mineralogy and composition. The ore was leached using hydrochloric acid, nitric acid, and sulfuric acid to extract antimony. Studies investigated electrolyte solutions for electrodepositing metallic antimony from the leach solutions. The purity of the deposited antimony metal was found to be over 99%.

![L.... i

ELSEVIER Hydrometallurgy43 (1996) 265-275

hydrometallurgy

Electrolytic recovery of antimony from natural

stibnite ore

Loutfy H. Madkour a, *, Ibrahim A. Salem b

a Chemistry Department, Faculty of Science, Tanta University, Tanta, Egypt

b Geology Department, Faculty of Science, Tanta University, Tanta, Egypt

Received l0 November 1995;accepted 6 December 1995

Abstract

Stibnite ore at Wadi Abu Quraiya, situated in the central Eastern Desert of Egypt has been

subjected to petrographical, mineralogical, infrared, X-ray diffraction, chemical and spectral

analyses. Hydrometallurgical treatment based on leaching with acids, precipitation and electrode-

position of metal values from the ore have been developed. Studies to investigate suitable

electrolytic baths for the cathodic deposition of metallic antimony either directly from the leach

liquor or in the presence of complexing agents have been carded out. The influence of various

factors on the electrodeposition process of the element from its electrolyte solutions is discussed.

Advantages of the flowsheet and various approaches depending on convenient electrolytes for the

deposition of antimony from the stibnite ore have been investigated. The results of spectrophoto-

metric and chemical analyses revealed that the purity of the metal is > 99%.

Keywords: stibnite; leaching; antimony extraction

1. Introduction

The occurrence of stibnite in Egypt is not common. Therefore, the stibnite mineraliza-

tion located at Wadi Abu Quraiya in the central Eastern Desert is considered [1] to be

the most important source of antimony in Egypt. More detailed studies are needed to

evaluate its potential. The stibnite-bearing quartz vein in the area is hosted in grey

granite in the form of a fissure vein deposit striking NE-SW and dipping 50°NW. It is

extends about 180 m in length and has a thickness ranging between 20 and 50 cm. The

stibnite is surrounded and encrusted by antimony oxides. The geology of the Abu

* Correspondingauthor.

0304-386X/96/$15.00 Copyright © 1996Elsevier Science B.V. All rights reserved.

SSDI 0304-386X(95)00113- 1](https://image.slidesharecdn.com/a788afd6-5a16-4798-84d2-30d0f406b638-150423131908-conversion-gate01/75/Hydro-Complete-1-2048.jpg)

![266 L.H.Madkour,1.4.Salem/ Hydrometallurgy43 (1996)265-275

Quraiya area has been studied in a number of reviews and research reports over the

years [2-4]. Most antimony deposits principally occur as either stibnite or native

antimony in siliceous gangue minerals commonly associated with pyrite and are formed

from hydrothermal solutions [5]. Antimony is recovered by reduction of the stibnite with

iron scrap, direct reduction of natural oxide ores and also from lead base battery scrap

metal. Antimony metal finds extensive industrial applications in the preparation of

hardening alloys for lead, pyrotechnics and semiconductor technology (99.999% grade).

Electrodeposition of metallic antimony (cathodically) might be possible from suitable

electrolyte solutions [6-8]. The aim of the present work was to develop a simple and

rapid method for the electrolytic extraction of antimony metal from stibnite, through

acid leaching and the use of complexing agents.

2. Experimental

2.1. Sampling

A total of 10 surface samples were collected along two traverses crossing the

stibnite-bearing quartz vein. Samples were split, crushed and then ground to pass 100

mesh (0.15 mm). The ground samples were analysed for the quantitative determination

of some major and trace elements. Mineralised stibnite ore was crushed to 100% minus

1.0 mm.

2.2. Chemical and spectral analyses

Spectrographic analysis of the ore sample was carried out at the Geology and

Prospecting Institute, Moscow, Russia. Ore mineralogical studies using polarized and

reflected light microscopy, scanning electron microscopy, X-ray diffraction and infrared

spectroscopic analysis were carried out on the stibnite ore sample in the Central

Laboratory at Tanta University, Egypt.

2.3. Leaching methods

Three different direct leaching agents were used for treatment of the stibnite ore:

Mixture of hydrochloric and tartaric acids: A sample of 1 g of the ore was

decomposed by boiling in 25 ml concentrated hydrochloric acid and 25 ml (20%)

tartaric acid until the mineral was completely decomposed. The insoluble residue was

removed by filtration and washed with a 0.5% tartaric acid solution in 5% HC1.

Mixture of nitric and tartaric acids: 20 ml (20%) tartaric acid was poured over a 0.5

g sample of the ore followed by 20 ml of concentrated HNO3 acid and the mixture

allowed to stand for 12 h at room temperature, followed by heating on a water bath for 3

h, until the sample had been completely decomposed. The insoluble residue was

separated by filtration and washed with a 0.3% tartaric acid solution in 2% nitric acid.

Hot concentrated sulphuric acid: The decomposition was carried out in a small

conical flask covered with a short-stem funnel; 20 ml of concentrated H2SO4 was](https://image.slidesharecdn.com/a788afd6-5a16-4798-84d2-30d0f406b638-150423131908-conversion-gate01/85/Hydro-Complete-2-320.jpg)

![L.H.Madkour,1.,4.Salem/Hydrometallurgy43 (1996)265-275 267

poured over a 0.5 g sample and spread over the bottom of the flask by a rotating motion.

The flask was heated gently at first, the temperature was then gradually raised to boiling

point. The decomposition was complete when the dark-coloured ore sample disappeared

and the residue was white. After cooling, the mixture was carefully diluted with about

100 ml H20 added in small portions. A small amount of tartaric acid was added to the

solution to avoid the hydrolysis of antimony and tin in the mineral. The solution was

boiled for about 30 min to dissolve the sulphates of iron and non-ferrous metals

completely. The insoluble residue was filtered and washed well with 1% H2SO4

solution.

2.4. Preparation of antimony complex salt ore electrolytes

Antimony exists in the leach liquor as trichloride, which forms antimony oxychloride

with water. A standard solution of antimony oxychloride (SbOC1) was prepared and its

concentration determined [9]. For each experiment 0.35-0.90 g antimony chloride in

solution was electrolysed in the presence of the appropriate quantity of a complexing

agent with constant agitation. The total volume of the electrolyte was 100 ml.

2.5. Analytical methods

X-ray diffraction analyses were carried out using a PW 1840 Phillips diffractometer

with CuK~ radiation (hl.5418). Infrared absorption analysis was done using a Perkin

Elmer 683 infrared spectrophotometer; the potassium bromide pellet method was used.

These analyses were carried out at the Central Laboratory, Tanta University, Egypt.

2.6. Apparatus and working procedures for electrolysis

The electrolytic cell design and general experimental procedure were the same as

described elsewhere [10-14]. The cathode was a platinum sheet with an area of 10 cm2.

The electrolyte temperature was maintained at 25 + I°C with constant stirring in all

experiments. All chemicals used were of Analar quality and were used without further

purification.

3. Results and discussion

3.1. Characteristics of stibnite ore sample

Mineralogically, the stibnite vein lode has a simple mineral assemblage and consists

exclusively of quartz and stibnite. Tetrahedrite, pyrite, chalcopyrite and sphalerite are

sparse and present as inclusions in the quartz and stibnite. Cervantite is a secondary

mineral formed from the oxidation of stibnite. Goethite also occurs. Quartz is the

predominant gangue mineral and occurs as subhedral to anhedral crystals ranging from

0.2 to 0.6 mm in diameter. Quartz may be colourless or stained yellow due to

replacement by goethite. It is frequently fractured, brecciated and exhibits wavy

extinction.](https://image.slidesharecdn.com/a788afd6-5a16-4798-84d2-30d0f406b638-150423131908-conversion-gate01/85/Hydro-Complete-3-320.jpg)

![270 L.H.Madkour,I.A. Salem/Hydrometallurgy43 (1996)265-275

Sti bnite

N

N N J~ .O

q~' m ill .D i~ N Ii~J j3 ..C)

m N O ~

m m

6B 60 50 40 30 20 14

Fig. 3. X-raydiffractionpatternfor separatedcrystalsof stibnite.

The infrared absorption spectrum of the sample of stibnite ore is represented

graphically in Fig. 4. Stibnite was detected by 2 moderate to weak absorption bands at

675 cm- ~ and 460 cm- ~. The band at about 1070 cm- ~ is characteristic of quartz.

3.2. Acid leaching treatment of sfibnite ore sample

3.2.1. Hydrochloric acid leaching

Stibnite dissolved very slowly and incompletely when boiled with concentrated

hydrochloric acid with the evolution of hydrogen sulphide, but decomposition with a

mixture of concentrated hydrochloric and tartaric acid has been recommended [15]. The

reaction is accompanied by intensive evolution of gases, so the oxidation was performed

in a conical flask or a high beaker, covered by a watch glass. Antimony ores are

decomposed easily by bromine solvents [16]. Whereas direct oxidation of sulphidic

Stibnite

I I I I 8100 I I I I I I

4000 3500 2S00 I 1400 1000 600

WAVENUMBE R ( C f61 )

Fig. 4. Infraredabsorptionspectrumforseparatedcrystalsofstibnite.

I

200](https://image.slidesharecdn.com/a788afd6-5a16-4798-84d2-30d0f406b638-150423131908-conversion-gate01/85/Hydro-Complete-6-320.jpg)

![L.H. Madkour, LA. Salem / Hydrometallurgy 43 (1996) 265-275 271

sulphur to sulphate takes place at room temperature, the method is not used generally to

determine the main components, but it has been found useful for the determination of

trace elements.

3.2.2. Nitric acid leaching

Nitric acid, dilute as well as concentrated, is a powerful solvent for a number of

minerals, especially for sulphides [10,11]. The acid alone is used only in a limited

number of cases; mixtures with other mineral acids are more frequently used. Being a

strong oxidant, it oxidises sulphides to sulphates; antimony sulphosalts are converted to

the respective metal acids of the higher oxidation states, which are generally only poorly

soluble. Sulphur in sulphide ores must be oxidised at room temperature, with the dilute

acid only. The metal acids precipitated adsorb a large amount of foreign ions in an

acidic medium. Therefore, hydrolysis must be suppressed by adding other mineral acids

or complexing agents.

A mixture of nitric and tartaric acid [17] was used in the present work to decompose

the stibnite ore sample. This method was proposed by Hampe [18] and has found wide

application in the analysis of minerals containing antimony and tin, as well as of

metallurgical products. Thus, tartaric acid is used mainly for the analysis of antimony

ores. After dissolving the ore in concentrated acids, tartaric acid is added to the solution

before dilution with water, to avoid the hydrolysis of antimony; tartaric acid alone

dissolves some oxidized antimony minerals.

3.2.3. Sulphuric acid leaching

Concentrated H2SO 4 is an efficient solvent for the decomposition of sulphide and

oxide antimony ores [19] and gives good recovery when used alone or, more frequently,

in mixtures with other solvents.

Hot concentrated H2SO 4 was employed here for the decomposition of the stibnite ore

sample in the presence of small amounts of tartaric acid. Antimony and arsenic were

easily precipitated from sulphate solution as sulphides, in a form easy to filter. Boiling

with concentrated H2SO4 at the same time also causes complete dehydration of silicic

acid, which is thus converted to a suitable form for quantitative precipitation. Any

antimony trisulphate Sb2(SO4)3 formed decomposes in water. The efficiency of the

various reagents for leaching and treatment of the stibnite ore are compared in Table 3.

3.3. Electrodeposition of antimony

The effects of concentration of antimony ions in the leach liquor, the nature of the

complexing agents, the current density, temperature and the presence of other impurities

were studied. The optimum conditions for the electrodeposition of metallic antimony

from its mother liquor and the various electrolyte solutions are summarized in Table 3.

Characterization of the solid complexes was investigated using elemental analysis,

conductance, magnetic susceptibility and spectroscopic methods. For each experiment,

the results of chemical and spectrophotometric analyses indicate that the purity of the

electrodeposited metal was 99%.](https://image.slidesharecdn.com/a788afd6-5a16-4798-84d2-30d0f406b638-150423131908-conversion-gate01/85/Hydro-Complete-7-320.jpg)

![L.H. Madkour, 1.4. Salem/Hydrometallurgy 43 (1996)265-275 273

Effect of the concentration of Sb ions: Silvery white, adherent deposition was found

to take place in the concentration range >_0.05 M. At very low concentrations of

antimony ions in electrolyte solution (< 0.05 M solution) no deposition takes place,

owing to the very small concentration of ions in solution. The results show that there is a

critical concentration at which one obtains the maximum rate of deposition.

Effect of complexing agents: Cathodic deposition takes place in the absence of

complexing agents, so the effect of the complexing agent [20] in rendering differences

between the reversible potential of antimony and its standard potential is important.

Table 3 shows the existence of the antimony complex species prepared from the leach

liquor chloride. These complex species in solution have recently been identified by

conductometric titrations using 0.001 M antimonyl chloride with 0.01 M complexing

solution. The measured conductance of the solution was plotted against the volume of

complexing agent (NaF, NaNO3, CH3COONa, C6HsO7Na 3, C4HsO4Na or NH4C1)

added. The conductance curves showed breaks at certain molar metal/complexing

agents ratios, corresponding to the formation of 2:1 antimony complexes with all ligands

used. Experiments using an ion-exchange resin technique [21,22] confirmed the presence

of positively charged complex species. The formation of the cationic complexes

indicated above has previously been reported [8]. Furthermore, complexing agents have

an important role in ensuring the presence of a sufficiently small SbO ÷ ion concentra-

tion at the cathode, suitable for the reduction and the smooth deposition of the metal.

Table 3 shows the most suitable concentrations of Sb ions and complexing agent

required in order to reach high current efficiency.

Effect of temperature: Increasing the temperature of the solution from 25°C to 60°C

favours the cathodic deposition of the metal. This is due to the improved mass transport

[23] of complex species towards the platinum cathode.

Effect of current density: At low current density (less than 100 A/m 2) only a thin

layer of antimony was deposited, owing to the low rate of cathodic reactions occurring

at the cathode. At higher current density (> 1000 A/m 2) the deposit formed was not

adherent. This is attributed to the rapid discharge of hydrogen ion.

Current efficiency: The decrease in the cathodic current efficiency (Q%) is related to

several factors, including a decrease in hydrogen overvoltage on certain areas of the

antimony electrodeposition [24], or an increase in the evolution of hydrogen; the

presence of other metal cations during the deposition process and the possible alteration

in the growth morphology of the antimony deposited by impurities originally present in

the leach liquor. The lower current efficiency values are attributed to the platinum plate

used as the cathode and the dilute solution of antimony [25] in the electrolyte.

3.4. Kinetics and mechanism

The rate of deposition (using electrolyses with controlled electric potential) increases

slowly at first and then increases sharply to attain a maximum value at 40 rain and then

decreases sharply. This may be attributed to the lower concentration of metal ion around

the cathode and the rapid formation of Sb powder in the bottom of the cathode

compartment. The cathodic deposition of antimony proceeds at first by the formation of

the corresponding complex species, followed by migration of the complex species

towards the platinum cathode and, finally, deposition of the antimony.](https://image.slidesharecdn.com/a788afd6-5a16-4798-84d2-30d0f406b638-150423131908-conversion-gate01/85/Hydro-Complete-9-320.jpg)

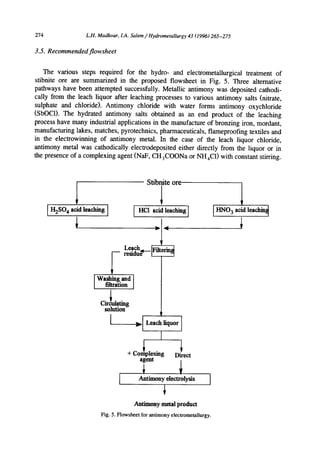

![L.H. Madkour, LA. Salem/Hydrometallurgy 43 (1996)265-275 275

It can be noticed that the reagents used either in the leaching treatment or in the

electrolysis process, such as hydrochloric acid, nitric acid, sulphuric acid and tartaric

acid, are relatively cheap and common reagents. The advantages of this flowsheet are

concerned also with the low temperature used for both the leaching and electrodeposi-

tion processes and, hence, the low energy consumption.

References

[1] Salem, I.A., The occurrence of stibnite mineralization at Wadi Abu Quraiya, Central Eastern Desert,

Egypt. Mineralogical Society of Egypt Conf. (1989).

[2] Moustafa, G.A., et al., Geology of Gebel El-ineigi District. Geol. Surv. Cairo, Egypt (1954).

[3] El-Ramly, M.F., et al., The Basement complex in the Central Eastern Desert, between latitudes 24° 30'

and 25° 40'. Geol. Surv. Cairo, 8 (1960): 35.

[4] Saber, A.H, et al., The intrusive complexes of Central Eastern Desert of Egypt. Ann. Geol. Surv. Egypt,

1 (1976): 53-73.

[5] Jensen, M.L., et al., Economic Mineral Deposits. Wiley, New York (1981), p. 953.

[6] del Boca, M.C., HeN. Chim. Acta, 16 (1933): 565.

[7] Emeleus, H.J. and Anderson, J.S., Modem Aspects of Inorganic Chemistry. Routledge and Kegan Paul,

London (1952), p. 470.

[8] Fouda, A.S., et al., Bull. Electrochem., 6(7) (1990): 677-678.

[9] Vogel, A.I., Quantitative Inorganic Analysis. Longmans, London, 3rd ed. (1968) p. 503.

[10] Afifi, S.E. and Madkour, L.H., Electrolytic deposition of metal values from Umm. Samiuki polymetal

ore. Egypt. J. Chem., 27(3) (1984): 275-296.

[11] Madkour, L.H., J. Chem. Tech. Biotecb., 35(A3) (1985): 108-114.

[12] Madkour, L.H., et al., J. Electroanal. Chem., 199 (1986): 207.

[13] Madkour, L.H., J. Erzmetal, 48 (1995): 104.

[14] Madkour, L.H., Indian J. Chem. Technol., 2 (1995): 343.

[15] Groenewald, I.D., Analyst, 89 (1964): 140.

[16] Allen, W.S., et al., Ind. Eng. Chem. (1919), 11, 46.

[17] Rubeska, I., et al., Anal. Chim. Acta, 37 (1967): 27.

[18] Hampe, W., Chem. Z., 15: (t891): 443.

[19] Zakharov, V.A., et al., Zavodskaya Lab., 28: (1962): 27.

[20] Fouda, A.S., J. Electroanal. Chem., 114 (1980): 83.

[21] Fouda, A.S., J. Electroanal. Chem., 110 (1980): 357.

[22] Elsemongy, M.M., et al., J. Electroanal. Chem., 76 (1977): 376.

[23] Fouda, A.S., et al., Indian J. Technol., 20 (1982): 139.

[24] Kerby, R.C. and Ingraham, I.R., Can. Mines Bur. Res. Rep., 35 (1971): 243.

[25] Fouda, A.S., et al., J. Electroanal. Chem., 124 (1981): 301.](https://image.slidesharecdn.com/a788afd6-5a16-4798-84d2-30d0f406b638-150423131908-conversion-gate01/85/Hydro-Complete-11-320.jpg)