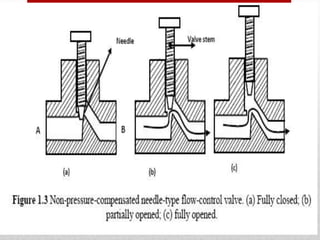

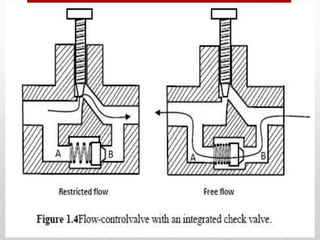

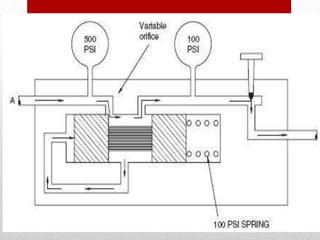

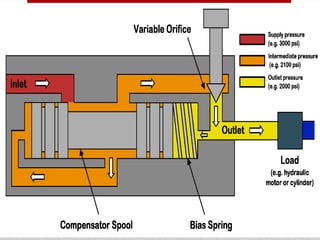

This document discusses flow-control valves used in hydraulic circuits. It defines flow-control valves as valves that control the rate of fluid flow. The document classifies flow-control valves into two types: non-pressure compensated and pressure compensated. Non-pressure compensated valves rely on a constant pressure drop across an orifice to control flow, while pressure compensated valves use a spring-loaded compensator spool to adjust the orifice size to maintain a constant flow rate despite changing pressures. Pressure compensated valves are needed when system pressures are variable or motoring speeds must be precise.