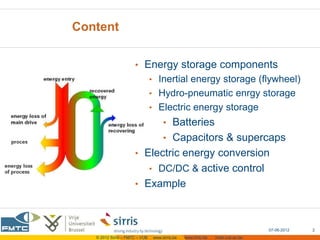

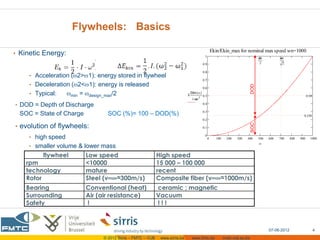

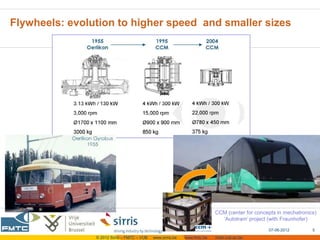

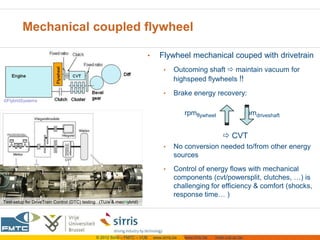

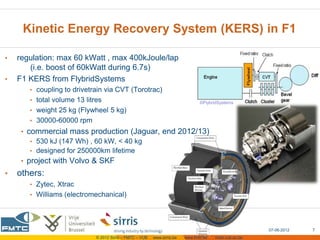

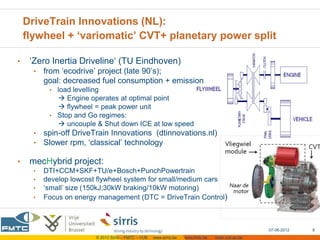

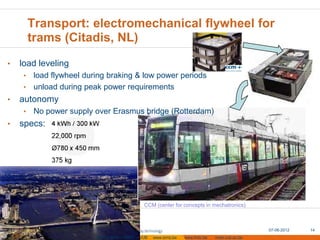

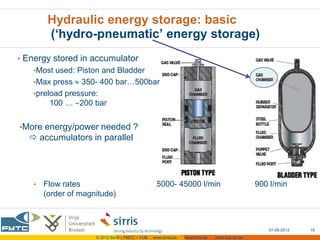

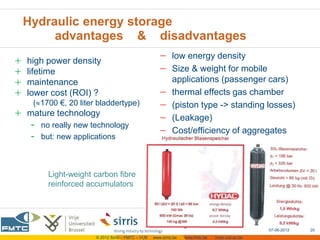

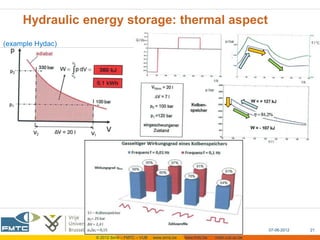

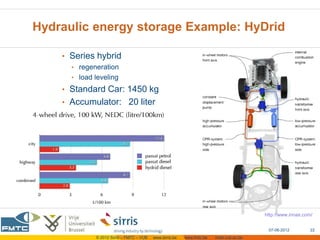

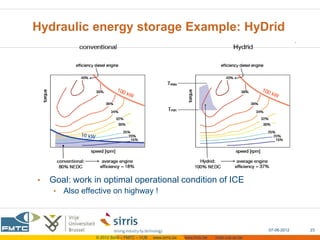

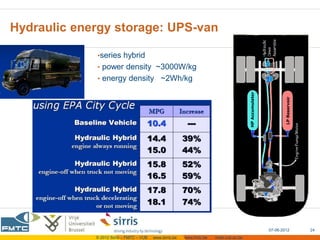

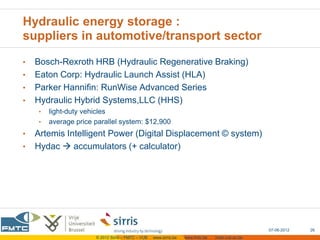

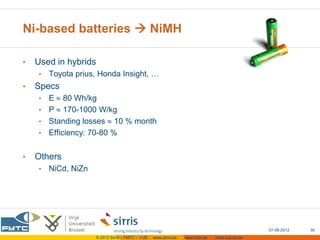

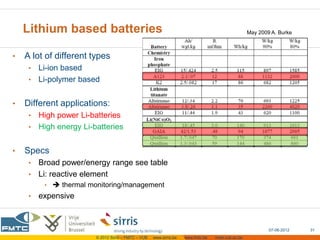

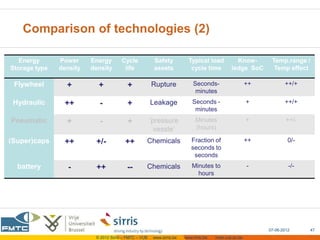

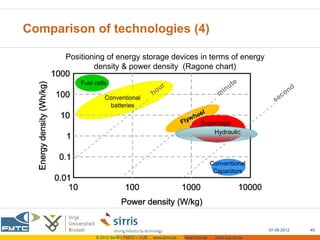

This document summarizes different energy storage technologies for hybridization, including flywheels, hydraulic energy storage, and batteries. It provides details on kinetic energy storage using flywheels, including the basics of flywheel energy storage and examples of applications in vehicles like Formula 1 cars. It also discusses hydraulic energy storage, including the basic operating principles and examples of applications in vehicles and UPS systems. Advantages and disadvantages of both flywheel and hydraulic energy storage technologies are presented.