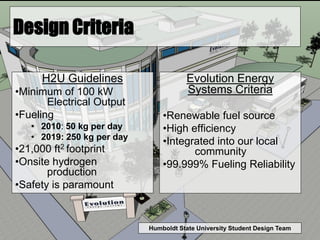

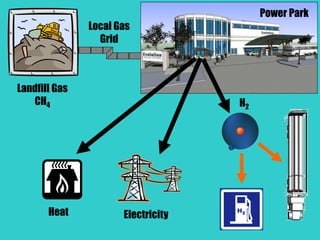

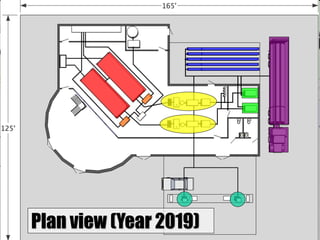

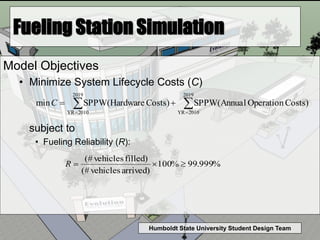

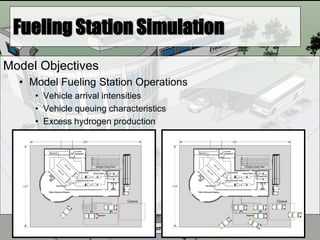

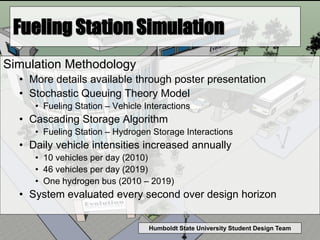

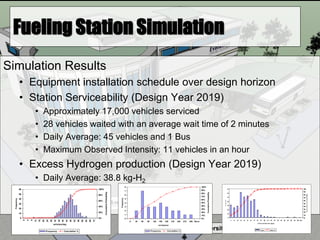

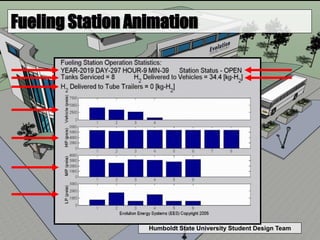

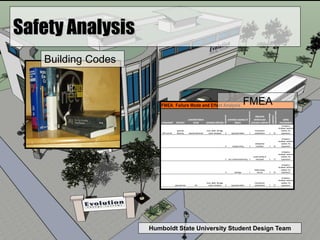

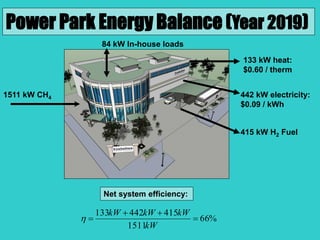

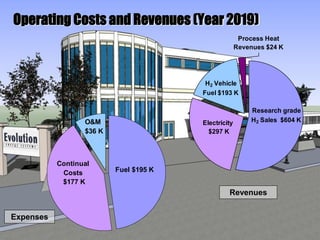

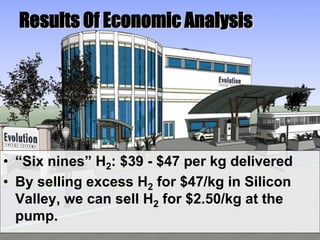

The Humboldt State University Student Design Team proposes a hydrogen power park to provide renewable energy. The power park would produce hydrogen fuel, electricity, and heat. It would use landfill gas from a local landfill as a renewable fuel source. The team's design criteria includes producing at least 100 kW of electricity and meeting increasing hydrogen fueling demands of 50 kg per day in 2010 and 250 kg per day in 2019. The team developed a simulation model to optimize the power park's design for reliability, serviceability, and economics. The simulation results showed the power park could reliably meet fueling demands and produce excess hydrogen for sale. An economic analysis found the power park could sell hydrogen for $39-47 per kg while offering $2