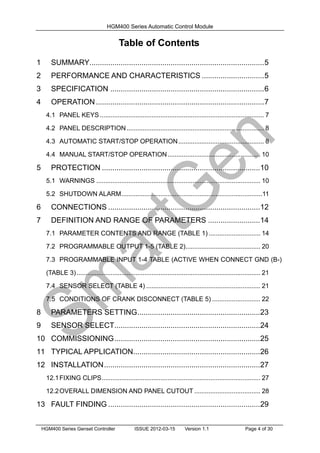

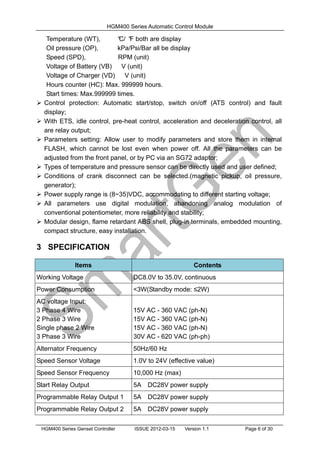

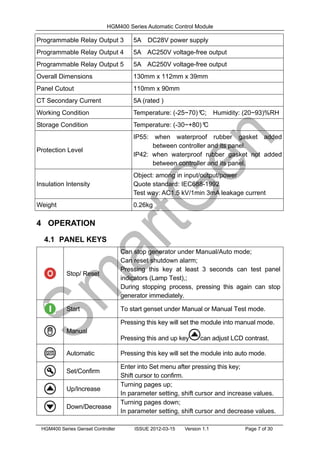

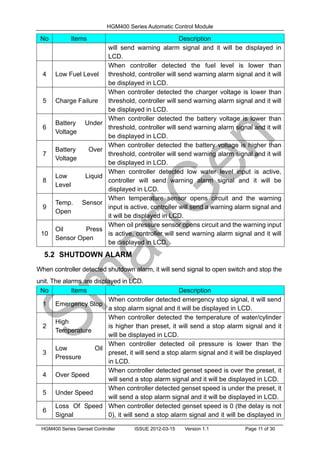

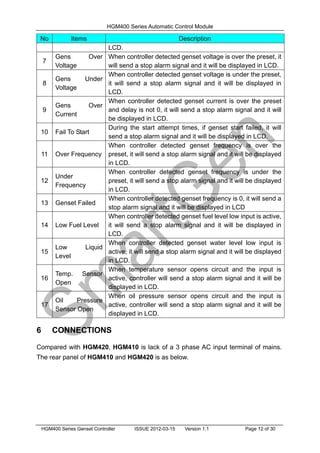

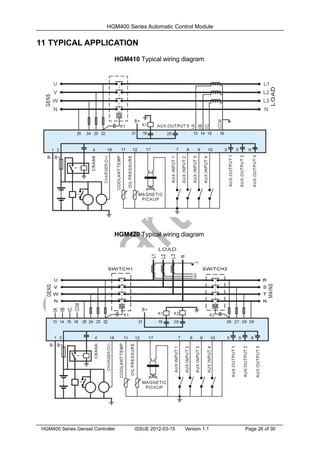

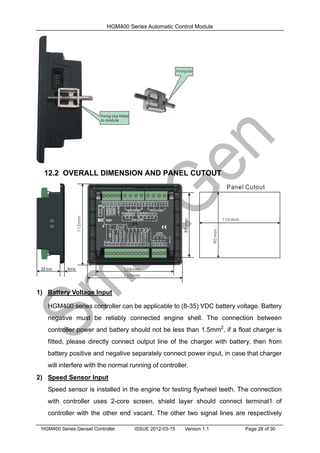

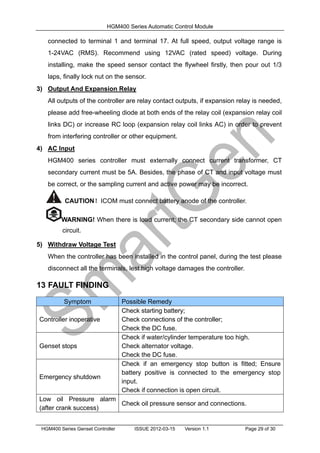

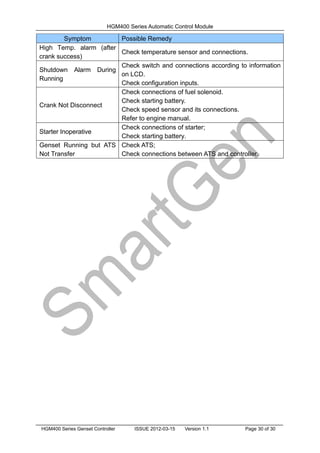

This document provides the user manual for the HGM400 series automatic genset controller. It describes the controller's performance, specifications, operation, protections, connections, parameter definitions and settings, sensor selection, commissioning, typical applications, and installation. The HGM400 series controllers can automatically start and stop generators, monitor engine parameters, control protections, and be configured through the front panel or via PC connection. They are suitable for automatic genset control systems in various applications.