More Related Content

PPTX

PDF

PPTX

PPTX

Quantitativetechniqueformanagerialdecisionlinearprogramming 090725035417-phpa... PPT

PPT

PPTX

Optimization using lp.pptx PPT

Mba i ot unit-1.1_linear programming Similar to heizer_om12_MB final.pptx Linear Programming

PPT

1 resource optimization 2 PPTX

PPTX

PPTX

Evans_Analytics2e_ppt_13.pptxbbbbbbbbbbb PDF

Quantitative Methods - section 6.pdf in business administration PPT

modB.ppt modA.ppt operation management slide for business PPT

LinearProgramming-Graphicalnethod.ppt PPTX

lec 9.pptxZXXXXxzZXZxZxZxZXZXZXZxZxZxzxzXZXZX PPTX

Chapter 3 linear programming PPTX

PPTX

Linear programming - Model formulation, Graphical Method PDF

PPTX

Unit 3 Lesson 1 - Linear Programming Lecture.pptx PPT

Mathematics For Management CHAPTER THREE PART I.PPT PPTX

chapter 2: LINEAR PROGRAMMING FORMULATION AND SOLUTION PPTX

04 Jan 30 Class SCM 416 (LP1).pptx PPTX

Graphical Solution in LPP along with graphs and formula PPT

linear programming model formulation and graphical solution PPTX

linear programing is the model that can be PPTX

introduction to Operation Research Recently uploaded

PDF

Ultra Map Section II Multifaceted Second Edition.pdf PDF

Top Five Trends Shaping RCM in 2026 - Revenue Cycle Resources-HUB PDF

Andria Sergio - Known For Her Accuracy And Professionalism PDF

AnyDesk, The Leading Remote Desktop Software | AnyDesk, o software líder em a... PDF

What Is the Fastest Way to Buy Facebook Accounts.pdf PDF

Safe Ways to Purchase Gmail Accounts (PVA & Aged) for Your Team.pdf DOCX

Buy Verified Paypal Accounts_ A Safely Complete Guide Usa.docx PDF

Certification Training Course On New Skills Across Globe PDF

Fraud Warning MOALA WALLET Exchange Exposed PDF

Comments on Ultra Map Section II Multifaceted Second Edition.pdf PDF

Stablecoins beyond narrow banking - Lombard Notes PDF

LA Building Inspections & Compliance offers DOCX

Important Asset To know About Buying Old or Aged Verified Bybit Accounts.docx PDF

Lessons on Branding from the Team Behind the World's Biggest Brands DOCX

What Are Telegram Accounts and Why Are They Important for Global Communicatio... PDF

Kirill Klip GEM Royalty TNR Gold Presentation PDF

rf_mccaffrey_stocksforthelongrun_revisited_online.v2 (1).pdf PDF

Serhii Herasymov: Expert sales in outsource companies: your technical special... PDF

Step-by-Step 17 Guide to Purchasing Verified PayPal Account.pdf PDF

Best Place to Learn Old or Aged Verified Paysera Accounts in WWW.pdf heizer_om12_MB final.pptx Linear Programming

- 1.

MB - 1

Copyright© 2017 Pearson Education, Inc.

PowerPoint presentation to accompany

Heizer, Render, Munson

Operations Management, Twelfth Edition

Principles of Operations Management, Tenth Edition

PowerPoint slides by Jeff Heyl

Linear Programming

B

MODULE

- 2.

MB - 2

Copyright© 2017 Pearson Education, Inc.

Outline

► Why Use Linear Programming?

► Requirements of a Linear

Programming Problem

► Formulating Linear Programming

Problems

► Graphical Solution to a Linear

Programming Problem

- 3.

MB - 3

Copyright© 2017 Pearson Education, Inc.

Outline – Continued

▶ Sensitivity Analysis

▶ Solving Minimization Problems

▶ Linear Programming Applications

▶ The Simplex Method of LP

▶ Integer and Binary Variables

- 4.

MB - 4

Copyright© 2017 Pearson Education, Inc.

Learning Objectives

When you complete this chapter you

should be able to:

B.1 Formulate linear programming

models, including an objective

function and constraints

B.2 Graphically solve an LP problem

with the iso-profit line method

B.3 Graphically solve an LP problem

with the corner-point method

- 5.

MB - 5

Copyright© 2017 Pearson Education, Inc.

When you complete this chapter you

should be able to:

Learning Objectives

B.4 Interpret sensitivity analysis and

shadow prices

B.5 Construct and solve a minimization

problem

B.6 Formulate production-mix, diet, and

labor scheduling problems

- 6.

MB - 6

Copyright© 2017 Pearson Education, Inc.

Why Use Linear Programming?

▶ A mathematical technique to help plan

and make decisions relative to the

trade-offs necessary to allocate

resources

▶ Will find the minimum or maximum

value of the objective

▶ Guarantees the optimal solution to the

model formulated

- 7.

MB - 7

Copyright© 2017 Pearson Education, Inc.

LP Applications

1. Scheduling school buses to minimize total

distance traveled

2. Allocating police patrol units to high crime

areas in order to minimize response time

to 911 calls

3. Scheduling tellers at banks so that needs

are met during each hour of the day while

minimizing the total cost of labor

- 8.

MB - 8

Copyright© 2017 Pearson Education, Inc.

LP Applications

4. Selecting the product mix in a factory to

make best use of machine- and labor-

hours available while maximizing the

firm’s profit

5. Picking blends of raw materials in feed

mills to produce finished feed

combinations at minimum cost

6. Determining the distribution system that

will minimize total shipping cost

- 9.

MB - 9

Copyright© 2017 Pearson Education, Inc.

LP Applications

7. Developing a production schedule that will

satisfy future demands for a firm’s product

and at the same time minimize total

production and inventory costs

8. Allocating space for a

tenant mix in a new

shopping mall so as

to maximize revenues

to the leasing

company

- 10.

MB - 10

Copyright© 2017 Pearson Education, Inc.

Requirements of an

LP Problem

1. LP problems seek to maximize or

minimize some quantity (usually

profit or cost) expressed as an

objective function

2. The presence of restrictions, or

constraints, limits the degree to

which we can pursue our objective

- 11.

MB - 11

Copyright© 2017 Pearson Education, Inc.

Requirements of an

LP Problem

3. There must be alternative courses of

action to choose from

4. The objective and constraints in

linear programming problems must

be expressed in terms of linear

equations or inequalities

- 12.

MB - 12

Copyright© 2017 Pearson Education, Inc.

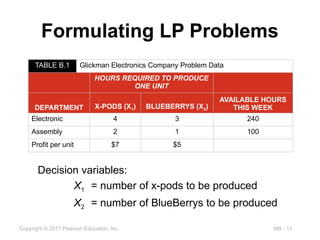

Formulating LP Problems

▶ Glickman Electronics Example

► Two products

1. Glickman x-pod

2. Glickman BlueBerry

► Determine the mix of products that will

produce the maximum profit

- 13.

MB - 13

Copyright© 2017 Pearson Education, Inc.

Formulating LP Problems

Decision variables:

X1 = number of x-pods to be produced

X2 = number of BlueBerrys to be produced

TABLE B.1 Glickman Electronics Company Problem Data

HOURS REQUIRED TO PRODUCE

ONE UNIT

DEPARTMENT X-PODS (X1) BLUEBERRYS (X2)

AVAILABLE HOURS

THIS WEEK

Electronic 4 3 240

Assembly 2 1 100

Profit per unit $7 $5

- 14.

MB - 14

Copyright© 2017 Pearson Education, Inc.

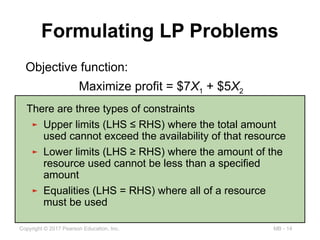

Formulating LP Problems

Objective function:

Maximize profit = $7X1 + $5X2

There are three types of constraints

► Upper limits (LHS ≤ RHS) where the total amount

used cannot exceed the availability of that resource

► Lower limits (LHS ≥ RHS) where the amount of the

resource used cannot be less than a specified

amount

► Equalities (LHS = RHS) where all of a resource

must be used

- 15.

MB - 15

Copyright© 2017 Pearson Education, Inc.

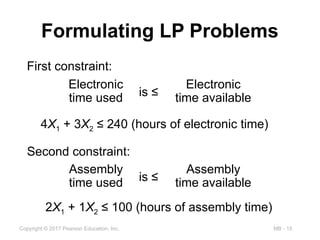

Formulating LP Problems

Second constraint:

2X1 + 1X2 ≤ 100 (hours of assembly time)

Assembly

time available

Assembly

time used is ≤

First constraint:

4X1 + 3X2 ≤ 240 (hours of electronic time)

Electronic

time available

Electronic

time used is ≤

- 16.

MB - 16

Copyright© 2017 Pearson Education, Inc.

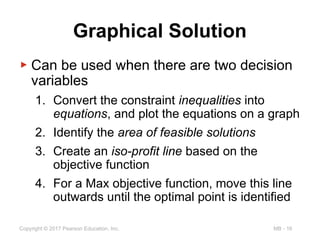

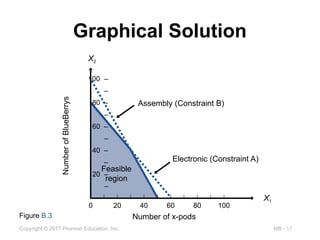

Graphical Solution

▶ Can be used when there are two decision

variables

1. Convert the constraint inequalities into

equations, and plot the equations on a graph

2. Identify the area of feasible solutions

3. Create an iso-profit line based on the

objective function

4. For a Max objective function, move this line

outwards until the optimal point is identified

- 17.

MB - 17

Copyright© 2017 Pearson Education, Inc.

Graphical Solution

100 –

–

80 –

–

60 –

–

40 –

–

20 –

–

–

| | | | | | | | | | |

0 20 40 60 80 100

Number

of

BlueBerrys

Number of x-pods

X1

X2

Assembly (Constraint B)

Electronic (Constraint A)

Feasible

region

Figure B.3

- 18.

MB - 18

Copyright© 2017 Pearson Education, Inc.

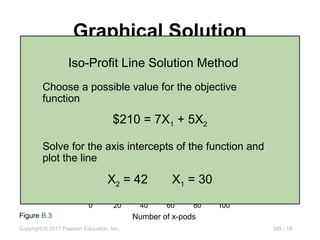

Graphical Solution

100 –

–

80 –

–

60 –

–

40 –

–

20 –

–

–

| | | | | | | | | | |

0 20 40 60 80 100

Number

of

BlueBerrys

Number of x-pods

X1

X2

Assembly (Constraint B)

Electronic (Constraint A)

Feasible

region

Figure B.3

Iso-Profit Line Solution Method

Choose a possible value for the objective

function

$210 = 7X1 + 5X2

Solve for the axis intercepts of the function and

plot the line

X2 = 42 X1 = 30

- 19.

MB - 19

Copyright© 2017 Pearson Education, Inc.

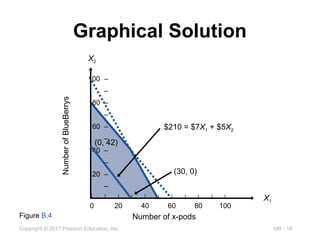

Graphical Solution

100 –

–

80 –

–

60 –

–

40 –

–

20 –

–

–

| | | | | | | | | | |

0 20 40 60 80 100

Number

of

BlueBerrys

Number of x-pods

X1

X2

Figure B.4

(0, 42)

(30, 0)

$210 = $7X1 + $5X2

- 20.

MB - 20

Copyright© 2017 Pearson Education, Inc.

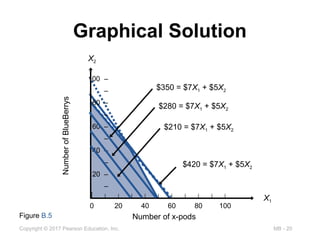

Graphical Solution

100 –

–

80 –

–

60 –

–

40 –

–

20 –

–

–

| | | | | | | | | | |

0 20 40 60 80 100

Number

of

BlueBerrys

Number of x-pods

X1

X2

Figure B.5

$210 = $7X1 + $5X2

$420 = $7X1 + $5X2

$350 = $7X1 + $5X2

$280 = $7X1 + $5X2

- 21.

MB - 21

Copyright© 2017 Pearson Education, Inc.

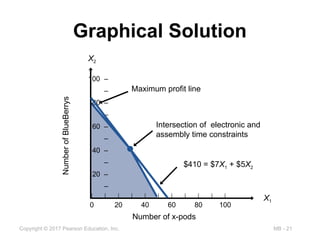

Graphical Solution

100 –

–

80 –

–

60 –

–

40 –

–

20 –

–

–

| | | | | | | | | | |

0 20 40 60 80 100

Number

of

BlueBerrys

Number of x-pods

X1

X2

$410 = $7X1 + $5X2

Maximum profit line

Intersection of electronic and

assembly time constraints

- 22.

MB - 22

Copyright© 2017 Pearson Education, Inc.

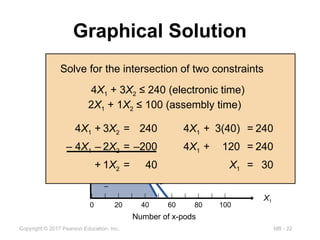

Graphical Solution

100 –

–

80 –

–

60 –

–

40 –

–

20 –

–

–

| | | | | | | | | | |

0 20 40 60 80 100

Number

of

BlueBerrys

Number of x-pods

X1

X2

$410 = $7X1 + $5X2

Maximum profit line

Intersection of electronic and

assembly time constraints

2

3

Solve for the intersection of two constraints

2X1 + 1X2 ≤ 100 (assembly time)

4X1 + 3X2 ≤ 240 (electronic time)

4X1 + 3X2 = 240

– 4X1 – 2X2 = –200

+ 1X2 = 40

4X1 + 3(40) = 240

4X1 + 120 = 240

X1 = 30

- 23.

MB - 23

Copyright© 2017 Pearson Education, Inc.

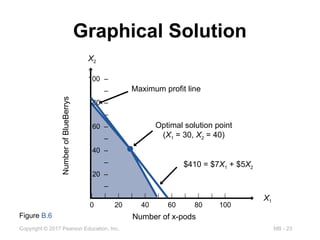

Graphical Solution

100 –

–

80 –

–

60 –

–

40 –

–

20 –

–

–

| | | | | | | | | | |

0 20 40 60 80 100

Number

of

BlueBerrys

Number of x-pods

X1

X2

Figure B.6

$410 = $7X1 + $5X2

Maximum profit line

Optimal solution point

(X1 = 30, X2 = 40)

- 24.

MB - 24

Copyright© 2017 Pearson Education, Inc.

100 –

–

80 –

–

60 –

–

40 –

–

20 –

–

–

| | | | | | | | | | |

0 20 40 60 80 100

Number

of

BlueBerrys

Number of x-pods

X1

X2

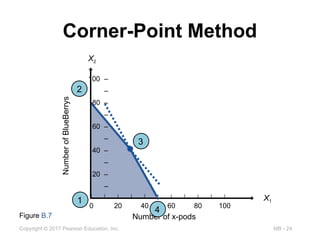

Corner-Point Method

Figure B.7

1

2

3

4

- 25.

MB - 25

Copyright© 2017 Pearson Education, Inc.

100 –

–

80 –

–

60 –

–

40 –

–

20 –

–

–

| | | | | | | | | | |

0 20 40 60 80 100

Number

of

BlueBerrys

Number of x-pods

X1

X2

Corner-Point Method

Figure B.7

1

2

3

4

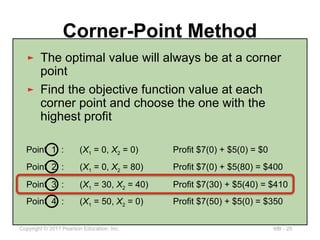

► The optimal value will always be at a corner

point

► Find the objective function value at each

corner point and choose the one with the

highest profit

Point 1 : (X1 = 0, X2 = 0) Profit $7(0) + $5(0) = $0

Point 2 : (X1 = 0, X2 = 80) Profit $7(0) + $5(80) = $400

Point 3 : (X1 = 30, X2 = 40) Profit $7(30) + $5(40) = $410

Point 4 : (X1 = 50, X2 = 0) Profit $7(50) + $5(0) = $350

- 26.

MB - 26

Copyright© 2017 Pearson Education, Inc.

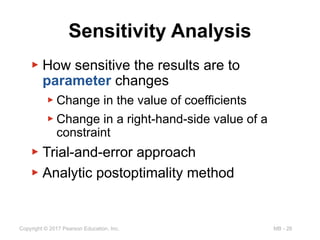

Sensitivity Analysis

▶ How sensitive the results are to

parameter changes

▶ Change in the value of coefficients

▶ Change in a right-hand-side value of a

constraint

▶ Trial-and-error approach

▶ Analytic postoptimality method

- 27.

- 28.

MB - 28

Copyright© 2017 Pearson Education, Inc.

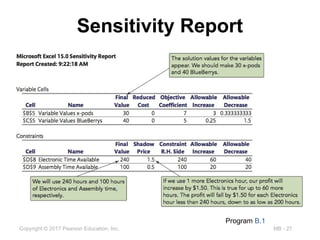

Changes in Resources

▶ The right-hand-side values of constraint

equations may change as resource

availability changes

▶ The shadow price for a constraint is the

improvement in the objective function

value that results from a one-unit

increase in the right-hand side of the

constraint

- 29.

MB - 29

Copyright© 2017 Pearson Education, Inc.

Changes in Resources

▶ Shadow prices are often explained as

answering the question "How much would

you pay for one additional unit of a

resource?"

▶ Shadow prices are only valid over a

particular range of changes in right-hand-

side values

▶ Sensitivity reports provide the upper and

lower limits of this range

- 30.

MB - 30

Copyright© 2017 Pearson Education, Inc.

Sensitivity Analysis

–

100 –

–

80 –

–

60 –

–

40 –

–

20 –

–

–

| | | | | | | | | | |

0 20 40 60 80 100 X1

X2

Figure B.8 (a)

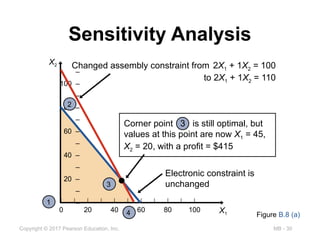

Changed assembly constraint from 2X1 + 1X2 = 100

to 2X1 + 1X2 = 110

Electronic constraint is

unchanged

Corner point 3 is still optimal, but

values at this point are now X1 = 45,

X2 = 20, with a profit = $415

1

2

3

4

- 31.

MB - 31

Copyright© 2017 Pearson Education, Inc.

Sensitivity Analysis

–

100 –

–

80 –

–

60 –

–

40 –

–

20 –

–

–

| | | | | | | | | | |

0 20 40 60 80 100 X1

X2

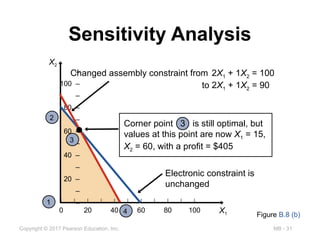

Figure B.8 (b)

Electronic constraint is

unchanged

Corner point 3 is still optimal, but

values at this point are now X1 = 15,

X2 = 60, with a profit = $405

1

2

3

4

Changed assembly constraint from 2X1 + 1X2 = 100

to 2X1 + 1X2 = 90

- 32.

MB - 32

Copyright© 2017 Pearson Education, Inc.

Changes in the

Objective Function

▶ A change in the coefficients in the

objective function may cause a different

corner point to become the optimal

solution

▶ The sensitivity report shows how much

objective function coefficients may

change without changing the optimal

solution point

- 33.

MB - 33

Copyright© 2017 Pearson Education, Inc.

Solving Minimization Problems

▶ Formulated and solved in much the

same way as maximization problems

▶ In the graphical approach an iso-cost

line is used

▶ The objective is to move the iso-cost line

inwards until it reaches the lowest cost

corner point

- 34.

MB - 34

Copyright© 2017 Pearson Education, Inc.

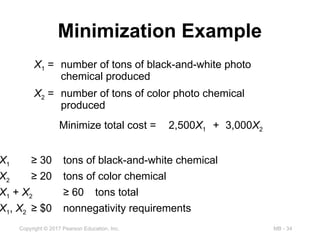

Minimization Example

X1 = number of tons of black-and-white photo

chemical produced

X2 = number of tons of color photo chemical

produced

Minimize total cost = 2,500X1 + 3,000X2

X1 ≥ 30 tons of black-and-white chemical

X2 ≥ 20 tons of color chemical

X1 + X2 ≥ 60 tons total

X1, X2 ≥ $0 nonnegativity requirements

- 35.

MB - 35

Copyright© 2017 Pearson Education, Inc.

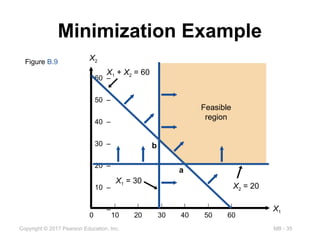

Minimization Example

Figure B.9

60 –

50 –

40 –

30 –

20 –

10 –

–

| | | | | | |

0 10 20 30 40 50 60

X1

X2

Feasible

region

X1 = 30

X2 = 20

X1 + X2 = 60

b

a

- 36.

MB - 36

Copyright© 2017 Pearson Education, Inc.

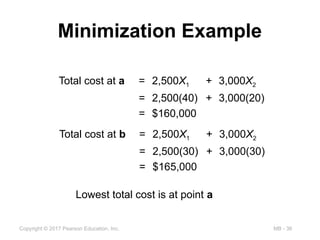

Minimization Example

Total cost at a = 2,500X1 + 3,000X2

= 2,500(40) + 3,000(20)

= $160,000

Total cost at b = 2,500X1 + 3,000X2

= 2,500(30) + 3,000(30)

= $165,000

Lowest total cost is at point a

- 37.

MB - 37

Copyright© 2017 Pearson Education, Inc.

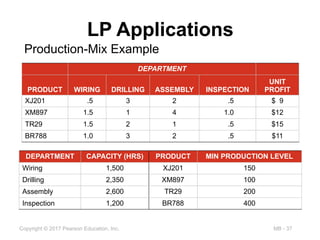

LP Applications

Production-Mix Example

DEPARTMENT

PRODUCT WIRING DRILLING ASSEMBLY INSPECTION

UNIT

PROFIT

XJ201 .5 3 2 .5 $ 9

XM897 1.5 1 4 1.0 $12

TR29 1.5 2 1 .5 $15

BR788 1.0 3 2 .5 $11

DEPARTMENT CAPACITY (HRS) PRODUCT MIN PRODUCTION LEVEL

Wiring 1,500 XJ201 150

Drilling 2,350 XM897 100

Assembly 2,600 TR29 200

Inspection 1,200 BR788 400

- 38.

MB - 38

Copyright© 2017 Pearson Education, Inc.

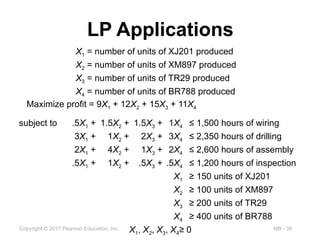

LP Applications

X1 = number of units of XJ201 produced

X2 = number of units of XM897 produced

X3 = number of units of TR29 produced

X4 = number of units of BR788 produced

Maximize profit = 9X1 + 12X2 + 15X3 + 11X4

subject to .5X1 + 1.5X2 + 1.5X3 + 1X4 ≤ 1,500 hours of wiring

3X1 + 1X2 + 2X3 + 3X4 ≤ 2,350 hours of drilling

2X1 + 4X2 + 1X3 + 2X4 ≤ 2,600 hours of assembly

.5X1 + 1X2 + .5X3 + .5X4 ≤ 1,200 hours of inspection

X1 ≥ 150 units of XJ201

X2 ≥ 100 units of XM897

X3 ≥ 200 units of TR29

X4 ≥ 400 units of BR788

X1, X2, X3, X4≥ 0

- 39.

MB - 39

Copyright© 2017 Pearson Education, Inc.

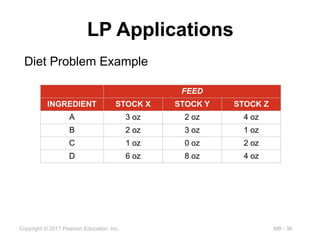

LP Applications

Diet Problem Example

FEED

INGREDIENT STOCK X STOCK Y STOCK Z

A 3 oz 2 oz 4 oz

B 2 oz 3 oz 1 oz

C 1 oz 0 oz 2 oz

D 6 oz 8 oz 4 oz

- 40.

MB - 40

Copyright© 2017 Pearson Education, Inc.

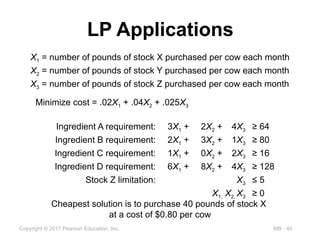

LP Applications

X1 = number of pounds of stock X purchased per cow each month

X2 = number of pounds of stock Y purchased per cow each month

X3 = number of pounds of stock Z purchased per cow each month

Minimize cost = .02X1 + .04X2 + .025X3

Ingredient A requirement: 3X1 + 2X2 + 4X3 ≥ 64

Ingredient B requirement: 2X1 + 3X2 + 1X3 ≥ 80

Ingredient C requirement: 1X1 + 0X2 + 2X3 ≥ 16

Ingredient D requirement: 6X1 + 8X2 + 4X3 ≥ 128

Stock Z limitation: X3 ≤ 5

X1, X2, X3 ≥ 0

Cheapest solution is to purchase 40 pounds of stock X

at a cost of $0.80 per cow

- 41.

MB - 41

Copyright© 2017 Pearson Education, Inc.

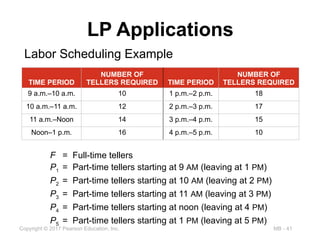

LP Applications

Labor Scheduling Example

F = Full-time tellers

P1 = Part-time tellers starting at 9 AM (leaving at 1 PM)

P2 = Part-time tellers starting at 10 AM (leaving at 2 PM)

P3 = Part-time tellers starting at 11 AM (leaving at 3 PM)

P4 = Part-time tellers starting at noon (leaving at 4 PM)

P5 = Part-time tellers starting at 1 PM (leaving at 5 PM)

TIME PERIOD

NUMBER OF

TELLERS REQUIRED TIME PERIOD

NUMBER OF

TELLERS REQUIRED

9 a.m.–10 a.m. 10 1 p.m.–2 p.m. 18

10 a.m.–11 a.m. 12 2 p.m.–3 p.m. 17

11 a.m.–Noon 14 3 p.m.–4 p.m. 15

Noon–1 p.m. 16 4 p.m.–5 p.m. 10

- 42.

MB - 42

Copyright© 2017 Pearson Education, Inc.

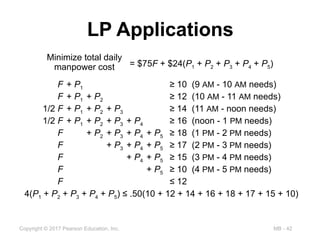

LP Applications

= $75F + $24(P1 + P2 + P3 + P4 + P5)

Minimize total daily

manpower cost

F + P1 ≥ 10 (9 AM - 10 AM needs)

F + P1 + P2 ≥ 12 (10 AM - 11 AM needs)

1/2 F + P1 + P2 + P3 ≥ 14 (11 AM - noon needs)

1/2 F + P1 + P2 + P3 + P4 ≥ 16 (noon - 1 PM needs)

F + P2 + P3 + P4 + P5 ≥ 18 (1 PM - 2 PM needs)

F + P3 + P4 + P5 ≥ 17 (2 PM - 3 PM needs)

F + P4 + P5 ≥ 15 (3 PM - 4 PM needs)

F + P5 ≥ 10 (4 PM - 5 PM needs)

F ≤ 12

4(P1 + P2 + P3 + P4 + P5) ≤ .50(10 + 12 + 14 + 16 + 18 + 17 + 15 + 10)

- 43.

MB - 43

Copyright© 2017 Pearson Education, Inc.

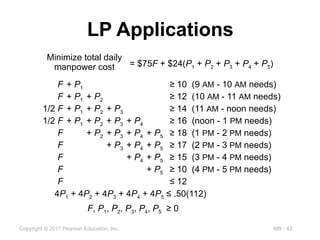

LP Applications

= $75F + $24(P1 + P2 + P3 + P4 + P5)

Minimize total daily

manpower cost

F + P1 ≥ 10 (9 AM - 10 AM needs)

F + P1 + P2 ≥ 12 (10 AM - 11 AM needs)

1/2 F + P1 + P2 + P3 ≥ 14 (11 AM - noon needs)

1/2 F + P1 + P2 + P3 + P4 ≥ 16 (noon - 1 PM needs)

F + P2 + P3 + P4 + P5 ≥ 18 (1 PM - 2 PM needs)

F + P3 + P4 + P5 ≥ 17 (2 PM - 3 PM needs)

F + P4 + P5 ≥ 15 (3 PM - 4 PM needs)

F + P5 ≥ 10 (4 PM - 5 PM needs)

F ≤ 12

4P1 + 4P2 + 4P3 + 4P4 + 4P5 ≤ .50(112)

F, P1, P2, P3, P4, P5 ≥ 0

- 44.

MB - 44

Copyright© 2017 Pearson Education, Inc.

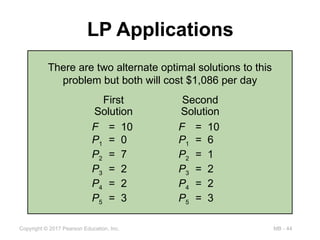

LP Applications

There are two alternate optimal solutions to this

problem but both will cost $1,086 per day

F = 10 F = 10

P1 = 0 P1 = 6

P2 = 7 P2 = 1

P3 = 2 P3 = 2

P4 = 2 P4 = 2

P5 = 3 P5 = 3

First Second

Solution Solution

- 45.

MB - 45

Copyright© 2017 Pearson Education, Inc.

The Simplex Method

▶ Real world problems are too complex to

be solved using the graphical method

▶ The simplex method is an algorithm for

solving more complex problems

▶ Developed by George Dantzig in the late

1940s

▶ Most computer-based LP packages use

the simplex method

- 46.

MB - 46

Copyright© 2017 Pearson Education, Inc.

Integer and Binary Variables

▶ In some cases solutions must be integers

▶ Binary variables allow for “yes-or-no”

decisions

▶ Not good practice to round variables to

integers

▶ Constraints can be added to force integer

or binary values

▶ Larger programs may take longer to solve

- 47.

MB - 47

Copyright© 2017 Pearson Education, Inc.

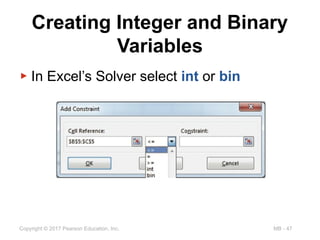

Creating Integer and Binary

Variables

▶ In Excel’s Solver select int or bin

- 48.

MB - 48

Copyright© 2017 Pearson Education, Inc.

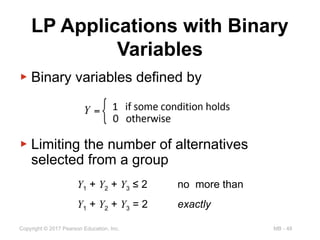

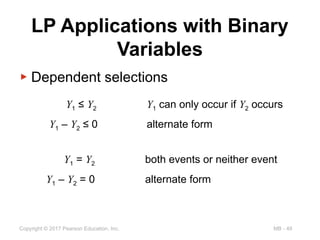

LP Applications with Binary

Variables

▶ Binary variables defined by

▶ Limiting the number of alternatives

selected from a group

Y1 + Y2 + Y3 ≤ 2 no more than

Y1 + Y2 + Y3 = 2 exactly

- 49.

MB - 49

Copyright© 2017 Pearson Education, Inc.

LP Applications with Binary

Variables

▶ Dependent selections

Y1 ≤ Y2 Y1 can only occur if Y2 occurs

Y1 – Y2 ≤ 0 alternate form

Y1 = Y2 both events or neither event

Y1 – Y2 = 0 alternate form

- 50.

MB - 50

Copyright© 2017 Pearson Education, Inc.

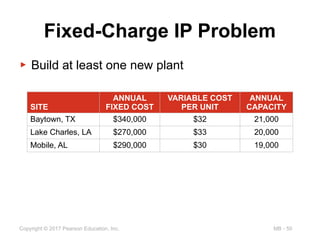

Fixed-Charge IP Problem

▶ Build at least one new plant

SITE

ANNUAL

FIXED COST

VARIABLE COST

PER UNIT

ANNUAL

CAPACITY

Baytown, TX $340,000 $32 21,000

Lake Charles, LA $270,000 $33 20,000

Mobile, AL $290,000 $30 19,000

- 51.

MB - 51

Copyright© 2017 Pearson Education, Inc.

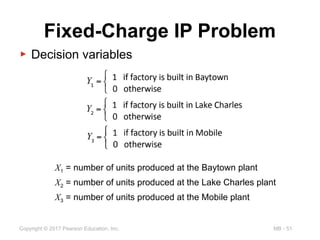

Fixed-Charge IP Problem

▶ Decision variables

X1 = number of units produced at the Baytown plant

X2 = number of units produced at the Lake Charles plant

X3 = number of units produced at the Mobile plant

- 52.

MB - 52

Copyright© 2017 Pearson Education, Inc.

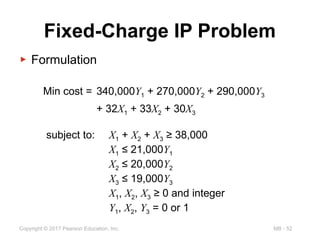

Fixed-Charge IP Problem

▶ Formulation

Min cost = 340,000Y1 + 270,000Y2 + 290,000Y3

+ 32X1 + 33X2 + 30X3

subject to: X1 + X2 + X3 ≥ 38,000

X1 ≤ 21,000Y1

X2 ≤ 20,000Y2

X3 ≤ 19,000Y3

X1, X2, X3 ≥ 0 and integer

Y1, X2, Y3 = 0 or 1

- 53.

MB - 53

Copyright© 2017 Pearson Education, Inc.

All rights reserved. No part of this publication may be reproduced, stored in a

retrieval system, or transmitted, in any form or by any means, electronic,

mechanical, photocopying, recording, or otherwise, without the prior written

permission of the publisher.

Printed in the United States of America.

Editor's Notes

- #33 It might be useful at this point to discuss typical equipment utilization rates for different process strategies if you have not done so before.

- #34 It might be useful at this point to discuss typical equipment utilization rates for different process strategies if you have not done so before.

- #35 It might be useful at this point to discuss typical equipment utilization rates for different process strategies if you have not done so before.

- #36 It might be useful at this point to discuss typical equipment utilization rates for different process strategies if you have not done so before.