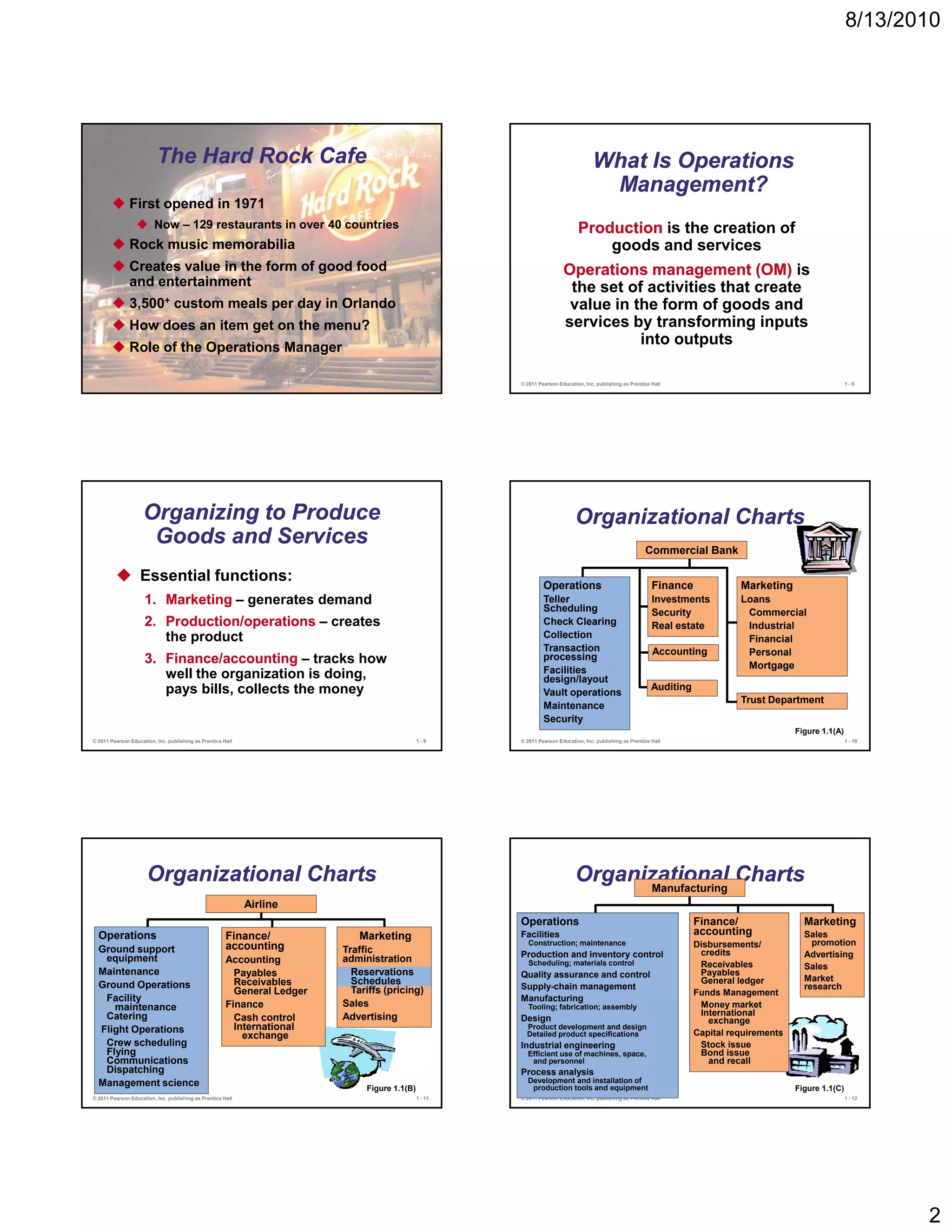

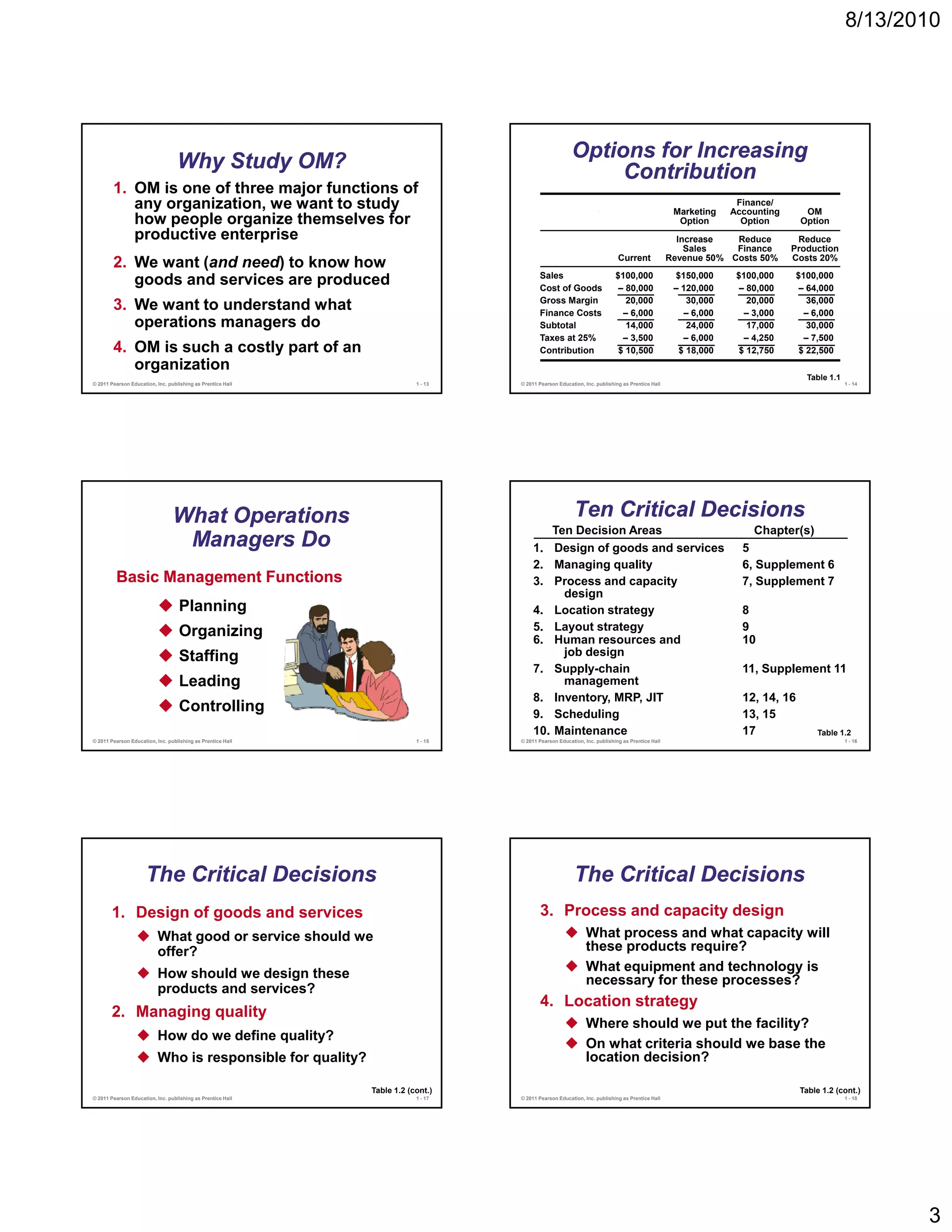

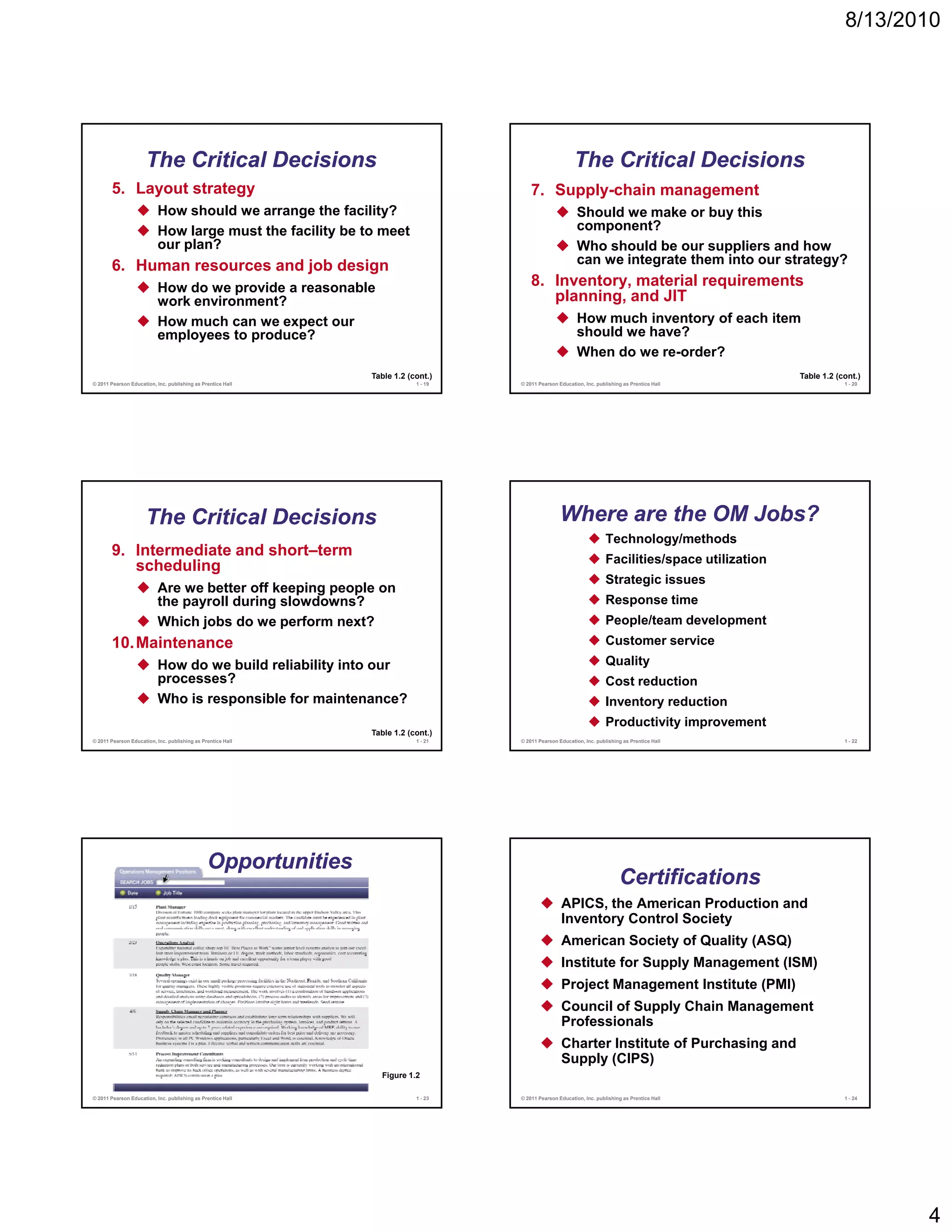

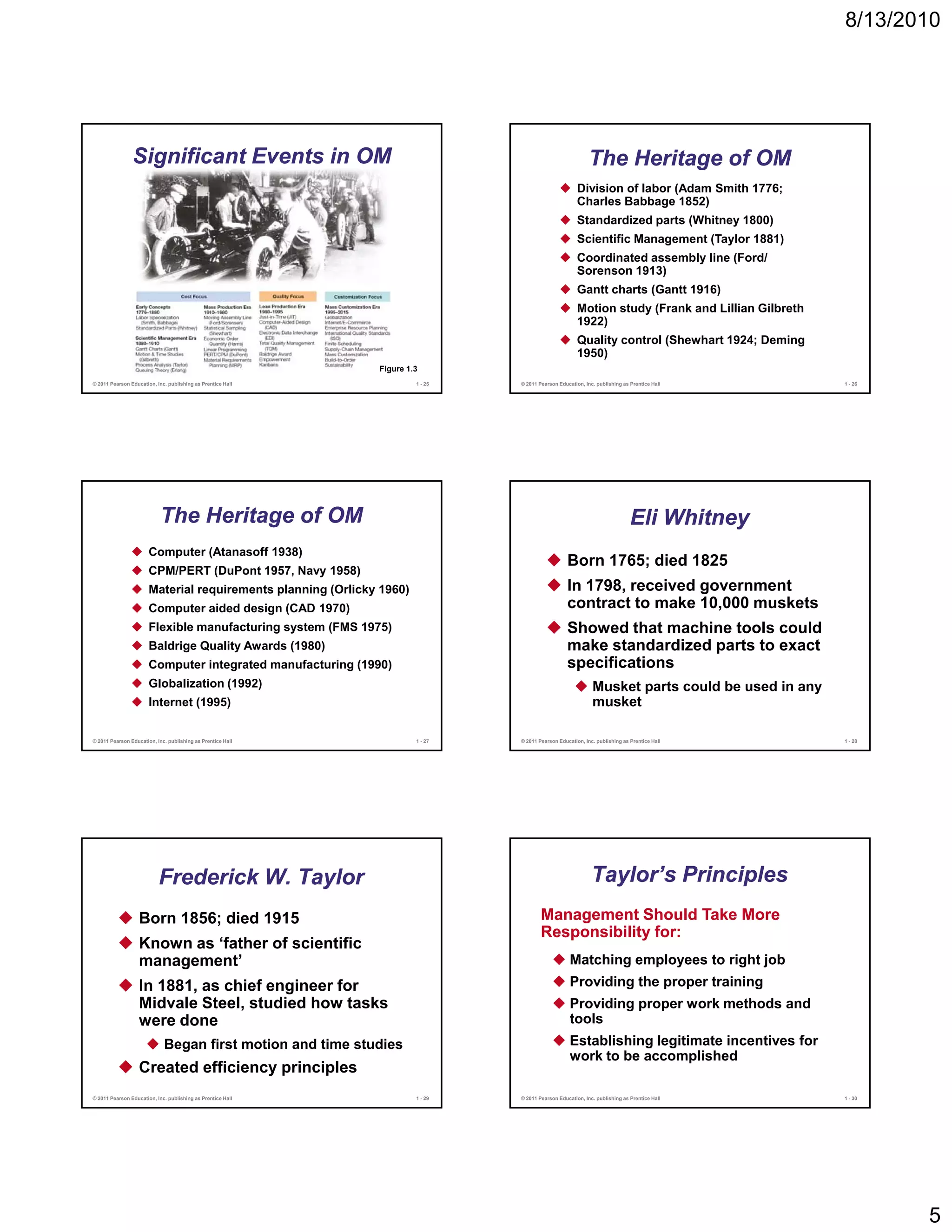

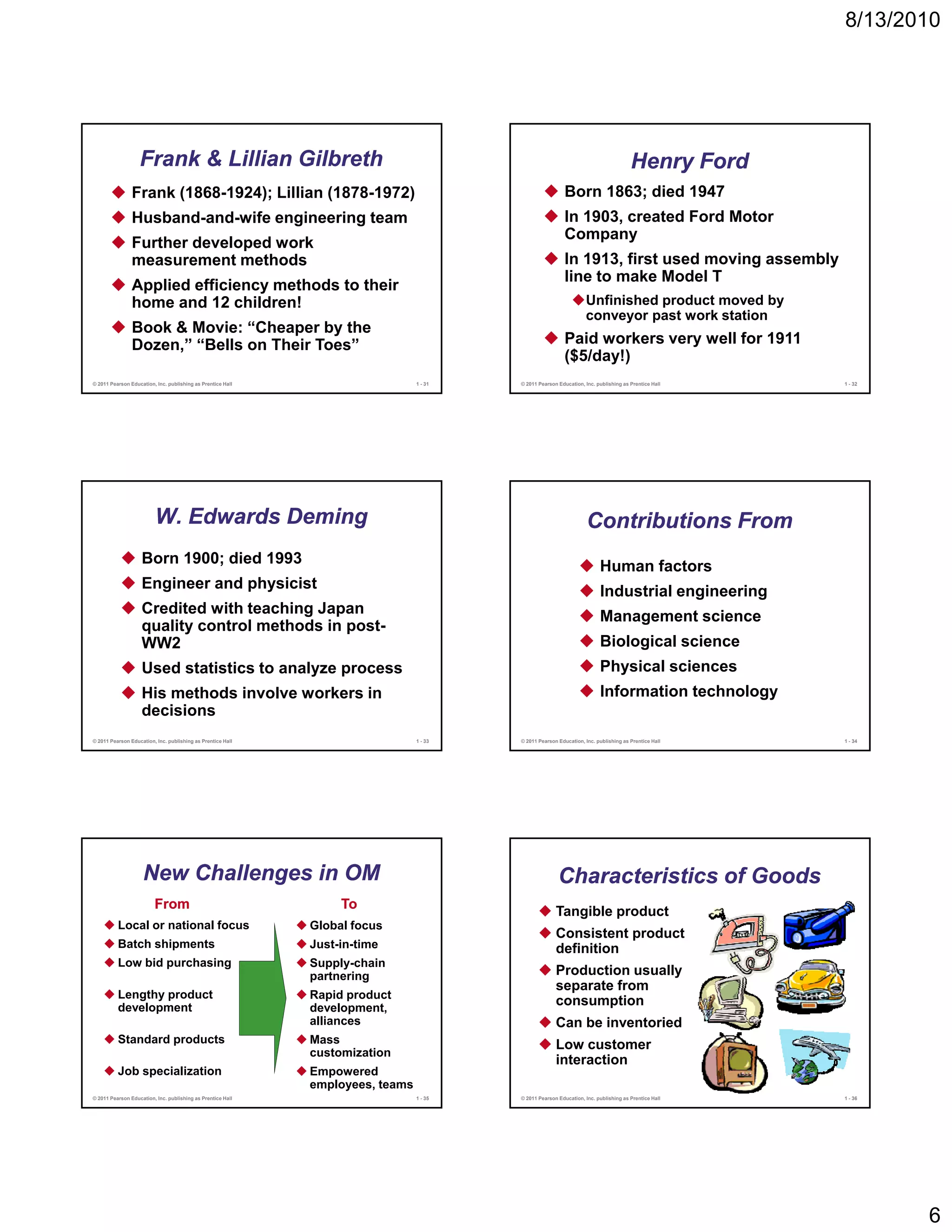

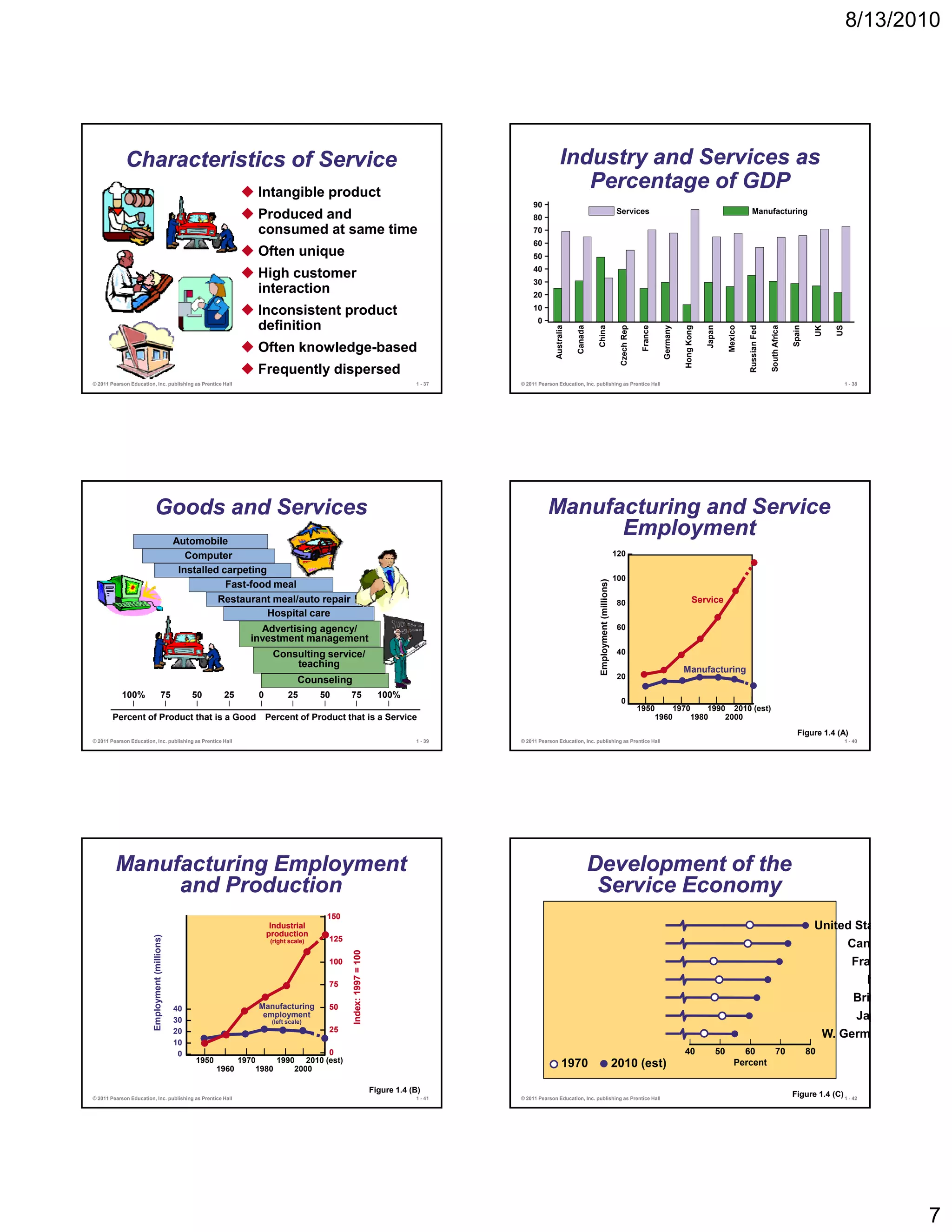

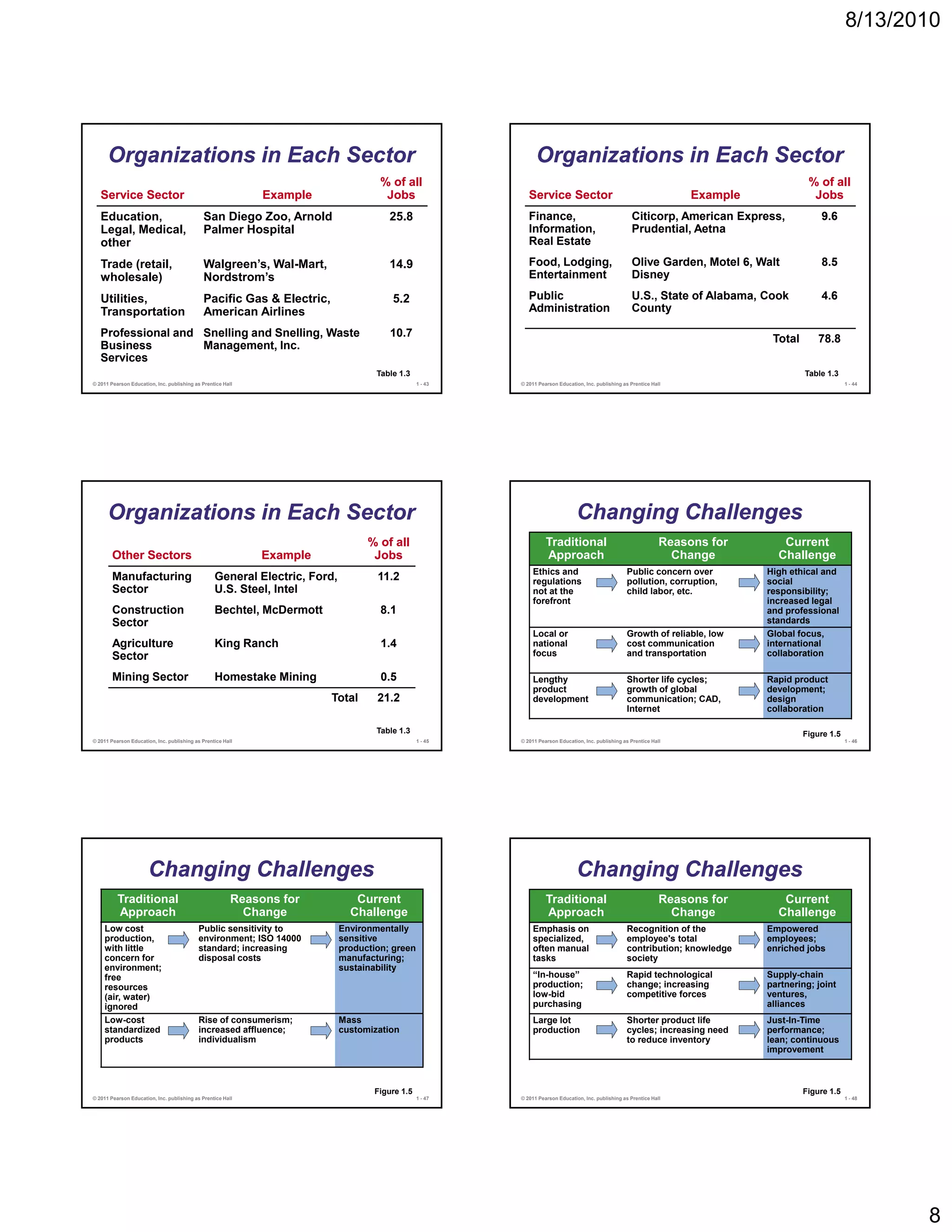

This document is a PowerPoint presentation on operations management. It covers topics such as what operations management is, the heritage and evolution of OM, characteristics of goods and services, and critical decisions that operations managers must make. Key figures discussed include Eli Whitney, Frederick Taylor, the Gilbreths, Henry Ford, and W. Edwards Deming. The presentation also examines new challenges in OM and trends toward globalization and customization.