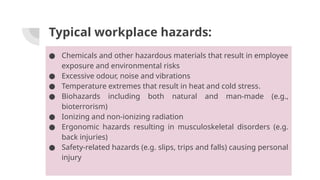

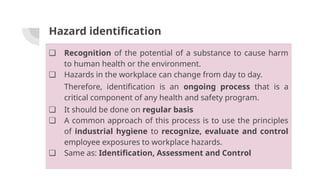

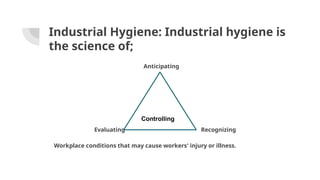

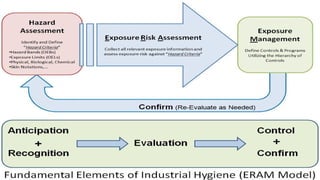

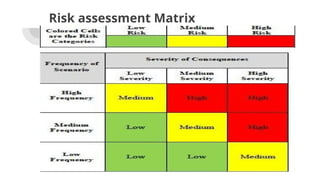

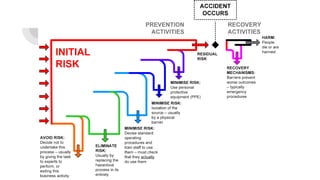

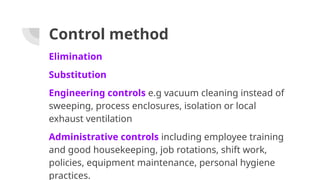

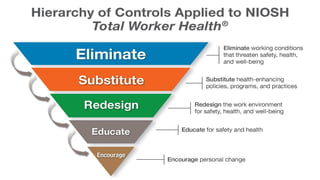

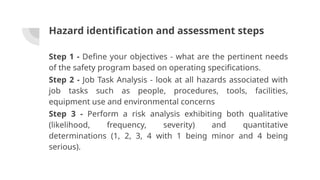

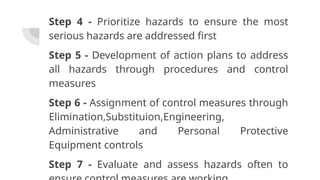

The document presents a comprehensive approach to hazard identification in the workplace, highlighting the various types of hazards and the importance of continually recognizing, evaluating, and controlling them. It emphasizes the need for occupational safety regulations to reduce workplace accidents, illnesses, and promote a healthy work environment. The process involves methods such as industry surveys, employee interviews, and risk assessments, concluding with strategies to control exposures through various methods and personal protective equipment.