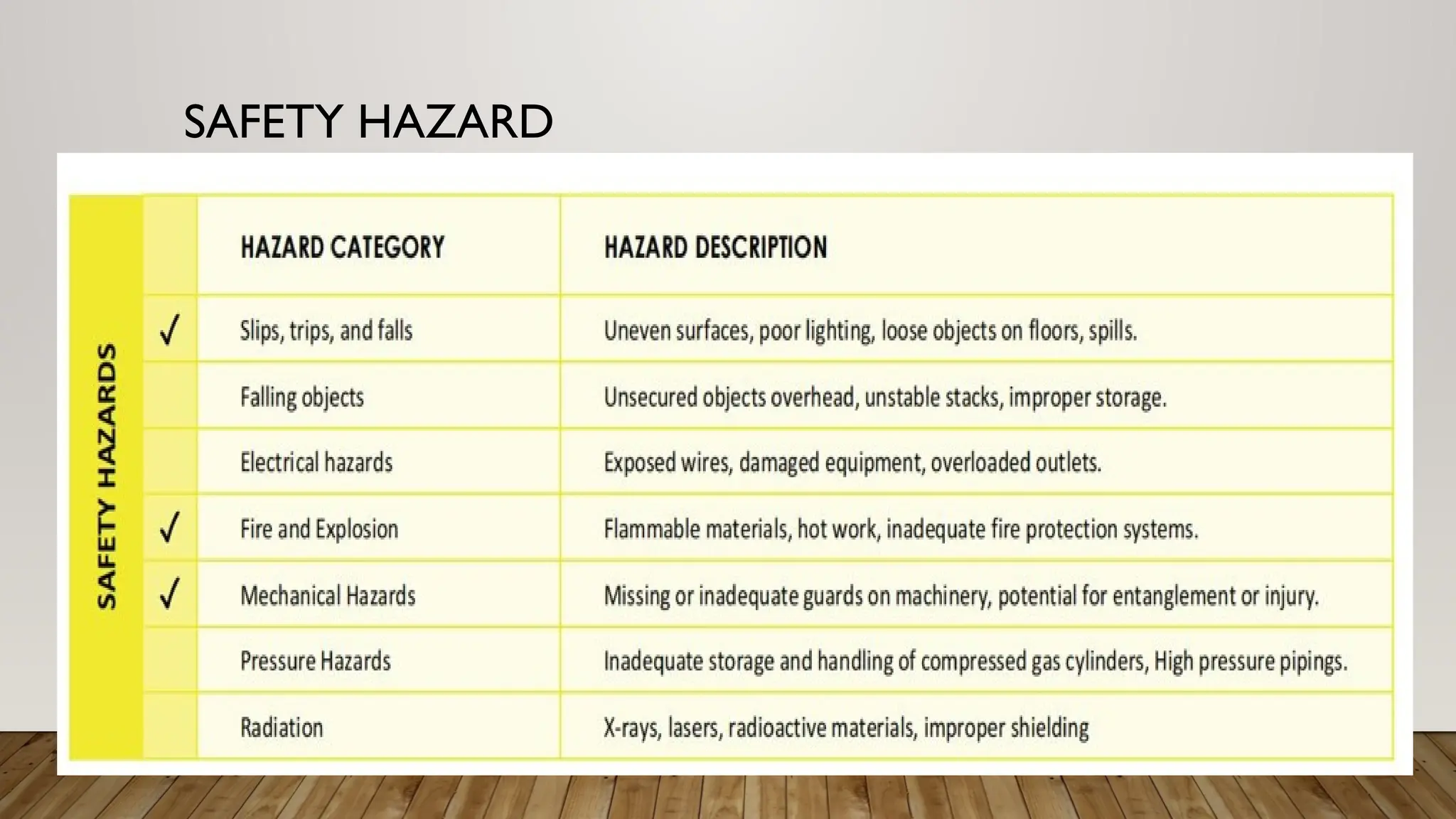

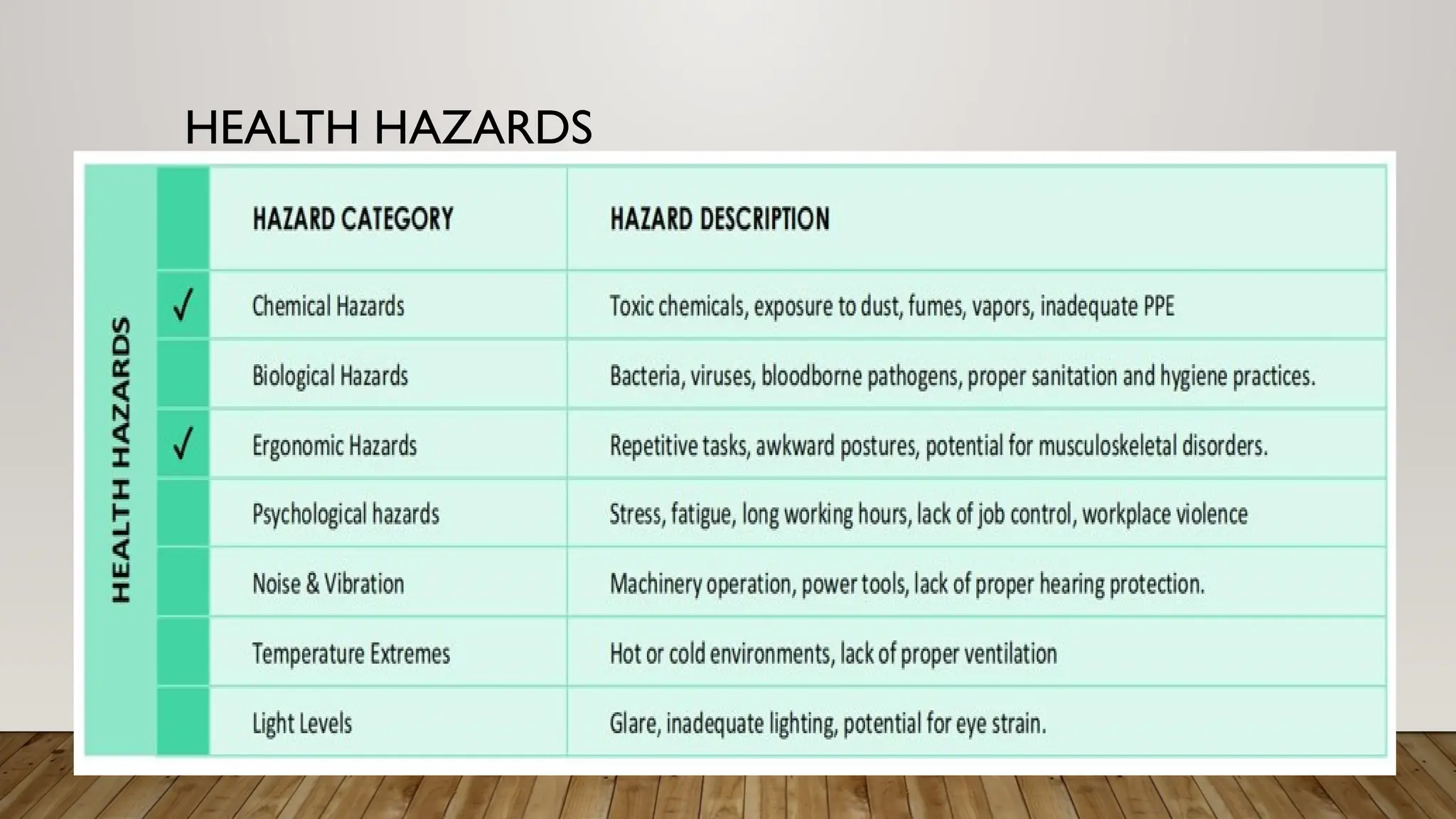

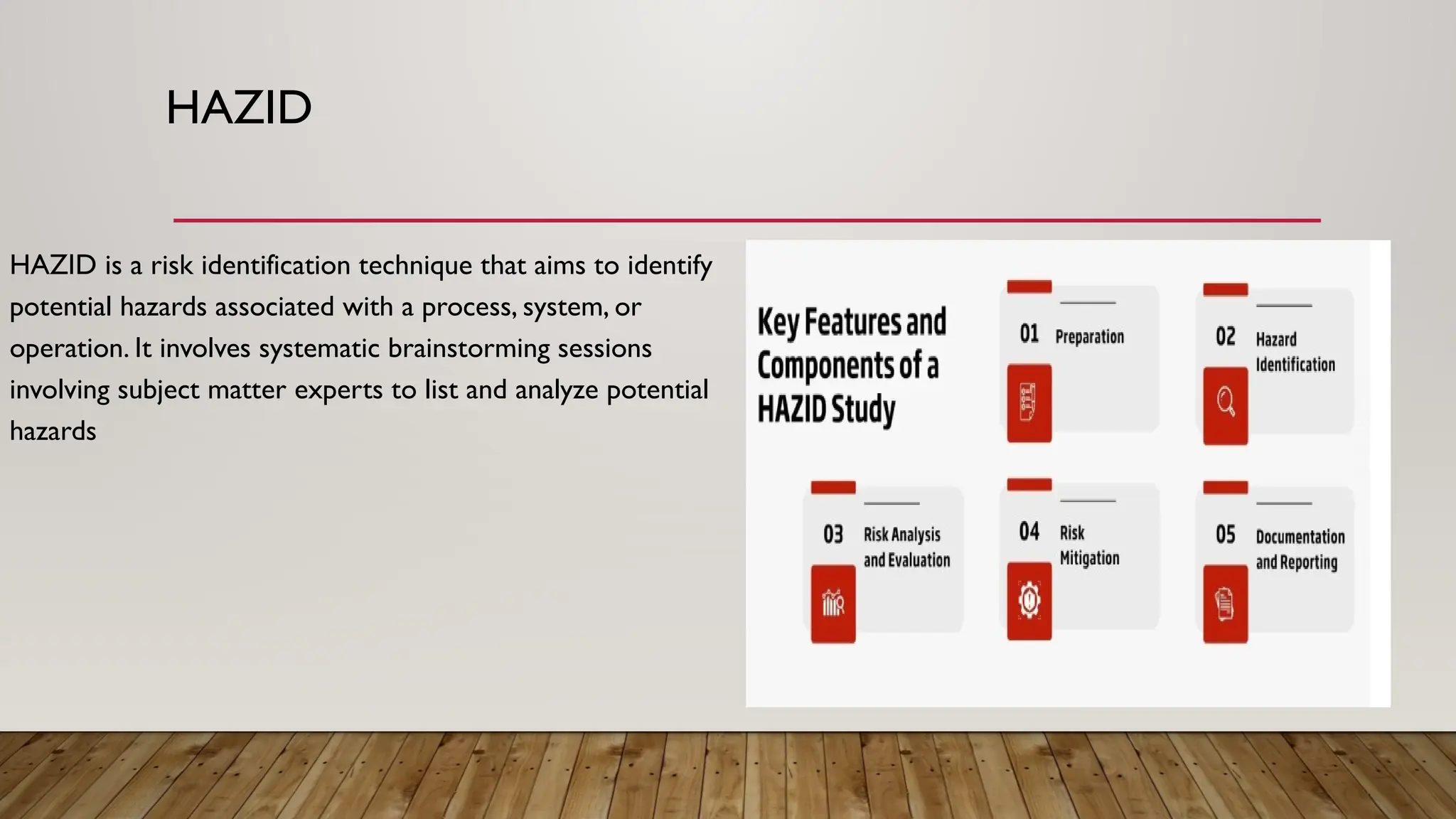

The document outlines a hazard checklist designed for identifying and analyzing safety, health, and environmental hazards in laboratory settings. It describes various hazard identification techniques such as HAZID, HAZOP, and FMEA, along with their advantages and disadvantages. Additionally, it emphasizes the importance of a structured approach to hazard analysis and provides examples of audit questions to ensure compliance and safety within laboratories.