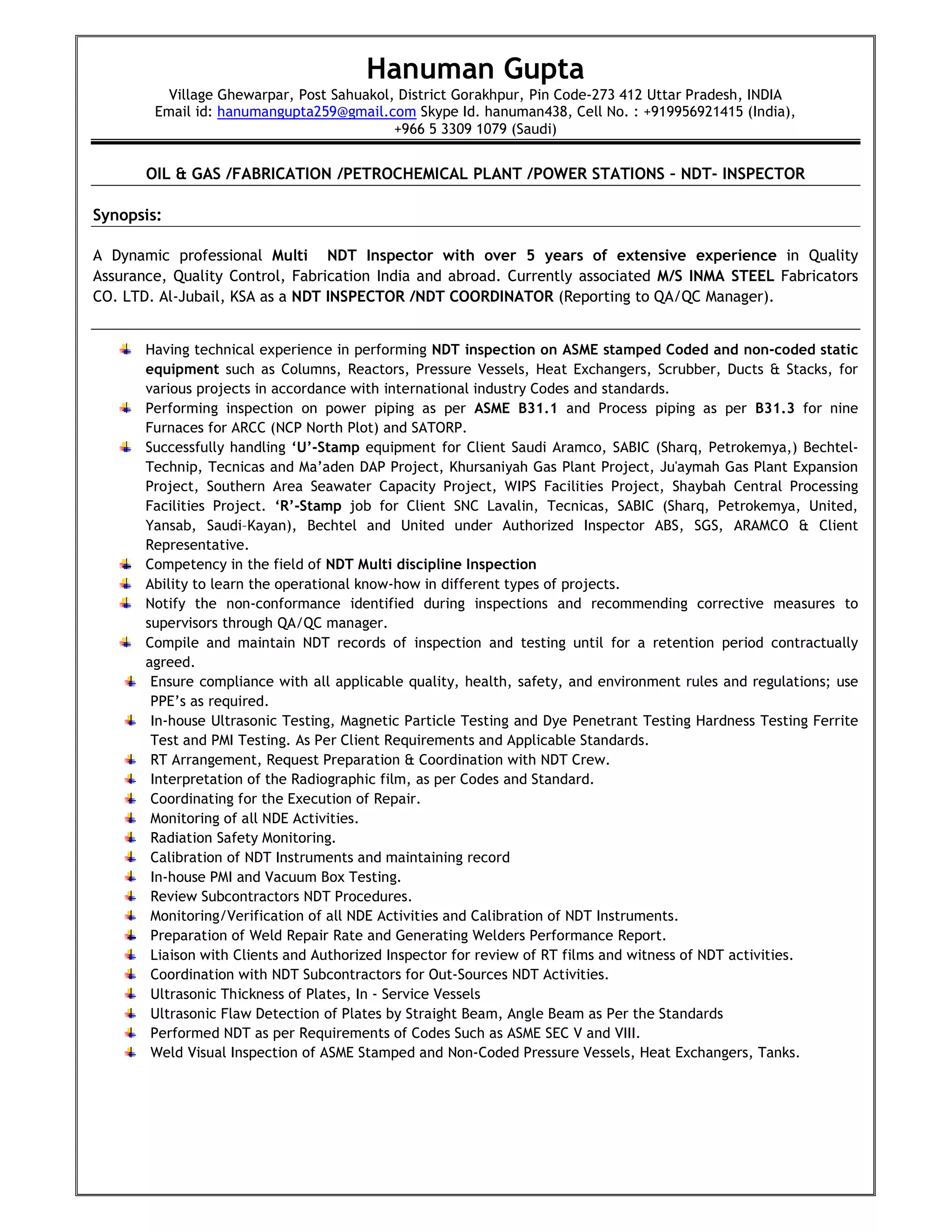

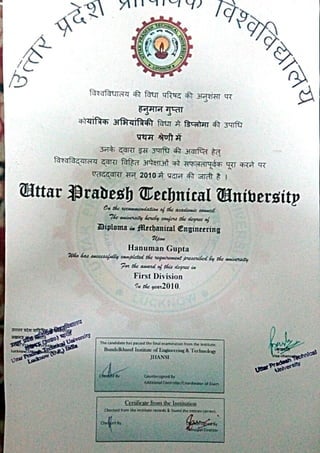

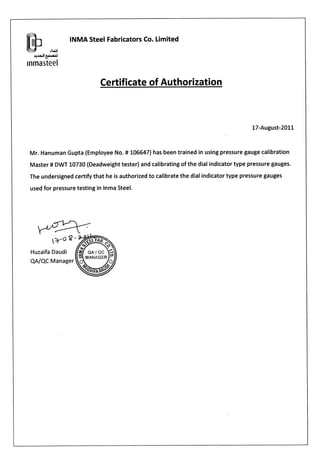

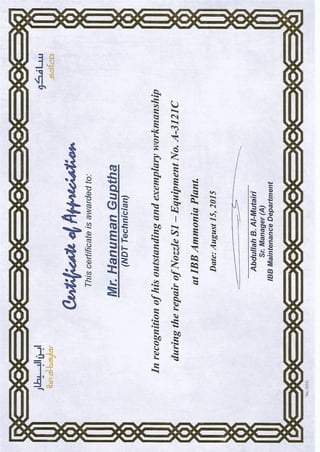

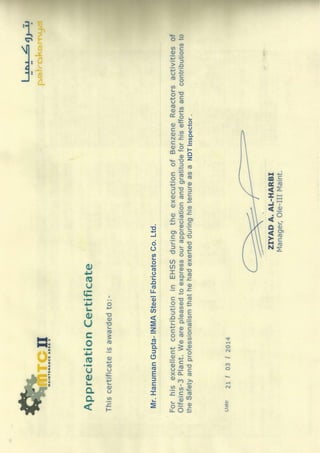

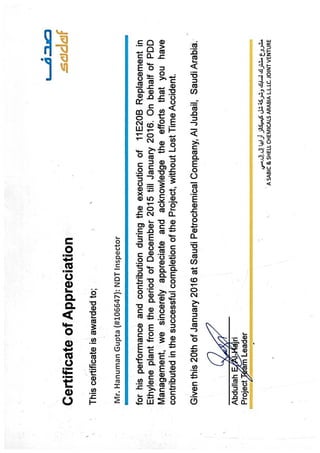

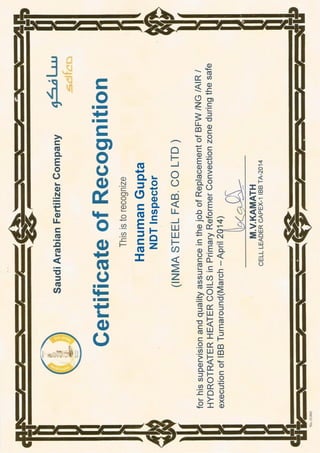

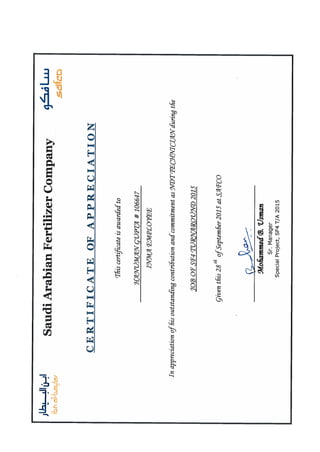

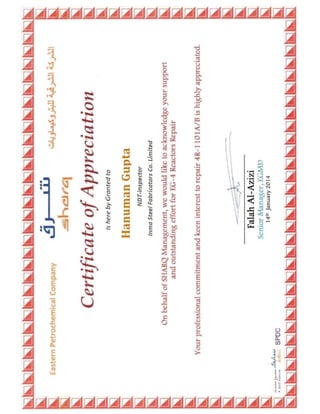

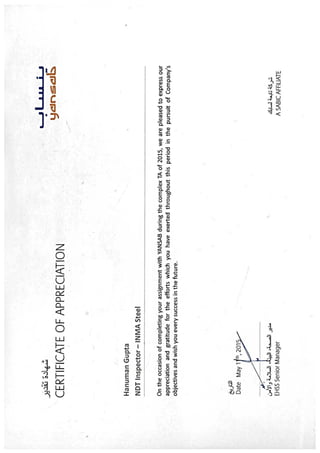

Hanuman Gupta is a dynamic NDT inspector with over 5 years of experience in quality assurance and control in India and Saudi Arabia. He is currently working for INMA STEEL Fabricators in Al-Jubail, Saudi Arabia as an NDT inspector and coordinator, reporting to the QA/QC manager. He has extensive experience performing various NDT inspections including ultrasonic, radiographic, magnetic particle, and dye penetrant testing on equipment according to international codes and standards. He is competent in inspection, testing, interpreting results, and ensuring compliance with health, safety, and environmental regulations.