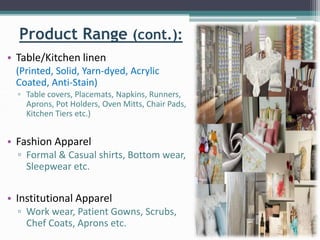

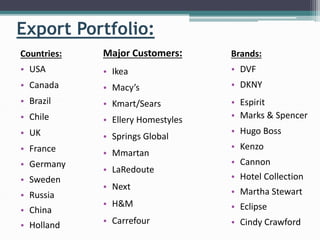

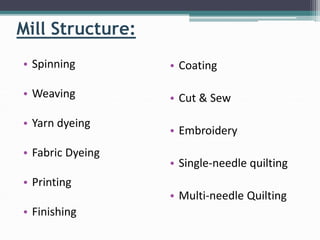

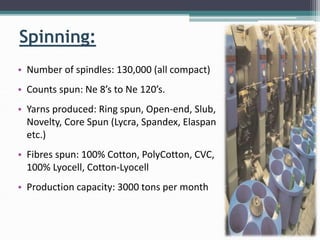

This document provides an overview of a vertically integrated textile mill located in Karachi, Pakistan. The mill was established in 1953 and employs over 10,000 people. It produces a range of textile products including fashion and institutional bedding, curtains, table and kitchen linens, and apparel. The mill has a large export portfolio shipping to over 20 countries. It has full textile production capabilities from spinning to cutting and sewing.