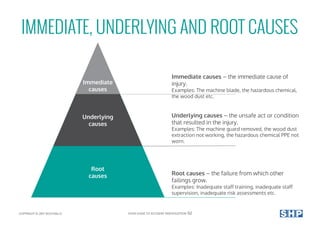

This document provides guidance on accident investigation and consists of several sections. It begins by explaining that the guide is intended to help businesses and individuals better understand the accident investigation process. It then outlines the four main steps of an accident investigation process: 1) gathering information, 2) analyzing the information, 3) identifying risk control measures, and 4) implementing an action plan. Finally, it provides some key questions to consider when investigating accidents to help identify immediate, underlying and root causes.