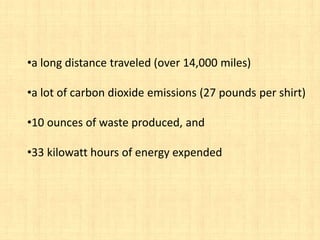

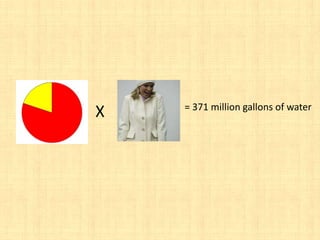

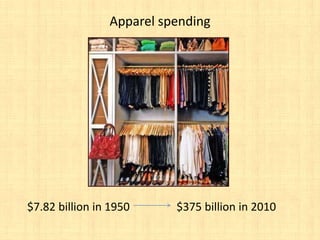

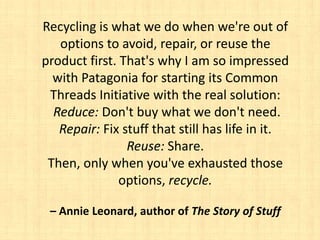

The document discusses the environmental impact of clothing production and provides tips for sustainable fashion. It notes that producing one pound of cotton requires 700-2,000 gallons of water and clothing travels over 14,000 miles from field to store while emitting 27 pounds of carbon dioxide per shirt. The document then discusses various natural and synthetic fabric types and provides suggestions for reducing consumption, reusing clothes through repair or upcycling, and prioritizing reduce, repair and reuse over recycling.