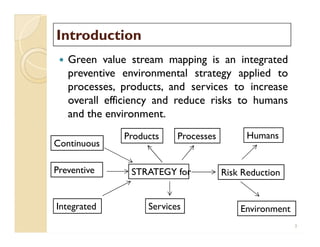

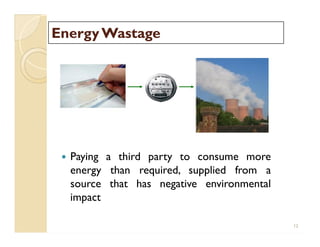

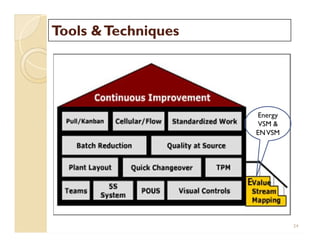

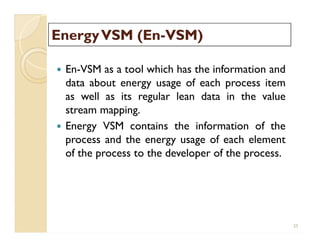

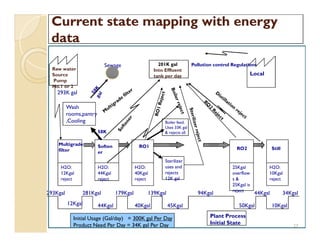

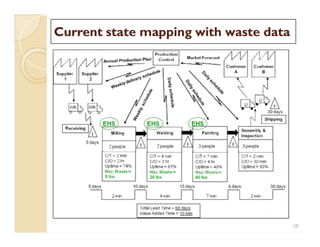

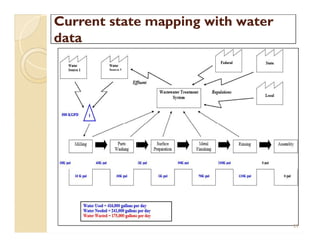

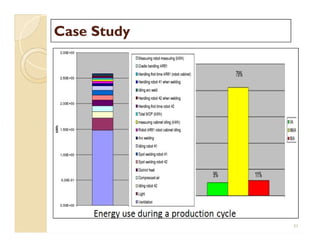

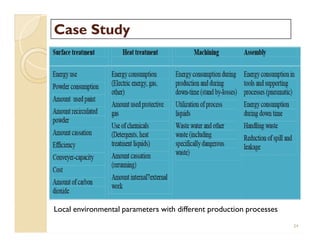

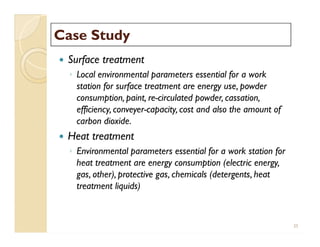

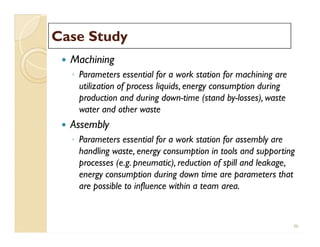

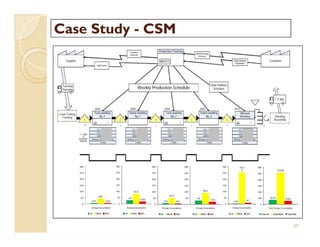

Green value stream mapping is a tool that integrates lean manufacturing principles with environmental considerations. It adds data on material and energy usage to traditional value stream maps. This allows companies to identify waste and inefficiencies in their processes in order to simultaneously reduce waste, pollution, and costs. A case study at a Volvo plant used green value stream mapping to analyze energy usage and identify opportunities to reduce unnecessary energy consumption from idling equipment and lighting/ventilation systems.