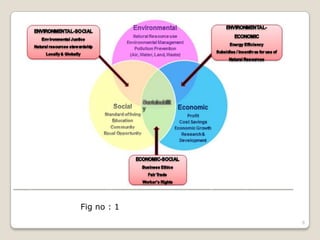

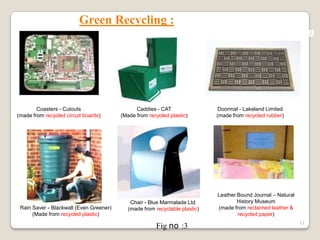

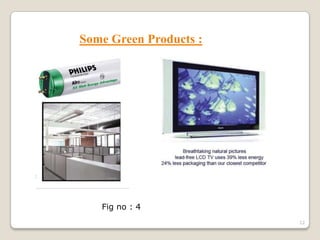

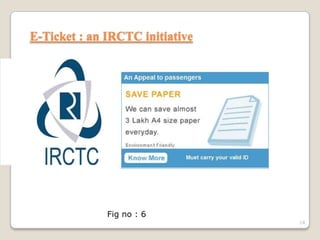

The document discusses green manufacturing, defining it as implementing substitutions that reduce energy, resource consumption, waste, and water usage. It outlines the need for green manufacturing due to environmental and business reasons. The goals of green manufacturing are achieving sustainability and conserving resources for future generations. Benefits include improved reputation and reduced costs. Examples of green manufacturing processes and products are provided.