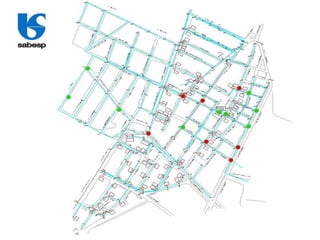

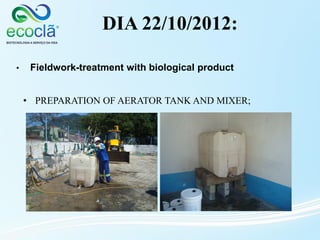

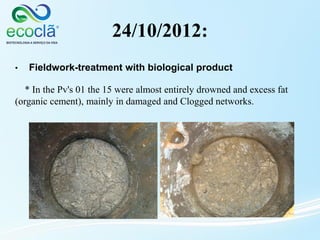

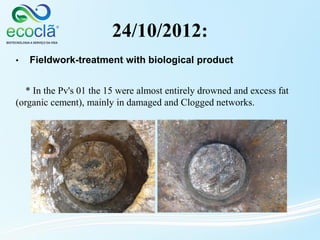

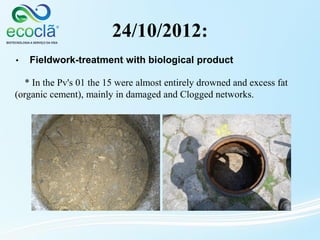

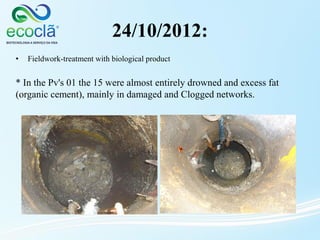

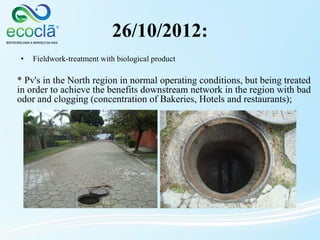

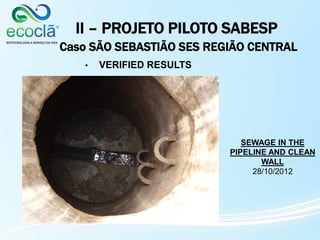

The document details a pilot project in São Sebastião, SP, focused on utilizing bioaugmentation with the biological product ecomix to improve sewage treatment by degrading fat and eliminating odors in collection systems. The project aimed to enhance sanitation efficiency in areas with high concentrations of restaurants and hotels, leading to successful reductions in fat and improved sewage flow. Recommended next steps include broader application of the biological treatment technology in other areas to address similar sanitation challenges.