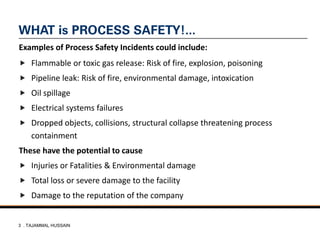

This document discusses process safety and introduces the bowtie methodology. It defines process safety as identifying and preventing releases of hazardous substances and energy. Process safety is ensured by maintaining safety barriers and equipment, following operating procedures, and knowing emergency response procedures. The bowtie methodology graphically illustrates how hazards are controlled through preventative and recovery controls. It links hazards, safety critical elements (SCEs), and performance standards to ensure effective risk management. The document emphasizes the importance of assuring critical controls such as identifying and testing SCEs, emergency response systems, and inspection regimes.