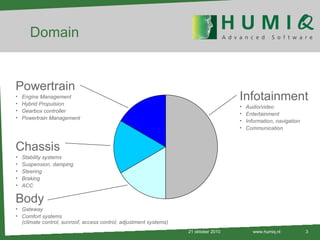

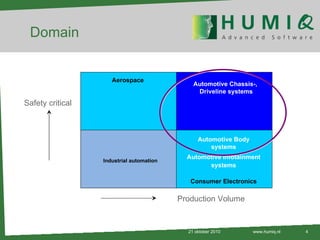

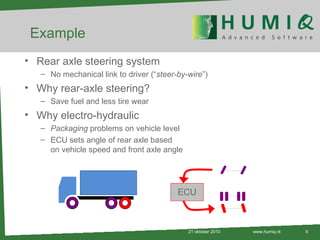

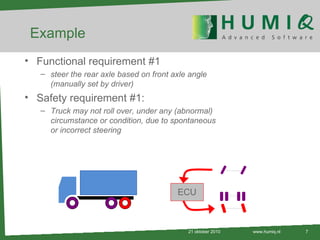

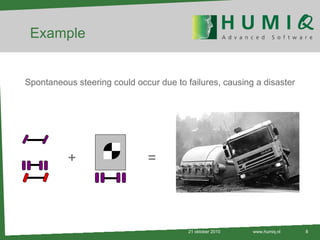

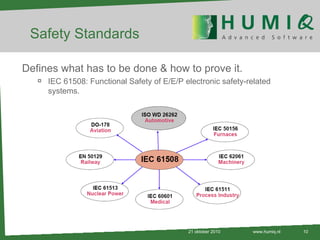

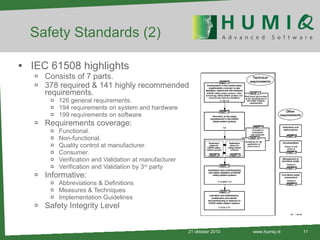

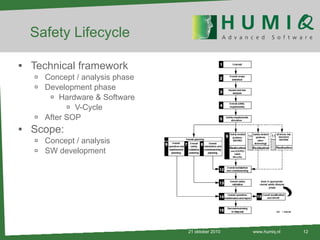

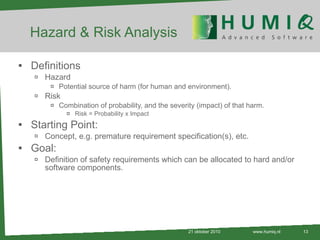

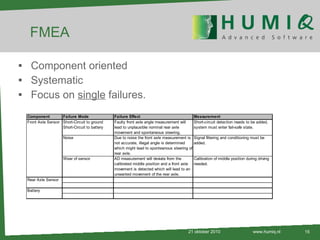

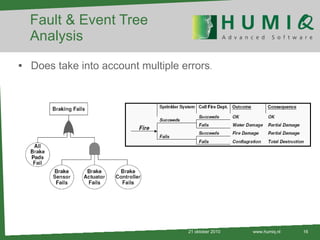

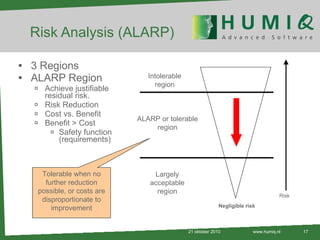

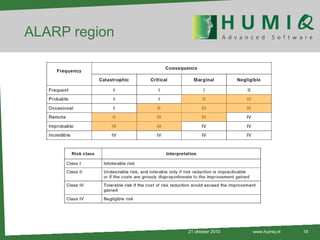

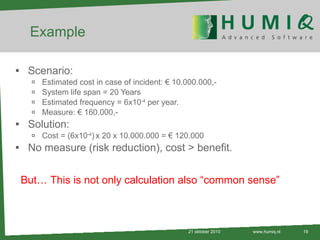

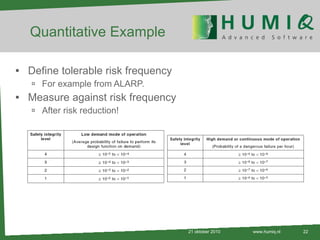

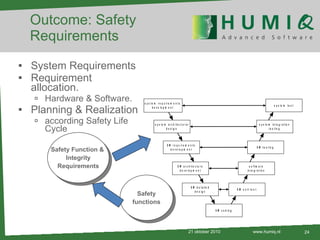

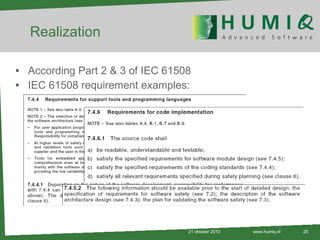

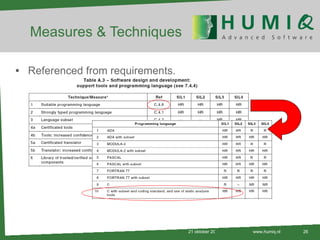

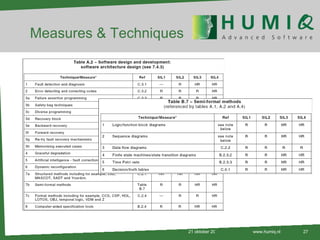

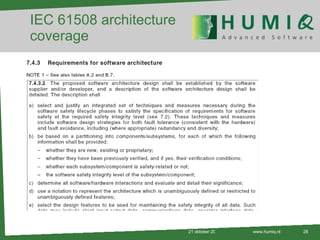

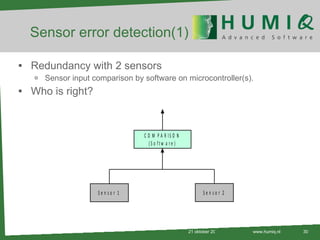

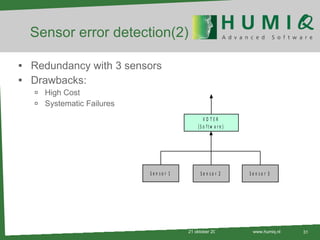

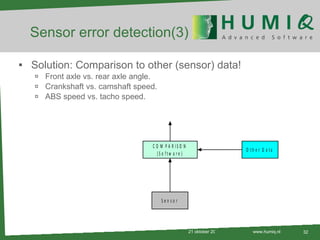

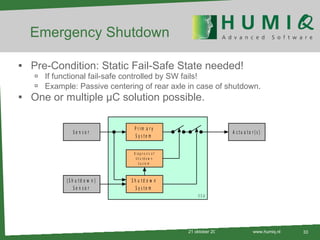

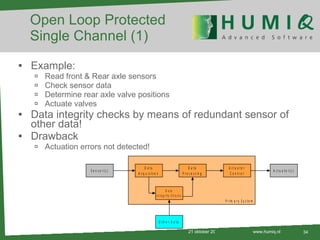

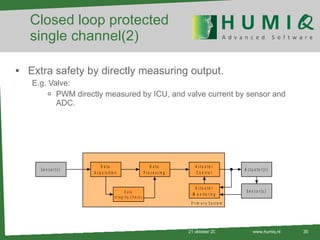

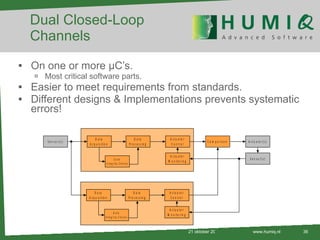

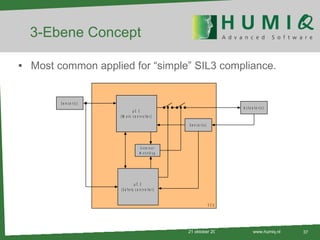

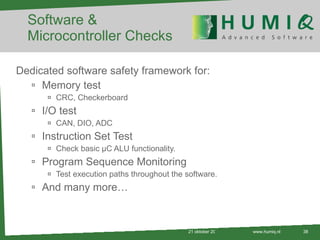

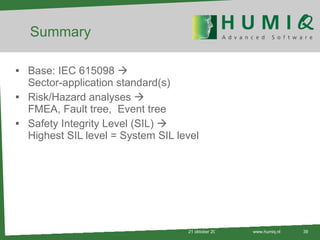

The document discusses automotive functional safety, emphasizing the importance of ensuring safe implementation in systems to prevent injuries or damage in case of malfunctions. It outlines safety requirements, risk analysis techniques like FMEA and fault tree analysis, and introduces IEC 61508 as a key standard for managing functional safety in electronic systems. The content further explains concepts such as safety integrity levels (SIL) and various practical examples of safety measures in automotive engineering.