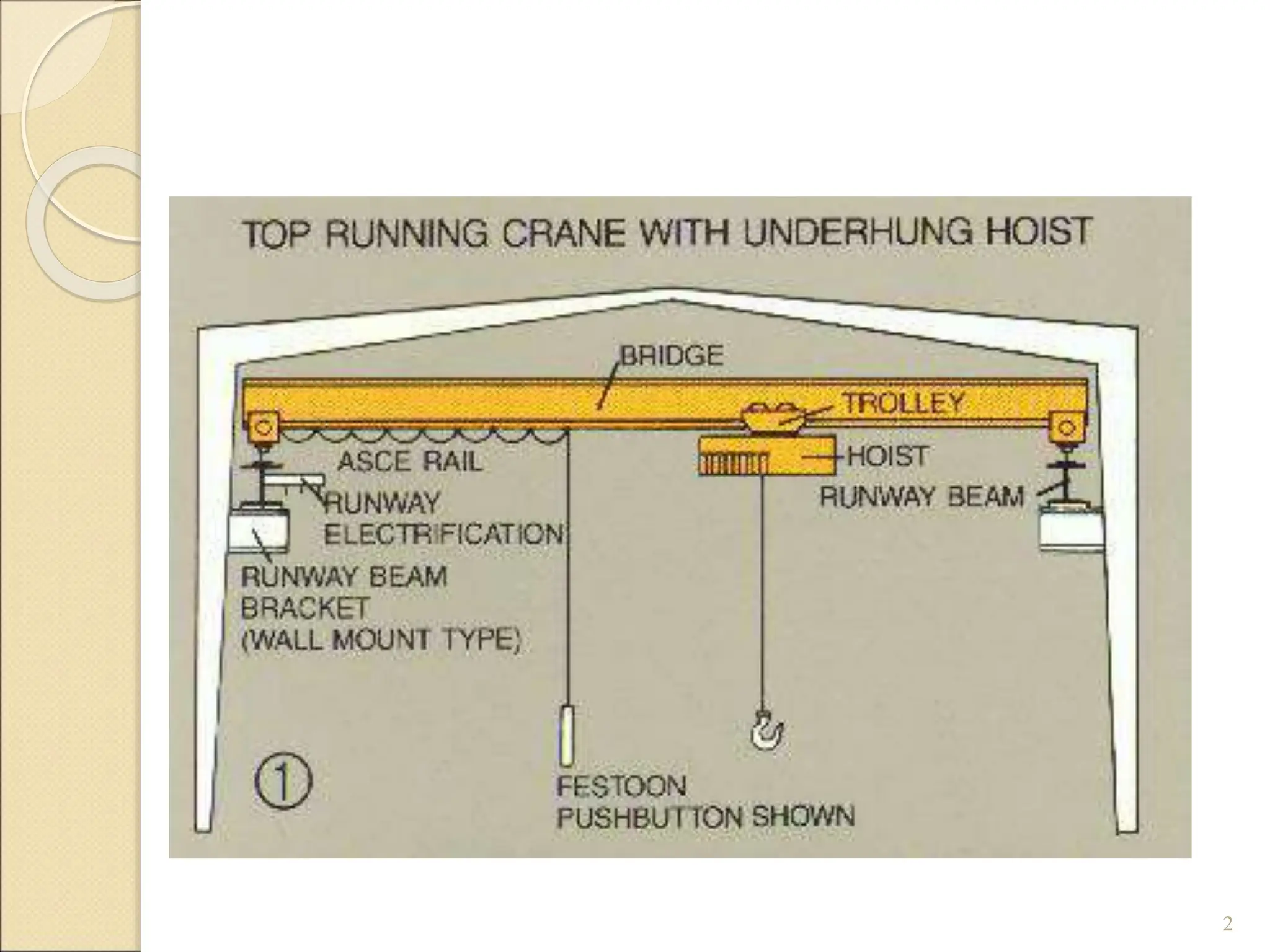

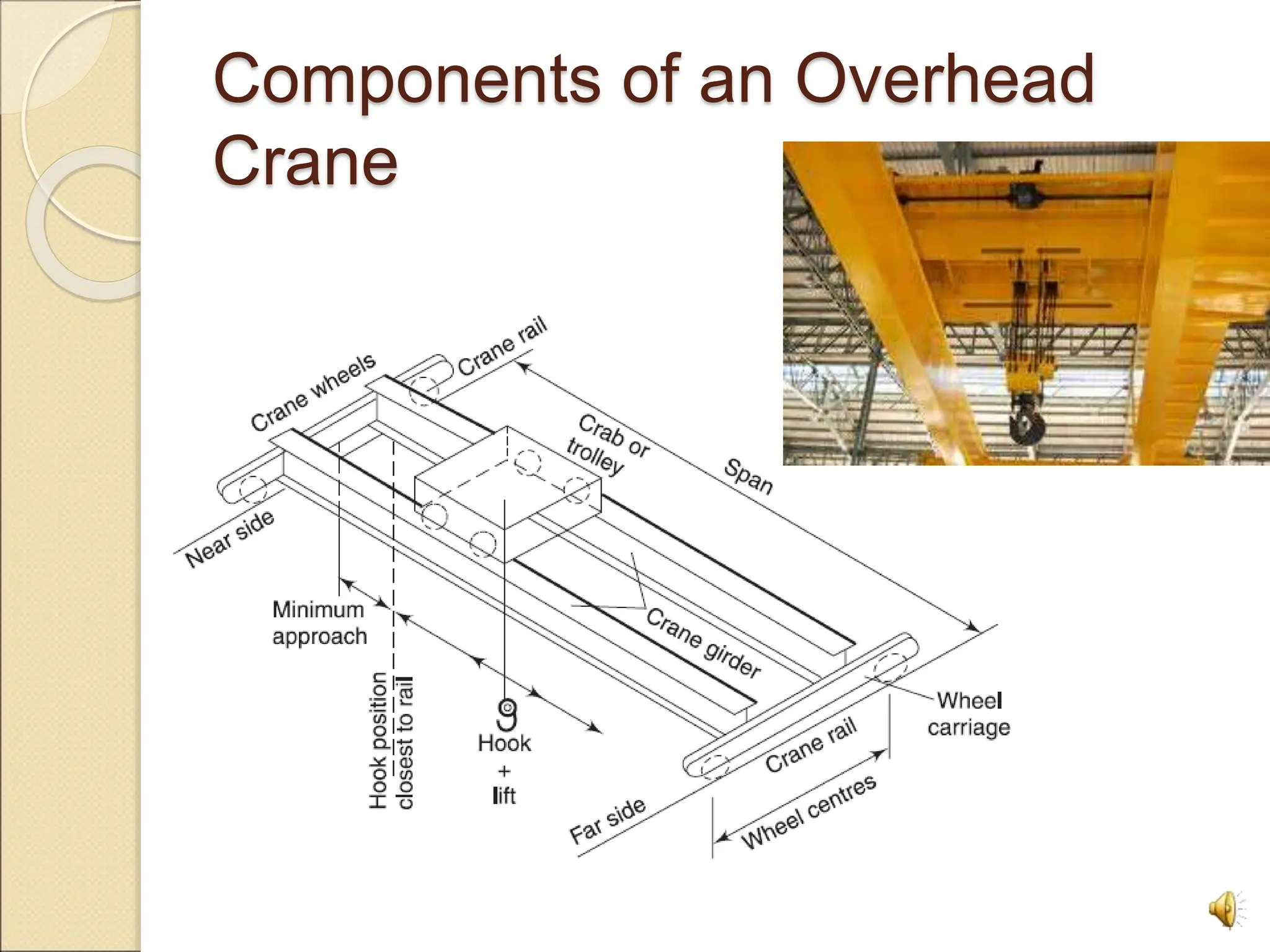

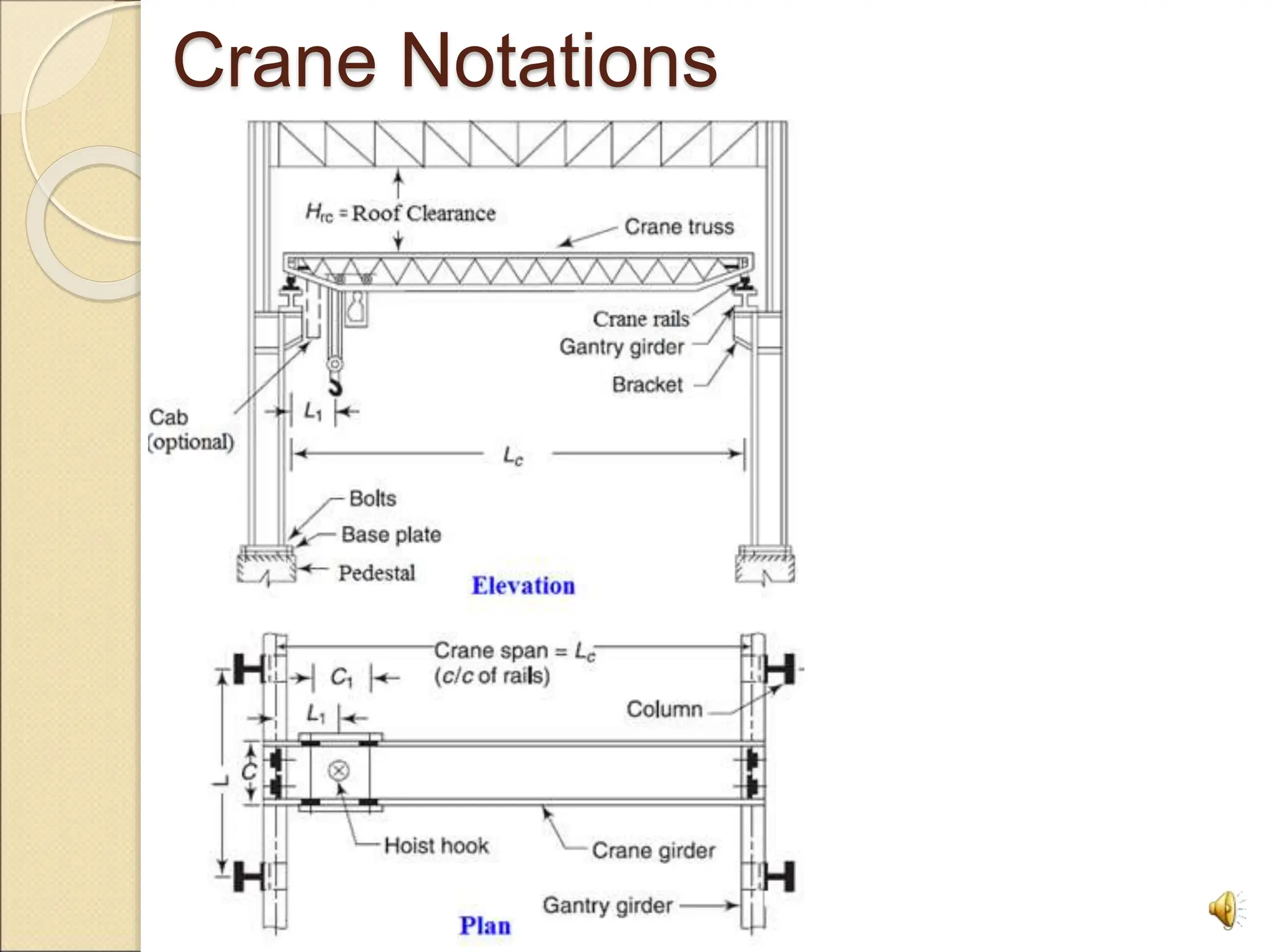

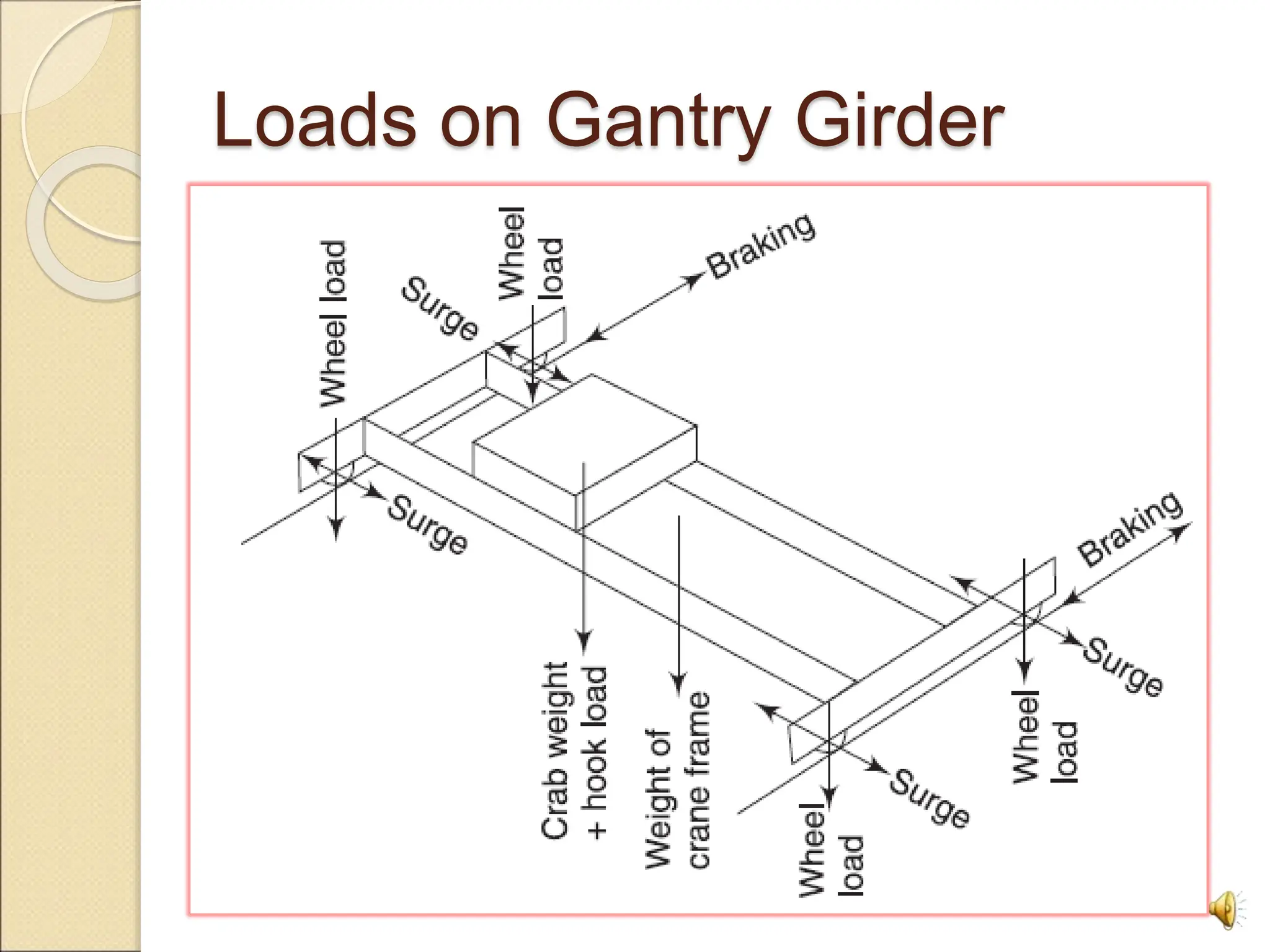

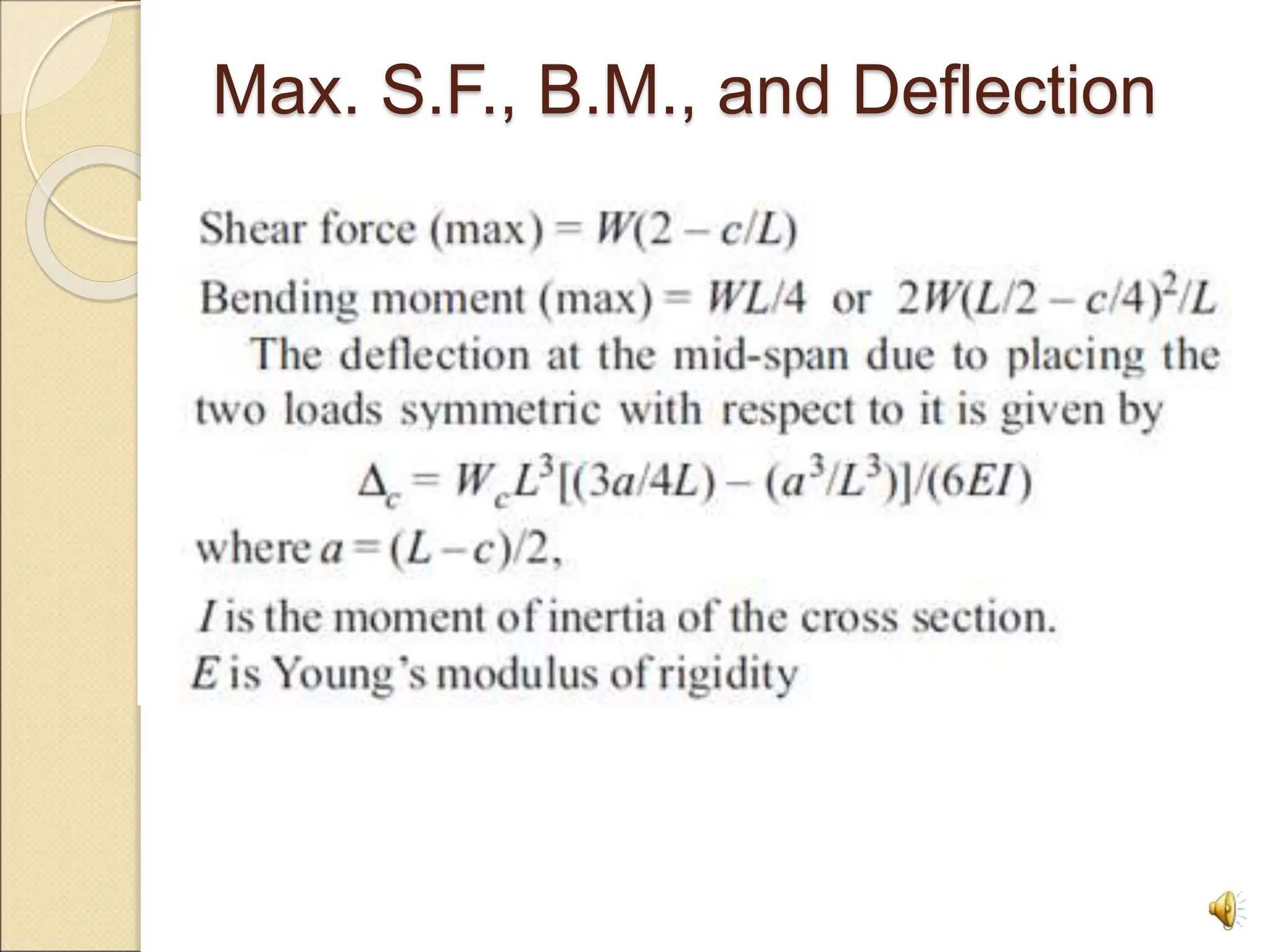

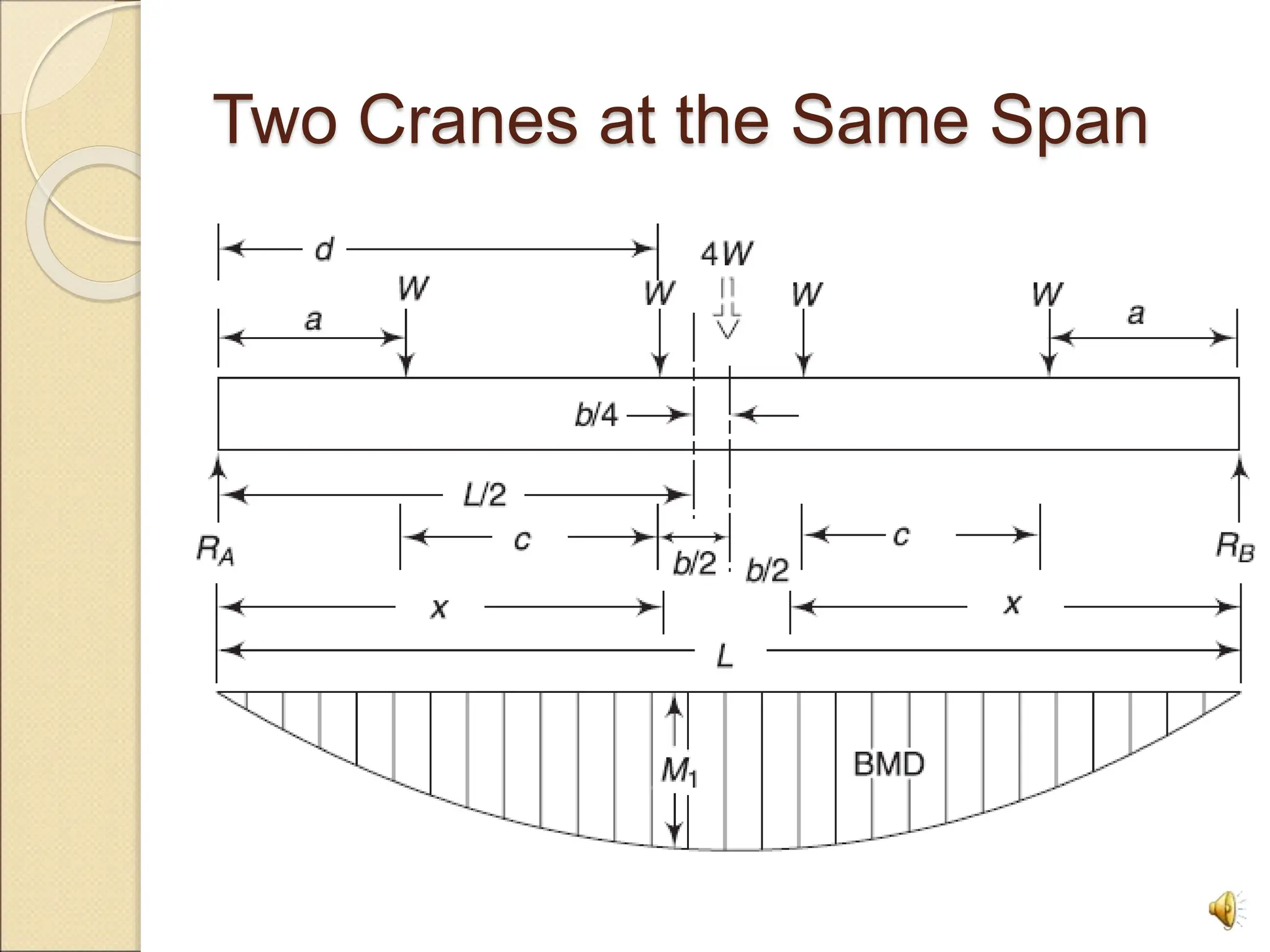

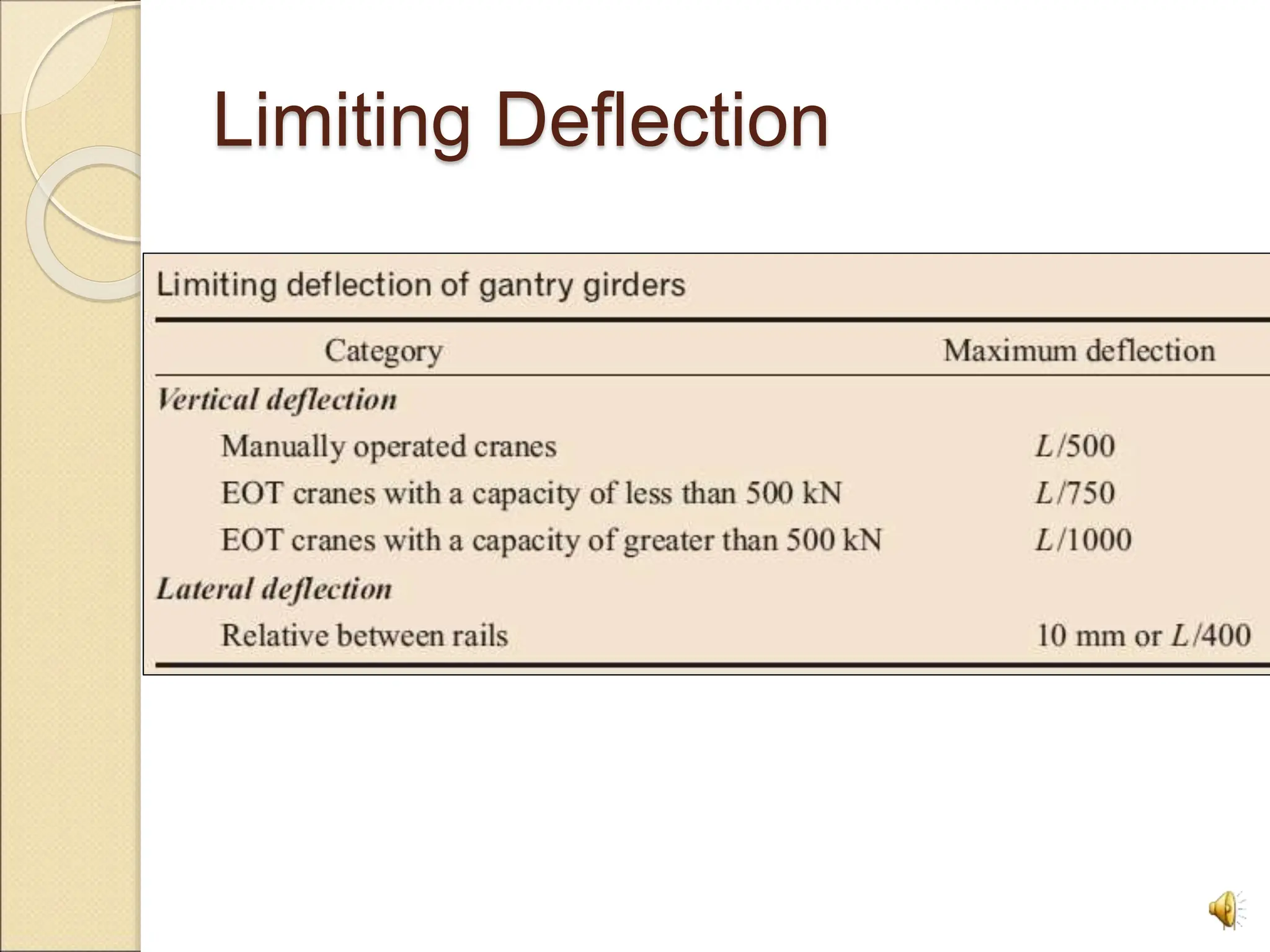

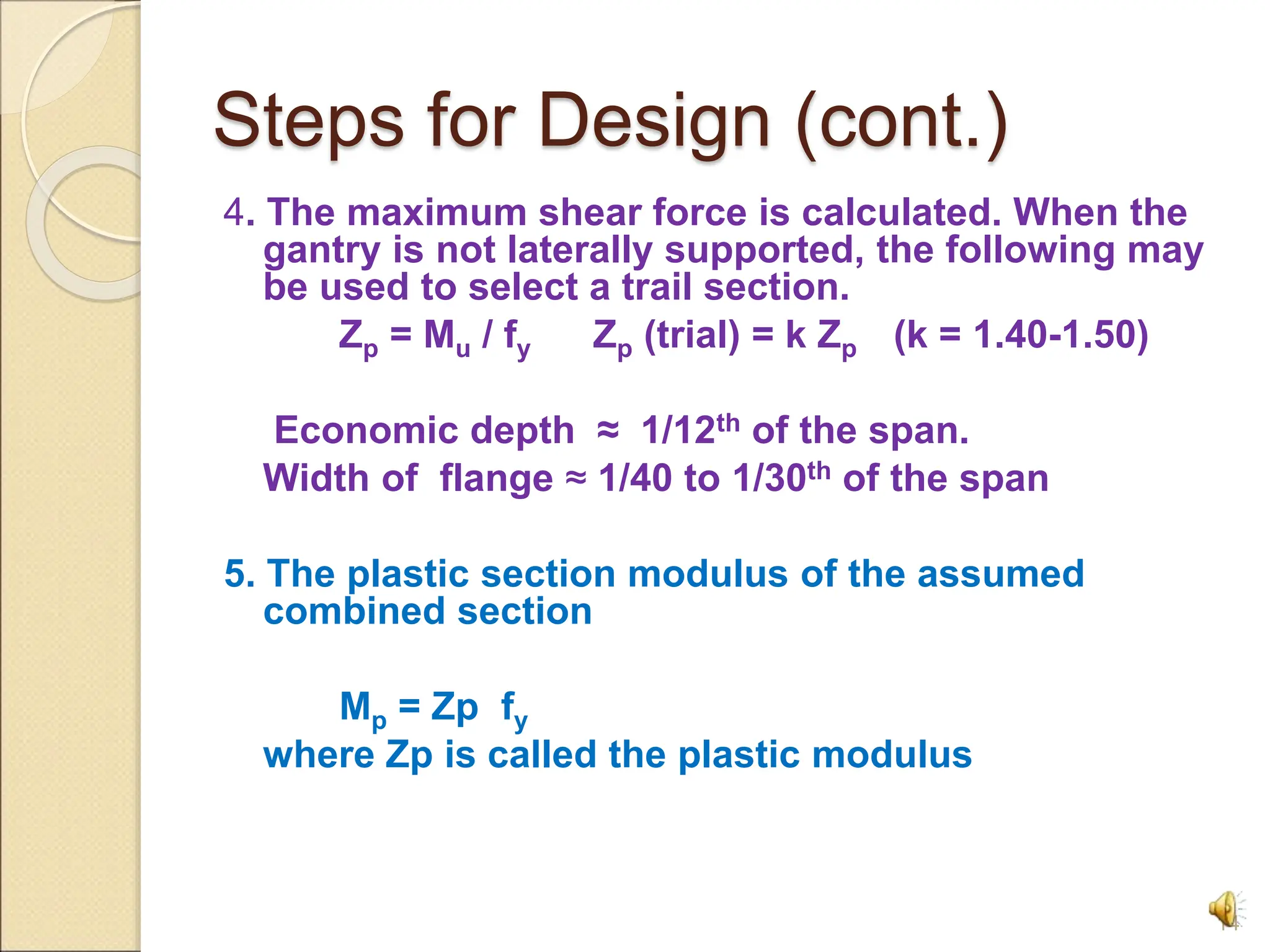

This document provides design considerations for gantry girders, which are laterally unsupported beams subjected to both vertical and horizontal loads. It outlines the key components of overhead cranes that impose loads on gantry girders. The document then describes the steps to design gantry girders, which include determining maximum wheel loads, calculating bending moments, selecting a trial cross section, checking the section's moment capacity, and verifying the top flange and web can resist buckling from applied loads and stresses. Deflection is also checked under working loads.