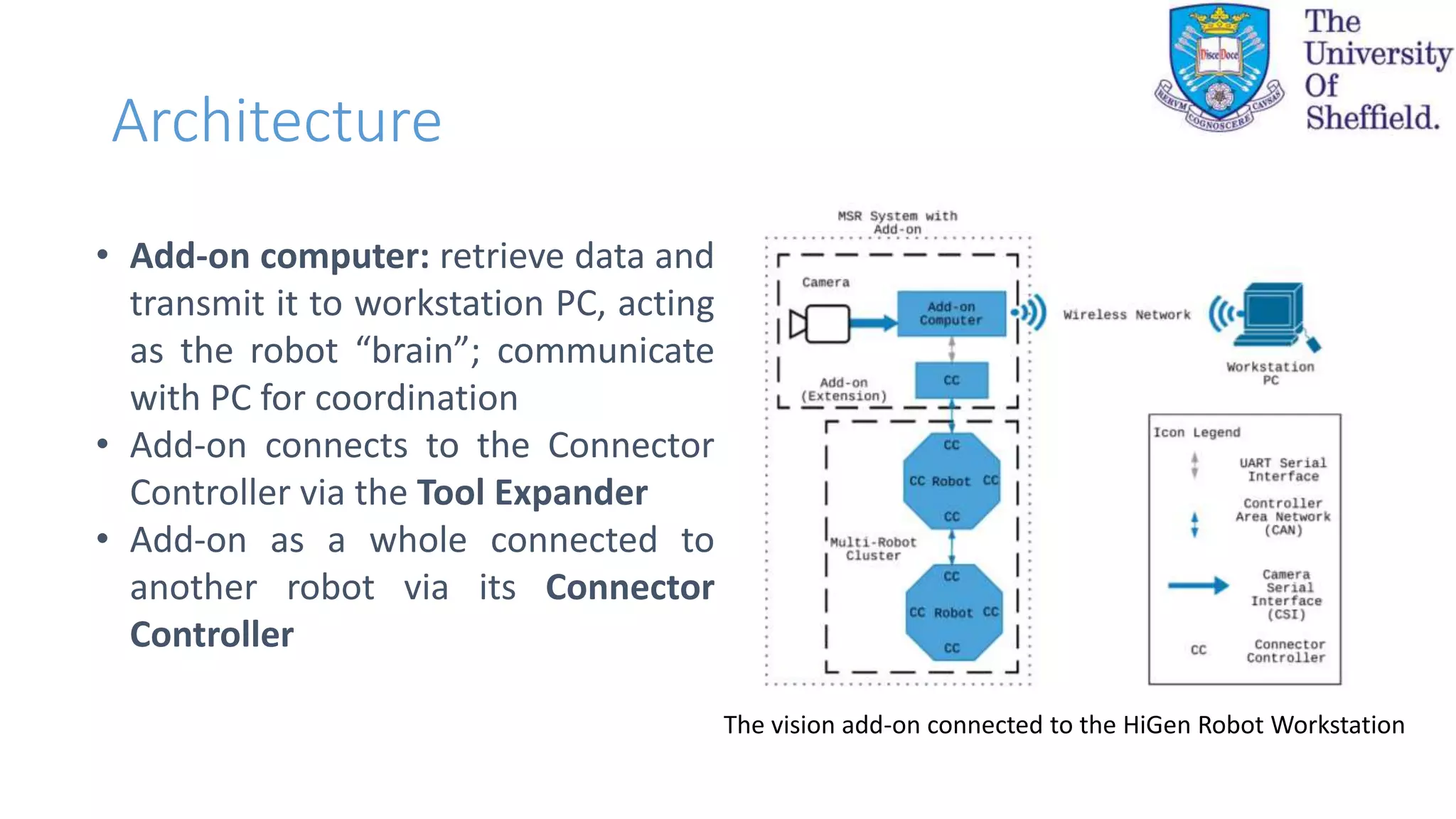

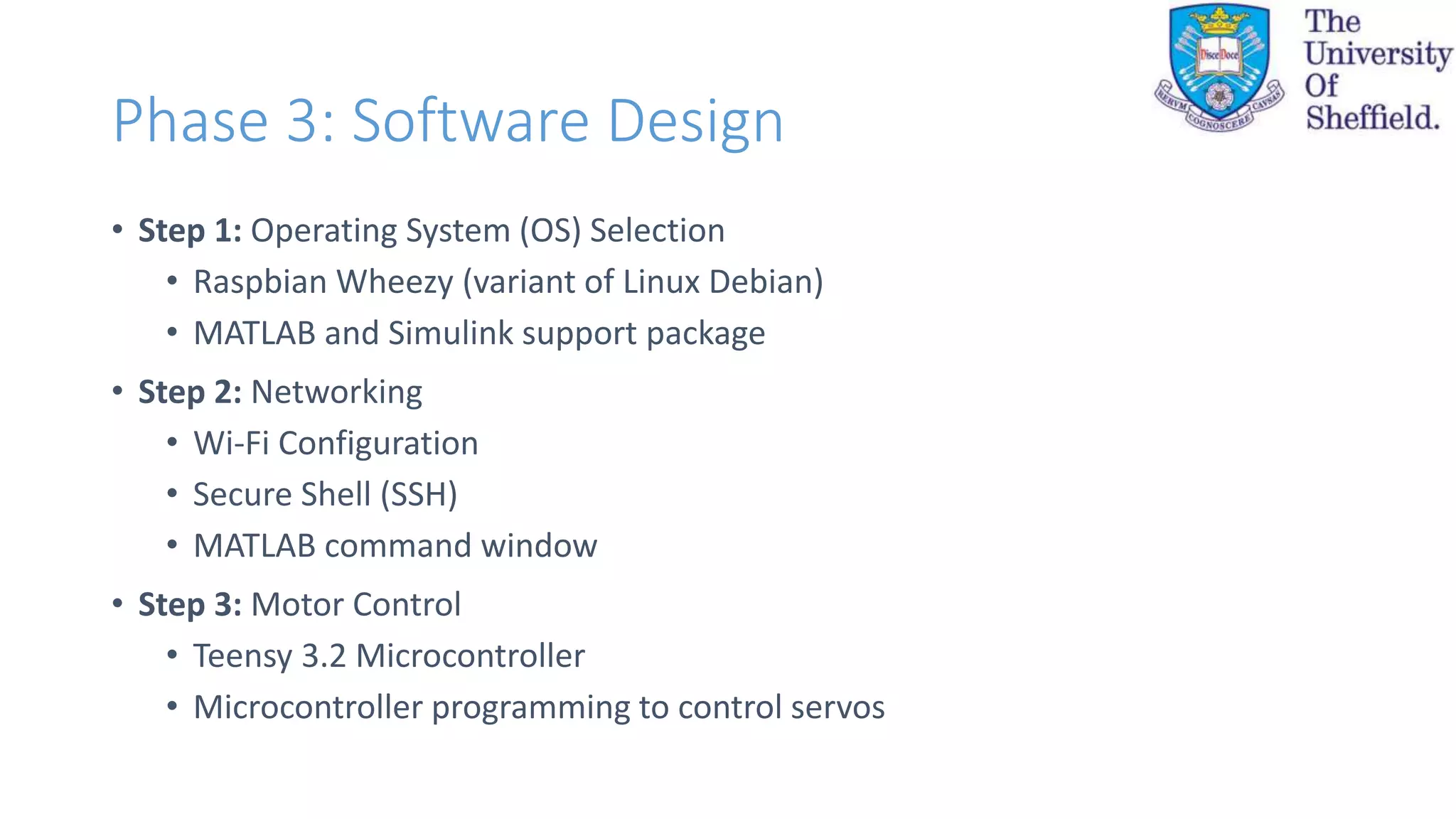

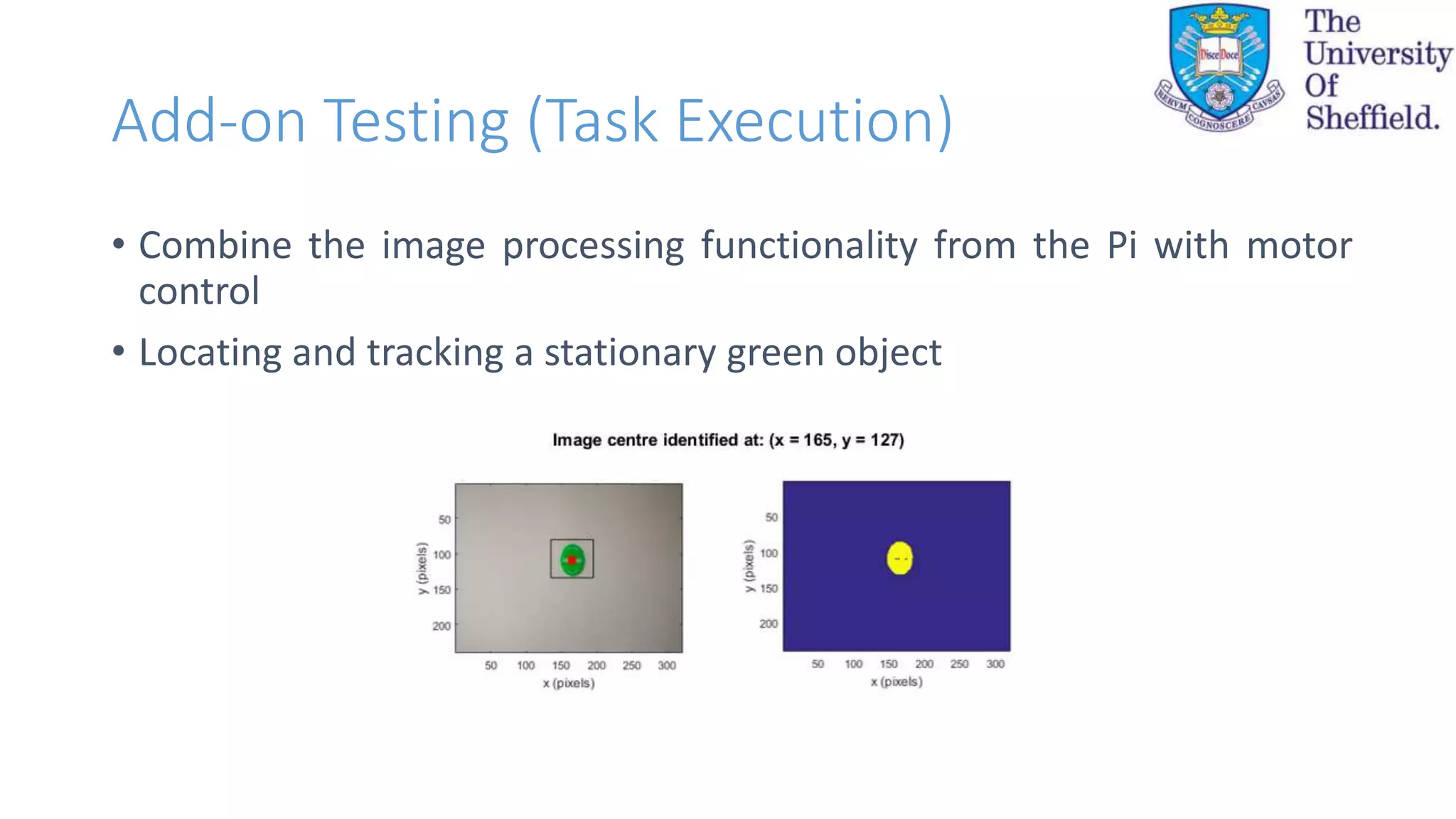

The document outlines the design and construction of a hardware add-on for a modular self-reconfigurable robot system called the HiGen Module. It discusses the aims of studying, designing and building an add-on to increase the robot's functionality. The phases included electronics design of the add-on board and chassis, software design using a Raspberry Pi and MATLAB, and testing of the add-on's ability to perform tasks like object tracking using the camera. Further work includes fully integrating the add-on with the robot and developing control algorithms.

![Introduction (MSR)

• Modular Self-Reconfigurable Robots (MSR)

• Concept credited to Fukuda (Dynamically Reconfigurable Robot) [1]

• Designed to fit any given task through reconfiguration

• Lattice, Chain, and Hybrid Architectures

• Homogeneous, Heterogeneous

ATRON: Snake and vehicle-like

[2]

Thor: Heterogeneous MSR

[3]

SuperBot: Bipedal Configuration

[4]](https://image.slidesharecdn.com/c469e807-40f7-451d-b785-25f79dfd0841-161122121610/75/FYP-Presentation-MAREI-4-2048.jpg)

![HiGen Module

• HiGen: High-speed Genderless Mechanical Connection Mechanism for Self-

Reconfigurable Modular Robots

• Genderless nature enables single-sided disconnect

• HiGen Module: Modular robot with four HiGen connectors

HiGen Module

[6]

Standalone HiGen Connector

[5]](https://image.slidesharecdn.com/c469e807-40f7-451d-b785-25f79dfd0841-161122121610/75/FYP-Presentation-MAREI-5-2048.jpg)

![Hardware Extensions (Add-Ons)

• Add functional “tools” to the robot

• Increase the utility of the robot

• Tool examples: sensors (camera modules); functional (grippers, wheels, etc.)

CKBot with camera module

[7]

Add-on Modules of Thor

[2]](https://image.slidesharecdn.com/c469e807-40f7-451d-b785-25f79dfd0841-161122121610/75/FYP-Presentation-MAREI-6-2048.jpg)

![Phase 1: Electronics Design

• Research into previous implementations of camera add-ons

• Based on Requirements decided with C. Parrott

• SBC (Single-board Computer) as the “brain” of the add-on

• Research into SBC’s Raspberry Pi Model A+ and NoIR Camera

Raspberry Pi Model A+Raspberry Pi NoIR Camera Teensy 3.2 Board Connector Controller

[Parrott]](https://image.slidesharecdn.com/c469e807-40f7-451d-b785-25f79dfd0841-161122121610/75/FYP-Presentation-MAREI-8-2048.jpg)

![Phase 3 (Continued): MATLAB

• Data acquisition

• Lightweight image processing (as opposed to using e.g. OpenCV [8])

• Simulink support package for hardware: Raspberry Pi and ARM

Microcontrollers

• Control design made easier through Simulink

• Integration of the steps in software design (Step 1, Step 2, and Step 3)

• Internet of Things support using ThingSpeak (later)](https://image.slidesharecdn.com/c469e807-40f7-451d-b785-25f79dfd0841-161122121610/75/FYP-Presentation-MAREI-15-2048.jpg)

![Add-On Testing (Control and Data

Acquisition)

• Pan-tilt tracking: modelling using framework outlined by Chen et al. [9]

• Experiment: Object fixed distance and position away from add-on

• Constant position constant tracking angles

• Not the case](https://image.slidesharecdn.com/c469e807-40f7-451d-b785-25f79dfd0841-161122121610/75/FYP-Presentation-MAREI-18-2048.jpg)

![Conclusion and Further Work

Achievements

• Hardware design of the add-on

• Successful programming and testing independent functions

• Attempted to combine functionality but faced problems

• Demonstrated the add-on’s ability to execute application-relevant tasks and acquire data

• Attempted to model and simulate the pan-tilt auto-tracking problem to develop a controller

Further Work

• Finalize integration and test with Connector Controller and HiGen connector

• Verify tracking model and implement on the Raspberry Pi

• Exploit the Raspberry Pi to enable Internet of Things (IoT) access through ThingSpeak [10]](https://image.slidesharecdn.com/c469e807-40f7-451d-b785-25f79dfd0841-161122121610/75/FYP-Presentation-MAREI-19-2048.jpg)

![References

• [1] Fukuda, T., & Nakagawa, S. (1987, October). A dynamically reconfigurable robotic system (concept of a system and optimal

configurations). In Robotics and IECON'87 Conferences (pp. 588-595). International Society for Optics and Photonics.

• [2] Østergaard, E. H., Kassow, K., Beck, R., & Lund, H. H. (2006). Design of the ATRON lattice-based self-reconfigurable robot.

Autonomous Robots, 21(2), 165-183.

• [3] Salemi, B., Moll, M., & Shen, W. M. (2006, October). SUPERBOT: A deployable, multi-functional, and modular self-

reconfigurable robotic system. In Intelligent Robots and Systems, 2006 IEEE/RSJ International Conference on (pp. 3636-3641). IEEE.

• [4] Lyder, A., Garcia, R. F. M., & Stoy, K. (2010). Genderless connection mechanism for modular robots introducing torque

transmission between modules. In Proceedings of the ICRA Workshop on Modular Robots, State of the Art (pp. 77-81).

• [5] Parrott, C., Dodd, T. J., & Gross, R. (2014, September). HiGen: A high-speed genderless mechanical connection mechanism with

single-sided disconnect for self-reconfigurable modular robots. In Intelligent Robots and Systems (IROS 2014), 2014 IEEE/RSJ

International Conference on (pp. 3926-3932). IEEE.

• [6] Parrott, C., Dodd, T. J., & Gross, R. (2014) Towards a 3-DOF mobile and self-reconfigurable modular robot.

• [7] Shirmohammadi, B., Taylor, C. J., Yim, M., Sastra, J., & Park, M. (2007, September). Using smart cameras to localize self-

assembling modular robots. In Distributed Smart Cameras, 2007. ICDSC'07. First ACM/IEEE International Conference on (pp. 76-

80). IEEE.

• [8] Open-Source Computer Vision Library (OpenCV). URL: http://opencv.org/

• [9] Chen, G., St-Charles, P. L., Bouachir, W., Bilodeau, G. A., & Bergevin, R. (2015, September). Reproducible Evaluation of

Pan-Tilt-Zoom Tracking. In Image Processing (ICIP), 2015 IEEE International Conference on (pp. 2055-2059). IEEE.

• [10] The Internet of Things: ThingSpeak. URL: https://thingspeak.com](https://image.slidesharecdn.com/c469e807-40f7-451d-b785-25f79dfd0841-161122121610/75/FYP-Presentation-MAREI-21-2048.jpg)