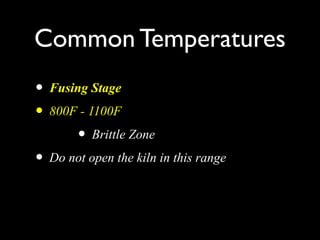

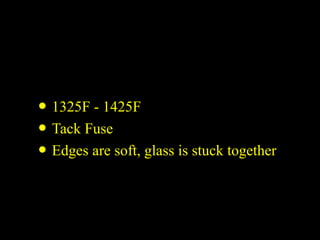

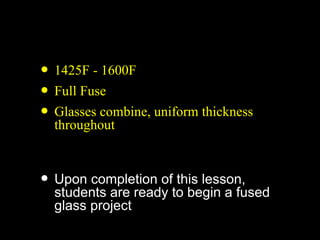

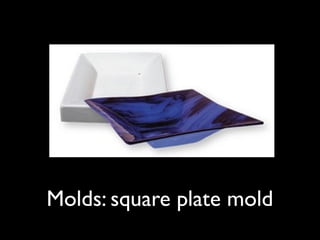

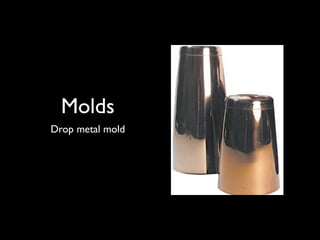

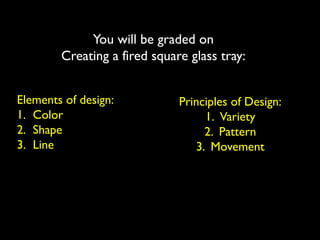

This document provides instructions for creating fused glass art. It discusses the history of fused glass dating back to ancient Mesopotamia. Specific instructions are given for heating and cooling glass slowly to prevent cracking, using compatible glass with the same coefficient of expansion, and applying kiln wash. Common temperatures for tacking, fusing and annealing glass are listed. Students will be graded on creating a square glass tray demonstrating elements of design like color and shape, and principles of design including variety, pattern and movement.